Preview text:

ễ ị ồ

Information Systems in Organizations Student’s Name: ễ ỷ Student’s ID:

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 EXECUTIVE SUMMARY

There is a lot of interest in the food industry. The food market is incredibly

large and diverse in terms of variety, quantity, and quality levels. Clemens Food

Group is well-known for manufacturing and submitting more than 1,200 fresh and

processed pork products. Pork-based meals include bacon, ham, hot dogs,

sausage, pork tenderloin, pork roasts, deli meat, scrapple, and pork buns. To be

successful, Clemens Food must have a firm grasp on order timeliness and accuracy,

as well as incredibly exact information on the state of its commodities and storage

operations throughout the farm network and manufacturing facilities. They

require a new platform to increase production intelligence, more efficient

planning, and tighter control over available-to-promise operations. They also want

real-time data on plan profitability, such as daily profit - ability margins on an

order-by-order basis. Clemens Food's current ERP system was outdated and

needed to be replaced with one that could manage growing volume and

multiplant complications. As a result, SAP software was the greatest choice for

assisting the organization in meeting its growth objectives. To explain, I will apply

my understanding of Information Systems in Organizations to study Clemens Food

Group and provide further ways to increase company efficiency. TABLE OF CONTENTS 2

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 lOMoARcPSD|47231818

EXECUTIVE SUMMARY……………………………………………………….2

INTRODUCTION………………………………………………………………...4

PART 1: COMPANY BACKGROUND…………………………………………4

(Business description, Core value, Mission)

PART 2: ENTERPRISE INFORMATION SYSTEMS ANALYSIS…...……...6

Analyze the company businesses – Business process description…………………6

o A Swimlane diagram illustrates the As-Is process………………………….7

Analyze the information systems to improve business process……………………8

o Was SAP S/ 4HANA a good solution for Clemens Food Group?..................8 o

What management, organizational, and technological concerns have to be

addressed at Clemens Food Group in order to install SAP S/4HANA?.........9

PART 3: PRACTICAL TASK…………………………………………………10

CONCLUSION………………………………………………………………….11

REFERENCES LIST……………………………………………………..…….11 3

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 INTRODUCTION

There is a huge demand for the food business. Eating is one of every human

being's basic necessities and a necessary prerequisite for development and

survival. As a result, we can observe that the food market is extraordinarily big and

diversified in terms of varieties, rich in supply, and of varying quality levels.

Understanding market demand and consumers' weak market for safe food to

assure food safety, Clemens Food Group has developed a business strategy and is

wellknown for its diverse company. Today, I will prepare a report about Clemens

Food Group using the knowledge I have gained about Information Systems in Organizations. 4

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 lOMoARcPSD|47231818

PART 1: COMPANY BACKGROUND

Clemens Food Group is a sixth-generation family owned company that has

proudly served its community for over 125 years, and continues to be an industry

leader in customer solutions. Clemens Food Group is well-known for producing

and supplying over 1,200 fresh and processed pork products. Bacon, ham, hot

dogs, sausage, pork tenderloin, pork roasts, deli meat, scrapple, and pork buns are

examples of pork-based dishes. Clemens Food, headquartered in Hatfield,

Pennsylvania, is a vertically integrated firm that specializes in antibiotic-free hog

farming, food manufacturing, logistics services, and shipping. Using a responsive

pork production system, the firm focuses on offering its partners with high-quality

goods as well as advanced solutions that streamline their operations. Clemens

Food Group's services and brands include pork product producers Hatfield Quality

Meats and Nick's Sausage Company, as well as logistics and transportation firms

(PV Transport) and CFC Logistics Country View Family Farms, a hog procurement

and production company that manages upwards of 100 local farmers raising hogs

under contract. The Clemens Food Group raises and processes around five million

pigs per year, managing procurement, production, and logistics services from

conception to completed food products. Clemens employs 3,350 people. However,

Clemens Food also has a lot of competitors with similar business models as

Yamazaki Baking, Nellson, Lancaster Colony,.. • Core value

Clemens Food Groups9 deep-rooted core Values are key to the strength and

longevity of the company. Clemens's core Values of Ethics, Integrity, and

Stewardship are the foundation behind every business decision made, including

the treatment of team members, customers, the environment, and our animals.

