Preview text:

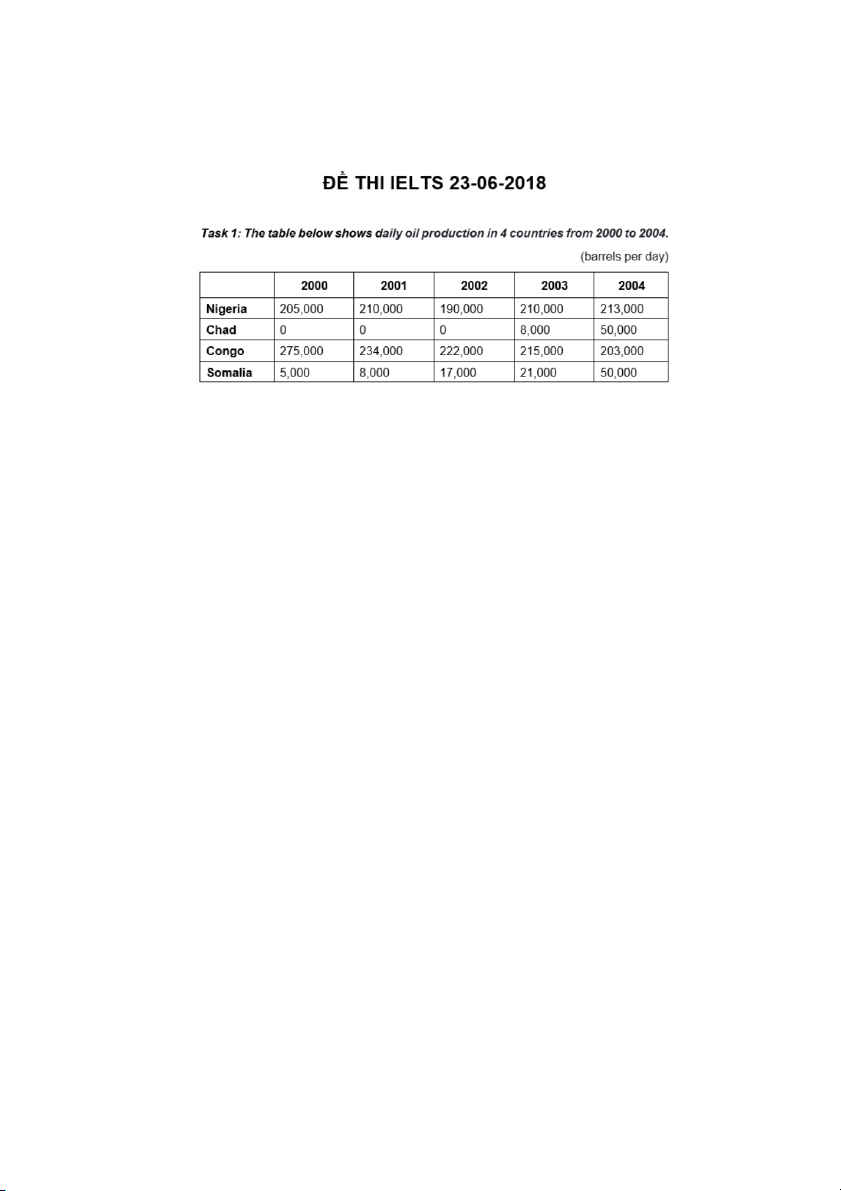

The chart illustrates how much oil was produced daily in four countries between 2000 and 2004.

Overall, there was an increase in the daily amount of oil produced in Nigeria, Chad and Somalia,

while a gradual decline in oil production was seen in Congo. In addition, Congo generally

produced the most oil among the 4 countries examined, but it was surpassed by Nigeria in the last year of the period.

Oil production in Congo started at 275,000 barrels per day (bpd), after which it experienced a

progressive fall to 203, 000 in 2004. Conversely, the figures for Somalia increased dramatically

from only 5.000 bpd in 2000 to 21,000 bpd in 2003, before reaching a peak at 50,000 bpd at the end of the period.

205,000 barrels of oil were produced in Nigeria in 2000, with subsequent fluctuations and a final

growth from 190,000 bpd in 2002 to 213,000 bpd in 2004. Meanwhile, Chad did not produce any

oil until 2002, but its oil production in 2003 was 8000 bpd, followed by a substantial rise to 50,000 bpd a year later.

