Preview text:

lOMoAR cPSD| 58950985

International Supply Chain Management Exam Semester 2/2021

Question 1: What roles do entities within the global supply chain play in the stable development of

multinational corporations (MNCs)? 2

Question 2: Analyze the competitive factors that influence the formation of MNCs' global supply chains 3

Question 1: Analyze the concept of global supply chain strategic management. Provide an example of 5 specific industry. 5

Question 2: Assess the influence of government factors on value creation for MNCs. 5

Câu 1. Chuỗi cung ứng là gì? Lấy ví dụ minh họa. (câu 1 ến câu 6: trang 13 ến 26) 5

Câu 3. Phân tích các bên có liên quan tới chuỗi cung ứng toàn cầu. Lấy ví dụ minh họa. 7 Câu 4. Phân tích

vai trò của các thị trường mới nổi trong chuỗi cung ứng toàn cầu. 7

Câu 6.Các nhóm nhân tố tác ộng như thế nào tới việc hình thành chuỗi cung ứng toàn cầu của các

MNCs. (có trong slide nha ^^) 9

Question 7: In your opinion, which of the world’s emerging markets is the most attractive for MNCs to

choose as part of the global supply chain? Illustrate with specific industries. 22 Question 8: Why

does the government play a role in creating added value in the global supply chain? The increase in added

value is analyzed from two aspects that MNCs are always concerned with: cost

reduction and quality improvement. 24

Question 10: Analysis of the Impact of Infrastructure on the Global Supply Chain with Illustrative Examples 25

Question 11: Analysis of Global Logistics Activities with Examples 27

Question 12: Analysis of Global Distribution Center Operations with Illustrative Examples 29 Question 13:

Analysis of forward and reverse logistics activities. Give example 33

Question 14. Analysis of Global Purchasing Activities and Illustrative Examples (Slides 97, 98, 99) 37

Key Activities in Global Purchasing: 37

Example of Global Purchasing in Practice 38

Question 15: Analysis of the Advantages and Disadvantages of In-House Production vs. Outsourcing, and

Factors Determining the Choice for MNCs. Give Example. 39

Question 16: Types of Global Production 41

Question 17: Distinguish between value chain and supply chain 42

Question 21: Research on the responsiveness of Vietnam's transportation infrastructure to the

development of international supply chains. 42

Question 21: What is sustainability in supply chains? What should businesses do to manage supply chains

towards sustainable development? Provide practical examples. Green supply chain. 45 Question 22:

Benefits and Drawbacks, Risks of Manufacturing in China 49

Question 23: Read the case and answer the question: 51

Question 1: The Role of Supply Chains in International Business. Example Illustration. 56

Câu 2. Distinguish between the value chain and the supply chain 58

Question 3. Analyze the concept of the global supply chain. Provide an example. 59 Question 4. Analyze

the role of emerging markets in the global supply chain. 61

Question 5. How do the influencing factors contribute to the formation of global supply chains for lOMoAR cPSD| 58950985

MNCs? 62 Question 6. In your opinion, which country among the emerging markets is most attractive for

MNCs to choose as links in the global supply chain? Illustrate with specific industries. 63

Question 7: Why does the government play a role in creating added value in the global supply chain?

The increase in added value is analyzed from two aspects that MNCs always focus on: cost reduction and quality improvement. 66

Question 8: Analyze the impact of infrastructure on global supply chains. Provide examples. 66

Question 9. Analyze global logistics activities. Illustrative example. 68

Question 10. Analyze the operations of global distribution centers. Illustrative example 70

Question 11. Analyze forward and reverse logistics activities. Illustrative example 73

Question 12. Analyze global procurement activities. Illustrative example. 76

Question 13: Analyze the advantages and disadvantages of in-house production and outsourcing. Factors

determining the choice of in-house production or outsourcing for MNCs. Example. 78 Question 15:

Why are emerging markets considered locations where MNCs can place value-added activities? 81

Question 16: Differentiate between Value Chain and Global Value Chain 81

Question 17: Distinguishing Global Value Chain and Global Supply Chain 82

Question 18: Analyze the potential for Vietnamese enterprises to become a link in the global value chain

and become one of the key players in the global supply chain (supplier, manufacturer, distributor) for MNCs worldwide. 83

Question 19: How does the rise of born global firms and the development of global networks impact the

competitive advantage of MNCs through the establishment of their global supply chains? 84

Question 20: Read the cases analyzing supply chains. Identify issues in the chains and lessons learned. 85

Question 21: Why did SS choose Vietnam as its production base, especially in the Asian market? What

are the notable benefits of market consumption (market access)? 86 Question 22: Why does Toyota support

suppliers in developing technology? 87

Question 23: What quality standards do Toyota and its suppliers apply? And what management system is

in place when these standards are applied? 87 Paper 1

Question 1: What roles do entities within the global supply chain play in the stable development of

multinational corporations (MNCs)?

Entities within the global supply chain include: The entities in the global supply chain play a crucial role in

the stable development of MNCs. Specifically, they fulfill the following roles:

● Resource provision for production and business: Global supply chain entities provide MNCs

with necessary resources for production and business, such as raw materials, equipment,

transportation services, warehousing, financial services, etc.

● Cost reduction: Global supply chain entities help MNCs minimize production and operational

costs through resource optimization, taking advantage of economies of scale, pricing, labor, etc.

● Enhancing competitiveness: MNCs can boost their competitiveness by collaborating with global

supply chain entities to improve product and service quality, meeting market demands. lOMoAR cPSD| 58950985

● Risk reduction: MNCs can distribute risks across different countries, helping mitigate the impact

of adverse factors like natural disasters and political instability.

=> This enhances MNCs' ability to maintain stable development, outperforming SMEs in facing external adverse factors.

Example: Dell collaborates with computer component suppliers like Philips, Intel, and Microsoft to secure

quality components. Dell then partners with assemblers like Foxconn and Compal in the Taiwan-China area

to leverage cost advantages in creating complete computers. Dell uses FedEx services, with its CHST

Logistics system and extensive distribution network, to deliver computers directly to customers. Dell

capitalizes on partner strengths to enhance its market competitiveness. Additionally, its large scale provides

an advantage in negotiations, allowing Dell to choose new partners if existing ones face risks in their operations.

Question 2: Analyze the competitive factors that influence the formation of MNCs' global supply chains.

Intensified competition leads companies to join forces, forming MNCs to maximize resource and strength

utilization in each field. Competition also pushes MNCs to expand globally, building supply links in various

countries to leverage cost advantages and market opportunities.

a. Mergers & Acquisitions (M&A)

● Horizontal mergers: Occurs between two companies in direct competition, sharing the same products and markets.