"We are committed to building a foundation for future generations. It is what we

call 8doing business the right way. It is who we are." – Clemens Food Group. 5

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 • Mission

To be a provider of wholesome, sustainable food for Clemens Food's families

and customers with a world-class team practicing ethics, integrity, and

stewardship. Even though Clemens business is built on producing pork, Clemens's

mission and vision are not simply about our products. Throughout every branch of

Clemens's company, the goal is to run our business with integrity, to live and work

ethically, and to build a strong foundation for tomorrow. "We work hard to build

respectful, beautiful relationships with everyone who comes into contact with

Clemens - from the people who enjoy our products, to the American family

farmers we work with, to the customers who rely on our consistent partnership, to

the team members who share our commitment to producing quality products, day

after day. You'll see our dedication, commitment, and work-ethic reflected in every aspect of what we do."

PART 2: ENTERPRISE INFORMATION SYSTEMS ANALYSIS

1. Analyze the company businesses – Business process description.

Clemens Food must have a clear handle on the timeliness and accuracy of

orders, as well as extremely precise information about the state of its goods and

warehousing operations throughout the farm network and production facilities, in

order to be successful. The organization was having a number of issues with

material management, planning, and timely performance. It is obvious from the

responsive pork production system that the firm demands a well - detailed supply

chain management system since its major goal is presenting high - quality items to

its clients. Furthermore, sophisticated solutions are intended to ease the

operations of its partners, as the company collaborates with pork product makers

such as Hatfield Quality Meats and Nick's Sausage Company, as well as logistics

and transportation organizations. Clemens Food's legacy systems, on the other

hand, can no longer keep up with output and support future development. The

primary cause of this dificulty was management9s failure to maintain a consistent 6

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 lOMoARcPSD|47231818

focus on technological progress. The second reason is that 15 years ago, Clemens

Foods implenmented ERP when it was outdated. That last implementation took

years and resulted in so many modifications that communication between the

departments was lost. As a result, they need a new platform to enable improved

insight into production, more efficient planning, and tighter control over available-

to-promise operations. They also want real-time information on plan profitability,

including daily profit - ability margins on an order - by - order basis.

In fact, in 2010, Clemens Food created a five-years plan to modemize its IT

infrastructure. The plan gained steam in 2014 when Clemens Food announced it

would develop a third pork processing plant comprising 550,000 square feet in

Coldwater Township, Michigan. Because Clemens Food9s existing ERP system is

old, it needed to be replaced by one that could handle increased volume and

multiplant complexities. Therefore, SAP software was the best solution for helping

the company achieve growth targets.

