Preview text:

lOMoAR cPSD| 59054137 GRAVITY BASE FOUNDATIONS lOMoAR cPSD| 59054137 lOMoAR cPSD| 59054137

Concrete gravity base foundations able to be

floated and towed out to deeper water

windfarms and installed without specialist

marine equipment with minimum seabed preparation. CONTEXT

The UK’s major programme towards sustainable,

resilient, low carbon energy generation is pushing

forward the next stages of offshore renewables. For the

extensions to Round 2 and Round 3 in deeper waters a

new reliable approach is needed for offshore wind

turbine foundations. The Arup/Costain/Hochtief gravity

base foundation provides this. lOMoAR cPSD| 59054137 Turbine Foundation Selection

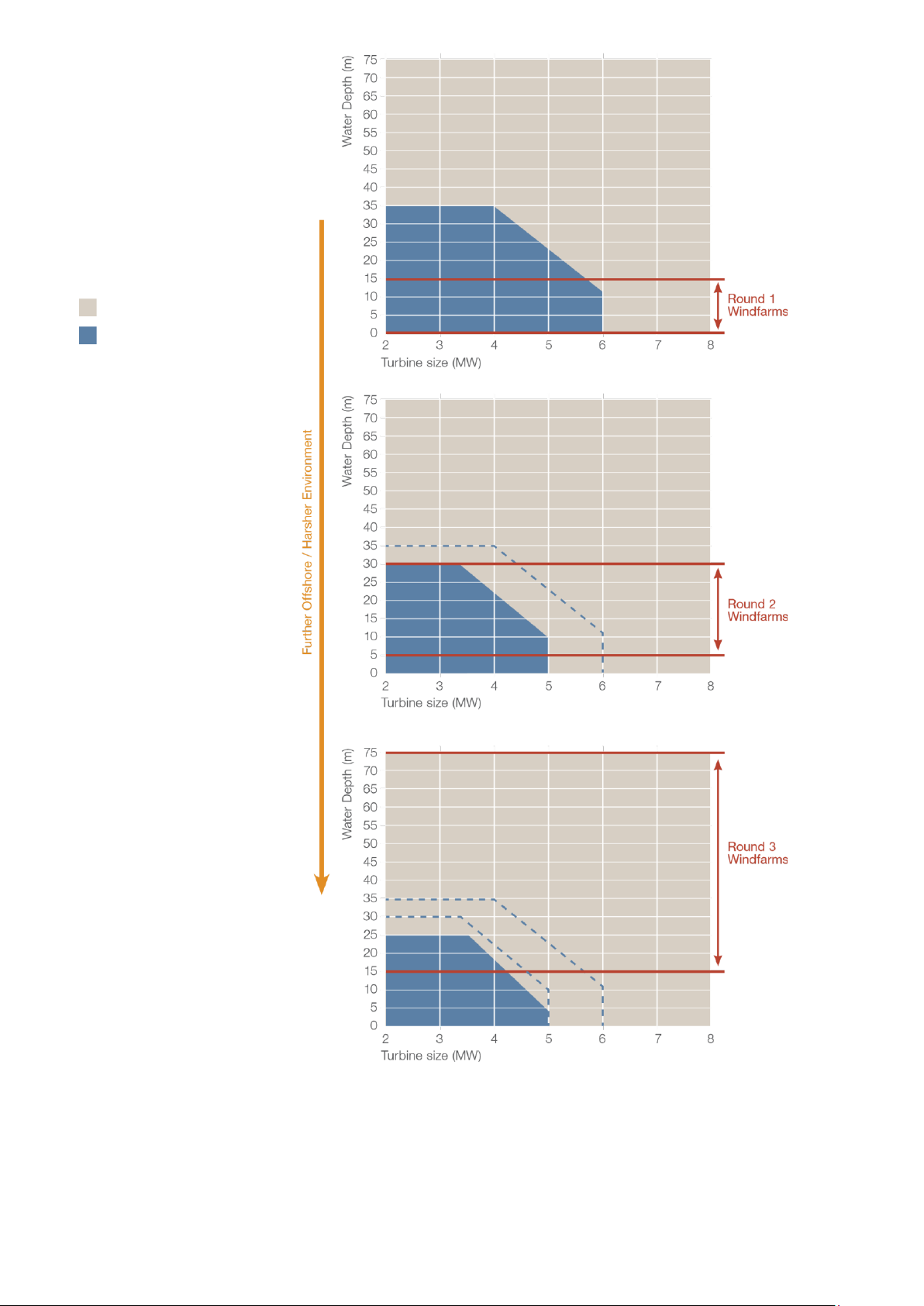

Optimum foundation selection is a function

of the variables of water depth, turbine size

and windfarm location conditions. As the

water depth and turbine size increase, the

applicability of steel monopiles becomes

limited. This limit is further constrained by

the harsher installation and operating

conditions that prevail as the windfarm

locations become progressively further

offshore. The gravity base foundation

provides an optimal solution for this

broader range of operating conditions. Gravity Base Foundations Monopile Foundations lOMoAR cPSD| 59054137 EXISTING FOUNDATION TYPES

optimising installation flexibility and facilitating

improved operation and maintenance.