● Vertical mergers: Takes place between companies in a supply chain, like a company with its customer or supplier.

● Market expansion mergers: Involves two companies selling similar products in different markets.

● Product expansion mergers: Involves two companies selling related but different products in the same market.

M&A affects MNCs' global supply chains by scaling operations, improving efficiency, leveraging partners’

expertise, and enhancing flexibility in response to market changes.

Example: In the automotive industry, Ford’s acquisition of Volvo in 1999 allowed access to European

manufacturing facilities and new Asian component suppliers, reducing costs and meeting diverse market demands.

b. Joint Ventures & Strategic Alliances

Strategic alliances involve two or more companies joining forces to develop, produce, or market

products/services for mutual benefit while remaining independent. Joint ventures create a new, jointly

owned company. These collaborations improve supply chain efficiency through cost reduction, flexibility, and innovation.

Example: Ford partnered with Austria’s Magna Steyr to produce the Escape model, reducing production

costs and boosting productivity. c. Global Trade Growth lOMoAR cPSD| 58950985

The growth of global trade allows MNCs to benefit from the comparative advantages of different countries,

thus reducing costs and increasing efficiency. However, it also creates interdependence among countries,

meaning if one link faces risks, it impacts the entire supply chain.

Example: COVID-19 caused major disruptions in global supply chains as ports closed, highlighting the

vulnerability of modern supply chains. d. Talent

Effective supply chains rely on talent, including skills in data analysis, leadership, risk management, and

teamwork, to drive innovation, efficiency, and risk mitigation.

Example: Jeff Bezos' leadership skills contributed to Amazon's global supply chain success through

innovations like Amazon Web Services (AWS) and automation in warehousing. e. New Competitors

New competitors heighten competition, pushing MNCs to reduce costs and improve efficiency. MNCs may

respond by globalizing their supply chains.

Example: Chinese smartphone brands like Huawei and Xiaomi have intensified competition, prompting

established companies like Apple and Samsung to innovate and reduce production costs.

f. Global Centers (Global Center Firms)

Global centers consolidate expertise from different countries, supporting innovation and efficiency in global supply chains.

Example: Samsung’s global center in Seoul integrates expertise from multiple countries, using advanced

technologies like automation and predictive modeling.

g. Competitive Playing Fields

Competitive markets offer MNCs cost-cutting opportunities but also challenge them to comply with the

"rules of the game," which may limit global supply chain expansion.

h. Global Companies (Born Global Firms)

Born global firms start with a global vision, leveraging technology and the internet to expand quickly.

Example: The rise of global service companies like Accenture has driven the development of global supply

chains to serve clients worldwide.

Question 4: Philips, a multinational electronics company from the Netherlands, invested over $2.5 billion

in China in the mid-2000s. China’s appeal to Philips lies in its skilled yet low-cost workforce, high

economic growth rate, and stable exchange rates.

a. What risks does concentrating too much production in China pose for Philips? lOMoAR cPSD| 58950985

Risks include supply chain disruption, political/legal risks, local labor unrest, information security risks,

and rising costs, all of which could impact global supply stability and costs.

b. What production strategy should Philips adopt to maximize profits and minimize risks

fromproduction centralization in China?

Philips should diversify production by relocating non-skill-intensive stages to other emerging markets with

labor cost advantages and resource abundance, while maintaining strict quality control to respond to market

demands flexibly and manage risks. Paper 2

Question 1: Analyze the concept of global supply chain strategic management. Provide an example

of a specific industry.

Strategic management is the process of planning, organizing, implementing, monitoring, and evaluating

activities within an organization to achieve set goals. Global supply chain strategy refers to a long-term

plan for managing supply chain decisions that support business strategy.

Example: The apparel industry relies on global sourcing for raw materials like cotton, fabrics, and

threads from leading producers like China, India, and the U.S., optimizing production costs and ensuring resource availability.

Question 2: Assess the influence of government factors on value creation for MNCs.

Government policies on taxes, tariffs, infrastructure investment, privatization, and sustainable development

affect supply chains by shaping business environments, impacting cost structures, encouraging investment,

and promoting competitive capabilities.

Example: Governments in free trade zones like the WTO provide tariff reductions, improving MNCs’

market access and competitiveness.

Câu 1. Chuỗi cung ứng là gì? Lấy ví dụ minh họa. (câu 1 ến câu 6: trang 13 ến 26) - Definition:

A supply chain is the network of all entities involved in producing and delivering a finished product

to the final customer. This includes sourcing raw materials and parts, manufacturing, producing,

and assembling the products, storing goods in warehouses, order entry and tracking, distribution,

and delivery to the final customer.

