Preview text:

lOMoAR cPSD| 59595715 I N T R O D U C T I O N T O AUTOMOTIVE ENGINEERING

Assoc. Prof. Dr. Duong Ngoc Khanh

Dept. of Transportation Engineering

School of Mechanical Engineering khanh.duongngoc@hust.edu.vn 1 lOMoAR cPSD| 59595715 1

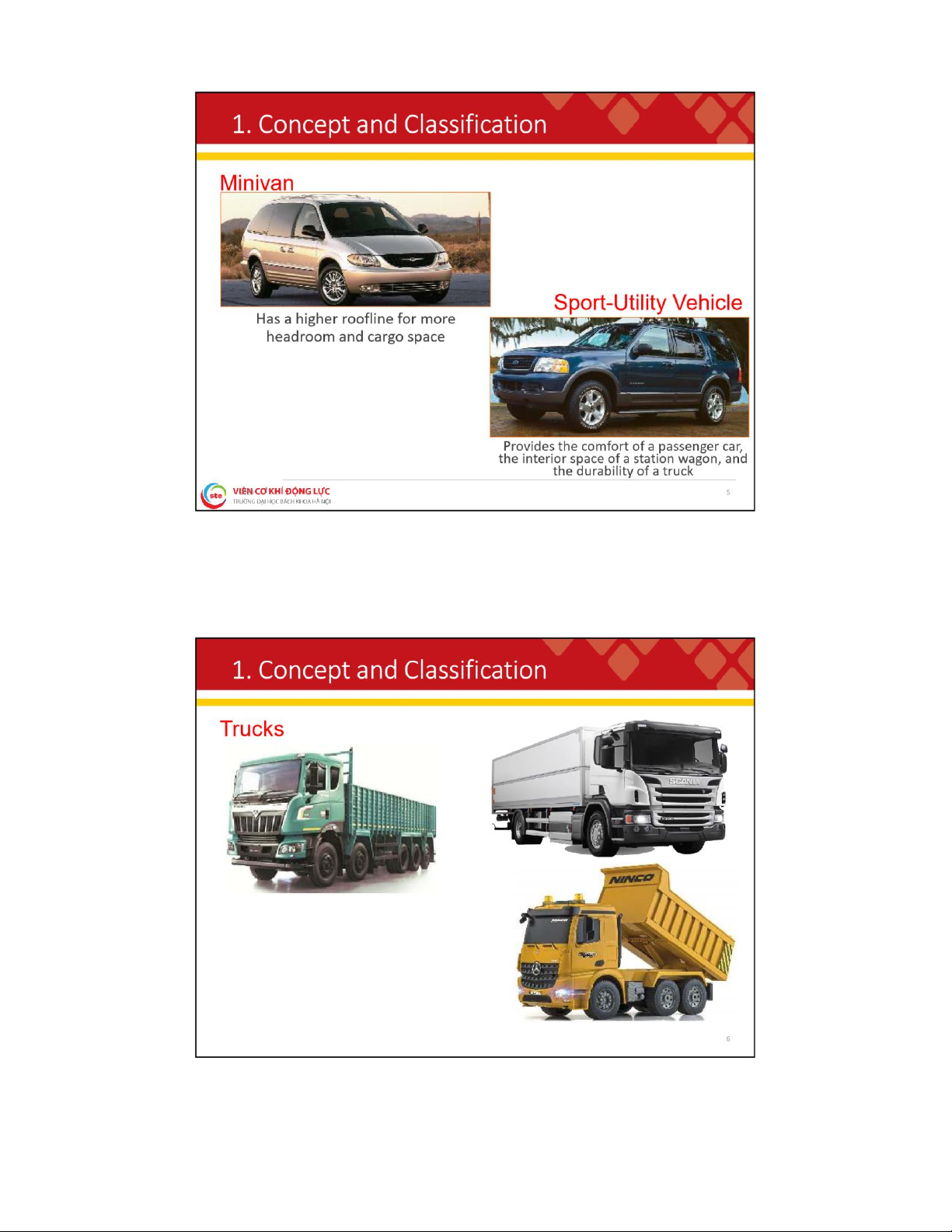

. C o n c e p t a n d C l a s s i f i c a t i o n Sedan Convertible

Uses center body pillars, or “B” pillars,

between the front and rear doors. A

hardtop does not use “B” pillars.