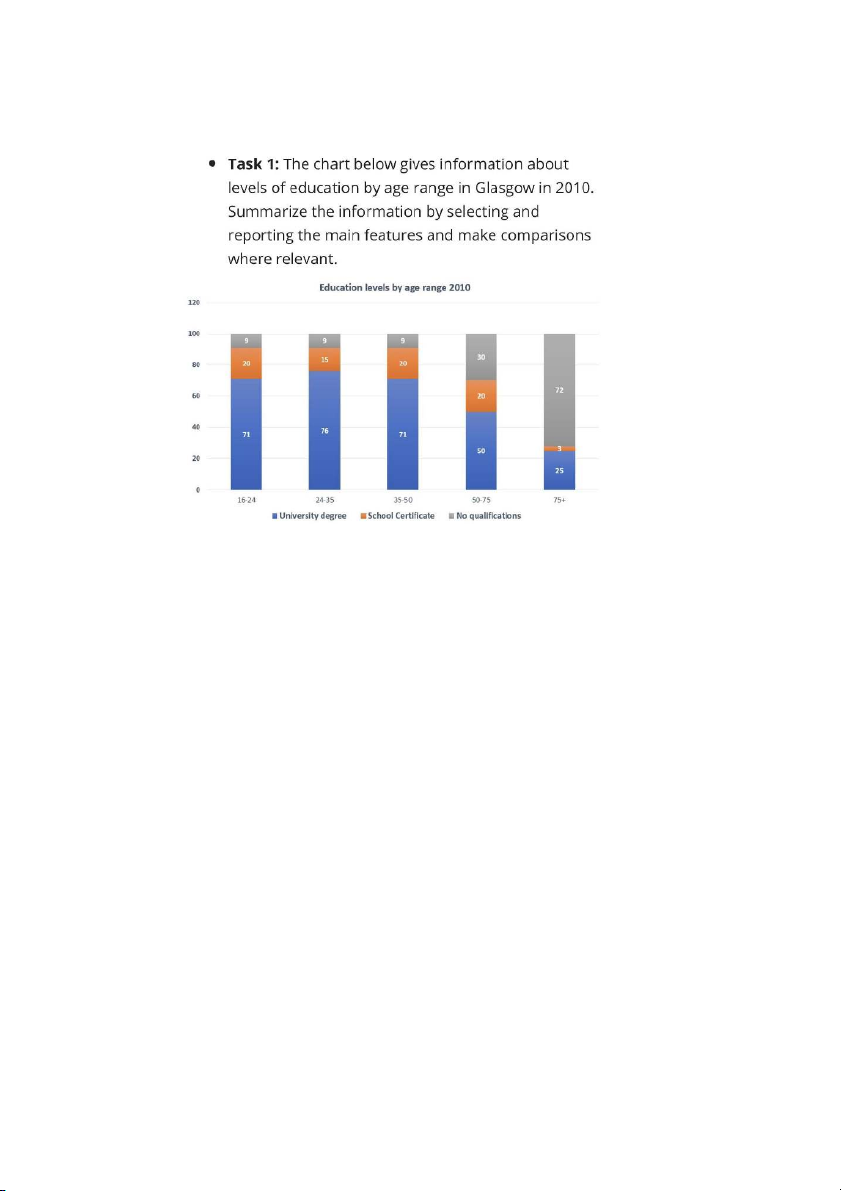

The bar chart illustrates whether and what kind of academic qualification people in Glasgow had in 2010.

Overall, the majority of people aged from 16 to 50 held a bachelor’s degree, while those who are

75 and over tended to have no qualifications. Also notable is that there is a parity in the

percentage of people having finished high school in all age groups, with the exception of the oldest one.

Regarding those having completed higher education, 76% of people who were in the 24-35 age

bracket had a university degree in 2010, followed by the 16-24 and 25-50 age groups (both at

71%). The figures for older age bands were smaller, with 50% of 50-to-75-year-olds having

received tertiary education, and only 25% of the elderly having done it. Significant differences

were also seen in the proportion of citizens in Glasgow who had not had any qualification until

2010, which was 9% for the first three youngest age groups, but 30% for those falling into the

50-75 age bracket and even 72% for senior citizens.

