Preview text:

lOMoAR cPSD| 58950985

NATIONAL ECONOMICS UNIVERSITY

SCHOOL OF ADVANCED EDUCATION PROGRAM

GLOBAL SUPPLY CHAIN MANAGEMENT TOPIC

Analysis of the Global Supply Chain Management of PANASONIC

Course: International Supply Chain Management 01

Instructor: M.S. Tran Hoang Kien

Presented by Group 5 - POHE Commercial Business Management 63 Student Name Student ID Luong Hai Yen 11216372 Hoang Thuy Duong 11211555 Nguyen Thu Hoa 11219700 Nguyen Minh Trang 11210154 Hanoi, 2023 lOMoAR cPSD| 58950985 TABLE OF CONTENTS

I. ABOUT PANASONIC ..................................................................................................... 5

1. Introduction of PANASONIC ...................................................................................... 5

1.1. Overview ............................................................................................................. 5

1.2. Mission ................................................................................................................ 5

1.3. The new slogan “Live Your Best” ....................................................................... 5

2. Development history of PANASONIC ........................................................................ 6

2.1. 1918-1961: Focus on domestic product development and export of

someproducts .............................................................................................................. 6

2.2. 1961-1990s: Establish many factories in foreign countries ................................ 6

2.3. 1990s-now: Rapidly expansion to global ............................................................ 6

II. MOTIVATION TO ESTABLISH A GLOBAL SUPPLY CHAIN OF

PANASONIC61. Business model ........................................................................................ 7

2. International business strategy ..................................................................................... 8

2.1. Pre-1990 period ................................................................................................... 8

2.2. Post-1991 period .................................................................................................. 8

3. Motivation to establish a Global Supply chain ............................................................ 8

III. FACTORS AFFECTING THE DECISION TO IMPLEMENT THE ................... 10

FUNCTIONS OF GLOBAL SUPPLY CHAIN MANAGEMENT OF PANASONIC . 10

1. Since 1950s ................................................................................................................. 10

1.1. Market globalization drivers .............................................................................. 10

1.2. Cost globalization drivers .................................................................................. 10

1.3. Government globalization drivers ..................................................................... 11

1.4. Competitive globalization drivers ..................................................................... 11

2. Since 1990s ................................................................................................................. 11

2.1. Market globalization drivers .............................................................................. 11

2.1.1. Common customer lifestyles, needs and tastes ......................................... 11

2.1.2. Global ecommerce .................................................................................... 12

2.1.3. Global marketing ....................................................................................... 13

2.1.4. Sustainability at customer levels ............................................................... 13

2.2. Cost globalization drivers .................................................................................. 14

2.2.1. Global scale economies ............................................................................. 14

2.2.2. Product development cost ......................................................................... 14

2.2.3. Accelerating innovation ............................................................................ 15

2.2.4. Logistics cost ............................................................................................. 15

2.3. Government globalization drivers ..................................................................... 16

2.3.1. Policies and regulations ............................................................................ 16

2.3.2. Tariff barriers ............................................................................................. 16

2.3.3. Non tariff barriers ...................................................................................... 17 lOMoAR cPSD| 58950985

2.4. Competitive globalization drivers ..................................................................... 17

2.4.1. Competitive advantages ............................................................................ 17

2.4.2. Competitors ............................................................................................... 17

IV. GLOBAL SUPPLY CHAIN MANAGEMENT ACTIVITIES OF PANASONIC . 18

1. Purchasing Activities .................................................................................................. 18

1.1. Purchasing planning and strategy ...................................................................... 18

1.2. Global Supplier Selection .................................................................................. 19

1.3. Global Supplier Network ................................................................................... 20

2. Operations Activities .................................................................................................. 20

2.1. Research and Development (R&D) Management ............................................. 20

2.1.1. Organization of R&D Centers ................................................................... 20

2.1.2. R&D activities ........................................................................................... 21

2.2. Production Management .................................................................................... 22

2.3. Quality management in global production ........................................................ 23

2.4. Lean supply chain management ........................................................................ 25

3. Logistics Activities ..................................................................................................... 26

3.1. Global Logistics Process ................................................................................... 26

3.2. Application of logistics ...................................................................................... 28

3.3. Global freight transport ..................................................................................... 29

3.4.1. Sea Transport ............................................................................................. 29

3.4.2. Rail Transport ............................................................................................ 29

3.4.3. Air Transport ............................................................................................. 30

3.4.4. Road Transport .......................................................................................... 30

3.5. Reverse Logistics ............................................................................................... 30

4. Market Channels Activities ........................................................................................ 31

4.1. 4P Strategy ......................................................................................................... 31

4.1.1. Place .......................................................................................................... 31

4.1.2.Price............................................................................................................ 31

4.1.3. Promotion .................................................................................................. 32

4.1.4. Product ...................................................................................................... 32

4.2. Customer Management in the Global Supply Chain ......................................... 32

4.2.1. Customer Management with Technology and Supply Chain Digitization32

............................................................................................................................. 32

4.2.2. Developing a Unified Data Platform ........................................................ 32

4.2.3. Enhancing Flexibility and Improving Customer Experience ................... 33

4.2.4. Strategic Partnerships for Digital Transformation .................................... 33

V. RECOMMENDATIONS .............................................................................................. 33

1. Adopt Technology ...................................................................................................... 33

2. Optimize online purchasing experience ..................................................................... 33

VI. RECOMMENDATIONS FOR PANASONIC VIET NAM ..................................... 34 lOMoAR cPSD| 58950985

1. About Panasonic Viet Nam ......................................................................................... 34

1.1. Overview ........................................................................................................... 34

1.2. Supply chain Management ................................................................................ 35

2. Recommendations ...................................................................................................... 37

2.1. Selecting domestic suppliers combined with increasing the domestic ratio

inproduction .............................................................................................................. 37

2.2. Optimize transportation processes to improve sustainability ............................ 37 lOMoAR cPSD| 58950985 CONTENT I. ABOUT PANASONIC 1. Introduction of PANASONIC 1.1. Overview

Panasonic is a famous Japanese manufacturer founded in 1918 by Kōnosuke

Matsushita to manufacture and market lightbulb sockets. It was incorporated in 1935 and

began expanding rapidly into several varied electrical product lines. During the 1930s it

added such electrical devices as irons, radios, phonographs, and light bulbs.