The current approach to turbine foundations

typically has been steel monopiles. However, in

The Arup/Costain/Hochtief gravity base responds,

deeper waters and with larger turbines these reach

following a research and development programme, as

an upper limit which does not meet the

a self-installing turbine foundation that can be mass

requirements of the new windfarms, both in terms

produced in construction facilities located in ports to

of technical performance and offshore installation.

suit rapid deployment to the UK windfarms.

There is also a need to achieve greater flexibility

through the supply chain that can increase the

Concrete gravity bases can be successfully

market’s capacity and avoid dependency on large

deployed at all upcoming windfarms around the UK scale steel tubulars.

coast. For example, 84% of the Round 3 sites are

in water depths over 30m, where concrete

foundations may prove the best solution. Our

gravity base foundation combines this with self-

installation to avoid the need for specialist and expensive marine equipment. < GRAVITY BASE FOUNDATION CONCRETE GRAVITY BASES

Offshore windfarms are capital intensive projects

and turbine foundations represent a quarter of

their total delivery cost. The renewable industry

is looking for creative yet dependable new

approaches to drive down this cost, whilst lOMoAR cPSD| 59054137

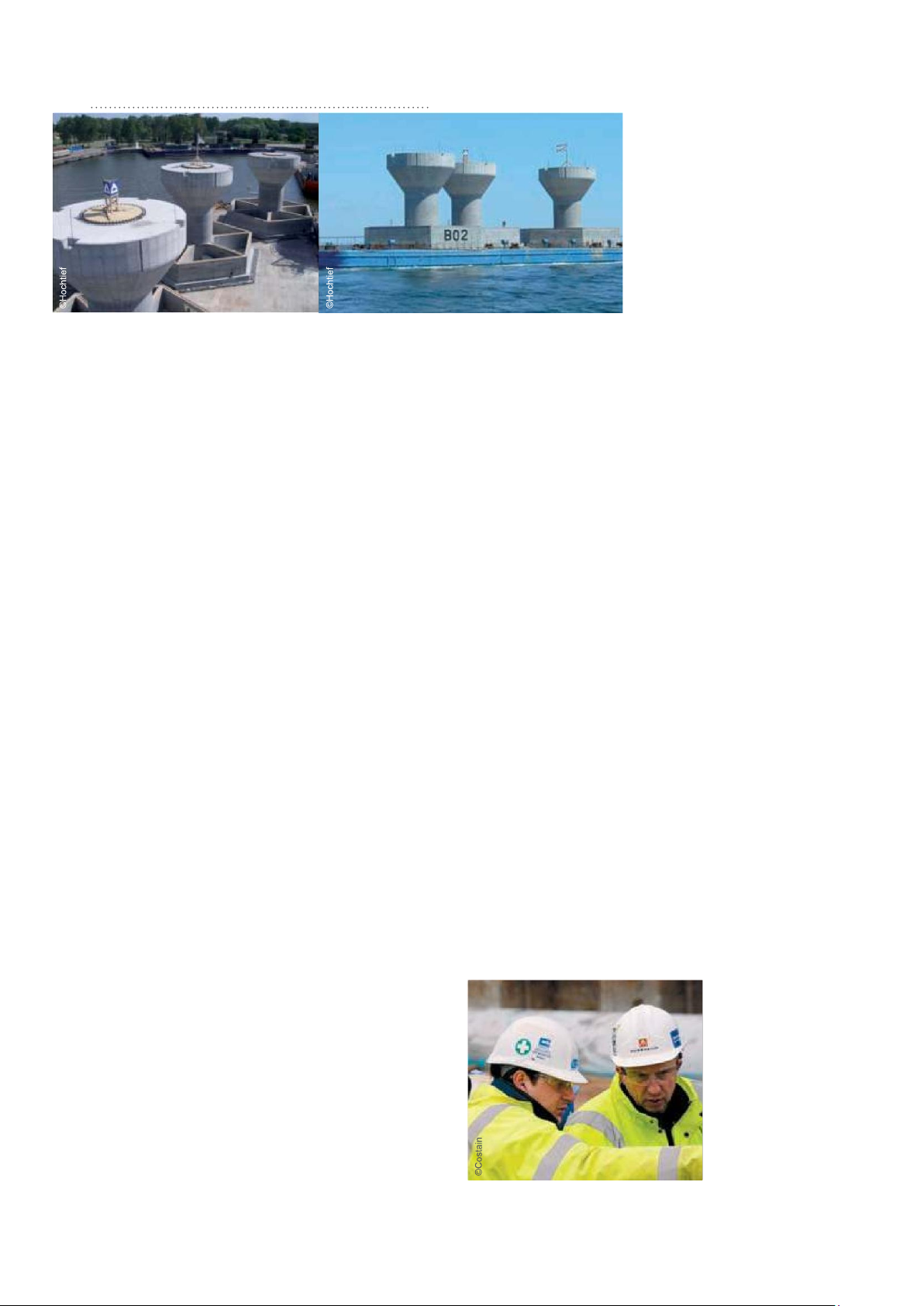

< Sweden’s largest offshore wind

energy farm, Lillgrund, required 49 large concrete foundations weighing around 1,400 tonnes each. These were constructed at a facility in Poland and transported by sea to their

required location. The concrete foundations were placed very

precisely onto their stone bases located in water up to 11 metres. KEY FEATURES & BENEFITS

• Construction can be sited at ports well placed

to suit windfarm locations, with discussions Foundation Design ongoing with selected ports

• Reinforced concrete, non-piled, ballasted

• Concrete costs are less dependent on gravity structure

commodities with high price volatility, such as

• Caters for water depths up to 60m steel

• Suits larger turbine sizes up to an anticipated

• Concrete gravity base foundations do not use 8MW

large scale steel tubulars, therefore they will

increase the market’s capacity to deliver

• The design minimises the need for seabed

preparation by accommodating existing

turbine foundations, release supply chain

seabed slopes and surface sediments

constraints and increase competition

• Construction can draw on existing resource

• The design incorporates skirt variants to suit seabed soil conditions

pools close to the construction facilities

• Existing supply chain capabilities can be

• Designs can be standardised across

< Safe working practices are

implemented throughout projects

from design to construction and installation.

