Preview text:

lOMoAR cPSD| 45349271 Table of Contents

CHAPTER 1: TOTAL QUALITY MANAGEMENT: AN OVERVIEW ........... 4

1. Define quality ........................................................................................................ 4

2. Why it is important to study matter ................................................................... 4

3. QUALITY CONTROL VS QUALITY ASSURANCE ..................................... 4

4. Discuss the three levels of quality ....................................................................... 5

5. What are the different types of quality? ............................................................ 6

6. List David Garvin’s five approaches to defining quality ................................. 7

7. Mention the five paradigms of quality ............................................................... 7

8. What are Garvin’s eight dimensions of product quality? ................................ 9

9. What are the SERVQUAL dimensions of service quality? ............................ 10

10. Differentiate between service quality and product quality .......................... 11

11. Differentiate between old quality and new quality ....................................... 11

12. What are the four categories of cost of poor quality? .................................. 11 CHAPTER 3: THE PHILOSOPHY OF TOTAL QUALITY

MANAGEMENT ................................................................................................... 12

1. Define TQM ........................................................................................................ 12

2. What are the four main stages in the development of TQM?........................ 12

3. List the five pillars of TQM ............................................................................... 14

4. Mention the eight key elements of TQM.......................................................... 14

5. What are the seven phases in the development of TQM? .............................. 18

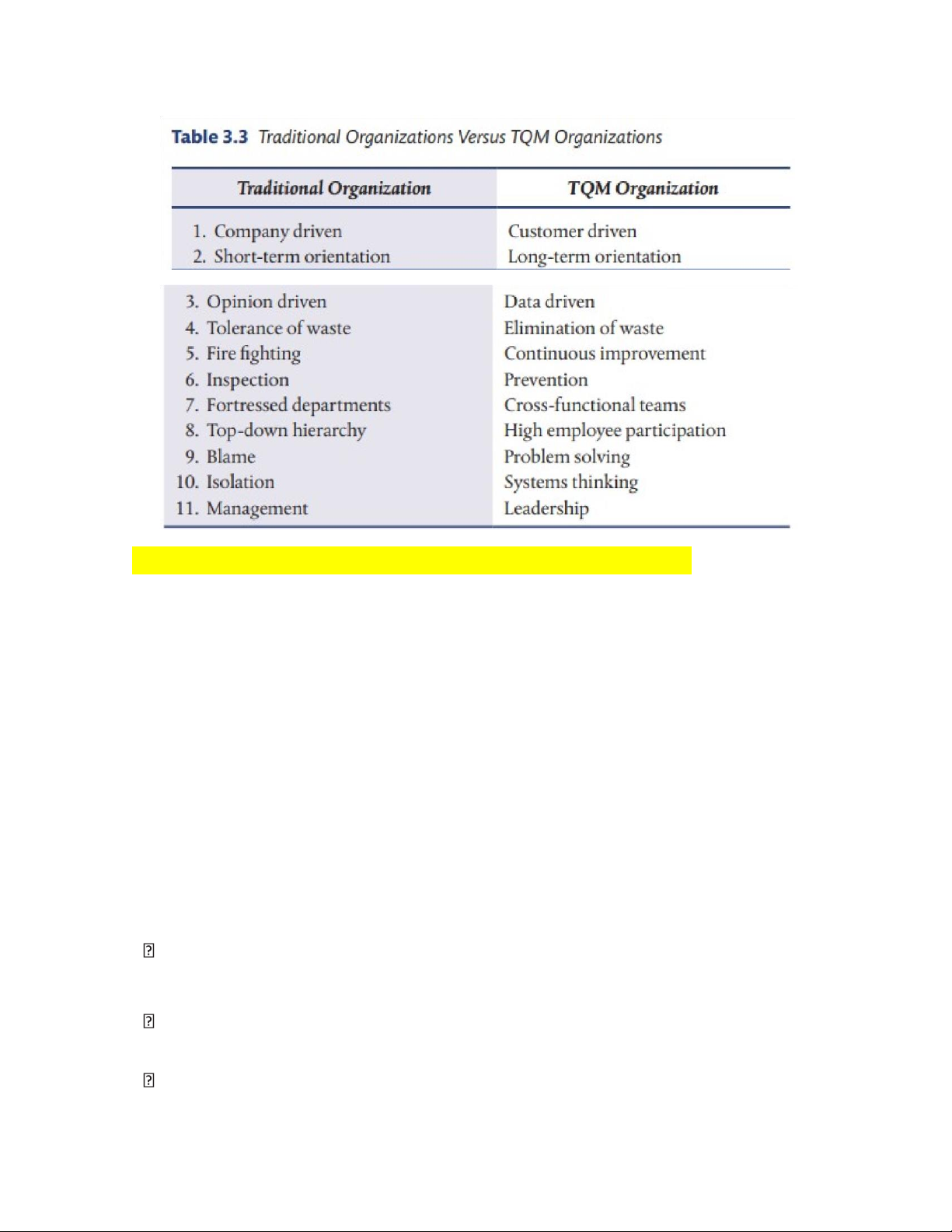

7. Differentiate between a TQM organization and a traditional organization. 20

.................................................................................................................................. 20

9. Explain the TQMEX model .............................................................................. 20

10. Discuss the prerequisites of TQM ................................................................... 20

11. What are the steps for implementing a TQM programme? ........................ 21

Establish quality improvement teams ................................................................... 21

13. Explain the benefits of TQM with an example.............................................. 22

CHAPTER 4: LEADERSHIP AND TOTAL QUALITY MANAGEMENT .... 22

1. Define leadership ................................................................................................ 22 1 lOMoAR cPSD| 45349271

2. Explain five traits of a successful leader .......................................................... 22

3. Leadership functions ......................................................................................... 23

4. Discuss visionary leadership with an example/ Name the eight principles

ofvisionary leadership ............................................................................................ 24

5. Describe six natural levels of leadership .......................................................... 24

6. What do you mean by CSR? ............................................................................. 26

7. Explain the main components of CSR ............................................................. 26

9. Discuss CSR issues for various stakeholders ................................................... 27

10. Describe the benefits of CSR ........................................................................... 28

11. Define SQM ....................................................................................................... 30

12. What is a vision, mission, value statement? ................................................... 30

13. Explain the five phases of SQM ...................................................................... 30

14. Explain balanced scorecard/ Name the four perspectives of a balanced

scorecard/ Benefit ................................................................................................... 31