After World War II, all consumers wanted a television, washing machine, and

refrigerator. Panasonic had foreseen the dawn of the electrification age, so it began

producing washing machines in 1951, TV sets in 1952, and refrigerators in 1953.

In 1956, the company’s first electric, automatic rice cooker was put on the market,

and this product suddenly increased in demand and led to the rice cooker boom of 1957. In

the next year, home air conditioner was released. Until now, Panasonic has provided various

home appliances, such as: air conditioner, air purifier, refrigerator, washer, shower, iron, vacuum cleaner, bidet, TV,...

Besides home appliances, Panasonic also manufactures other product lines, including

rechargeable batteries, automotive and avionic systems, industrial systems,...

Currently, Panasonic has 166 bases with around 90,000 employees worldwide. The head

office location is 1006, Kadoma, Kadoma City, Osaka 571-8501, Japan. 1.2. Mission

In 1932, at the first company foundation meeting, the Founder, Konosuke Matsushita

said "The mission of a manufacturer is to overcome poverty by producing an abundant

supply of goods. Even though water can be considered a product, no one objects if a passerby

drinks from a roadside tap. That is because the supply of water is plentiful and its price is

low. Our mission as a manufacturer is to create material abundance by providing goods

as plentifully and inexpensively as tap water. This is how we can banish poverty, bring

happiness to people's lives, and make this world a better place."

“Ideal society with affluence both in matter and mind” is an ideal society that the

Founder Konosuke pursued throughout his life and until now, the next generations of

Panasonic are still following.

1.3. The new slogan “Live Your Best”

Mr. Yuki Kusumi - the current CEO of Panasonic has launched a new slogan for

Panasonic “Live your Best” to improve the happiness of each individual in society by

helping them pursue happiness both in matter and mind. At the same time, Panasonic will lOMoAR cPSD| 58950985

continue addressing global environmental issues. This slogan still commits to the mission that Panasonic is pursuing.

2. Development history of PANASONIC

2.1. 1918-1961: Focus on domestic product development and export of some products

In 1918, Panasonic was founded in 1918 as Matsushita Electric Housewares

Manufacturing Works in Fukushima, Osaka by Kōnosuke Matsushita with two products:

attachment plug and two-way socket. Then, Panasonic invented and manufactured many

other electrical products such as square bicycle lamps, radios, washing machines, black and

white TVs, and refrigerators,...

In 1932, the company established an export department and started exporting such

products as wiring devices and dry batteries.

In 1959, ready to expand business activities abroad, Konosuke founded MECA in

New York as the first post-war overseas sales company.

2.2. 1961-1990s: Establish many factories in foreign countries

In 1961, the company began to provide technical assistance to several overseas

countries and construct plants abroad to expand its operations on a global scale.

In 1961, Panasonic’s first overseas manufacturing facility, National Thai

Manufacturing Company was established. Manufacturing facilities were subsequently

established in countries with difficulty importing household appliances due to foreign

exchange shortages. In the same year, Founder Matsushita visited the United States and met

with American dealers, then the company began producing televisions for the American

market under the Panasonic brand and expanded the use of this brand to Europe in 1979.

In 1972, Matsushita established its first overseas factory producing air conditioners in Malaysia.

In 1987, Panasonic expanded production in Taiwan, Thailand, and Indonesia.

Panasonic established its first overseas factories producing wiring devices in Taiwan and

conduit pipes in Thailand. Through a technology licensing agreement with National Gobel

in Indonesia, its fluorescent lamp ballasts were produced outside of Japan for the first time.

2.3. 1990s-now: Rapidly expansion to global

In the early 1990s, Panasonic focused on expanding to the Chinese market, which

was growing and developing rapidly. Based on its experience in delivering comfortable

lifestyles for Japanese consumers, Panasonic established a joint company for manufacturing

and sales in China, promoting globalization while responding to high demand.

Post 2000, Panasonic rapidly expanded its global reach through. In 2007, Panasonic

acquired Anchor Electricals in India. In 2014, Panasonic acquired VIKO in Turkey and also

opened a new factory for electrical installation materials in Binh Duong, Viet Nam to expand

its production presence in Vietnam and ASEAN countries. lOMoAR cPSD| 58950985

Now, Panasonic has a strong global presence when sells in more than 50 countries

around the world, mainly in Asia with 512 consolidated companies (including the parent

company). The company is committed to innovation and technological advancements, has a

reputation for producing high-quality products, and has a strong responsibility to

environment and sustainability.

II. MOTIVATION TO ESTABLISH A GLOBAL SUPPLY CHAIN OF PANASONIC 1. Business model BUSINESS MODEL CANVAS Key partners Key Value Customer Customer - Suppliers activities propositions relationships segments - Retailers - - - New slogan - Pre and - Mass Research Manufacturin “Ideas for post-sales market institutions - g Life” assistance - - Home Subsidiaries - Research & - To Online - Businesse -

Distributor Development become one communities s -Technological s - Contract - Marketing & of and forums - enthusiastic manufactures Promotio the largest Loyalty n - Sales Japanese program and electronics - Retail stores distribution producers - Qualit Key y high-tech Channels resources products - - Online - Staff Solutions for stores - business and - Website Manufacturin homes - - Sale team g Customer- - Distributor facilities - focused s - Partnered Intellectual products that service centers property - enhance Distributio convenience n network and - R&D efficiency centers - Strong brand reputation Cost structure Revenue streams - R&D expense - Sales - Manufacturing cost - Licensing fee - Marketing cost -

Subscription model for software - Staff compensation and services

- Distribution and logistics costs -

Extended warranties and service - Operational cost contracts - Acquisitions lOMoAR cPSD| 58950985

=> This model shows that Panasonic is a large-scale, diversified company with a sustainable

development strategy. Panasonic has built a strong business ecosystem based on the

foundation of product quality, technological innovation, and customer satisfaction.