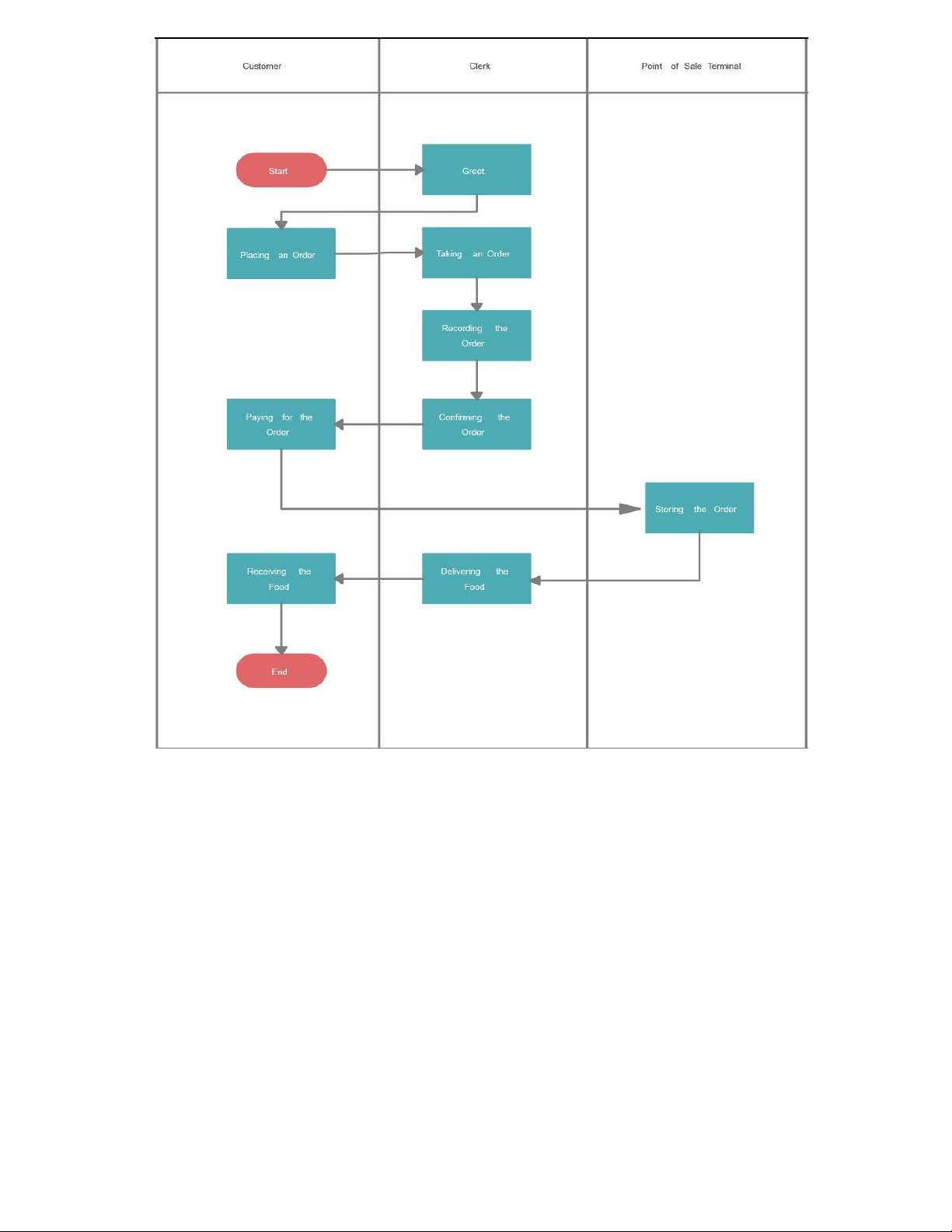

• A Swimlane diagram illustrates the As-Is process.

At Clemens Food Group, the procedure of submitting goods divided into two

different ways: Order taking - Payment - Package disposal - Customer service -

Feedback and response, or, more simply: Before - In - After.

Customers enter the store and pick the item they wish to purchase. If the

consumer does not have a precise choice, the cashier can help the customer

choose the suitable products from the counter.

Payment will be made after the order is completed. Clemens Food accepts a

range of payment methods, including cash, online banking, and credit card. During

the payment process, the staff is in charge of double-checking the order with the

client one more time and packing the items into bags for the consumers. 7

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01

2. Analyze the information systems to improve business process.

A delay is one sort of inefficiency associated with the human execution of

this activity. Because Clemens Food Group is a perishable firm, raw material

procurement and customer delivery are constrained by extremely short

timescales. If the purchase or supply is delayed, the items cannot be utilised,

resulting in a significant loss to the company's business. Furthermore, because the

storage duration of the items is restricted, it is not possible to store the goods for

an extended period of time, and all supply chain operations must follow a

specified pattern (FIFO) in order to avoid goods perishing. Perishable commodities

supply chain is an expensive issue since it requires refrigeration of both moveable