Uses a vinyl or cloth top that can be raised and lowered Hatchback Station Wagon

The large rear door allows easy

Provides a large rear interior compartment access when hauling items 4 lOMoAR cPSD| 59595715 lOMoAR cPSD| 59595715 2

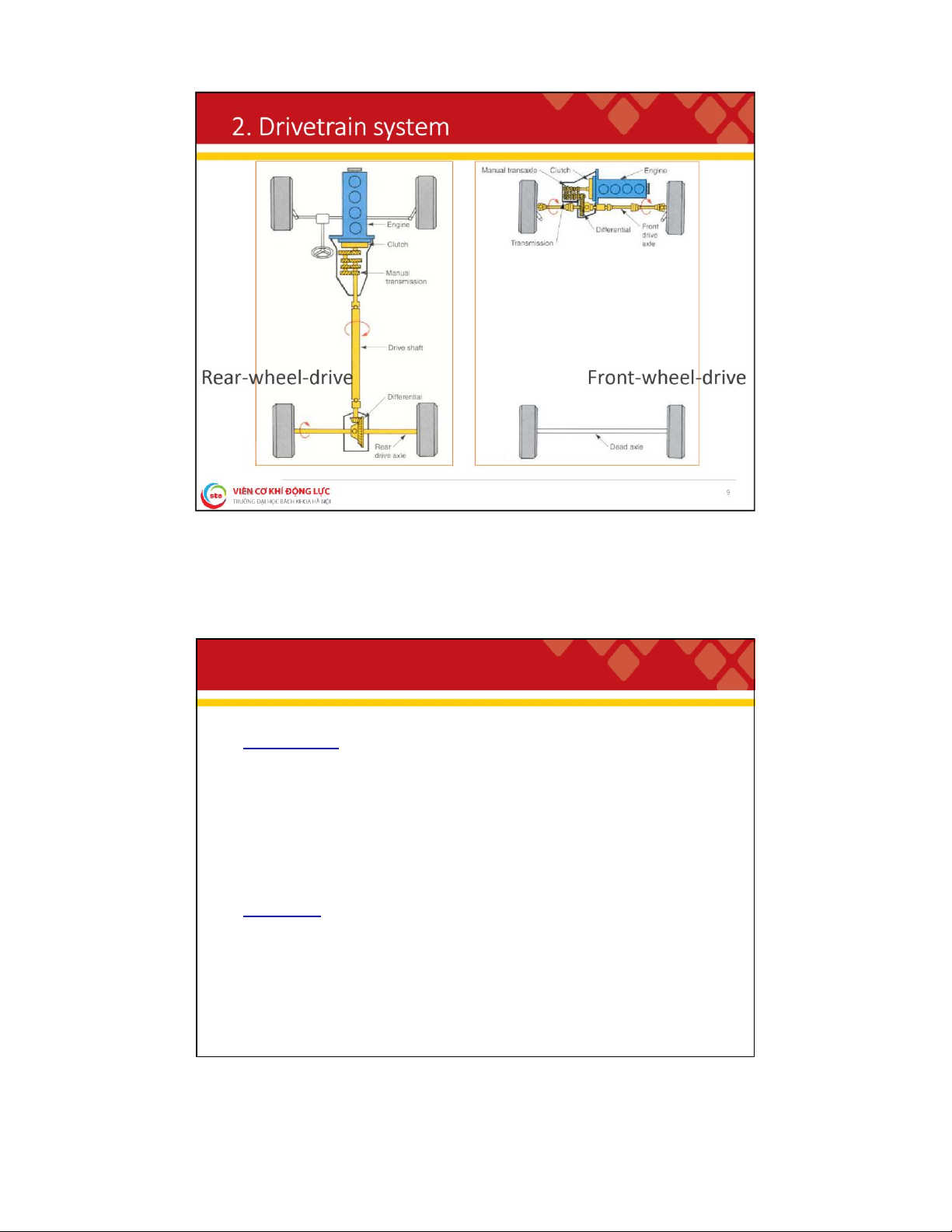

. D r i v e t r a i n s y s t e m Functions:

To couple the engine to the driving wheels;

To increase torque from the engine to the active wheels ;

To change the traction and speed at the wheels to suit the motion conditions;

To uncouple power transmission when needed ;