2. International business strategy

2.1. Pre-1990 period

Matsushita's strategic development orientation during this period was based on a

global strategy. The company increased profits by focusing on cutting costs through the

construction of centralized manufacturing plants and exploiting regional advantages. -

Strategic tasks that create competitive advantages for company, such as R&D and

marketing are mostly decided and implemented in Japan. -

Production and assembly work are implemented in convenient locations such as

China, Taiwan,... where manufacturing facilities are large-scale and focus on mass production.

2.2. Post-1991 period

During this period, globalization took place strongly, the growth rate of information,

technology, and engineering increased rapidly. Along with that, emerging economies such

as China and India required Panasonic to restructure the old organization to better meet the

needs of each specific market. Therefore, in April 2001, the reform of the distribution and

sales system of consumer products was implemented.

At the same time, as concerns for the Earth's environment increased throughout the

world, Panasonic has taken the lead in the global move for corporate environmental responsibility -

In 1991, Panasonic drew up the "Environmental Charter". This charter calls for the

adoption of the latest environmentally-friendly technologies and processes. -

After that, Panasonic's Green Environment policies were subsequently established:

Green Plan 2010, Green Plan 2018, and Green Plan 2021.

=> Panasonic continues focusing on R&D, not only in Japan but also expanding R&D

centers in other countries worldwide. Currently, Panasonic has 24 R&D centers, mainly in

Asia. The company continues to expand the market, change to adapt to the market and pursue sustainable production.

3. Motivation to establish a Global Supply chain

Panasonic’s global supply chain formation process took place gradually, starting with

exporting its products to other countries and gradually expanding its scale. The motivation

for Panasonic to establish the global supply chain came from many factors, and the two most important factors are “Optimized production cost” and “Product diversification” lOMoAR cPSD| 58950985 -

Mission’s Konosuke for Panasonic: “Our mission as a manufacturer is to create

material abundance by providing goods as plentifully and inexpensively as tap water”,

which means Panasonic wants to provide various products with diverse types and cheap prices. -

Global business strategy: With a global strategy, Panasonic has continuously

expanded its market to new countries and regions, creating high demand for its products. In

addition, Panasonic has a strategy of localizing products and services to suit each market,

helping to increase competitiveness. -

The Japanese market is saturated and resource costs in Japan are high:

Japan is known as one of the world's economic powers. Despite heavy losses after the

Second World War, Japan has made great strides in restoring and building its economy

thanks to the government’s right policies. Japan is not only famous for cars, motorbikes, and

bicycles but also very famous for electrical equipment with many familiar products such as

LG TVs, Toshiba washing machines, etc. The coverage of Japanese electronic devices is

very large. Companies in this field not only compete abroad but also compete in the domestic

market. They compete on product quality, brand, price, etc. Therefore, the Japanese market

is saturated. To increase competitiveness, companies must participate in the global supply

chain to increase surplus value for businesses.

Japan is an island nation with few natural resources and many natural disasters, so

the cost of production in Japan is higher than in mainland countries such as China or

countries in the Southeast Asian region. In addition, emerging markets like China, India,

Southeast Asia, etc are attractive places for companies like Panasonic to set up their supply

chains there. Because in those markets, production costs are low, the labor force is abundant,

the consumer market is large and the government has many preferential policies for foreign companies to invest. -

Globalization trend: From the 1990s, the globalization process was taking place

strongly in the world, and information technology and engineering developed at a rapid

pace. This led to increasingly fierce competition between companies, especially in the

consumer electronics industry. This is an industry that requires better and higher technology

research and development, so companies in this field need to exploit resources to the

maximum efficiency in order to survive.

=> Production costs can be optimized by accessing cheap raw materials and taking

advantage of cheap labor in emerging markets. Building a global distribution network

helps Panasonic choose the shortest and most efficient transportation routes, thereby

reducing transportation costs. In addition, the global supply chain also helps Panasonic

reach many different suppliers to meet product diversification. lOMoAR cPSD| 58950985

III. FACTORS AFFECTING THE DECISION TO IMPLEMENT THE

FUNCTIONS OF GLOBAL SUPPLY CHAIN MANAGEMENT OF PANASONIC 1. Since 1950s

1.1. Market globalization drivers

The consumer electronics and technology market was booming, with an ever-

increasing demand for quality products and cutting-edge technology, forcing Panasonic to

respond. After World War II, the US economy recovered strongly and grew, becoming the

world's largest. This period also saw increased consumption, infrastructure construction, and

the development of the middle class. (The US economy grew at an average rate of 3.8% per

year from 1946 to 1973, while the median household income grew by 74% (or 2.1% per

year). The US is one of the largest consumer markets with a high demand for electronics and

technology products. It is home to a strong culture of innovation, with many leading

universities and research institutes, facilitating the development of new technology. After

his visit to the United States, Matsushita realized that America had a special way of science

and technology between Japan and the United States.

⇒ Being present here helps Panasonic approach and serve the market more effectively, easily

finding a partner to establish a technical cooperation agreement.

⇒ In 1959, Matsushita Electric Corporation of America (MECA) was established in New

York to research and develop televisions, VCRs, microwave ovens, audio components and other products.

Since the 1960s, signs of increasing environmental degradation have become

increasingly clear, and people have begun to realize their harmful effects on the environment.

The United Nations Conference on Human Environment held in Stockholm (Sweden's

capital) from June 5-6, 1972 was the result of these new perceptions, the first action marking

the joint efforts of all mankind to solve environmental problems. In the late 1980s,

environmental awareness began to be concerned, placing higher demands on

environmentally friendly products and clean production processes.

The third industrial revolution began in the 1970s, although it has not yet had a clear

impact, it has gradually changed consumers' perception of technology. The Internet began

to take shape and develop, consumers around the world gradually became more aware of

Panasonic's technological home appliances and wanted to be able to buy these items locally

→ Panasonic needed to expand its distribution network.

1.2. Cost globalization drivers

Panasonic's goal in globalized production is to establish production units in optimal

locations to reduce costs and shorten transportation times. lOMoAR cPSD| 58950985

Some countries such as Thailand and Malaysia have begun the industrialization

process, leading to an increase in labor costs. However, they are still lower than those of

developed countries such as Japan, the United States, and Western countries.