and immovable storage. As a result, in the perishable foods market, Clemens Food

Group places the most emphasis on the supply chain. 8

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 lOMoARcPSD|47231818

Joshua Rennells, Senior Vice President of Clemens Food Group, and his

colleagues have spent years developing innovative technology. Clemens Food

created and integrated SAP software into the company's operations. Clemens Food

replaced their traditional ERP system, which was tied to more than 70

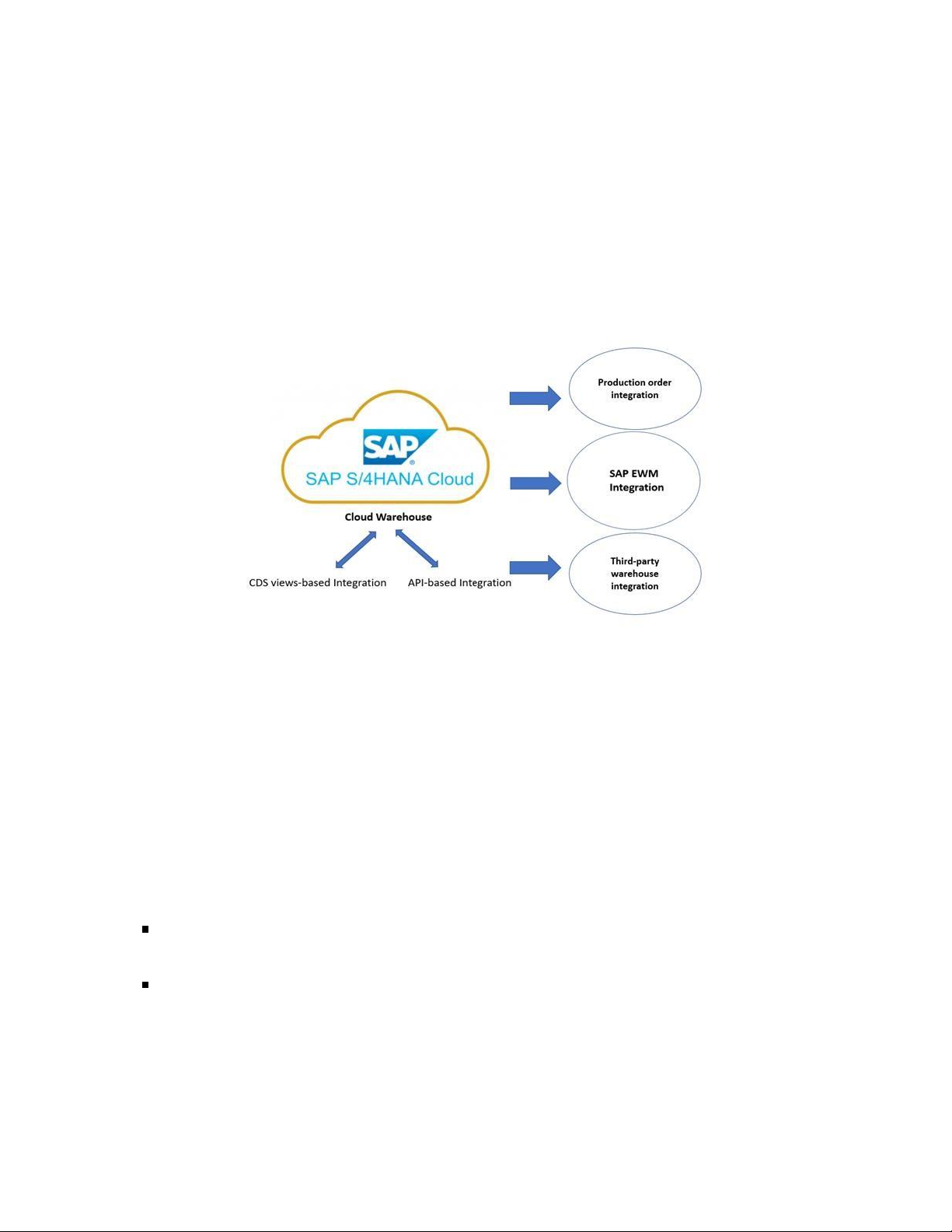

applications, with SAP S /4HANA.

Was SAP S/ 4HANA a good solution for Clemens Food Group?

SAP S/4HANA is an enterprise software package built on the SAP HANA in-

memory computing platform. It includes enterprise resource planning software

designed to cover all of a business's day-to-day procedures, as well as integrations

with SAP Business Suite products for customer relationship management, supplier

relationship management, and supply chain management. SAP S/4HANA is offered

on-premises, in the cloud, and in a hybrid computing environment. It has

enterprise resource planning software that is meant to cover all day-to-day

processes of a business and also integrate parts of SAP Business Suite products for

customer relationship management, supplier systems and supply chain management.

SAP S/ 4HANA ERP system linked to 70 applications. Includes all processes of

a business and also integrates parts of SAP Business Suite products.

SAP S/4HANA assists with master data defects that would be cleaned up

and in place prior to the system becoming live. The corporation can

calculate profitability on an invoice-by-invoice basis, and it knows the

profitability of each order immediately. Prices in the perishable food 9

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01

industry vary on a daily basis, thus the value of having real-time profitability

statistics cannot be understated.