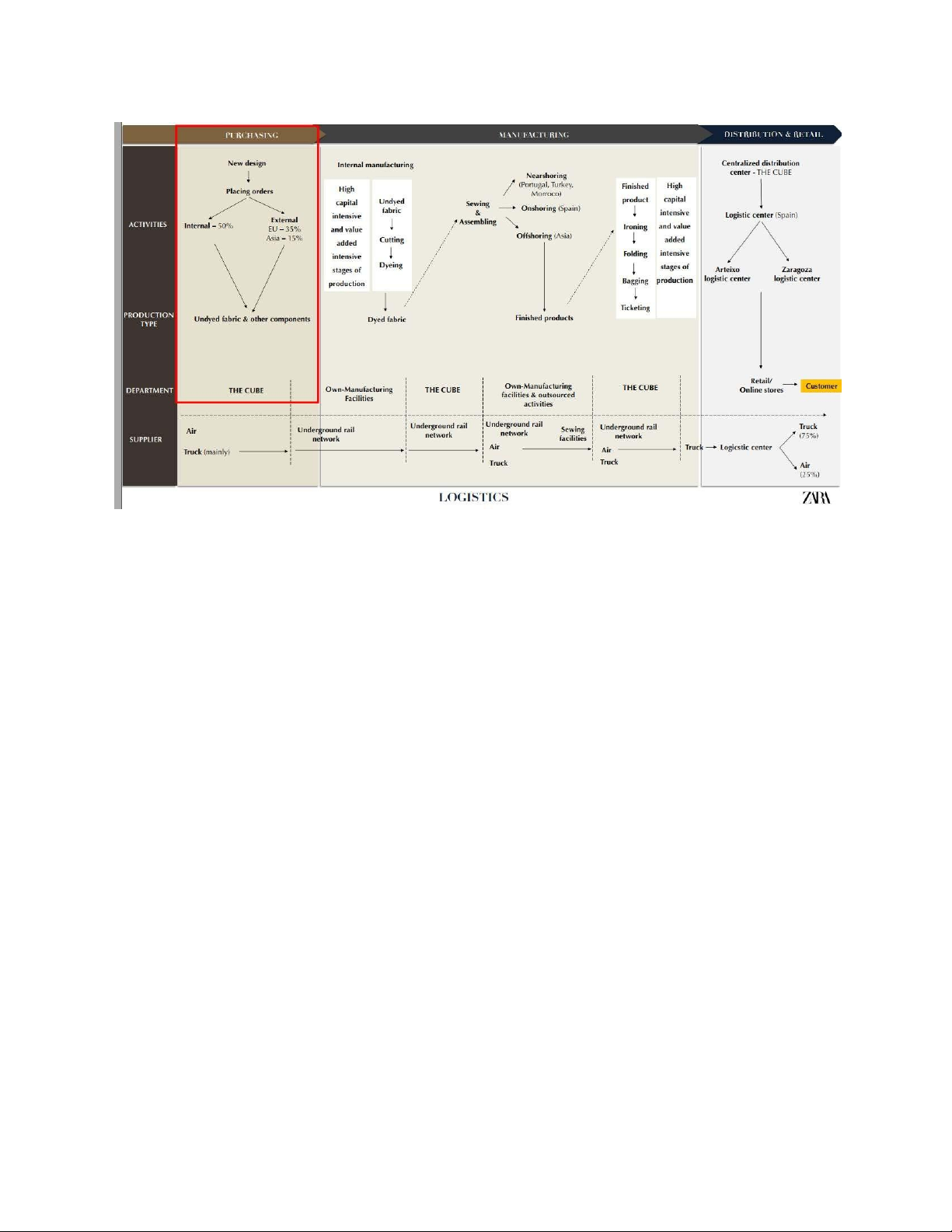

Ví dụ: Zara’s supply chain lOMoAR cPSD| 58950985

After completing the new design, Zara places orders based on accurate information and careful

calculations. Zara bought undyed fabric and other components. 50% of its products are directly from

the Group of Inditex and the remaining 50% is procured from the outside, Europe (35%) and Asia (15%).

Prioritizing suppliers from Euro (like Spain, Portugal, Italy) allows the brand to respond quickly

towards intensive demands from customers, as well as cutting logistics costs and avoiding potential risks

of being out-of-stock. From Asia, Zara purchases “basic” components and those for which the region has a

clear cost or quality advantage. And The Cube places orders and receives materials within 5 days from the order placement time.

The Cube sent those materials above to its own manufacturing facilities. The uncolored status

allows the brand not only flexibility to change the color of the fabric to match with current trends but also

minimizing wastage. After completing these 2 steps, dyed fabric would be sent back to The Cube. Zara did

not have the ability to sew all dyed fabric. 50% of that were manufactured internally in Spain, and the

remainder were made Euro which are close to the host country and Asia

The most fashionable items tended to be the riskiest and consumed following European fashion

trends were produced in Spain, Portugal and Morocco. More basic items that were more price-sensitive

than time sensitive were particularly likely to be outsourced to Asia. The finished products are then

dispatched by model and size to Zara’s distribution center - The Cube for ironing, folding, bagging and

ticketing before being sent to the logistics center.

ZARA is adopting the Direct Channel of distribution through the practice of Chain stores.

Finished products will be gathered at the distribution center (DC) - The Cube. DC serves as a connection

point on the trait of moving products, rather than storing them. Therefore, orders from each retail store are

prepared and packed with the exact size and style required and ready for shipment.

From the DC, clothing products will be transported to 2 principal logistics centers around Spain

and will continue to be delivered to every retail store globally.

Customers can either shop for ZARA clothes via online platforms or directly at ZARA flagship stores globally. lOMoAR cPSD| 58950985

Câu 3. Phân tích các bên có liên quan tới chuỗi cung ứng toàn cầu. Lấy ví dụ minh họa.

- Suppliers: Specializing in the production and supply of input materials to manufacture products

such as: raw materials and production of semi-components and components for products.

- Manufacturing companies: include companies that produce parts such as components, sell

components and assemble to manufacture products. Usually, the stages of manufacturing

components and selling components and assembling can be done by companies in the supply

chain in different countries, but the research and production activities of core components and

products are done by companies that order in the supply chain. For example: Apple's iPhone

products have chips, microcircuits, and assemblies located in different countries and

companies in the supply chain, but the design and product breakthroughs are only produced at

the parent company to create different values.

- Retailers: Specialize in distributing and selling products to consumers.

- Distributors: are companies that buy large quantities of products from manufacturers and

wholesale the product lines to customers

+ Material flow: the process of moving goods from suppliers to manufacturers,

distributors, and end customers. When customers return products, the goods continue

the flow in the opposite direction to the manufacturer.

+ Information flow: the process of sharing information among members of the supply

chain. This information can be about demand or sales, and is used to trigger

replenishment and forecasting. In real-world situations, sales information is shared in

real-time to reduce uncertainty in supply chain management. The result of sharing

accurate and timely information is a reduction in inventory throughout the supply chain.

+ Financial flow: In the supply chain, finance flows in the opposite direction to the

material flow. Shorter order fulfillment times allow customers to receive orders and

pay faster, impacting business profits.

Ví dụ minh họa (phân tích từ cái Zara ở trên câu 1)

Câu 4. Phân tích vai trò của các thị trường mới nổi trong chuỗi cung ứng toàn cầu.

- Definition: An emerging market economy is the economy of a developing country that is

increasingly integrated with global markets. Countries classified as emerging market

economies have some (but not all) of the characteristics of a developed market.-

Currently, some notable emerging market economies include India, Mexico, Pakistan and Saudi Arabia,..

The most important thing is that an emerging market economy is often moving from a pre-

industrial, underdeveloped, low-income economy to a modern industrial economy with a higher standard of living.

Emerging markets are a good place to invest, an important link in the global supply chain. lOMoAR cPSD| 58950985

- Characteristics of emerging markets:

+ High economic growth rate. High unemployment, abundant labor force, large population,

large unskilled labor. Many natural resources will bring opportunities for the development

of supply chain networks. Emerging markets have a lot of potential to be exploited,

investment capital is lacking, so developed countries will invest directly to gain high

profits. Low labor costs, abundant labor, abundant resources suitable for manufacturing

components, raw material suppliers, assemblers, distributors, etc. bring cost savings,

efficiency of global supply chains

+ Emerging markets are in the process of moving from closed economies to open market

economies. While everyone hopes the result will be favorable policies, there are also

increased political and currency risks. Young and large population

+ Emerging markets often have younger populations that can boost long-term growth rates by

supplementing aging workers and consuming goods. However, younger cohorts can also

lead to increased risk of political instability. Underdeveloped infrastructure

+ Emerging markets are in the early stages of building infrastructure. While this means there

is often a need for strict government spending, it can also mean higher costs and less efficiency for businesses.