To reverse movement (reverse gear) . Components: Clutch; Transmission/Transaxle; Propel er shaft; Front/Rear axle. 8 lOMoAR cPSD| 59595715 2 . 1 . C l u t c h Functions:

❑ Used to connect and disconnect the engine and manual transmission or transaxle;

❑ Allows the driver to control power flow between the engine and transmission or transaxle;

❑ To serves as a safety device of the drivetrain system. Classify:

❑ Clutch (Manual transmission);

❑ Torque converter (Automatic transmission); ❑ Others. 10 lOMoAR cPSD| 59595715 2

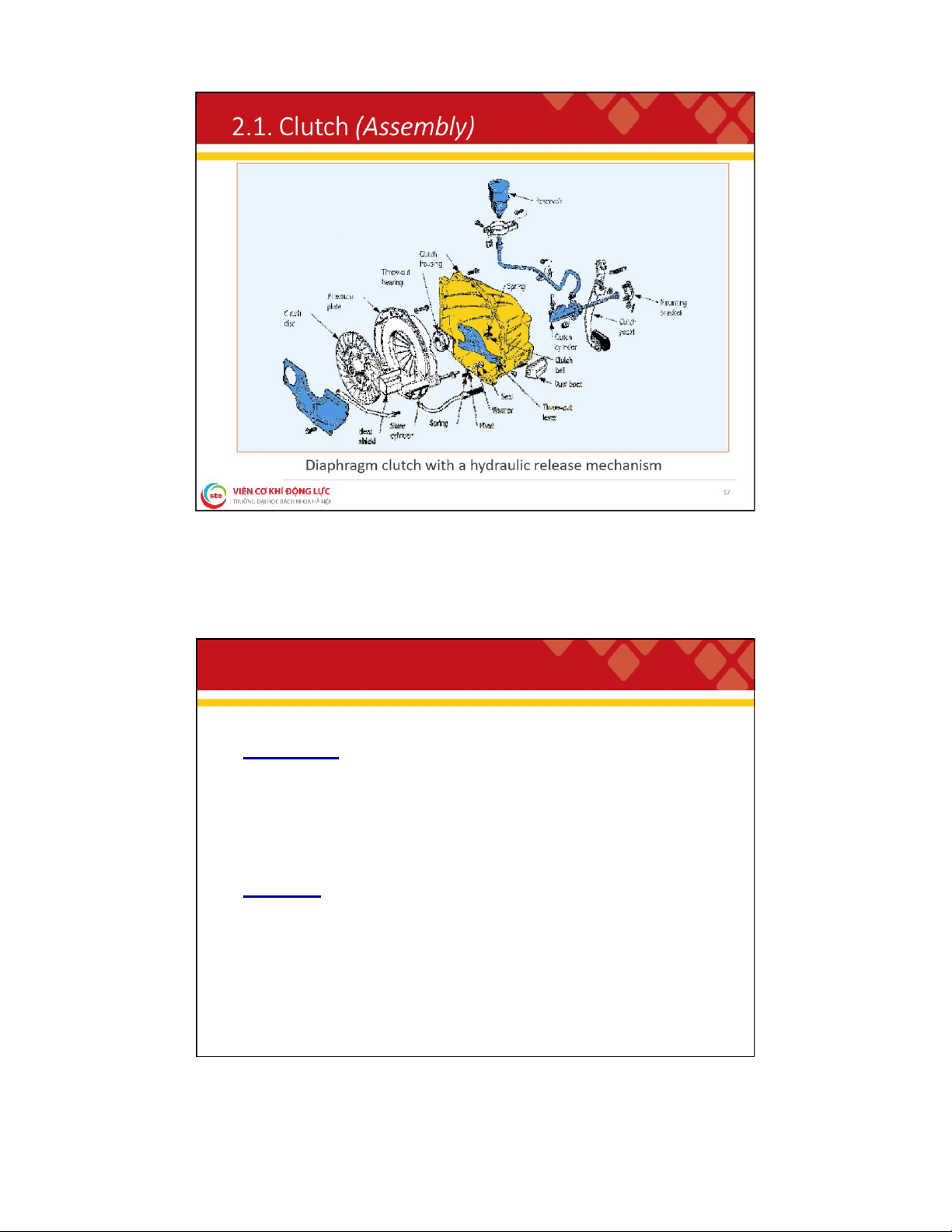

. 1 . C l u t c h ( B a s i c P a r t s ) Components: • pilot bearing • flywheel • clutch disc • pressure plate • release bearing