Customer service has improved as a result of deeper knowledge and

visibility provided by new technology. Clemens Food can tell clients who

purchase by phone whether items are in stock or not by performing

available to promise procedures on SAP S/ 4HANA, which is coupled with

the company's system management system. This may be an exceedingly

difficult process in the pork sector, because a single hog can be broken

down into hundreds of by products.

Activity in a perishable industry makes it imperative for Clemens Food have

key data available when the new system is in operation to avoid disrupting

production or shipping capabilites.

SAP S/ 4HANA was a good solution for Clemens Food Group.

What management, organizational, and technological concerns have to be

addressed at Clemens Food Group in order to install SAP S/4HANA?

SAP S/4 HANA interacts with a variety of operating platforms to assist

Clemens Food manage client orders and the quantity of commodities purchased.

This allows managers to have a more optimistic outlook while planning

forthcoming operations and prevent squandering product surplus, which helps the

organization cut losses. Furthermore, this helps the organization cut product

storage time, allowing them to deliver more fresh items. On the other hand, by

giving online information regarding account receivables and payable accounts

payable, the distance between departments is also minimized. PART 3: PRACTICAL TASK

To increase company business efficiency, I recommend that Clemens Food

Group use an Internet of Things (IoT) solution to boost company business

efficiency. The Internet of Things (IoT) is a network of physical objects-

"things"embedded with sensors, software, and other technologies for connecting

and sharing data with other devices and systems over the internet.

Clemens Food may use IoT to boost company productivity by connecting

ordinary things to the internet via embedded devices, such as machinery and

equipment. This will allow for continuous contact with employees, people, 10

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01 lOMoARcPSD|47231818

processes, and everything else. Instrumentation technology may be used in food

production industrial situations such as Clemens Food Group to measure and

control sensors and equipment utilizing cloud technology.

o Access to sensor technology that is low-cost and low-power.

o Connectivity. A plethora of internet network protocols have made it simple

to link sensors to the cloud and other "things" for efficient data transfer.

o Platforms for cloud computing Because of the increased availability of cloud

platforms, both enterprises and consumers may now obtain the

infrastructure they require to scale up without having to manage it all.

o Analytics and machine learning Businesses can acquire insights faster and

more simply thanks to developments in machine learning and analytics, as

well as access to diverse and large volumes of data stored on the cloud. The

advent of these linked technologies continues to push the frontiers of IoT,

and IoT data feeds these technologies as well.

o Artificial conversational intelligence (AI). Natural-language processing

(NLP) has been introduced to IoT devices (such as digital personal assistants

Alexa, Cortana, and Siri) through advances in neural networks, making them

attractive, inexpensive, and feasible for home usage.

Machine-to-machine communication (M2M) has recently been employed in

industries to enable wireless automation and control. However, with the rise of

cloud and related technologies (such as analytics and machine learning), industries

may attain a new level of automation, resulting in new income and business

models. Industry IoT is also known as Industry 4.0 or the fourth wave of the

industrial revolution. Some common applications for Industry IoT include: o Smart manufacturing

o Connected assets and preventive and predictive maintenance o Smart

power grids o Smart cities o Connected logistics o Smart digital supply chains CONCLUSION

To be successful, Clemens Food must have a firm grasp on order timeliness

and accuracy, as well as incredibly exact information on the state of its

commodities and storage operations throughout the farm network and

manufacturing facilities. They require a new platform to increase production

intelligence, more efficient planning, and tighter control over available-to-promise

operations. SAP software was the greatest answer for assisting the organization in 11

Nguyễn Thuỷ Linh – 20071030. Course code: INS2025 01

meeting its growth objectives. Furthermore, Clemens Food may use IoT to boost

company productivity by connecting daily things to the internet via embedded

devices, such as machinery and equipment. This will allow for continuous contact

with employees, people, processes, and everything else. REFERENCES

1. Chapter 9, page 368, Book: Management Information Systems, Kenneth

C.Laudon and Jane Price Laudon.

2. https://www.clemensfoodgroup.com/our-company

3. https://craft.co/clemens-food-group-coldwater/competitors

4. https://www.studocu.com/row/document/international-

university/social/misvideo-lecture-notes-1/15770766 12