+ An important aspect of emerging market economies is that they are gradually adopting

reforms and institutions similar to those of modern developed countries, promoting economic growth.

+ Emerging market economies tend to gradually reduce their resource extraction and

agricultural activities, focusing on industrial and manufacturing activities. Emerging

market economies often pursue deliberate industrial and trade strategies to encourage

economic growth and industrialization.

+ The development of privatization and free trade, the gradual shift to mixed and market economies, and improved infrastructure

- Vai trò ( Có thể giải thích cho câu hỏi Tại sao những thị trường mới nổi ược cho rằng là

những ịa iểm mà các MNCs có thể ặt các hoạt ộng tạo giá trị gia tăng tại ó) + R&D:

In emerging markets, taking advantage of the large population, research and development activities

take place most conveniently and easily, with high accuracy thanks to surveying a large number of

subjects. Cost savings due to taking advantage of scale, resource costs such as low human resources.

The government offers many incentives and support to encourage R&D activities. + Production:

Taking advantage of abundant natural resources at low prices, many outstanding economic

advantages such as: scale, labor efficiency, technical level, investment attraction policies...

For example: Regarding the lack of natural resources in the United States, MIT Technology

Review pointed out that there are 75 main components to produce iPhones, accounting for

3/4 of the periodic table and only a few of them are available in the United States. For

example, even the iPhone's outer shell is made from raw materials that cannot be purchased

in the United States. Aluminum is made from bauxite and there are no bauxite mines in this

country. The elements known as rare earths will need to be sourced primarily from China,

which produces 85% of the world’s production. Neodymium is used to make magnets in lOMoAR cPSD| 58950985

phones, which are found in vibrators, microphones and speakers. Lanthanum, another rare

earth element, is found in camera lenses. Hafnium, an extremely rare metal, is especially

important for the transistors in the iPhone.

Labor costs are cheap due to abundant labor resources, moderate labor levels, and are often much

lower than labor costs in the countries where MNCs are headquartered.

For example, Apple CEO Tim Cook gave an interview to CBS 60 Minutes in December 2015,

saying that the US workforce lacked the skills needed to manufacture iPhones, and estimated

that it would take Apple nine months to hire the 8,700 industrial engineers who would oversee

the US assembly line. In contrast to China, Shenzhen is home to 240,000 Foxconn employees

- and millions of additional engineers and workers - Marketing & sales:

The large and multi-segmented market is a fertile ground for MNCs to exploit to create more

added value for themselves. In addition, in these markets, MNCs have a large competitive

advantage over domestic enterprises, easily applying their own marketing methods to create

more profits such as expansion, raising prices by increasing the "luxury" level of the product.

For example: 36% of iPhones worldwide were sold in China in the fourth quarter of 2014 while the figure in the US was 26%. - After-sales service:

MNCs place after-sales service in emerging countries because in these countries the quality

of labor resources is quite good, the technology network is developed, making it easy to

establish a large-scale facility serving many regions in the world.

Câu 6.Các nhóm nhân tố tác

ộng như thế nào tới việc hình thành chuỗi cung ứng

toàn cầu của các MNCs. (có trong slide nha ^^) Có 4 nhóm nhân tố tác ộng

NHÓM 1: MARKET GLOBALIZATION

1.1. Global e-commerce:

The global trade trend with the 4.0 industrial revolution and the world situation with many

fluctuations such as political conflicts, the Covid19 pandemic... has gradually made e-

commerce become a business trend and an indispensable link in the global supply chain.

E-commerce creates a cross-border sales network with many customer files, a "lucrative"

market, full of potential for multinational corporations to exploit. At the same time, it helps

businesses around the world cooperate with each other more easily, leading to the

development of global supply chains with larger scale and scope. E-commerce helps promote

the development of express delivery, transportation, delivery services,... of domestic and

international express delivery companies. Reduce the worry of releasing goods, avoiding

long-term backlog of businesses in storage and warehousing.

For example, from the early stages of the covid-19 pandemic, Nike has stepped up its use of

e-commerce, digital sales channels to advertise and sell products such as on global e-

commerce platforms Alibaba, Amazon or even its own website to quickly and directly reach

the customer market and minimize inventory across the network, while shortening the supply lOMoAR cPSD| 58950985

chain to minimize risks. As a result, Nike was able to limit its regional sales decline to just

5% while its major competitors suffered a much more significant sales decline.

1.2. Competition between global companies:

With the context of the developing technology era, strong competition between global

companies will push companies to develop more and more to avoid being left behind and

meet the needs of consumers, creating great pressure on the supply chain of multinational corporations such as:

Competition on price creates pressure to reduce prices => motivates companies to optimize production

processes and work with partners to minimize costs

Competition to improve production efficiency and product quality through increasing added value

=> promote more investment in science and technology

Being the driving force to change and expand supply strategies such as finding new markets, new

suppliers, distributors, developing new products, etc.

In addition, global companies also open many branches in many different countries, creating

opportunities for consumers to have more opportunities to access new sources of goods,

helping to optimize the global supply chain.

For example: The world's largest car manufacturers such as Toyota, Honda, Hyundai,

Mercedes-Benz, Ford, BMW, ... are growing stronger and showing their global influence not

only with companies in the same industry but in many different fields, promoting each other

to improve their position and compete according to the general trend. A typical example is the

Just in Time production model in Toyota's supply chain, which has brought significant

efficiency when eliminating interruptions, waste and increasing flexibility to the maximum

level, bringing value to the entire supply chain when many other car manufacturers learn and apply it. 1.3. Media:

Helps increase the influence and promote the image of the business to the public. From there,

businesses can improve their competitiveness, find new partners and reach many new

customers. Media is also an effective information channel that helps businesses be proactive

in managing the chain, thereby achieving more flexibility to meet the specific needs of each

different customer. In addition, this is a channel where customers will give honest feedback

on product quality, businesses can rely on it to promptly answer questions or adjust quality in

the input supply, production and distribution stages to optimize the supply chain. For example:

Social media such as Facebook, Twitter, ... are a large information portal for businesses to

collect, select and analyze data on both customers and competitors in the market to thereby

find new business opportunities, choose suitable countries and markets to become links in

their global supply chain. At the same time, through online communication applications such

as Zalo, Skype, Telegram ... help businesses connect with partners more effectively,

overcoming language and geographical barriers.