The household electrical industry in Southeast Asian countries in the 1960s was still

in its infancy, input materials such as copper, plastic, steel, etc. were relatively low in price

due to the supply mainly coming from agriculture and primitive mining. Technology was

not yet strongly developed, so the cost of finished products in these countries was still low.

1.3. Government globalization drivers

Countries around the world have introduced many policies and incentive programs to

support research projects and businesses in the electronics sector (including household

appliances). Programs such as ARPA (Advanced Research Projects Agency) of the US

government have provided financial support for research projects, especially in the high-

tech sector. The Japanese government has implemented many policies to encourage

companies to invest in research and development, including funding and tax reductions for R&D projects.

General Agreement on Tariffs and Trade (GATT): signed in 1947 to reduce tariffs and

other trade barriers, promoting global free trade.

1.4. Competitive globalization drivers

The boom in the electronics industry in the 1960s led to increased competition from

other Japanese and international companies. Panasonic needed to strengthen its position so

as not to fall behind its competitors. To stay competitive, Panasonic needed to constantly

innovate and improve its technology. Opening factories in Europe allowed the company to

quickly test and implement new technologies.

Competitors such as RCA, Sony, and LG were also increasing their presence in

Europe. Opening factories helped Panasonic protect and increase its market share in the face of fierce competition.

⇒ Increased competition from other electronics companies, both in Japan and

internationally, forced Panasonic to innovate and improve its technology to stay competitive. 2. Since 1990s

2.1. Market globalization drivers

2.1.1. Common customer lifestyles, needs and tastes

The global village creates a convergence of lifestyles and with similar tastes that

stimulate the global standardization of products. The expectation is that the brand’s market

channels will be able to deliver on these converging lifestyles and tastes.

At the same time, the domestic appliance sector is increasingly witnessing the

emergence of trends related to: First, sustainability and energy efficiency. The goal is not

only to save costs for consumers but more importantly, to minimize the impact of domestic lOMoAR cPSD| 58950985

appliances on the environment. Manufacturers are now offering green household appliances,

equipped with more efficient technological solutions and programs that, when used

correctly, help to reduce energy and water waste. Second, smart features and modern

design.Today, consumers are not only seeking high performance with low energy impact but

also an appealing aesthetic that seamlessly integrates into household spaces. Also,

technological innovation continues to drive the evolution of household appliances, offering

new features and greater user experience customization. These factors have encouraged

Panasonic to bring out products that are safe, smart and sustainable, minimizing the

environmental impact throughout their lifecycle, from manufacturing to disposal.

In addition, Panasonic products cater to a global audience with similar tastes, such as

TVs, audio equipment, and smart appliances. This encourages standardization across

markets, which simplifies production and supply chain processes. Panasonic can leverage

economies of scale by producing standardized components and products at large volumes.

While global customer lifestyles converge in certain aspects, Panasonic must also address specific regional needs.

2.1.2. Global ecommerce

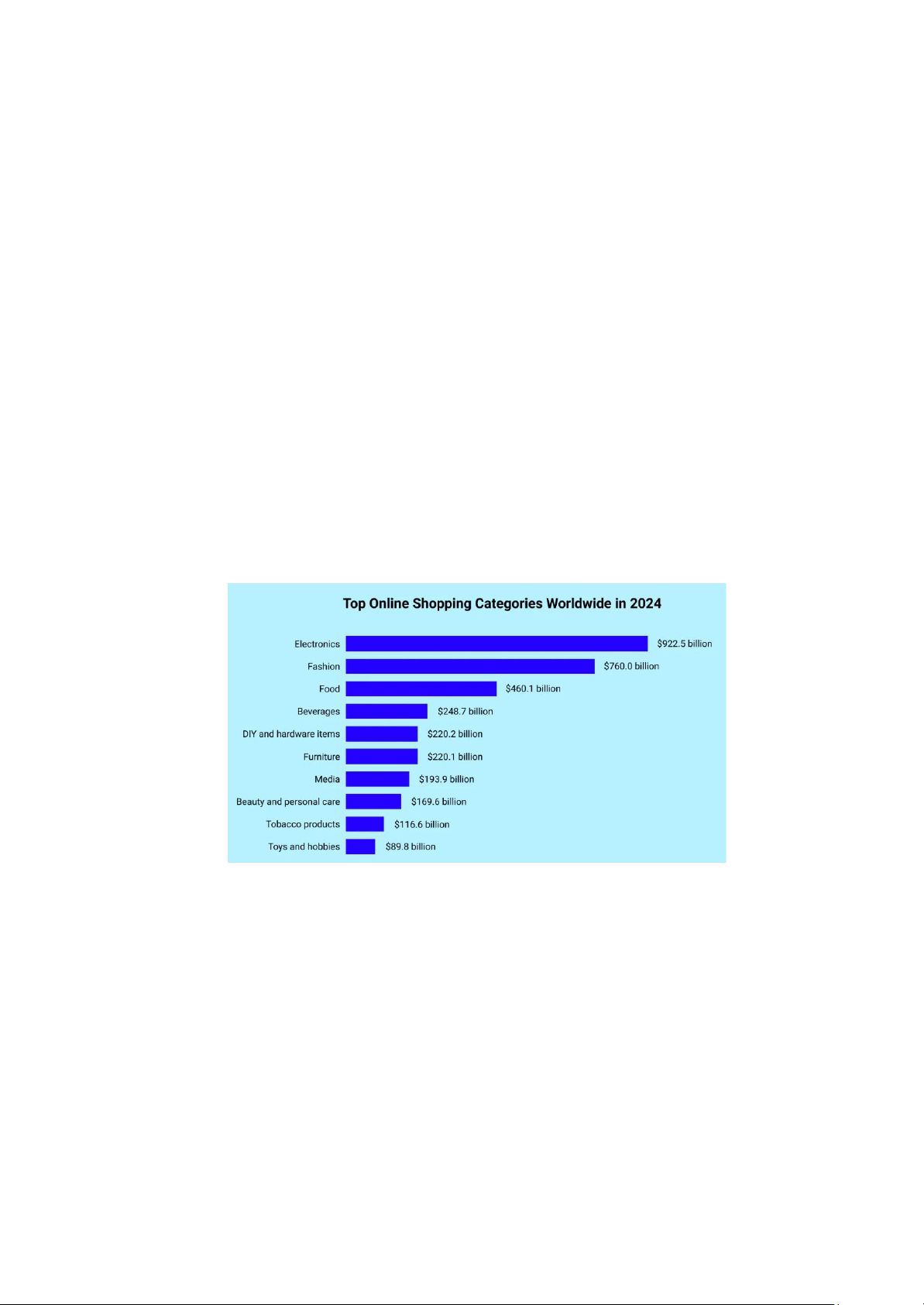

Top online shopping categories worldwide in 2024 Source: Statista

With a forecasted spend of $922.5 billion, electronics represent a significant portion

