Preview text:

lOMoAR cPSD| 58583460

BÀI TẬP CƠ LƯU CHẤT

Họ Tên: Lê Anh Thơ MSSV: 23150064 Câu 1:

- The Bernoulli equation is an important tool in hydraulics, but it can only

beapplied under specific conditions. Below are three cases where this equation

does not apply and four conditions under which it can be used.

- Three cases where the Bernoulli equation does not apply:

1. Dòng chảy rối (Turbulent flow):

- Reason: The Bernoulli equation is based on laminar flow, where fluid particles

move along parallel straight lines. In turbulent flow, fluid particles move

chaotically, disrupting this property.

- Example: Water flowing through a narrow pipe or around an object at high speed.

2. Dòng chảy không ổn định (Unsteady flow):

- Reason: The equation only applies to steady flow, where properties like

velocity and pressure at a point do not change over time. In unsteady flow, these

properties continuously change, making the equation inaccurate. - Example:

Waves on the surface of water or flow in a pipe with varying discharge over time.

3. Dòng chảy có độ nhớt cao (Viscous flow):

- Reason: The equation assumes an ideal fluid with no viscosity. When viscosity

is too high, friction between fluid layers significantly affects the distribution of

pressure and velocity, leading to inaccuracies in the results.

- Example: The flow of honey or oil through a narrow pipe.

- Four conditions required to apply the Bernoulli equation:

1. Incompressible fluid: The fluid’s density remains constant throughout its motion.

2. No friction: Frictional forces between fluid layers and between the fluid and

the pipe walls must be nonexistent or negligible.

3. Steady flow: The properties of the flow at any given point do not change over time. lOMoAR cPSD| 58583460

4. Laminar flow: Fluid particles must move along parallel paths without intersecting. Câu 3:

Cavitation Phenomenon

- Cavitation occurs when the pressure of a liquid drops below its vapor pressure,

causing the formation of vapor bubbles. These bubbles collapse in higher-

pressure areas, creating shock waves that lead to erosion and damage in pumps. Effects:

- Material Erosion: Causes severe damage to impeller surfaces and pump casings.

- Reduced Efficiency: Leads to higher energy consumption and shorter equipment lifespan.

- Noise and Vibration: Produces loud noise and vibrations, destabilizing the system.

- Leaks: Can cause cracks or holes in material surfaces, leading to fluid leakage. Prevention:

- Proper Design: Use durable materials and optimize impeller design to reduce bubble formation.

- Adjust Operating Conditions: Lower impeller speed, increase suction pressure,

and prevent air from mixing with the fluid.

- Control Fluid Temperature: Lower the liquid temperature to reduce vapor bubble formation. lOMoAR cPSD| 58583460

- Use Cavitation Prevention Devices: Install bubble generators and use anti-

erosion coatings on surfaces exposed to the liquid.

- Regular Maintenance: Inspect and maintain pumps frequently to detect and fix

issues before cavitation occurs.

Cavitation is a serious issue in fluid systems, and a combination of technical

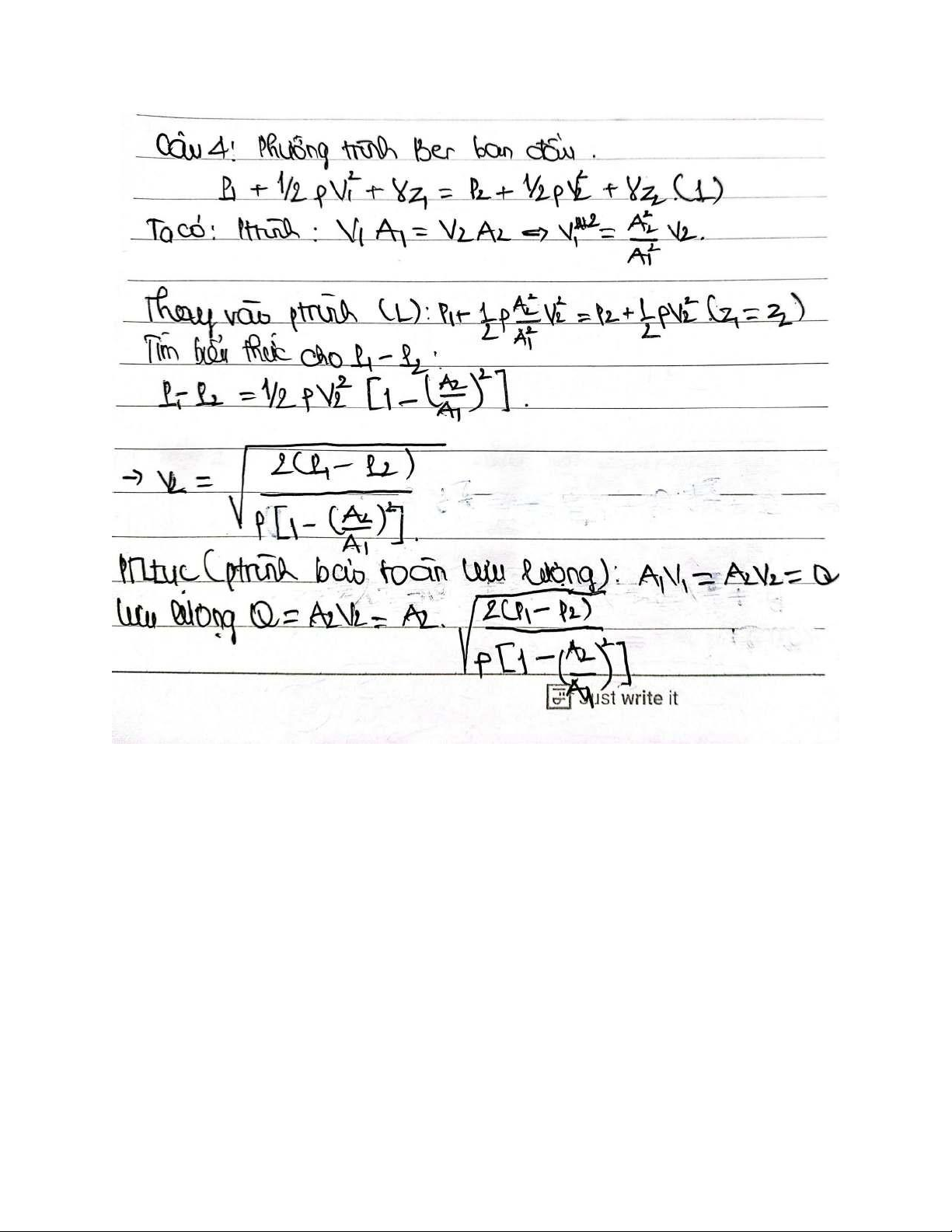

measures and operational management is necessary to minimize its effects and prolong pump life. Câu 4: lOMoAR cPSD| 58583460