1.4. Consumption style:

Consumers often have a consumption style of products with the most economical cost, which

makes the supply chain sometimes have to simplify, eliminate unnecessary stages to avoid

increasing costs, or move the global supply chain to achieve the highest economic efficiency

in minimizing production costs.

Some recent consumption styles are the green shopping trend with sustainable products,

making the supply chain tend to become green. If a company's supply chain is found to have lOMoAR cPSD| 58950985

questionable environmental impact activities or wasteful exploitation of natural resources...

then consumers can turn their backs on the brand and switch to supporting other companies.

Or during the pandemic, people tend to shop online, creating the development of e-commerce,

businesses also have to change their business models from production to distribution,

transportation, and consumption to best meet consumer needs.

For example: Logistics service businesses are developing sustainable solutions, such as using

clean fuels and efficient transportation. Or international travelers today choose green travel,

so they will prioritize airlines using clean fuel. This leads to a series of major airlines such as

American, Delta, and United ... using more fuel-efficient aircraft, choosing environmentally

friendly green - clean fuel suppliers for their flights and testing battery / hydrogen powered

aircraft. 1.5. Customer understanding level

The more knowledge and experience customers have about products, the higher their

consumption demands, requiring product quality to meet standards, as well as a transparent

and clear production process to demonstrate prestige, creating trust for customers =>

requiring multinational corporations to improve not only product prices and quality but also

the global supply chain system. The popularity of social networking sites makes it easy for

customers to search for information about products and services before deciding to buy. This

makes the market more competitive, businesses have to analyze competitors to gain an

advantage over them. Customers who have experienced using products and services will also

have a higher level of understanding and higher requirements for subsequent experiences,

including requirements for origin, environmental safety, and transparent information.

For example: Kitkat chocolate candy products were "turned away" by millions of customers

when purchasing raw materials from a company accused of growing "unsustainable" palm

oil. The rapid spread of information leads to customers' rapid understanding and grasp of

information, causing a wave of criticism to spread around the world. As a result, Nestlé had

to temporarily stop purchasing palm oil from this supplier and implement a series of policies

and measures to certify the sustainability of the new palm oil supplier.

1.6. Global advertising:

Contributes to widely spreading the company's brand to target markets, helping customers

have an overall view of the company to decide to use the product, thereby contributing to

expanding the company's market scope. This can lead to an increase in demand for raw

materials, semi-finished products and finished products. Global advertising campaigns also

help save costs for the company when achieving the same brand recognition and

communication effectiveness but at a lower cost.

For example, Coca-Cola is one of the multinational companies that effectively uses global

advertising. Coca-Cola's advertising has helped increase demand for the company's products

worldwide, leading to the company having to expand its supply chain to new markets to meet the needs of new customers.

1.7. Famous Brands in the World

Famous brands often attract a large number of loyal customers and consumers. This can create

pressure to increase demand and quality standards for their products or services. MNCs are

important supply partners of these brands and must ensure that they have the capacity to

provide a reliable, standardized supply of products and services to meet the growing demand.

Famous brands are often pioneers in innovation. This can lead to changes in the supply chain, such

as the use of new technologies or new production methods. lOMoAR cPSD| 58950985

On the other hand, famous brands are a barrier for new brands to enter a market that is already

dominated by a large brand. However, small companies can leverage the supply chains of

large brand companies to save on the company's resource sourcing costs.

For example, Apple is one of the most famous brands in the world. Apple products, such as the

iPhone and iPad, are loved globally. This has led to an increase in demand for electronic

components, such as chips and displays.

Walmart is one of the largest retailers in the world. Walmart sets high standards for price and

quality for its products. This has created competitive pressure on Walmart's suppliers, forcing

them to improve their supply chains to meet Walmart's requirements.

1.8. Logistics infrastructure

Including transportation, information technology, and electricity and water, etc.

Improved logistics infrastructure helps transport goods faster, deliver products on time, on

time, at a lower cost, quickly leveling the gap between supply and demand, thereby facilitating the flow of goods trade.

Improving logistics infrastructure helps expand global markets: When logistics infrastructure

improves, it will promote the network connection of global logistics companies, which helps

goods reach customers in all locations around the world.

At the same time, the quality of infrastructure can affect the sustainability of the supply chain.

For example, using clean energy sources in infrastructure can help reduce the environmental

impact of the global supply chain.

For example: Many large technology and electronics corporations such as Samsung, Intel, LG

... invest in Vietnam in the strategy of shifting the global supply chain. Especially Samsung

when its factories located in Vietnam currently supply more than 50% of Samsung's mobile

production globally. As Vietnam's infrastructure is increasingly improved with the

government's policies and construction implementation, Samsung increasingly benefits and

optimizes production (in terms of cost, time, quality) in its entire supply chain.

1.9. Population growth:

Population growth increases demand for products, creating business opportunities and

development for the supply chain. Population growth can also create fiercer competition in

the market when a new number of customers appear, businesses must find ways to compete

to attract this new number of customers in the context of increased demand, one of which is to improve the supply chain.

Rapid population growth puts pressure on resources and supply sources, forcing multinational

corporations to seek new sources of supply in the chain or optimize the chain to operate faster

and with larger volumes to ensure market supply. Along with that is the pressure on increased

demand for transportation and logistics to ensure continuity in the supply of products and

services to areas with large populations.

The increasing young population also creates an abundant source of human resources for production

and transportation activities of the supply chain.

For example, Unilever, which specializes in manufacturing consumer goods such as

cosmetics, laundry chemicals, shampoos, etc., had to expand its production scale in the Indian

market to meet the increasing demand of consumers when the population increased by nearly

one and a half times from 900 million people (in 1991 - the milestone of opening up and

integrating) to 1.4 billion people (in 2022). NHÓM 2: COST lOMoAR cPSD| 58950985

2.1. Technological innovation:

Technological innovation (with technologies such as delivery robots, autonomous delivery

vehicles, etc.) helps optimize steps in the transportation process, packaging, warehouse

management, route optimization and predict incidents in the supply chain => reduce costs and

transportation time => improve time and cost of the entire supply chain => increase shopping

demand when transportation costs are cheap and timely.

Technology helps manage large amounts of data to improve the supply chain (for example,

synthesizing big data without missing orders, or statistics on transportation time, ranking and

evaluating the transportation process to make appropriate changes)

Innovative technology also helps increase connectivity in the supply chain when information is

transmitted faster, even immediately.