of global ecommerce sales. Along with the development of advanced technology devices,

the consumption habits of the majority of customers have clearly changed, consumers flock

online for the cutting-edge gadgets and convenience, trusting detailed product descriptions,

reviews, and comparison tools to make informed purchases. The coronavirus pandemic also

helped push e-commerce to new levels.

The rise of global e-commerce has a significant impact on Panasonic's supply chain

operations. This shift in distribution channels requires robust logistics and fulfillment

systems capable of managing global demand, including last-mile delivery and localized

customer service. To support global e-commerce, Panasonic needs an agile supply chain that

can quickly respond to shifts in demand. This includes maintaining inventory in strategic lOMoAR cPSD| 58950985

locations, integrating real-time data analytics, and using automated warehousing solutions

to fulfill online orders efficiently.

E-commerce expansion also necessitates the optimization of international shipping

and handling of tariffs, duties, and trade regulations. Panasonic must manage complex

logistics to ensure timely delivery while navigating international trade laws.

E-commerce requires a responsive, flexible supply chain with advanced logistics to

manage cross-border sales and direct-to-consumer models. Therefore, Panasonic must

manage complex logistics to ensure timely delivery while navigating international trade laws.

2.1.3. Global marketing

Global marketing practices must resonate across diverse regions while maintaining

Panasonic's brand identity. This includes creating adaptable and transferable marketing

campaigns that meet the specific needs of various markets

Panasonic maintains a strong global brand by emphasizing innovation, quality, and

sustainability in its marketing efforts. A consistent brand message allows for marketing

strategies that can be replicated across markets with minimal adjustments. This enables cost

efficiencies and coherence in brand identity worldwide. Despite a unified message, local

nuances are crucial. Panasonic adjusts its messaging to address regional market trends,

cultural differences, and local preferences. For example, Panasonic's marketing in the US

may emphasize smart home technologies, while in Asia, the focus might be on energy-

efficient solutions. A combination of global branding with localized marketing helps

Panasonic maintain a strong presence in different regions while ensuring consistency in its messaging.

Also, global digital platforms like YouTube, Instagram, and Twitter allow Panasonic

to launch campaigns that reach global audiences with transferable content.

Simultaneously, local influencers and platforms enable Panasonic to create region-specific promotions.

The trend in the electronics industry in recent years is movements for environmentally

friendly products. The company must aim to position itself as a healthy brand and participate

in many green and socially sustainable campaigns.

2.1.4. Sustainability at customer levels

Sustainability is increasingly becoming a key purchasing criteria for consumers

across the globe. Panasonic integrates sustainability into its products and supply chain to

align with customer values. With rising global demand for socially responsible procurement

- taking into account the environment, human rights, fair labor conditions, and fair trade -

Panasonic strives to conduct its business with suppliers in a way that not only provides

excellent technology and quality but also fulfills its corporate social responsibility (CSR) in lOMoAR cPSD| 58950985

the areas of human rights and responsible employment, occupational health and safety, green

procurement, clean procurement, compliance, and information security.

Panasonic’s focus on sustainable innovations like energy-efficient home appliances

that appeal to environmentally-conscious consumers. These products require specific

materials and components, pushing the company to focus on responsible sourcing and

reducing carbon footprints across its supply chain. The company must commit to reducing

greenhouse gas emissions by adopting renewable energy in manufacturing plants, recycling

electronic waste, and using sustainable packaging materials.

Panasonic also concentrates on creating products that are durable, repairable, and

recyclable, which aligns with growing customer expectations for sustainable and long-

lasting goods. This requires a reverse supply chain to manage product returns, repairs, and recycling processes.

Panasonic has been promoting activities with long-term environmental management

vision such as formulating factories that do not emit CO2 during their operation; establishing

the “Rules on Supply Chain Compliance” that stipulates the basic policy regarding supply

chain compliance and internal rules for its CSR implementation. Since 2007, Panasonic has

joined with Sharp and Toshiba to form an e-waste collection and recycling management

company called Electronics Manufacturers Recycling Management Company (MRM), with

the purpose of bringing manufacturers together into a collective effort to recycle electronic products.

2.2. Cost globalization drivers

2.2.1. Global scale economies

Global scale economies arise when a company can reduce its per-unit costs by

producing larger quantities of products, leveraging global operations to spread fixed costs

across a broader market. Panasonic, being a multinational corporation, benefits significantly

from these economies of scale.

Many of Panasonic’s products share common components across different regions,

such as screens for TVs or processors in appliances. Standardizing components across global

markets allows Panasonic to reduce manufacturing complexity, inventory costs, and

procurement expenses, further driving economies of scale.

2.2.2. Product development cost

Panasonic operates in industries where innovation and technological advancement

are critical. The product industry that Panasonic pursues is consumer electronics. They have

many industry characteristics that directly affect the choice of a reasonable production

strategy and technological competition is inevitable, so Panasonic constantly focuses on

upgrading the R&D department not only to serve the product design stage but also to ensure lOMoAR cPSD| 58950985

the entire production process is reasonable. Therefore, managing R&D costs is a significant challenge.