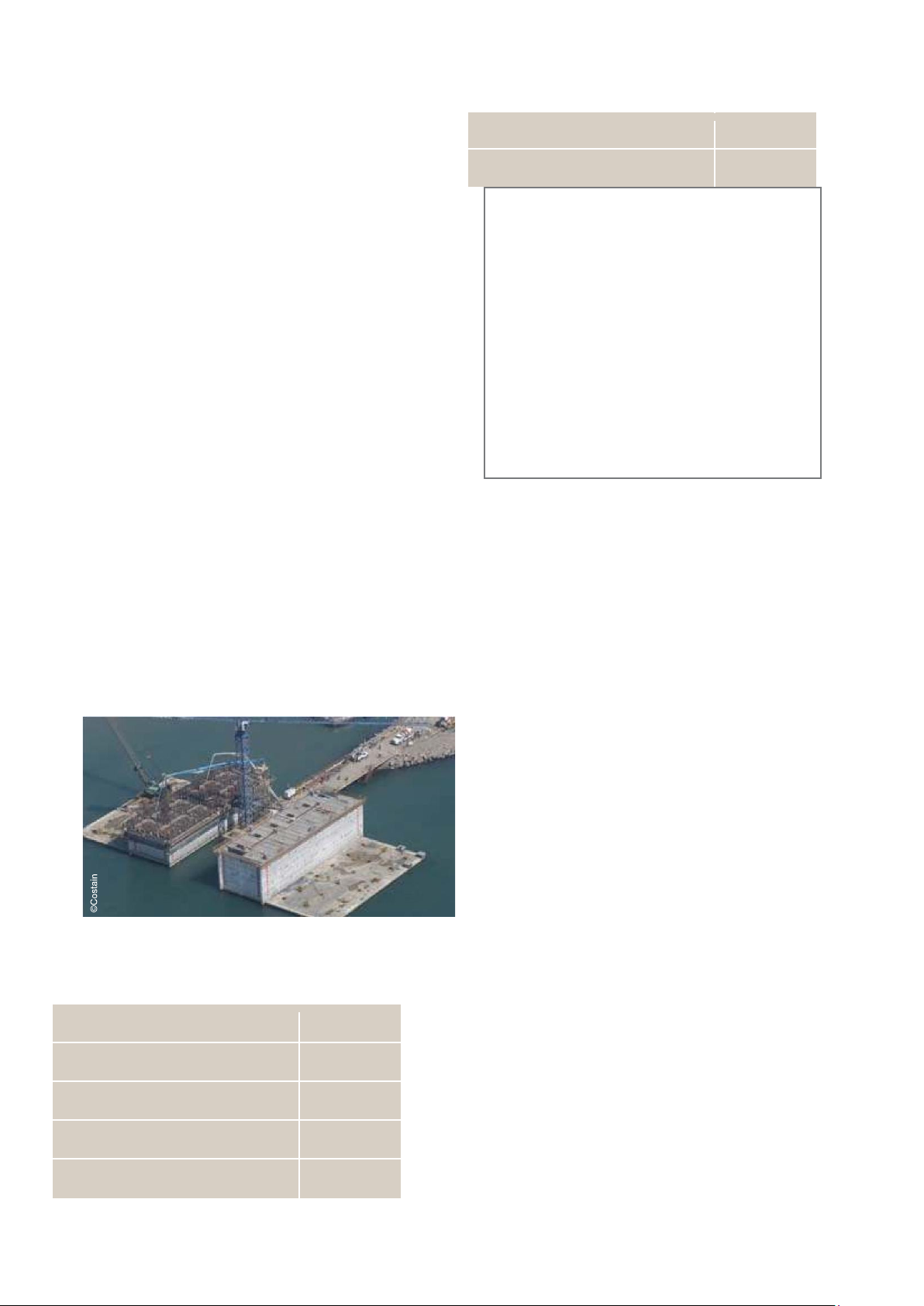

> Building on existing experience of

successfully installing a 600m long

breakwater in the Pacific Ocean that was made out of 12 slipformed 25,000t caisson

structures fabricated in a purpose

individual or multiple sites to enable cost

leveraged to enable projects to start optimisation immediately

• Collar design for the turbine mast connection

• A dedicated mass construction facility will

can accommodate ~2o vertical alignment

deliver productivity benefits and reduce costs tolerance

• Health and safety considerations will be

• Offers life cycle carbon footprint benefits

integral to the development of the new through material selection

construction facilities and foundations

constructed in them, using well proven safe

• Unlike many alternatives, the design offers the

potential to repower without foundation construction expertise

replacement Construction / Fabrication

• The concrete bases are configured for rapid

construction using readily available construction skills

• Construction is an onshore activity and

tailored for ease of subsequent installation

• Construction does not require deep water (10m draft) built dry dock. lOMoAR cPSD| 59054137 Installation Concrete volume 1,910m3

• Foundations are self-buoyant for ease of

deployment to the windfarm location Steel reinforcement 720 tonne

• Standard tugs that are readily available and Partnership

abundant are used to install the foundations

The gravity base foundation is a development by a

• Sea-borne noise and vibration is minimised so

partnership between Hochtief, Costain and Arup,

installation can progress year-round

founded on long term relationships from previous

projects and combines unique capabilities to serve