16. Define quality culture. 5 stages of quality culture ........................................ 32

19. Forces for change ............................................................................................. 33

21. Describe the six approaches to deal with resistance to change .................... 35

1. Which are the two main approaches to quality control? ............................... 36

2. Variability ........................................................................................................... 37

3. Describe SPC ...................................................................................................... 38

4. Describe probability ........................................................................................... 38

5. What are the different types of probability distributions? ............................ 38

6. five parameters used to investigate measurement system analysis ............... 38

7. What is process capability? ............................................................................... 38

8. Discuss process capability studies ..................................................................... 38

10. Two widely used process capability indices ................................................... 39

11. What is sampling? ............................................................................................ 40

12. What is a good sampling plan? ....................................................................... 40

13. The advantages of sampling inspections ........................................................ 40

14. What are the two ways in which inspection is carried out? ......................... 41 2 lOMoAR cPSD| 45349271

15. Name the two broad classification of sampling methods ............................. 41

16. What is acceptance sampling? What are the reasons for acceptance

sampling? ................................................................................................................ 42

17. Name the three types of acceptance sampling plans ..................................... 42

18. What is an OC curve? How can we make an acceptance sampling plan

stricter? ................................................................................................................... 43

19. Name the quality indices for acceptance sampling ....................................... 43

20. What is an ideal OC curve? Explain the producer’s and consumer’s risk. 43

.................................................................................................................................. 43

21. Define quality assurance .................................................................................. 44

22. What is a quality policy? ................................................................................. 45

23. Explain the meaning of a quality manual ...................................................... 45 3 lOMoAR cPSD| 45349271

CHAPTER 5: STATISTICAL CONCEPTS IN QUALITY MANAGEMENT36

CHAPTER 1: TOTAL QUALITY MANAGEMENT: AN OVERVIEW 1. Define quality.

Quality is about meeting the needs and expectations of customers Customer-driven

(Definitions of Quality)

• Value for price paid: Quality is defined in terms of the utility of the product

or service for the price paid.

• Support services: Quality is defined in terms of the support provided after the

product or service is purchased.

• Psychological criteria: A way of defining quality that focuses on judgemental

evaluations of what constitutes product or service excellence.

2. Why it is important to study matter. IMPORTANCE OF QUALITY - Meet customer expectations

- Increase reputation and image

- Meets or exceeds industry standards - Effective cost management

3. QUALITY CONTROL VS QUALITY ASSURANCE Quality control Quality assurance

It’s a set of activities for ensuring quality It’s a set of activities for ensuring quality

in products. The activities focus on in processes by which products are

identifying defects in the actual developed. produced.

It aims to identify and correct defects in It aims to prevent defects with a focus

the finished product and is a reactive on the process used to make the product. process.

It’s a proactive quality process. 4 lOMoAR cPSD| 45349271

The goal is to idenfify defects after a The goal is to improve development and

product is developed and before it’s test processes so that defects don’t arise released.

when the product is being developed

Finding and eliminating sources of It establishes a good quality quality problems through

tools management system and conducts equipment so that

customer’s assessment of its adequacy and periodic

requirements are continually met.

conformance audits of the operations of the system

The activities or techniques used to Prevention of quality problems through

achieve and maintain the product planned and systematic activities

quality, process, and service.

including documentation is done.

It’s usually the responsibility of a All team members involved in

specific team that tests the product for developing the product are responsible defects. for quality assurance. It is a corrective tool It is a managerial tool

Statistical quality control (SQC) is a part Statistical process control is a part of of quality control quality assurance

Validation/Software testing is an Verification is an example of quality example of quality control assurance

4. Discuss the three levels of quality.

Viewing organization from three levels helps clarify roles and responsibilities for

quality management, requiring total involvement of all employees in a committed organization.

1. Organizational level

Quality concerns at this level involve meeting external customer requirements,

requiring regular customer inputs and top managers to focus on organizational level.

The following questions are designed to help define at this level.

What products and services meet your expectations?

What products and services do not meet your expectations?

What are the products or services that you need but are not receiving? 5 lOMoAR cPSD| 45349271

Are you receiving products or services that you do not need? 2. Process Level

Organizational units like marketing, design, product development,boperations,

finance, purchasing, and billing can optimize activitiesbunder their control,

potentially sub-optimizing the entire organization.

What products or services are the most important to external customers?

What processes produce those products and services?

What are the key inputs to the process?

Which processes have the most significant effect on the organization’s

customer- driven performance standards?

Who are my internal customers and what are their needs

3. The performer or job level or the task design level

At the performer level, output standards should align with organizational and

process-level quality and customer service requirements, requiring employees to

understand and adhere to these standards.

To define quality at the job level, one must ask questions such as:

What is required by customers, both internal and external?

How can the requirements be measured?

What is the specific standard for each measure?

5. What are the different types of quality?

Types of quality are recognized to ensure consistent production of goods and services at reasonable costs. 1) Quality of Design

- Quality of the design is the quality which producer and supplier is intended to offer to customer.

- The quality of design is determined by conducting market research to identify

product characteristics that equate to customer satisfaction.

2) Quality of Conformance

- Quality of conformance is the level product actually produced and delivered

through the production or service process of the organization as per the specification design. 6 lOMoAR cPSD| 45349271

- Quality of conformance is the ability of a company and its suppliers to produce

products with predictable dependability and uniformity at a given cost, based on design quality requirements.

3) Quality of Performance

Quality of performance is the process of organizing manufacturing to ensure product

quality adheres to specifications.

6. List David Garvin’s five approaches to defining quality.

GARVIN’S APPROACHES TO DEFINING QUALITY

1) The Transcendent Approach:A product or service possesses excellence based

on its subjective relationship to some standard.

2) The Product-based Approach:Quality is the degree to which a product

possesses a specified set of attributes necessary to fulfill a stated purpose.”

3) The User-based Approach:Quality is the degree to which a product or service

satisfies the user’s needs, wants, or preferences.

4) The Manufacturing-based Approach: This approach seeks to objectively

measure the degree to which a product or service complies with predetermined specifications.

5) The Value-based Approach: This approach assesses quality in terms of costs

and benefits: the more benefits outweigh costs, the more a product or service

increases in value. Products or services with higher value enjoy higher quality

7. Mention the five paradigms of quality. 1. Customer-craft Paradigm 7 lOMoAR cPSD| 45349271

The product is created or services are rendered exactly in the manner desired by the

customer. Hence, the focus on the product/service and their performance is relative to the demand.