Panasonic has R&D centers in key regions such as Japan, the US, and Europe. This

global network enables the company to tap into local expertise, innovation ecosystems, and

access to new technologies. The globalization of R&D allows Panasonic to distribute

development expenses while enhancing innovation efficiency. Also, by developing

technologies that can be applied across multiple product categories, Panasonic can maximize

the return on R&D investments.

2.2.3. Accelerating innovation

Innovation within the supply chain is critical to Panasonic's ability to reduce costs,

improve efficiency, and remain competitive on a global scale. As globalization accelerates,

so does the need for Panasonic to continuously innovate its supply chain.

Automation and Robotics: Using robotics and AI-driven automation systems to

reduce labor costs and increase production efficiency. Automation also enhances precision

and reduces the likelihood of errors, which leads to cost savings through reduced waste and

higher-quality outputs. In high-labor-cost regions such as Europe and North America, this

automation significantly offsets labor expenses.

Digital Transformation and Data Analytics: Leveraging digital tools such as real-time

data analytics, predictive maintenance, and Internet of Things (IoT) technologies helps

Panasonic enhance its supply chain visibility and reduce inefficiencies. For example, IoT

sensors in factories provide real-time monitoring of equipment performance, reducing

downtime and maintenance costs. Similarly, data analytics allows Panasonic to optimize its

inventory management and forecast demand more accurately, reducing excess stock and minimizing holding costs.

Sensing: Sensing technology is for real-time analysis of worker and object

movements to enhance efficiency in inventory management, workflow optimization, and spatial data digitization. 2.2.4. Logistics cost

Logistics is a critical area where cost optimization can have a direct impact on

Panasonic's bottom line. As a global company, Panasonic faces significant logistics

challenges, including shipping costs, distribution complexities, and the need for timely delivery.

By leveraging technology, optimizing its global distribution network, and

implementing lean logistics strategies, Panasonic reduces logistics expenses and improves delivery efficiency. lOMoAR cPSD| 58950985

2.3. Government globalization drivers

2.3.1. Policies and regulations

Government policies and regulations significantly affect Panasonic’s global supply

chain operations, as different countries have distinct standards regarding trade, labor, safety,

and environmental sustainability. Key policy areas that impact Panasonic include:

Trade and Investment Policies: Many countries encourage foreign investment

through favorable trade agreements or economic partnerships. Panasonic benefits from these

agreements, such as free trade agreements (FTAs), which reduce trade restrictions and

facilitate smoother cross-border operations. For example, trade agreements between Japan

(Panasonic's home country) and other regions like the European Union (EU) or ASEAN

enable Panasonic to export goods and services with lower tariffs and simplified customs procedures.

Labor and Employment Laws: Panasonic must comply with labor regulations in

various countries where it operates factories and distribution centers. Labor policies

regarding wages, working conditions, and safety standards vary significantly between

regions, affecting the company’s operational costs and supply chain efficiency. For instance,

stricter labor laws in European countries may lead to higher production costs, while more

flexible labor policies in countries like Vietnam or India could offer cost advantages but

require compliance with local labor protections.

Intellectual Property (IP) Protection: Strong IP regulations in certain regions (e.g., the

US, EU, and Japan) offer Panasonic protection for its innovations and technologies,

particularly in high-tech industries like electronics and batteries. Ensuring compliance with

IP laws helps Panasonic safeguard its R&D investments, but weak IP enforcement in some

countries poses risks, particularly with potential imitation or infringement.

Environmental Regulations: Panasonic must also comply with varying environmental

policies across countries. Stringent environmental regulations in the EU (such as the EU’s

Restriction of Hazardous Substances Directive and the Waste Electrical and Electronic

Equipment Directive) force Panasonic to design and manufacture products with eco-friendly

materials and manage electronic waste responsibly. Similarly, Japan's environmental

policies push Panasonic to implement green manufacturing practices. 2.3.2. Tariff barriers

Tariffs are taxes or duties imposed by governments on imports and exports. They play

a significant role in shaping Panasonic’s global supply chain by influencing the cost of cross- border trade.

High tariffs increase the cost of importing components or finished products,

potentially affecting Panasonic's pricing strategies in international markets. For example, lOMoAR cPSD| 58950985

tariffs imposed by the US on imported electronics or components from countries like China

could impact the profitability of Panasonic’s products in the US market.

To mitigate the impact of tariffs, Panasonic may strategically locate manufacturing

plants in countries with lower or no tariff barriers, either to serve regional markets or to

export goods to tariff-friendly markets. For instance, Panasonic’s expansion of

manufacturing operations in Southeast Asia, particularly in Vietnam and Malaysia, allows

the company to avoid high tariffs when exporting to the US and EU, thanks to existing trade

agreements with these regions.

Panasonic benefits from regional trade blocs like the EU, ASEAN, and the North

American Free Trade Agreement (NAFTA)/ASEAN and Japan signed the ASEAN

Comprehensive Economic Partnership (AJCEP). These agreements lower or eliminate

tariffs on intra-regional trade, reducing costs and improving the competitiveness of

Panasonic’s products in member countries.

2.3.3. Non tariff barriers

Non-tariff barriers, such as import quotas, licensing requirements, and product

standards, can increase compliance costs and complicate Panasonic’s supply chain,

especially when operating across multiple jurisdictions with differing regulations.

2.4. Competitive globalization drivers

2.4.1. Competitive advantages

Panasonic’s competitive advantages revolve around its diversified product portfolio,

innovation capabilities, strong brand reputation, focus on sustainability, and global presence.

These advantages provide the company with leverage in its global supply chain and help it

maintain competitiveness across different markets.

Brand Image: Panasonic is one of the giants in the home appliances industry in the

market with its brand positioning along with “Japanese-style products”. Therefore, the

company is highly appreciated by customers with its product philosophy of bringing the

highest technology to bring customers the most authentic experience.