However, technological innovation also requires highly skilled human resources and brings security

risks that increase the cost of operations for MNCs

For example: Using artificial intelligence (AI) and machine learning (ML) to optimize inventory management

AI and ML can be used to analyze large amounts of data to identify patterns and trends that

are difficult or impossible to detect manually. This information can then be used to optimize

inventory management methods, such as: forecasting demand; optimizing inventory levels;

improving inventory turns. AI and ML can help businesses reduce inventory costs by up to 30%.

2.2. Improved Logistics

Helps reduce transportation costs (through optimal route selection, use of appropriate means

of transport, etc.), improve warehouse management (through optimizing storage space,

reducing inventory, etc.), improve customs clearance processing and shorten delivery times, ensuring timely delivery.

At the same time, it increases the connectivity of activities in the supply chain, increases

business value, competitiveness of enterprises and expands markets in international trade. For

example, route optimization software is a type of software that uses algorithms to find the

most efficient routes for transporting goods. This software can take into account many

different factors, such as traffic conditions, road closures and delivery schedules, to find the

fastest and most cost-effective routes.

By using route optimization software, businesses can reduce transportation costs by up to 20%.

2.3. Security and risk. Supply chain risks by scope:

Internal supply chain risks: Production risks, business risks, planning and control risks, mitigation and

contingency risks, cultural risks.

External supply chain risks: demand risks, supply risks, environmental risks, business risks. Supply chain risks by origin:

Supplier risks: Supply chain risk problems caused by suppliers come from the following

causes: Poor supply quality, unclear inspection process. Risk factors for businesses: Raw

material risks. Intellectual property risks. Delivery time risks.

Risks from the manufacturer: Supply chain risks from the manufacturer come from the

following causes: Insufficient production capacity, inflexibility in capacity. Risk factors: Risk

of production interruption, Risk of losing core competencies due to sharing designs and documents with suppliers. lOMoAR cPSD| 58950985

Demand risk: due to failure to predict customer demand. Causes leading to this risk include:

Failure to anticipate customer demand or unstable customers, errors in demand forecasting,

frequent late deliveries. Risk factors: Acceptance risk, reputation risk.

Logistics risk: Wrong choice of transportation method, Incorrect packaging and marking,

Poor transportation network design, Warehousing problems. Risk factors: Delivery time risk, Risk of damage to goods.

Information risk: Supply chain risk due to information disruption

Environmental risk: Operational risk, increased product cost due to inflation, exchange rate

fluctuations in payment transactions for imported raw materials

Legal risk: legal differences between countries => need to add provisions to help protect businesses from legal risks

For example: In the recent past, Chinese partners have pursued the "Zero COVID" strategy, so

a large number of Trung Nguyen coffee products are stuck at the border gate

In 2000, it was an event that perhaps the owner of Trung Nguyen had to buy back his own

brand in the US market. Because he had not yet registered for trademark protection, the US

company Rice Field registered for protection of the Trung Nguyen coffee brand in the US and

WIPO. To settle this matter, Trung Nguyen had to spend hundreds of thousands of USD and 2 years to get back its brand

2.4. Product development:

With today's fiercely competitive business environment, businesses must constantly innovate

and create new values. Developing new products helps increase competitiveness, increase

sales, and at the same time check and reorient consumer trends in the global supply chain of MNCs.

Product development contributes to the sustainable development of the supply chain:

increased quality leads to increased consumption, thereby expanding the supply chain. At the

same time, creating a vibrant competitive environment among suppliers in the common chain

to continuously improve product quality.

For example, Lifebuoy uses plastic bags instead of plastic boxes to help reduce production

and transportation costs, thereby reducing product costs. Specifically, plastic bags are about

20% cheaper than plastic boxes. In addition, plastic bags are also lighter than plastic boxes,

helping to reduce transportation costs. Using plastic bags can save space and increase the quantity in one shipment. 2.5. Business costs

Business costs will affect product prices and company profits. The lower the business costs -

> the company can provide cheaper products -> increase the number of customers, increase profits.

Business costs will also affect the choice of suppliers in the supply chain. Business costs will

put pressure on the supply chain of companies to change to optimize chain operating costs as

well as find suppliers with competitive prices.

Business costs are different in different countries => affecting the movement of supply chain links

For example: Apple sets up a factory in China instead of the US because to produce a finished

iPhone in the US, Apple will have to spend about 65 USD more than when producing in

China. China is a market with a skilled, low-cost workforce, they are also used to the

extremely fast pace and working style. In addition, China currently has an abundant source

of mid-level engineers with skills that are not inferior to American engineers, they are capable

of performing many complex operations while not requiring much in terms of income.

2.6. Economies of scale lOMoAR cPSD| 58950985

By taking advantage of economies of scale: expanding production scale, producing in larger

quantities, the cost per product will be reduced, achieving an advantage in the experience

curve to increase profits. At the same time, it reduces risks and limits vulnerability to

unexpected threats, thereby enhancing the competitiveness of enterprises in the global supply

chain. MNCs can choose suitable production locations to take advantage of local economies of scale.

For example, Amazon's advanced distribution network takes advantage of scale through a

combination of bulk purchasing and optimized shipping routes. By purchasing products in

large quantities, Amazon negotiates better prices with suppliers, receiving lower prices.

In addition, strategically located warehouses reduce transportation time and costs, allowing

products to be delivered quickly and efficiently. Amazon's big data analytics application

forecasts demand and ensures that products are stocked when they are most needed, saving costs.

2.7. Resource scarcity:

Resources are scarce because the amount of resources used to produce goods and services is limited

and is gradually depleted. We can see the depletion of mineral resources, land, forestry products,

seafood... At the same time, there are also limitations in human resources, foreign language skills,

information technology. Meanwhile, the demand for goods and services is unlimited, increasing,

more diverse and abundant, especially the quality is getting higher and higher.

Scarcity of resources causes a shortage of supply, broken chains increase costs and the choice

will bring about trade-offs - To produce one more unit of this good, you have to give up

another quantity of goods. Scarcity of resources reduces the potential for development and

expansion of the supply chain. Therefore, it is necessary to locate the supply source near

locations that solve the problem of scarcity.

For example, Nissan announced a temporary shutdown at three manufacturing plants in

Mexico in June 2021 to deal with the shortage of microprocessors, while Daimler and

Volkswagen also started reducing working hours at some factories for the same reason.

2.8. Newly industrialized countries (NICs)

Industrialized countries with economic development potential, large foreign investment

capital and cheap labor force create a shift in the supply chain position (change of production

location - relocation of supply chain to these countries) to take advantage of costs, support policies, and labor.

Newly industrialized countries lead to an increase in people's quality of life and increased

demand for products and services => the global supply chain needs to expand to distribute enough to these markets.