Ex: bank loans, coffee shops, furniture supplier, etc. 2. Mass-production Paradigm

- This paradigm developed post mechanization.

- Focuses on speed of production without direct customer involvement ( Even

though the product is defined with the customer in mind).

- Product performance is relatively low and rework and waste generation are evident.

- Delivery times are often low due to sales from available inventory. -

Service organizations in this model are labor intensive.

Ex: Readymade buildings for commercial enterprises.

3. Statistical Quality Control Paradigm

This is similar to the mass production paradigm except that the emphasis here is more

on the process. Applied together with mechanized production, the statistical process

control results in low scrap and rework and low cost of production. Products are

designed and built, and statistical techniques are used after which customers are acquired.

Ex: automobile parts, electronic components, etc.

4. Total Quality Management Paradigm

- The focus here is on the customer and the supplier.

- Product lines here are the same as in the case of the mass production paradigm.

However, the customer is a part of the product definition, creation and

performance evaluation phases.

- Employee involvement and empowerment, customer-focus, continuous

improvement, top management commitment, training, teamwork are its key tenets.

- The result is a high quality product, low cost, fast delivery and substantially

reduced opportunities for rework and low generation of scrap 5. Techno-craft Paradigm

- A new frontier of quality that seeks to employ the custom-craft paradigm in

performance while reducing delivery time. 8 lOMoAR cPSD| 45349271

- Requires a high level of product process flexibility.

- The requirement is to integrate machine (computer), men and automation.

- Each unit is designed and built on the basis of customer requirements. -

Examples: in the software and apparel industries.

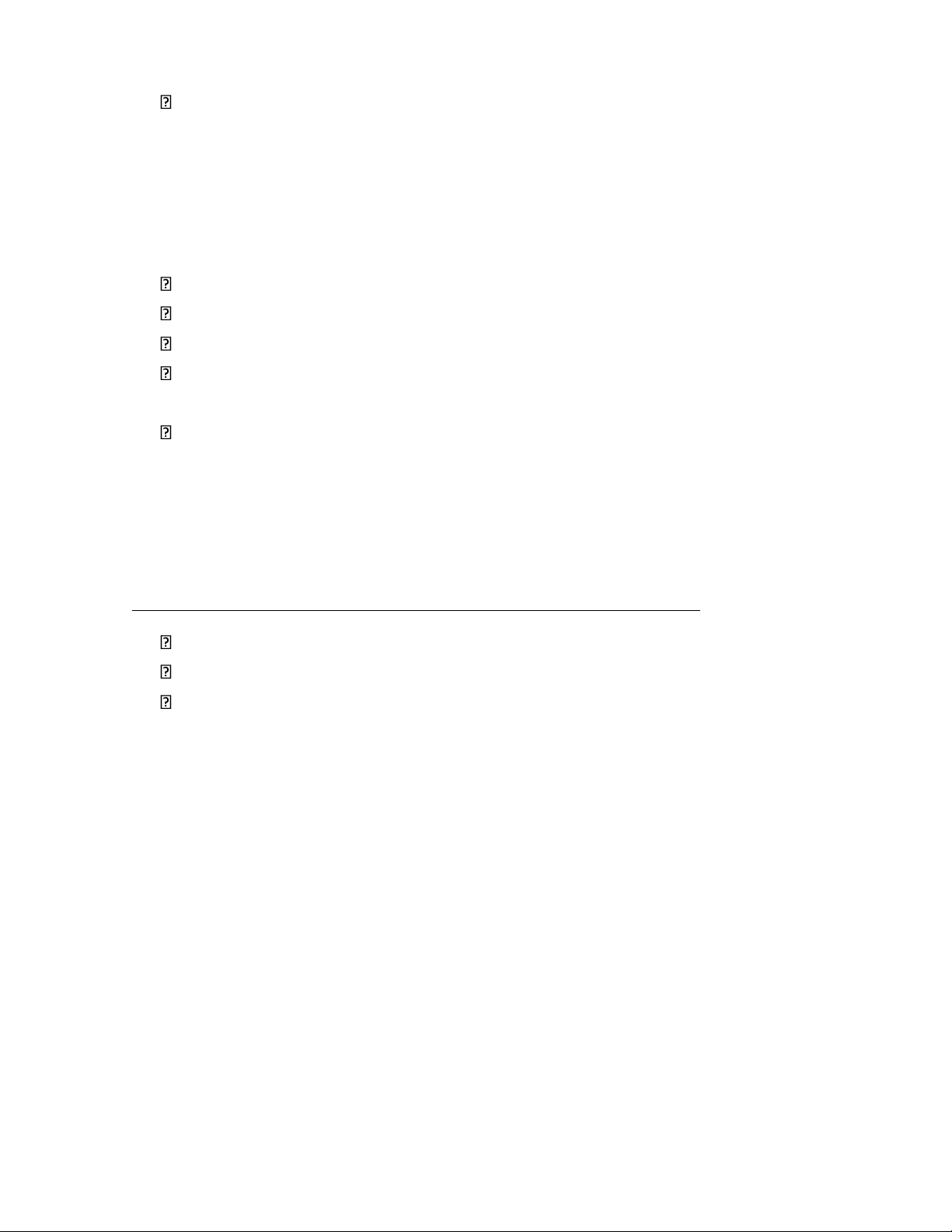

8. What are Garvin’s eight dimensions of product quality?

A quality product is a product that meets the expectations of the customers. The eight

dimensions of quality help producers to meet these expectations.

Performance: refers to the basic requirements that a product or service must meet to

satisfy the customer’s needs.

Features: refers to the additional capabilities or characteristics that a product or services may have.

Realiability: refers to the ability of a product or service to perform consistently and dependably over time. 9 lOMoAR cPSD| 45349271

Conformance: refers to the degree to which a product or service meets establiched standards and specifications.

Durability: refers to the ability of a producr or service to withstand normal wear and

tear and continue to perform over time. Serviceability:

Aesthetic: refers to the visual and sensory appeal of a product or service.

Perceived quality: refers to the customer’s overall i,pression of the quality of a product or service.

