Preview text:

PROCESS Introduction Overview lOMoAR cPSD| 39651089

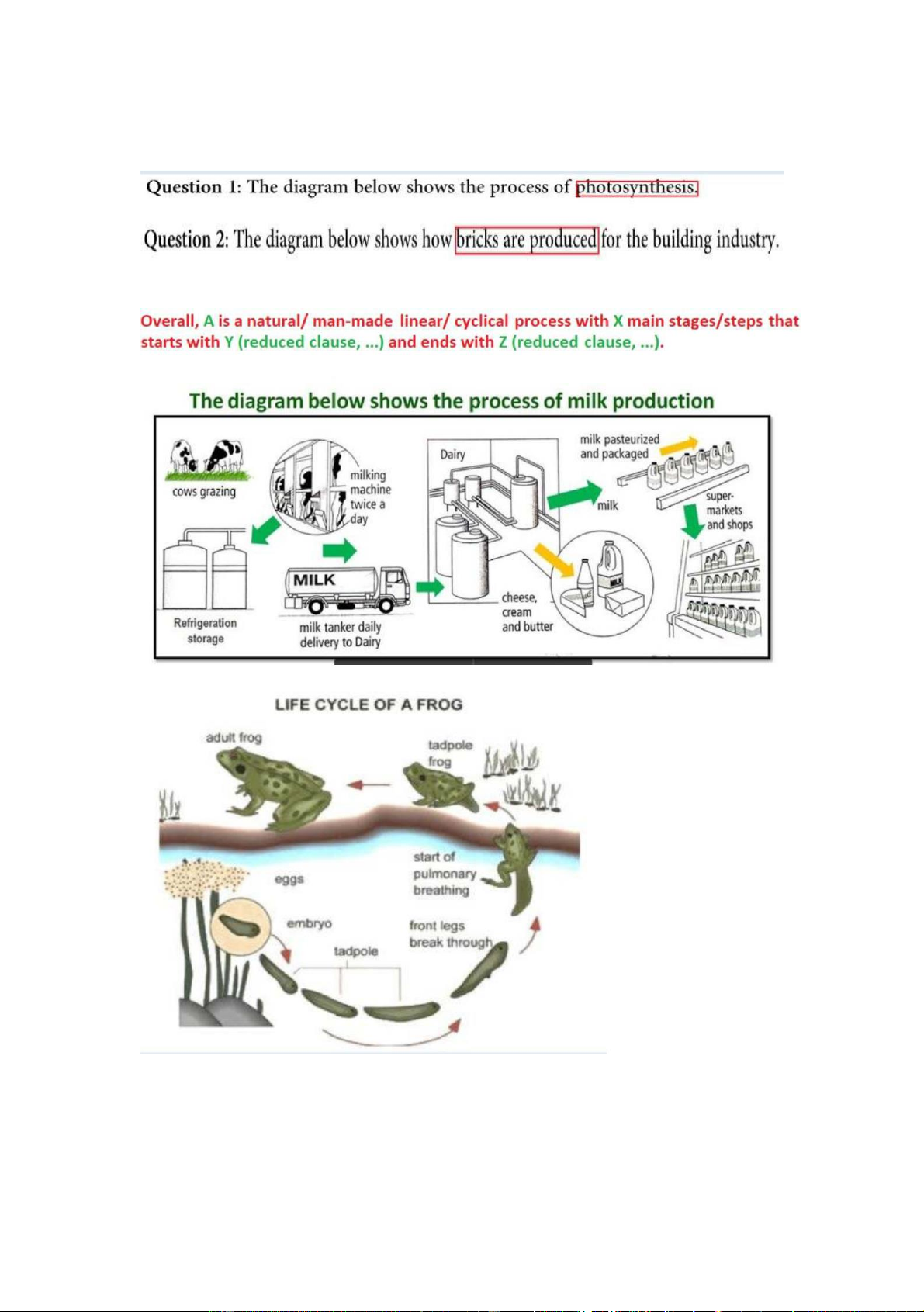

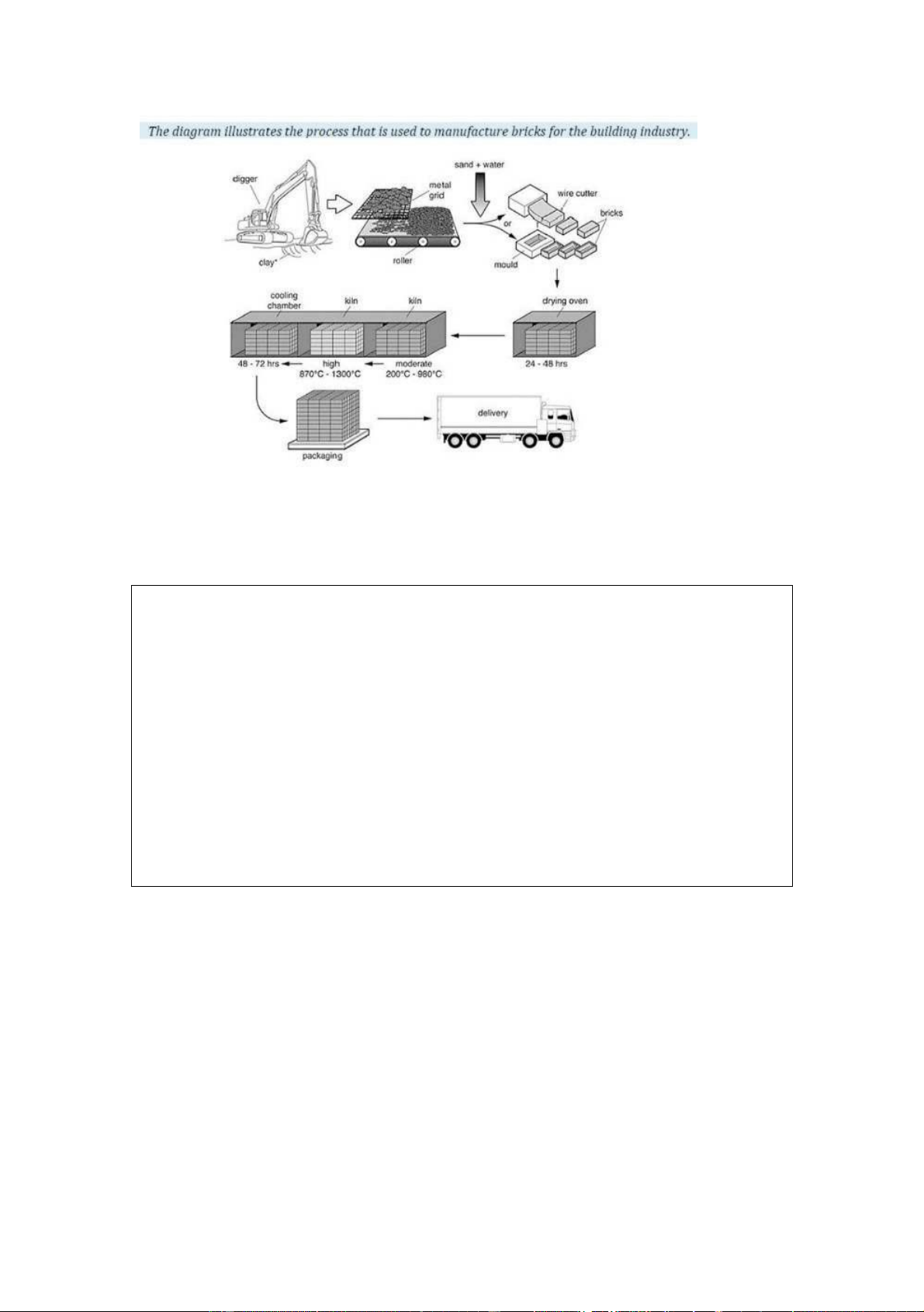

As can be clearly seen from the diagram, making bricks is a man-made

linear process with seven main stages that starts with clay exploited

from the ground and ends with final products delivered by trucks. BODY

Looking at the pictures/ illustrations more minutely, … To begin with, In the first step, In the initial step, Next, In the next stage, Subsequently, In the subsequent stage, In the following stage, In the final step/ finally In the last stage. EX:

Looking at the picture more closely, to begin with, clay is dug from the

ground by a digger so that such amount can be filtered. To be more specific,

such material is placed on a metal grid to eliminate all unwanted rocks,

which is followed by the delivery by the usage of a roller. In the next step,

the filtered clay is added with sand and water before being shaped by two

different methods. Namely, the first way is to use the mould while the

second way is done by wire cutters. After the previous step, original bricks

are stored in a drying oven from one to two days. Subsequently, such dried

bricks experience more intense heat in two kilns whose temperatures range

from 200 to 980 in the first level and from 870 lOMoAR cPSD| 39651089

to 1300. Next, these heated bricks are cooled down in a chamber over a

period of two or three days. In the subsequent step, bricks are placed in a

pallet before the final stage which is the delivery to construction sites. We

can see that standardized bricks are eventually loaded onto trucks.