For example: Some large enterprises such as Samsung have started to boost their supply chain in

India since 2018. Samsung currently manufactures most of its phones

2.9. Adapting to local conditions:

Depending on the cultural conditions, habits, and lifestyles in each locality, the global supply chain

must change in production, sales, marketing, etc., creating deep specialization.

Different local conditions create differences in lOMoAR cPSD| 58950985

Customer tastes and preferences: products as well as marketing messages must be

differentiated to appeal to the tastes and preferences of local customers. This creates pressure

to delegate production and marketing functions to subsidiaries. Infrastructure differences:

For example, consumer electrical systems in North America are built on the basis of a standard

voltage of 110V, while in European countries it is a 240V system. Thus, domestic electrical

machines must be customized to serve these differences in infrastructure.

Differences in traditional habits:

For example, in the UK people drive on the left side of the road, creating a demand for right-

hand drive cars. Obviously, right-hand drive cars are customized to take into account traditional habits.

Distribution channel differences: distribution channels must be appropriate for each country

Differences in local government policies: whether the government encourages or restricts trade

Adapting to local conditions will help reduce risks in the supply chain. However, it can lead

to increased costs (CF changes in product features, CF training of workers, etc.) Therefore,

some cost improvement measures are needed such as: cooperating with local suppliers to

reduce transportation and warehousing costs, etc. 2.10. Time

Time puts pressure on all stages of the supply chain. For example:

The production process is prolonged -> Increases costs for human resources, machinery, etc.

-> Increases product prices and affects the process of distributing products to customers =>

Therefore, the stages in the global supply chain of MNCs need to find ways to optimize time

to save costs, increase purchasing demand when product prices are cheaper

Some products/services are seasonal => create pressure in the chain with the requirement to

diversify output products, respond and consume in a timely manner with fast shipping time

to ensure that the products can be preserved. Time zone differences when links in the chain

conduct exchanges and transactions. Effective communication and connection measures are

needed to minimize this limitation.

For example: The root of Toyota's growth today that even their competitors do not understand

is that Toyota has turned the work that needs to be done into a "Chain of interwoven jobs".

By applying the Just in time model, the entire management process from production to

distribution of Toyota vehicles will not have the phenomenon of inventory vehicles, inventory

materials, vehicles are produced according to orders and delivered on time at the right location for customers

The core purpose of Just in time is to ensure balance in the production system, that

is, to ensure the flow of goods is continuously circulated, production takes place

regularly throughout the system. Shortening the implementation time and using

resources effectively is the way to help Just in time achieve 3 main goals: Eliminate

interruptions: Interruptions have a negative impact on the regular working system so

they need to be eliminated. Usually, interruptions are mainly due to factors such as

equipment damage or delayed supply, ...

Make the system more flexible: Flexibility in production is the ability of the system

to respond to changes. System flexibility helps increase production capacity and ensure resource balance.

Eliminate waste: When resources are not used efficiently, it causes waste and it needs to be eliminated. NHÓM 3: GOVERNMENT lOMoAR cPSD| 58950985

3.1. Policies and regulations

General policies and regulations ensure the safety of MNCs when participating in the global

supply chain. Policies also affect the production process, creating differences in

transportation, customs clearance, import and export between countries due to different

policies and regulations in the host countries => both an opportunity and a challenge. Policies

and regulations can cause shifts in the supply chain (change of production location relocation

of the supply chain to countries with open legal corridors with many incentives in policies, or

lower logistics transportation costs)

For example: Vietnam has advantages in human resources, economic development but

Vietnam's logistics costs are always sky-high because domestic enterprises are still small,

medium and micro-sized, not many enterprises can undertake all stages in a logistics supply

chain but only undertake parts, leading to increased costs and poor competitiveness compared

to foreign enterprises. At the same time, infrastructure and transportation are still weak.

For countries with synchronous regulations, streamlined administrative procedures will promote the

development of the logistics service market serving the supply chain.

When participating in expanding the supply chain in any country, MNCs must comply with

regulations on the environment, natural resources, regulations on localization rates, rules of origin, etc.

3.2. Non-tariff barriers:

Currently, countries around the world tend to tighten non-tariff barriers (quality, technical,

and food safety standards, etc.) to protect consumers and the domestic market. Impacts

include: increased costs, reduced ability to expand the chain and delays in transportation due to strict regulations.

This situation has created pressure for businesses in the supply chain to focus more on

investment, technological innovation, development of modern production lines, improvement

of labor productivity and treatment of workers to be able to meet safety and hygiene standards,

environmental protection standards, etc. in accordance with regulations and international

standards, thereby helping to improve competitiveness. In addition, non-tariff barriers also

affect the location of businesses to locate components of the chain.

For example, to avoid facing strict non-tariff barriers in Europe, businesses can choose to develop

chains in Asia or Latin America.

The US has decided that from January 1, 2018, aquatic and seafood products imported into

the country must have labels proving their origin, production and processing process. This

regulation does not exclude any product or country. Of course, it will include shrimp and

pangasius, Vietnam's main export products. 3.3. Tariff barriers

Tariffs can reduce bilateral trade, then spread widely, even disrupting the global supply chain through:

- Price increases: When tariffs are applied, the price of goods when reaching international

consumers will increase, demand for products will decrease, affecting the competitiveness and profits of MCNs.

- Reduced benefits of scale: One of the benefits of a supply chain is the ability to leverage

scale and efficiency in production and distribution. However, when there are tariff barriers, lOMoAR cPSD| 58950985

companies may have to disaggregate their supply chains and seek to produce in locations with

lower tariffs. This can reduce benefits of scale and increase transportation and management costs.

- Disruption in the supply chain: Tariff barriers can increase the time and cost of transporting

goods across borders, leading to disruptions in the supply chain.

For example, on March 15, 2018, the US Department of Commerce (DOC) issued the final

conclusion in the 13th administrative review (POR 13) of anti-dumping measures on

Vietnamese pangasius (review period from August 1, 2015 to July 31, 2016). Based on this

conclusion, Vietnamese tra and basa fish exporting enterprises will be subject to anti-dumping

tax rates ranging from 2.39 USD/kg to 7.74 USD/kg for the above review period. These are

very high tax rates and will have a major impact on Vietnamese tra and basa fish exports to

the United States. This will cause product prices to increase and consumption to decrease. 3.4. WTO

International trade helps the economies of member countries specialize in production more

deeply, taking advantage of comparative advantages. Thanks to global trade cooperation,

countries will exploit resources, labor and land more effectively, thereby becoming a key link

in the supply chain of MNCs effectively. WTO reduces trade barriers (tariffs and non-tariffs)

to create favorable conditions for exporting to international markets, creating conditions for MNCs to expand the chain.