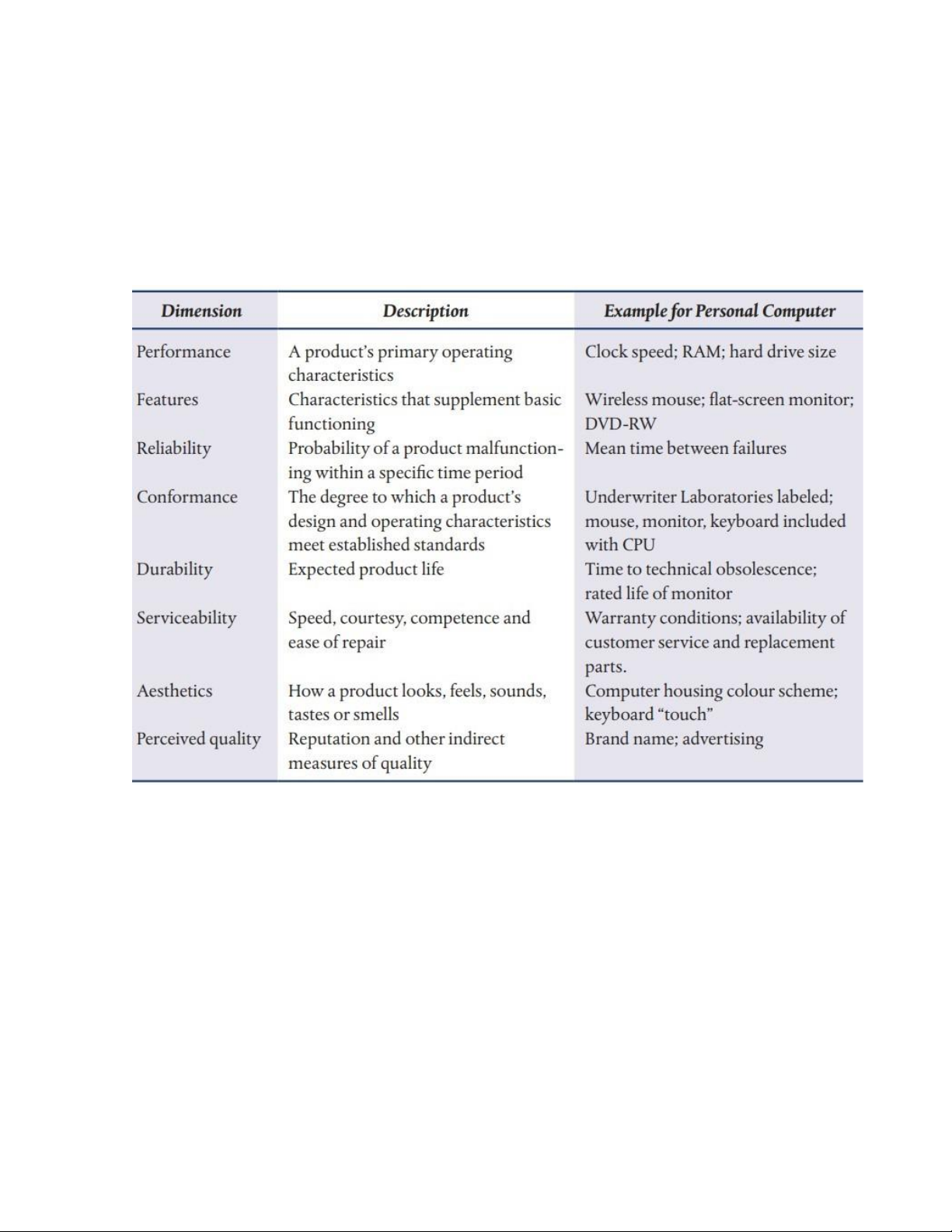

9. What are the SERVQUAL dimensions of service quality? 10 lOMoAR cPSD| 45349271

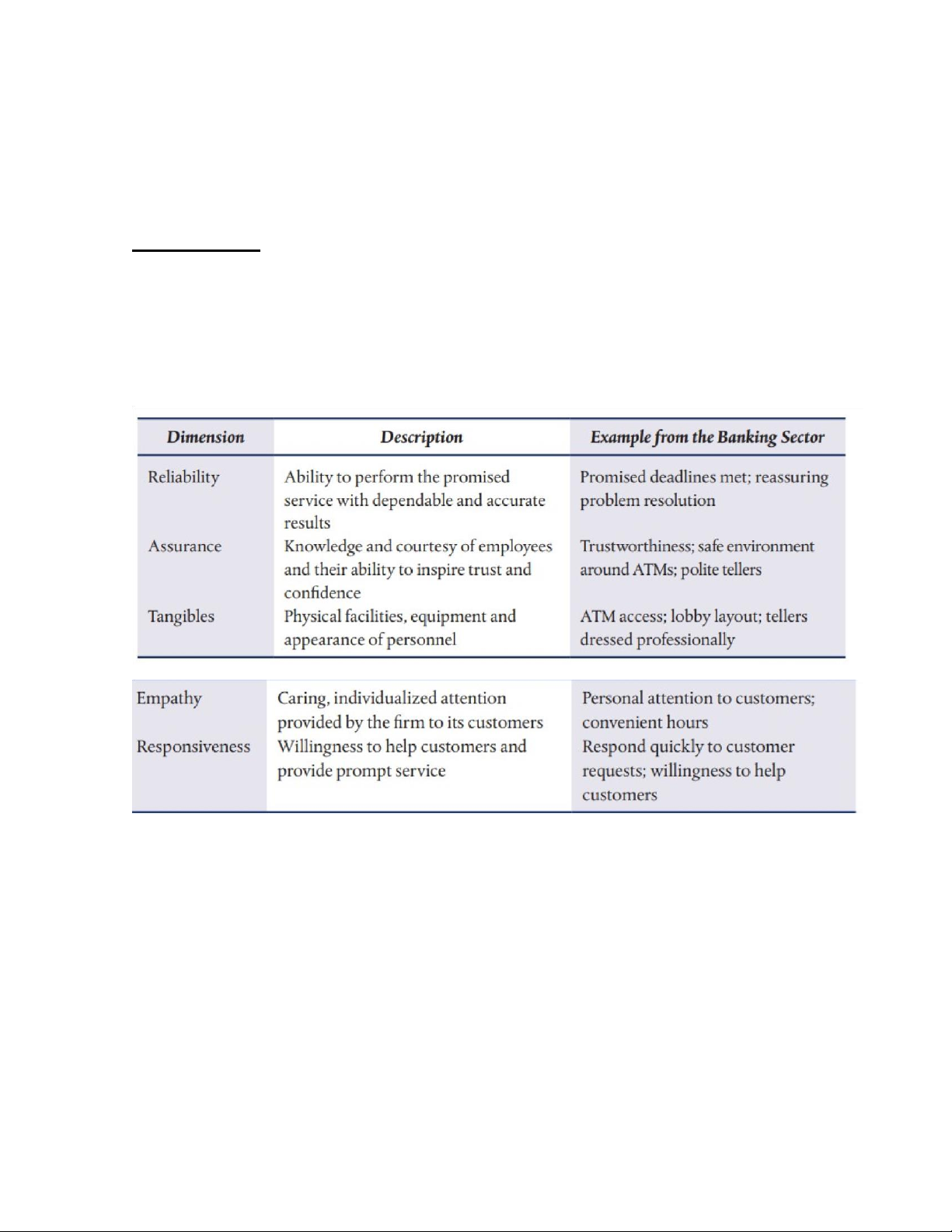

10.Differentiate between service quality and product quality.