• Reduced weather dependency

significantly extends the installation season

the growing energy sector. Hochtief’s strong giving security of programme

marine competence, Costain’s civil engineering

and marine construction experience and Arup’s

• Installation wil be achieved by sinking through

offshore marine and concrete structure design

the controlled influx of water, followed by

expertise are the ideal basis to offer a unique and sand/aggregate ballasting

differentiated solution that ful y integrates the

design, construction, offshore installation and Operation

decommissioning of foundations for offshore

• Concrete has low maintenance requirements windfarms.

being inherently durable in the marine environment

• Scour protection wil be designed for minimum

maintenance over the design life of the windfarm

• The durability of the concrete gravity

foundations could allow developers to re-deploy

them in different locations with new turbines fitted

• Concrete gravity bases can be completely

removed for recycling at the end of their useful life Principal Data

Key figures for 35m water depth, Central North

Sea environmental conditions and 6MW can be found below: Air gap concrete structure 20m Hub height above LAT 90m Base outer diameter 34m Outer diameter, caisson 31m Outer diameter, top of shaft 6m lOMoAR cPSD| 59054137 Contacts: Gordon Jackson Colin Duff Fenno Leeuwerke T +44 207 755 2289 T +44 1628 842444 T +49 40 21 986350

E gordon.jackson@arup.com E colin.duff@costain.com E fenno.leeuwerke@hochtief.de

For further information contact: (Back: Contact Title) Name (Back: Contact Name)

T xxxxxxxxxxxxxxxxxxx (Back: Numbers) E

xxxxxxxxxxxxxxxxxxxx ( Back: Numbers) www.arup.com