Market Position: Panasonic aims to serve global customers with its highest quality

products, but at the most reasonable prices. The company ensures the availability of products

to every segment of society through its affordable and reasonable pricing policy. Therefore,

reasonable pricing policies and cost-cutting strategies are implemented to penetrate each

market that the company wants to focus on. 2.4.2. Competitors

In the home appliance sector, Panasonic competes with global giants like Samsung,

LG, Sony. Both Samsung and LG have strong positions in consumer electronics, particularly

in TVs, smartphones, and home appliances. Samsung and LG leverage their economies of

scale, strong brand recognition, and advanced technology to compete with Panasonic. lOMoAR cPSD| 58950985

Samsung’s global reach and ability to produce components in-house (such as displays and

semiconductors) give it a cost advantage over Panasonic. Panasonic must therefore rely on

supply chain innovations, product differentiation (e.g., energy efficiency and eco-friendly

features), and strong customer loyalty to maintain competitiveness in this sector. On the

other hand, Sony is another key competitor in areas such as home entertainment systems and

digital cameras. Sony’s competitive advantage lies in its strong brand and innovation in high-

end electronics. Panasonic’s response is to differentiate its products through sustainability

features and smart home integration, while also optimizing its supply chain for cost savings.

The competitive pressures and increased motivation to establish a global presence

have taken on greater importance for Panasonic to develop an efficient supply chain to

maintain its market position and satisfy its customers.

IV. GLOBAL SUPPLY CHAIN MANAGEMENT ACTIVITIES OF PANASONIC 1. Purchasing Activities

1.1. Purchasing planning and strategy

Panasonic is well-known as a manufacturer of electronic devices and household

appliances. In recent years, the company has increasingly focused on producing components

and providing services for other businesses, such as electric vehicle batteries for Tesla.

Originating as a leading manufacturer of high-quality electronic components and

semiconductors, Panasonic predominantly produces its own products. However, the

company mainly purchases raw materials like copper, aluminum, steel, and nickel for

manufacturing purposes. For instance, Panasonic typically imports plastic from China,

purchases nickel powder from Australia, and sources lithium from the United States.

In addition, Panasonic also imports most of the machined parts needed for its

production lines that it does not produce itself or cannot produce efficiently. Importing these

parts allows Panasonic to focus on the important parts of its production process that it is

strong at, while still maintaining the majority of its production in-house. lOMoAR cPSD| 58950985

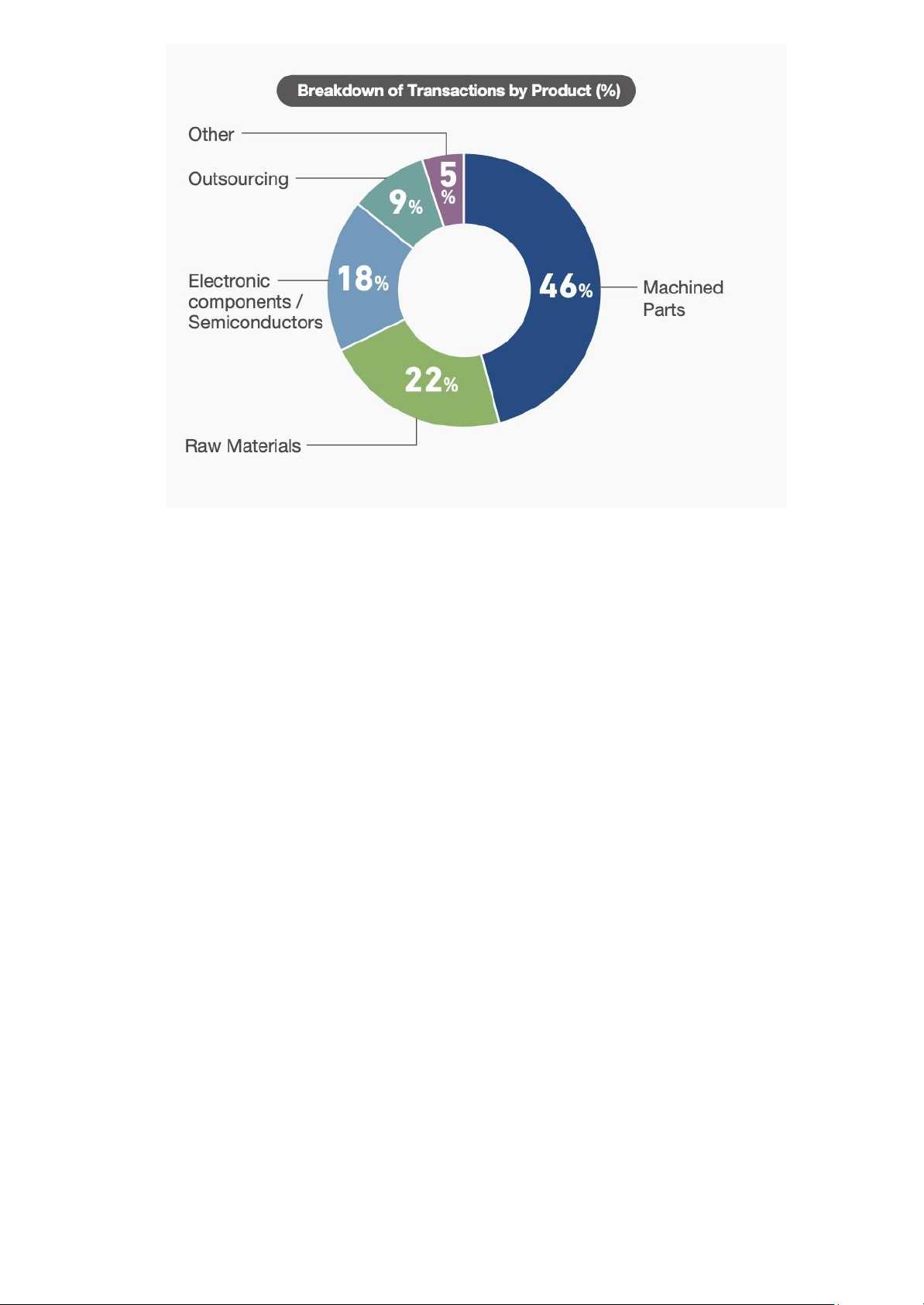

Sources: Sustainability Data Book 2022

1.2. Global Supplier Selection

Since its establishment, Panasonic has conducted business in line with its philosophy:

“The company is a public entity of society, contributing to society through our business

activities.” The company’s standard procurement agreements encompass CSR-related

matters, such as human rights, safe working environments, and environmental

consciousness. Consequently, Panasonic also sets requirements for its suppliers based on CSR criteria.