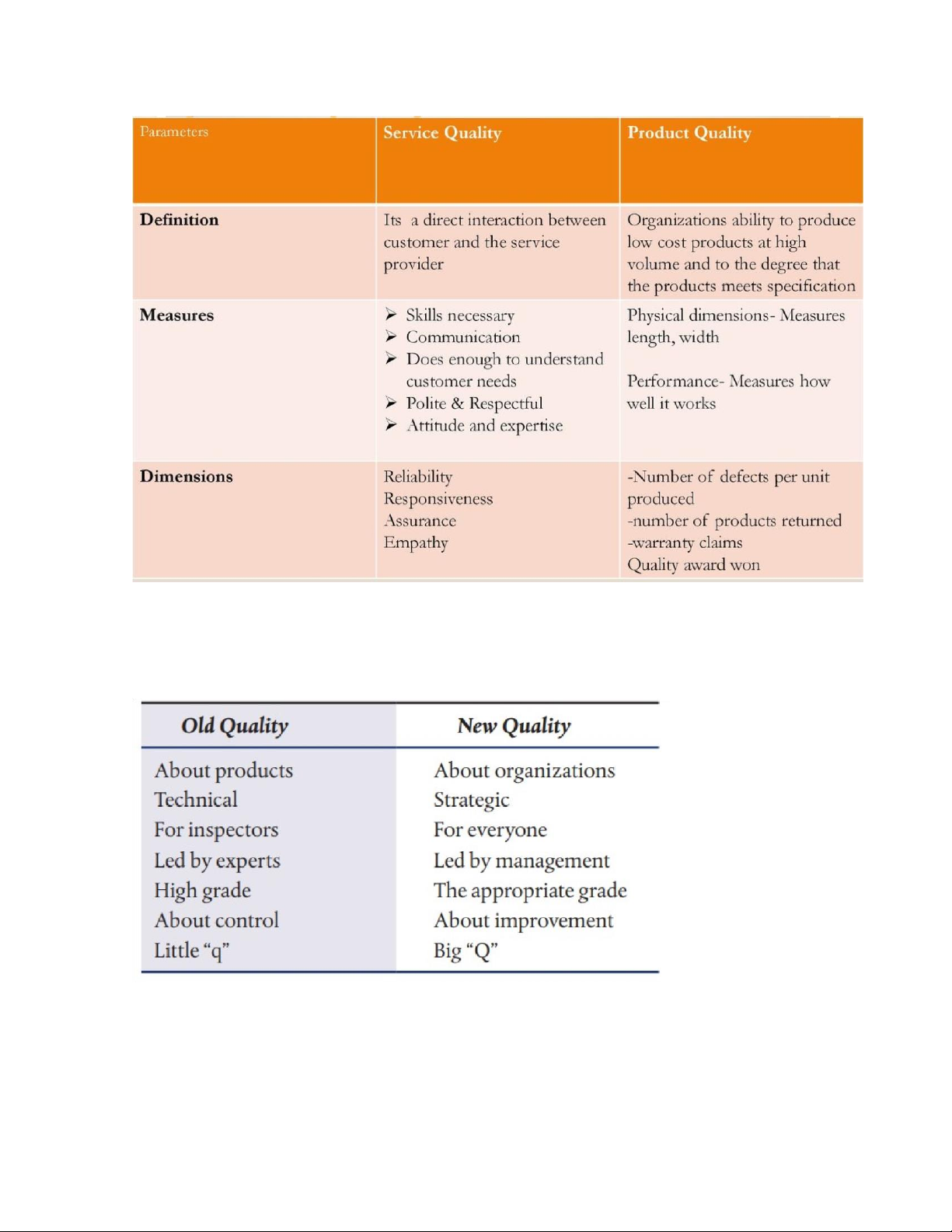

11.Differentiate between old quality and new quality.

The difference between old and new quality lies in the fact that the old is the work of

craftsmen, wheares the new os the work of a system.

12.What are the four categories of cost of poor quality?

Cost of poor quality (COPQ): the cost associated with providing poor quality

products or services. There are 4 categories: internal failure costs, external failure

costs, appraisal costs amd prevention costs. 11 lOMoAR cPSD| 45349271

Cost of Quality = Cost of Conformance + Cost of Non-conformance

Prevention costs: are incurred to prevent or avoid quality problems: These costs are

associated woth the design, implementation, and maintenance of the quality management system.

Appraisal costs: are associated with measuring and monitoring activities related to

quality. These costs are associated with the suppliers’ and customers’ evaluation of

purchased materails, processes, products, and services to ensure that they conform to specifications Failure cost

Internal failure costs: are incurred to remedy defects discovered before the product

or service is delivered to the customer. These costs occur when the results of work

fail to reach design quality standards and are detected befor they are transferred to the customer.

External failure costs: are incurred to remedt defects discoverd by customers. These

costs occur when products or services that fail to reach design quality standards are

not detected until after transfer to customer.

CHAPTER 3: THE PHILOSOPHY OF TOTAL QUALITY MANAGEMENT 1. Define TQM.

TQM is an integrated effort designed to improve quality performance at every level of the organization.

Total: Quality involves everyone and all the activities performed in the company.

Quality: Conformance to the requirements (meeting customer requirements).

Management: Quality can and must be managed.

A core definition of Total Quality Management (TQM) describes a management

approach to long–term success through customer satisfaction.