20% of 16-to-24-year-olds, 35-to-50-year-olds and 50-to-75-year-olds had chosen to only

complete their high school education, so had/ compared to 15% of those in the age from 24 to

35. Only a mere 3% of those aged 75 and older had graduated from high school and decided not

to pursue university education.

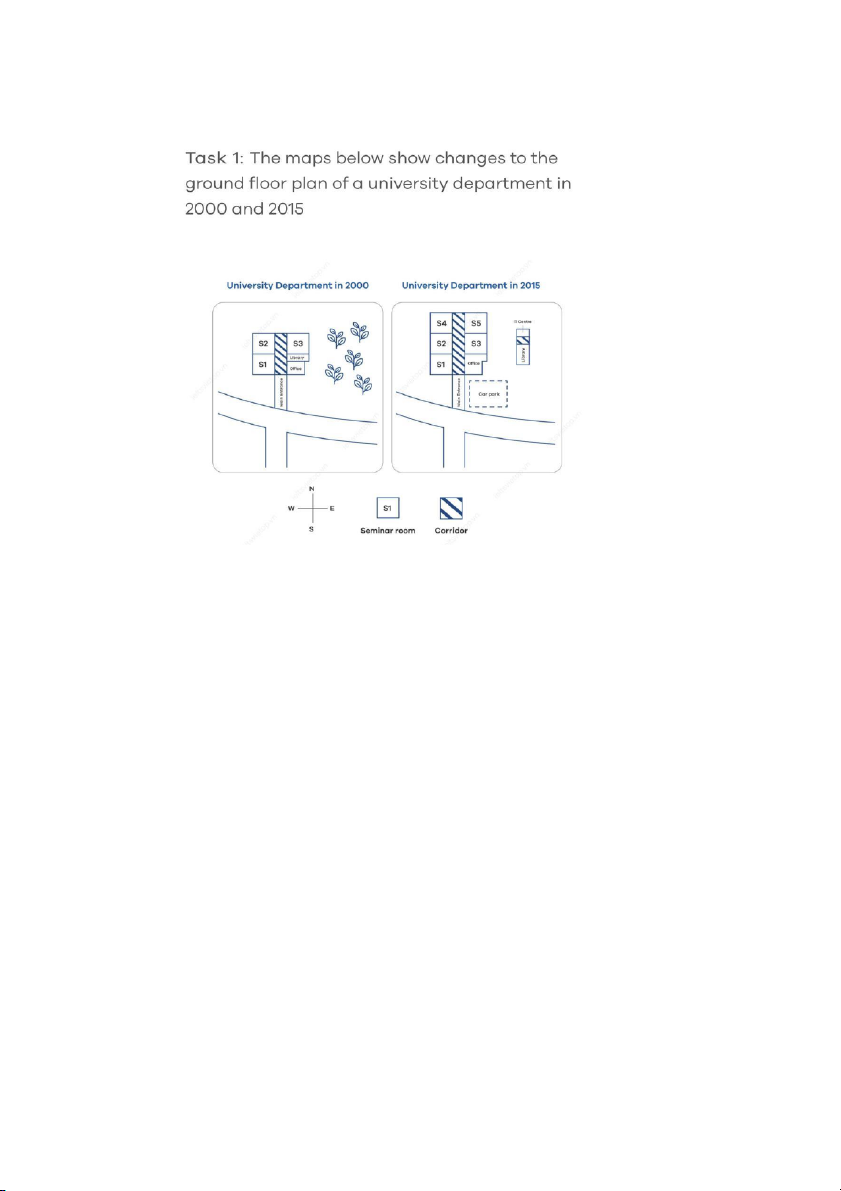

The maps illustrate how a university's campus changed between 2000 and 2015.

Overall, the university underwent a number of significant changes, the most important of which

are the expansion of classrooms and the disappearance of all of the trees in the school.

The main building in the northwest of the map had only three seminar rooms in 2000, with

seminar room 1 and 2 on the left and seminar room 3 on the right, and it was expanded

northwards with two more classrooms. The corridor separating those seminar rooms was also

extended to cater for the expansion of the building. Another change is that the library opposite

seminar room 1 through the corridor was removed to allow the office next to it to expand.

The main entrance in the middle of the map allowing access to the main building from the main

road remained, while a car park was constructed on the right of the entrance. The trees in the

northeast were cleared to facilitate the construction of a library and an IT center. A corridor was built between these two rooms.