When selecting new suppliers, Panasonic stipulates that they must engage in

Corporate Social Responsibility (CSR) practices. The company carries out assessments to

verify suppliers’ performance in areas like human rights, labor conditions, health and safety,

environmental protection, and information security. Since 2015, Panasonic has required new

suppliers to conduct CSR self-assessments, using these reports as one of the tools for

evaluation. In March 2016, Panasonic Group released the “Panasonic Supply Chain CSR

Promotion Guidelines” (Version 1.0), which referenced international standards. This

document was later updated and revised in July 2018, now titled the “Panasonic Supply

Chain CSR Promotion Guidelines” (Version 2.0). These efforts reflect Panasonic’s

commitment to selecting suppliers that not only meet high standards but also align with the

sustainable strategies the company pursues. lOMoAR cPSD| 58950985

1.3. Global Supplier Network

Panasonic Group does business with approximately 13,000 suppliers worldwide. The

Group promotes activities with its global business partners across its entire supply chain to

fulfill its Corporate Social Responsibility.

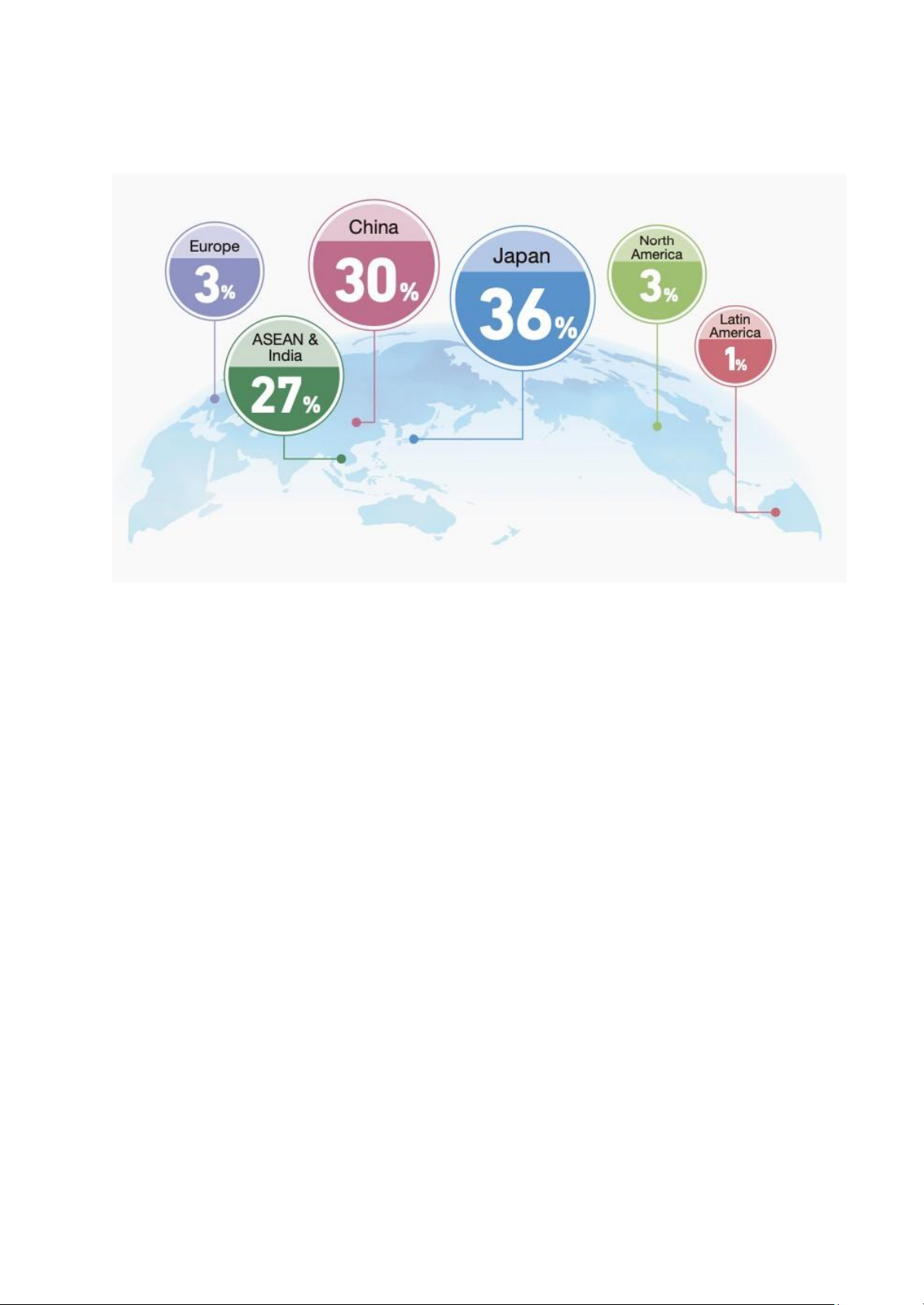

Sources: Sustainability Data Book 2022

Panasonic develops partnerships with suppliers in various regions to support global

manufacturing operations, helping to ensure quality and technological excellence, while also

complying with social responsibilities in issues such as human rights, health, safety, and

environmental protection. On the other hand, it minimizes the risk of dependence on a single

region, while leveraging technology and materials from key markets. The high regional

allocation in Japan, China, and ASEAN/India reflects a strategy of focusing on regions with

abundant supply and the ability to support large-scale production. 2. Operations Activities

2.1. Research and Development (R&D) Management

2.1.1. Organization of R&D Centers

Panasonic Group's R&D activities are primarily carried out by the parent company,

Panasonic Holdings Co., Ltd., which is involved in researching and developing company-

wide strategies related to technology and manufacturing, developing advanced technologies

from a medium - to long-term perspective, and creating production and foundational

technologies. Simultaneously, Panasonic is advancing R&D on a global scale at optimal

locations in Japan, North America, Europe, and Asia, utilizing a local talent-driven R&D system.