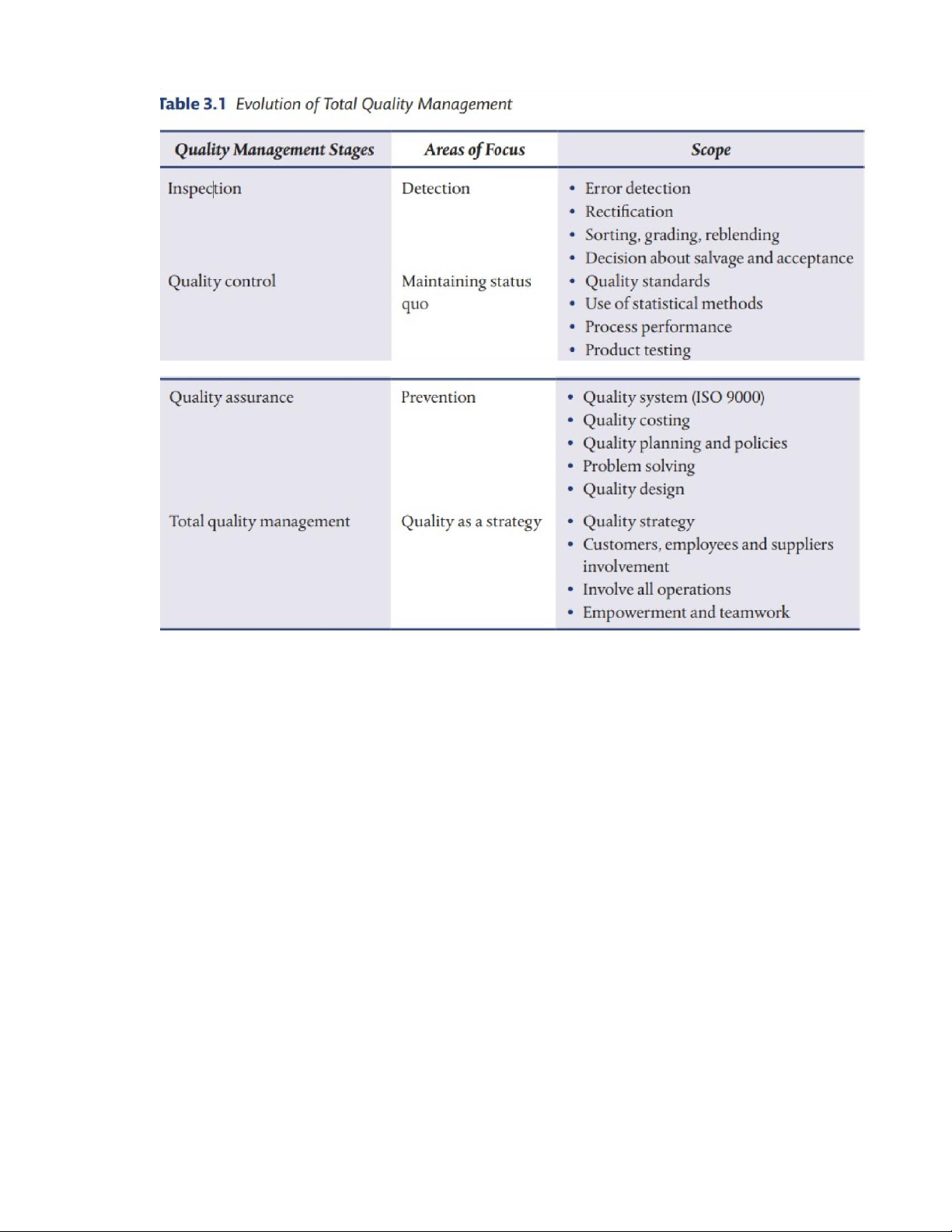

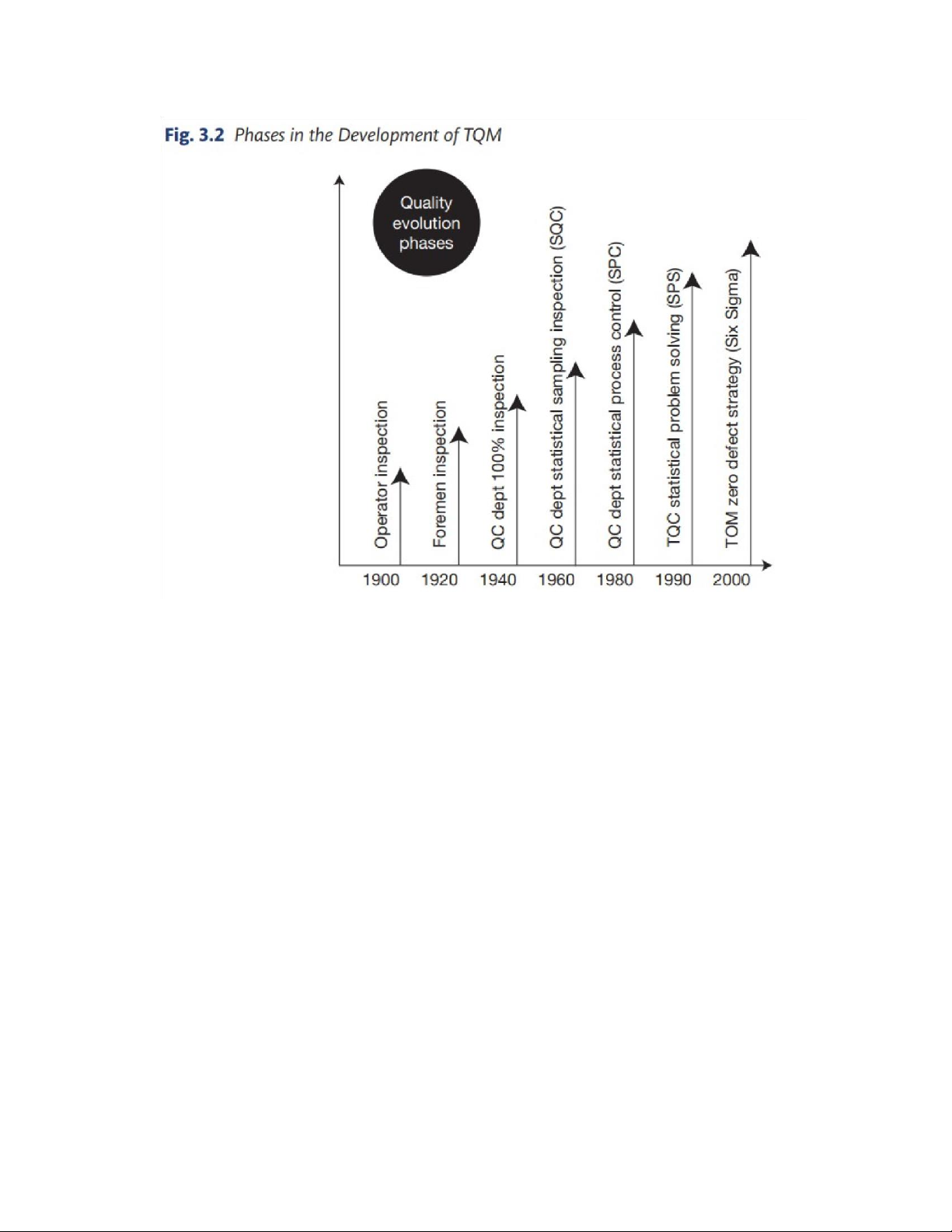

2. What are the four main stages in the development of TQM?

The four stages identified in the evolution of TQM are: Inspection; Quality

Control; Quality Assurance; TQM. 12 lOMoAR cPSD| 45349271

TQM will force change in culture, processes and practice. These changes will be

more easily facilitated and sustained if there is a formal management system in place.

Quality Control was introduced to detect and fix problems along the production

line to prevent the production of faulty products. Statistical theory played an important role in this area.

Statistical Quality Control (SQC) is the term used to describe the set of

statistical tools used by quality professionals. SQC is used to analyze the quality problems and solve them.

Quality assurance is a component of quality management and is ‘focused on

providing confidence that quality requirements will be fulfilled. TQM •

Emphasis is placed on the target and achieving the target as soon aspossible. •

The system is simple and straight-forward. 13 lOMoAR cPSD| 45349271 •

Information delivery is accurate. •

The process is considered after the goal has been established.

Downside: Employees stop actively thinking of and implementing process

improvement – they don’t want to risk making a mistake or creating delays.