For example: After joining the WTO, the investment wave from multinational corporations

from the world's leading economies has become increasingly clear, making Vietnam gradually

become an important location in the global supply chain. The first mark is the investment of

search Samsung (Korea) with 4 production facilities, contributing about 30% to the total

revenue of the Group. At the end of 2022, Samsung officially opened the Research and

Development Center (R&D) in Hanoi, with the ambition to develop it into a strategic base for

large-scale research and development.

A series of leading US enterprises such as Apple, Intel, Ford, General Electric, Pepsi,

CocaCola, Nike, Microsoft, Citigroup, P&G ... have been increasing investment and business in Vietnam.

3.5. Government spending:

Government spending on infrastructure, technology lines, ... will be a great advantage for the supply chain in this country.

Government spending creates commitment: when there is government investment and

spending in the supply chain, businesses will feel confident to participate and invest, thereby expanding the supply chain

In addition, government spending will also affect macroeconomic factors such as (inflation,

CPI, aggregate demand, ...) affecting the business and production environment of the supply chain.

For example: The State has started the Long Thanh International Airport project to transport

goods smoothly, thereby accessing many markets, upgrading logistics infrastructure to create

conditions for Vietnam to participate in the international supply chain. 3.6. Privatization

Privatization is the process of converting part or all of an enterprise's assets from government

ownership to private ownership.

The privatization process will eliminate restrictions from the State apparatus and optimize

business activities in the market by allowing enterprises to freely participate in production lOMoAR cPSD| 58950985

activities according to their needs and the market and optimize resources => promote the

process of transporting goods and services faster => contribute to improving the supply chain. For example:

3.7. Trade linkage area

Large potential market => expand production and distribution facilities in these economic trade areas.

Facilitate logistics, import-export, customs clearance, and transactions of countries in the

same trade linkage area (reduce barriers, such as tariffs and import regulations) => save time and costs.

Influence the choice of partners in the supply chain and import-export of each country =>

prioritize choosing countries in the same trade/economic agreement as partners in the supply

chain to enjoy incentives and take advantage. The result is an optimized supply chain for a

company when it bases its production and distribution in countries within the same trade link.

However, trade link regions also create challenges in ensuring regulations and standards:

Companies must ensure compliance with regulations and standards to participate in the regional supply chain

For example: When participating in RCEP, tariffs on some Vietnamese products such as

textiles, automobiles, and some electronic products will be reduced, and the application of

unified rules of origin in RCEP will help Vietnam participate more deeply in the regional

supply chain. The trend of shifting supply chains to Vietnam, which has been happening

before thanks to bilateral agreements or within the ASEAN+6 framework, will continue to be

promoted thanks to RCEP. Vietnam's FDI inflows are also expected to increase as large

investors in the region promote specialization to develop supply chains. 3.3. Tariff Barriers

Tariffs can reduce bilateral trade, subsequently causing widespread effects and even disrupting global supply chains through: ●

Price Increases: When tariffs are applied, the cost of goods for international consumers rises,

leading to decreased demand for these products, impacting the competitiveness and profits of multinational corporations (MNCs). ●

Reduction in Economies of Scale Benefits: One of the advantages of supply chains is the ability

to capitalize on economies of scale and efficiency in production and distribution. However, tariff barriers

may require companies to divide their supply chains and seek production locations with lower tariffs. This

can diminish economies of scale benefits and increase shipping and management costs. ●

Supply Chain Disruptions: Tariff barriers can increase the time and cost of moving goods across

borders, leading to disruptions in supply chains.

Example: On March 15, 2018, the U.S. Department of Commerce (DOC) issued its final determination in

the 13th administrative review (POR 13) of anti-dumping measures on Vietnamese tra and basa fish (for

the review period from August 1, 2015, to July 31, 2016). According to this conclusion, Vietnamese tra and

basa fish exporters would face anti-dumping duties ranging from $2.39/kg to $7.74/kg for the review period.

These high tariffs will significantly impact the export of Vietnamese tra and basa fish to the U.S., leading

to increased product prices and reduced consumption. 3.4. WTO lOMoAR cPSD| 58950985

International trade allows member economies to specialize more deeply in production, capitalizing on their

comparative advantages. Through global trade cooperation, countries can more efficiently exploit

resources, labor, and land, enabling them to become key links in MNCs’ supply chains. The WTO reduces

trade barriers (both tariff and non-tariff), facilitating exports to international markets and enabling MNCs

to expand their supply chains.

Example: Since joining the WTO, investment waves from leading multinational corporations from the

world’s major economies have increasingly positioned Vietnam as a critical destination in the global supply

chain. The first milestone was Samsung (South Korea) investing in four production facilities in Vietnam,

contributing about 30% of the corporation's total revenue. By the end of 2022, Samsung inaugurated a

Research and Development (R&D) Center in Hanoi, aiming to establish a large-scale strategic hub for

research and development. Numerous top U.S. companies, including Apple, Intel, Ford, General Electric,

Pepsi, CocaCola, Nike, Microsoft, Citigroup, and P&G, have been expanding their investments and

business operations in Vietnam.

3.5. Government Spending

Government spending on infrastructure, technological systems, etc., provides a significant advantage for

the supply chain within a nation. Government expenditure creates a commitment: when the government

invests in and spends on supply chain infrastructure, businesses feel more confident to participate and

invest, thereby enabling supply chain expansion. Moreover, government spending influences

macroeconomic factors such as inflation, the Consumer Price Index (CPI), aggregate demand, etc., which

affect the supply chain’s business and production environment.

Example: The government has launched the Long Thanh International Airport project to facilitate seamless

cargo transportation, thereby accessing more markets and enhancing logistics infrastructure to enable

Vietnam’s participation in international supply chains. 3.6. Privatization

Privatization is the process of transferring some or all of a business's assets from government ownership to

private ownership. The privatization process eliminates restrictions from government structures and

optimizes business activities in the market by allowing companies the freedom to engage in production

according to their own and the market's needs, thereby optimizing resources. This can accelerate the

transportation of goods and services, contributing to improvements in the supply chain. Example:

3.7. Trade Association Areas

A large potential market expands production and distribution facilities within these economic-trade zones.

These zones facilitate logistics, import-export, customs clearance, and transactions among countries within

the trade association (reducing barriers such as tariffs and import regulations), saving time and costs. They

influence supply chain and import-export partner selection for each country, favoring partnerships with

countries within the same trade or economic agreement to benefit from incentives and leverage advantages.

As a result, a company’s supply chain is optimized when it establishes production and distribution facilities

in countries within the same trade association. However, trade association areas also create challenges in