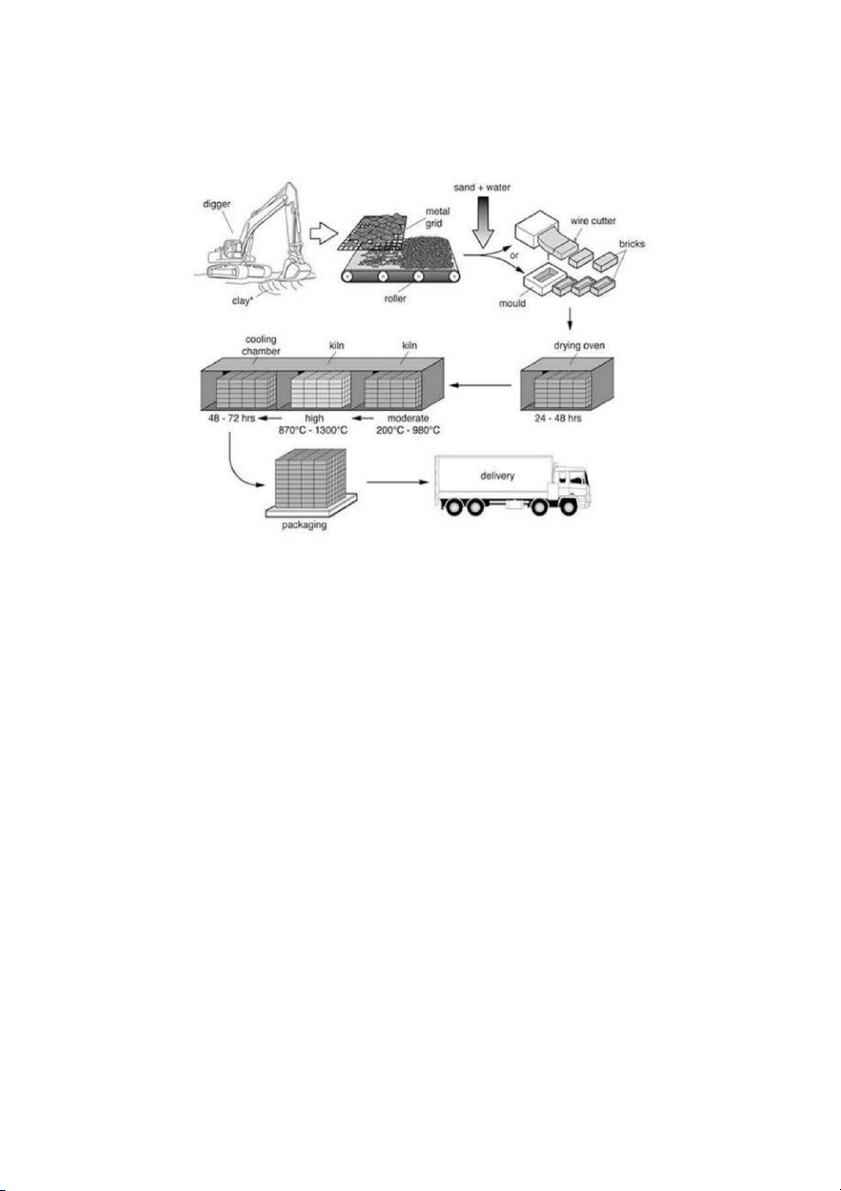

The picture depicts how bricks are made for the construction industry.

Overall, the process comprises a number of consecutive steps, starting with the collecting of clay,

through different mixing and burning stages, and ending with the shipping of the finished

products to their final destination, whether it be a construction site or storage.

At the beginning of the process, clay is excavated by a large digger to prepare for production.

After being transported to a factory, the clay goes through a metal grid in order to break up the

large chunks of clay and then small lumps of clay fall onto a roller, which moves the sieved clay to

a designated place to be mixed with sand and water. The mixture either is molded or goes

through a wire cutter to make raw bricks, after which the bricks are kept in an oven to dry for 24

to 48 hours to be ready for the next steps.

The process continues with the dried bricks being baked in a kiln at 200*C to

980*C. They are then burned at higher temperatures (870*C to 1200*C) before

being moved to a cooling chamber where they are stored for 2 to 3 days in order for them to cool

down and become hard. Once the finished bricks are packaged, they

are delivered to storage facilities or building sites.