TQC (total quality control)

Emphasis is placed on the process and continuous process improvement. •

Total participation is required. Employees are encouraged to generate ideasand implement them. •

It is flexible – processes and methods can be easily changed. •

The target is not absolute - good for a changing market.

Downside: Sometimes the end result is very different from the original target

employees tend to lose sight of the goal because they are too focused on the process.

3. List the five pillars of TQM.

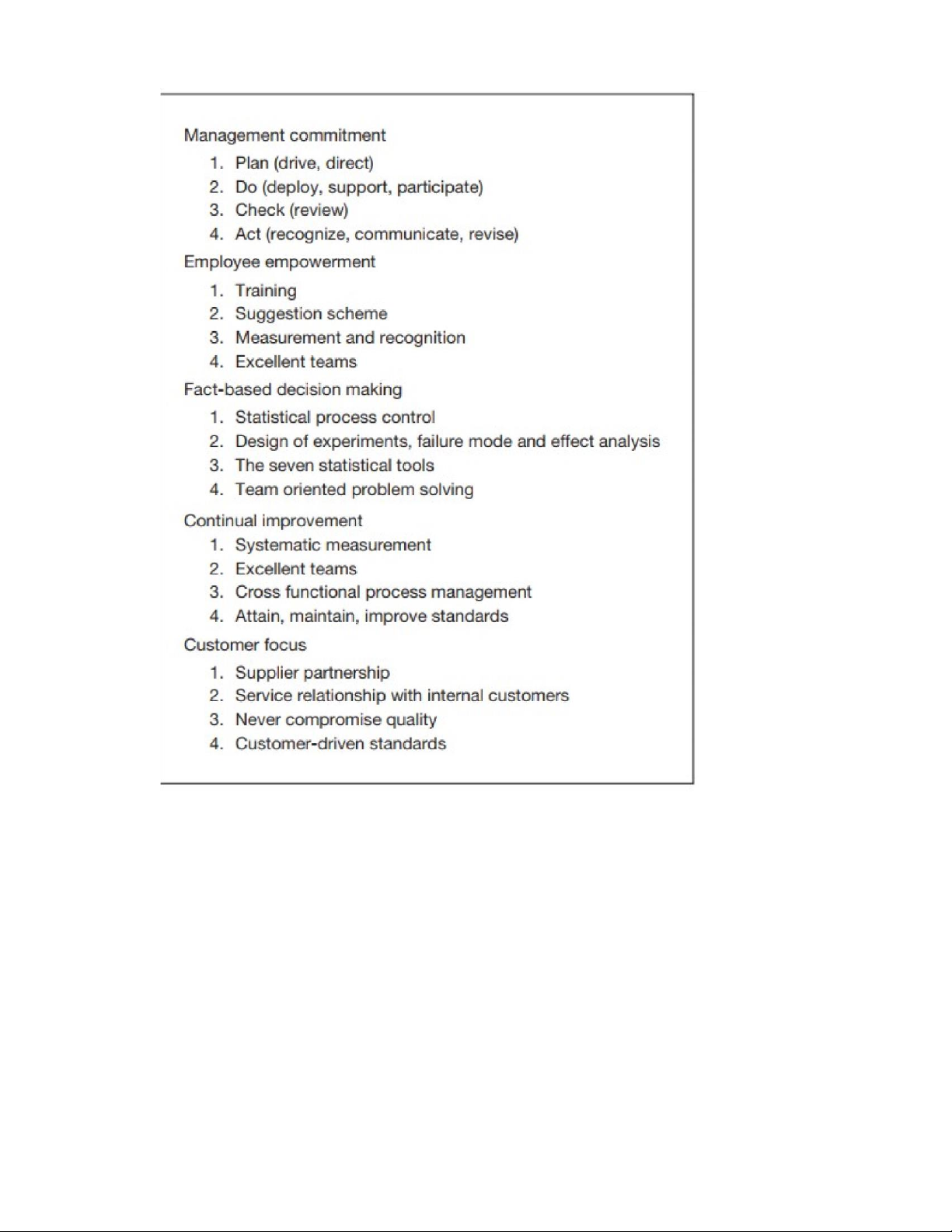

4. Mention the eight key elements of TQM

To be successful in implementation of TQM there are eight key elements. These eight

key elements of TQM are: ethics, integrity, trust, leadership, teamwork, training,

communication and recognition.

The term TQM has been coined to describe a philosophy that makes quality the

driving force behind leadership, design, planning and improvement initiatives. For

this, the organization needs to concentrate on eight key elements—ethics, integrity,

trust, leadership, teamwork, training, communication and recognition as shown in 14 lOMoAR cPSD| 45349271

Figure 3.4. These elements can be divided into the following four groups—

foundation, building bricks, binding mortar and roof. I. Foundation:

It includes ethics, integrity and trust.

TQM is built on a foundation of ethics, integrity and trust. It fosters

openness, fairness and sincerity and encourages the involvement of

everyone in the organization. This is the key to unlocking the ultimate

potential of TQM. Though these three elements coexist, each offers

something unique to the TQM concept.

1. Ethics: It is a combination of written and unwritten codes of principles and

values that govern decisions and actions within a company. In the business

world, an organization’s culture sets standards for determining the difference

between good and bad decision making and behaviour. Business ethics boils

down to knowing the difference between right and wrong and choosing to do

what is right. It describes the actions of individuals within an organization, as

well as those of the organization as a whole.

2. Integrity: It is the consistency of actions, values, methods, measures, principles,

expectations and outcomes. As a holistic concept, it judges the quality of a

system in terms of its ability to achieve its own goals. Integrity may be seen as

the quality of having a sense of honesty and truthfulness in regard to the

motivation for one’s actions.

3. Trust: Trust builds a cooperative environment essential for TQM. Trust is a

byproduct of integrity and ethical conduct. It is a relationship based on reliance.

Trust fosters everybody’s participation and allows empowerment that

encourages pride of ownership and commitment. Trust fosters individual

risktaking for continuous improvement and is essential to ensure customer satisfaction.

II. Building Bricks: It includes leadership, teamwork and training. Leadership,

teamwork and training are the building bricks of TQM. Leadership in TQM

requires the manager to provide an inspiring vision, make strategic

decisions and instill values that guide subordinates. Teamwork offers

continuous improvement in processes and operations. The teams may be

quality improvement teams or excellence teams, problemsolving teams or

natural work teams. Training is very important for employees to be highly productive. 15 lOMoAR cPSD| 45349271

4. Leadership: It is the most important element in TQM. Leadership is about

raising the aspirations of followers and enthusing people with a desire to reach

the goals. A good leader creates a vision, passionately owns it and relentlessly

drives it till completion. Total quality management initiatives have to be

introduced and led by the top management.

5. Teamwork: There are some well-established links between the use of work

teams and the development of total quality management programmes. There are,

however, a great variety of teams that are used in conjunction with the

philosophy of TQM and there is seemingly no settled or dominant combination

of team types that are used. The attributes of teams that are used in conjunction

with TQM may vary greatly. Teams may be temporary, adhoc or permanent,

they may be functional or cross-functional, voluntary or compulsory, have

members with multiple skills or complementary skills, and may have a limited

scope of responsibility or they may exercise considerable autonomy and selfdirection.

TQM organizations mainly adopt three types of teams: a.

Problem-solving teams: These are temporary and formed to solve

certainproblems, identify and overcome causes of those problems. They generally

last from one week to three months. b.

Quality improvement teams: These are temporary teams with the purpose

ofdealing with specific problems that often recur. These teams are set up for a

period of three to twelve months. c.

Natural work teams: These teams consist of small groups of skilled

workerswho share tasks and responsibilities. These teams use concepts such as

employee involvement teams, self-managing teams and quality circles.

6. Training: Training is essential for all the employees to be highly productive. All

the employees will need to be trained in interpersonal skills, ability to function

in teams, problem solving, decision making, job performance and improvement,

business economics and technical skills. Employees are trained by supervisors

of each department so that they can become effective employees of the company.

Bird’s-eye view: Total quality is a description of the attitude, culture and

organization of a company that strives to provide customers with products and

services that satisfy their needs. 16 lOMoAR cPSD| 45349271

III. Binding Mortar: It includes communication. Communication binds

everything together, starting from the foundation and going up to the roof.

Communication is the vital link between all the TQM elements and must

be prevalent in an organization in order for TQM to work the way it should.

The channels of communication need to be credible and easily interpreted

for all members of the organization.

6. Communication: It acts as a link between all the elements of an organization.

For communication to be effective, the receiver must interpret the message in

the way the sender intended. The different types of communication are downward communication, upward communication and lateral communication.

Downward communication: This is a dominant form of communication in an

organization. Presentations and discussions are two examples of this form of

communication. The supervisors are able to make the employees clearly understand TQM using this.

Upward communication: The lower-level employees are able to offer

suggestions on the effects of TQM to the upper management using upward

communication. Supervisors must listen effectively and incorporate the insights

and constructive criticism offered by the employees in correcting the situations

that arise through the use of TQM. This creates a level of trust between

supervisors and employees. This is also similar to empowering communication,

where supervisors listen to others.

Lateral communication: This type of communication is important because it

breaks down barriers between departments. It also allows a more professional

dealing with customers and suppliers.

IV. Roof: It includes recognition. Recognition is the last and final element of

TQM. There can be a huge change in self-esteem, productivity and quality

when the contributors are recognized. This recognition brings greater

internal customer satisfaction, which in turn leads to external customer

satisfaction in the organization.

8. Recognition: Recognition should be provided for both suggestions and

achievements, for both teams and individuals. The most important

responsibility on a supervisor is that of according recognition to the employees under him. 17 lOMoAR cPSD| 45349271

5. What are the seven phases in the development of TQM?

6. Mention the key principles of TQM.

People at all levels are the essence of an organization and their full involvement

enables their abilities to be used for the organization’s benefit.

The process approach is a management strategy. When managers use a process

approach, it means that they manage and control the processes that make up their organizations. 18 lOMoAR cPSD| 45349271 19 lOMoAR cPSD| 45349271

7. Differentiate between a TQM organization and a traditional organization.

8. Differentiate between conventional quality and total quality.

9. Explain the TQMEX model.

The TQMEX Model advocates an integrated approach in order to support the

transition to systems management, which is an ongoing process of continuous

improvement that begins when the company commits itself to managing by

quality. The model illuminates the elements that help us to understand the TQM

philosophy and its implementation company-wide. It is necessary to develop a

conceptual model in order to have a systematic approach to TQM. TQMEX model

is a sequence of steps arranged logically to serve as a guideline for the

implementation of a process in order to achieve the ultimate goal.

10. Discuss the prerequisites of TQM.

The following points should be kept in mind while implementing TQM:

Top management must be able to overcome the obstacles, most of which will

emanate from the management itself.

It must be understood that TQM cannot be accomplished with the participation of

only a few. All employees in the organization must pursue this end.

Resources, i.e. people, time, money and effort, must be dedicated over a long period of time. 20