• clutch housing (bell housing) • clutch fork • clutch release mechanisms • clutch start switch 12 lOMoAR cPSD| 59595715 2

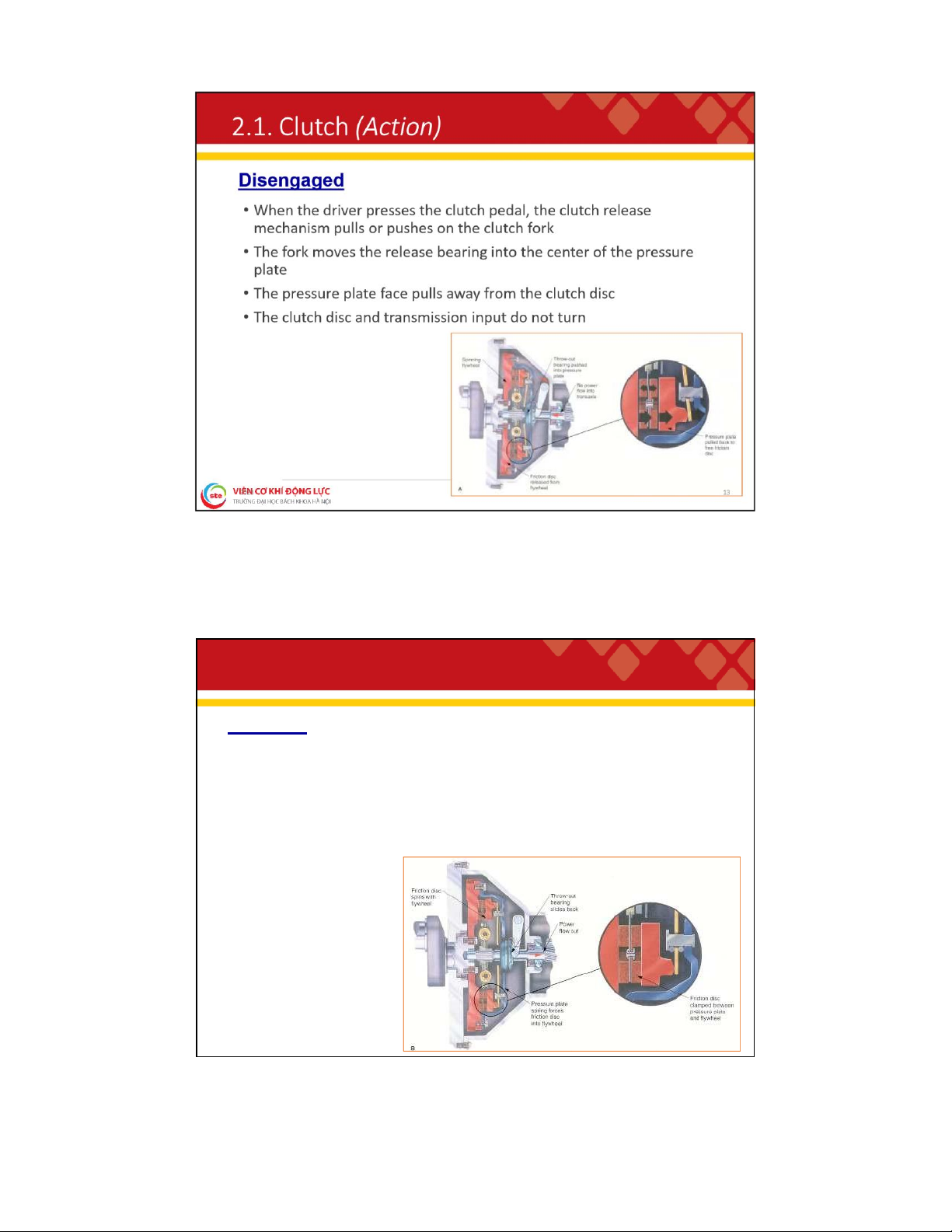

. 1 . C l u t c h ( A c t i o n ) Engaged

• When the driver releases the clutch pedal, the spring pressure

inside the pressure plate pushes forward on the clutch disc

• This locks the flywheel, disc, pressure plate, and transmission input together

• The engine rotates the transmission input 14 lOMoAR cPSD| 59595715 2

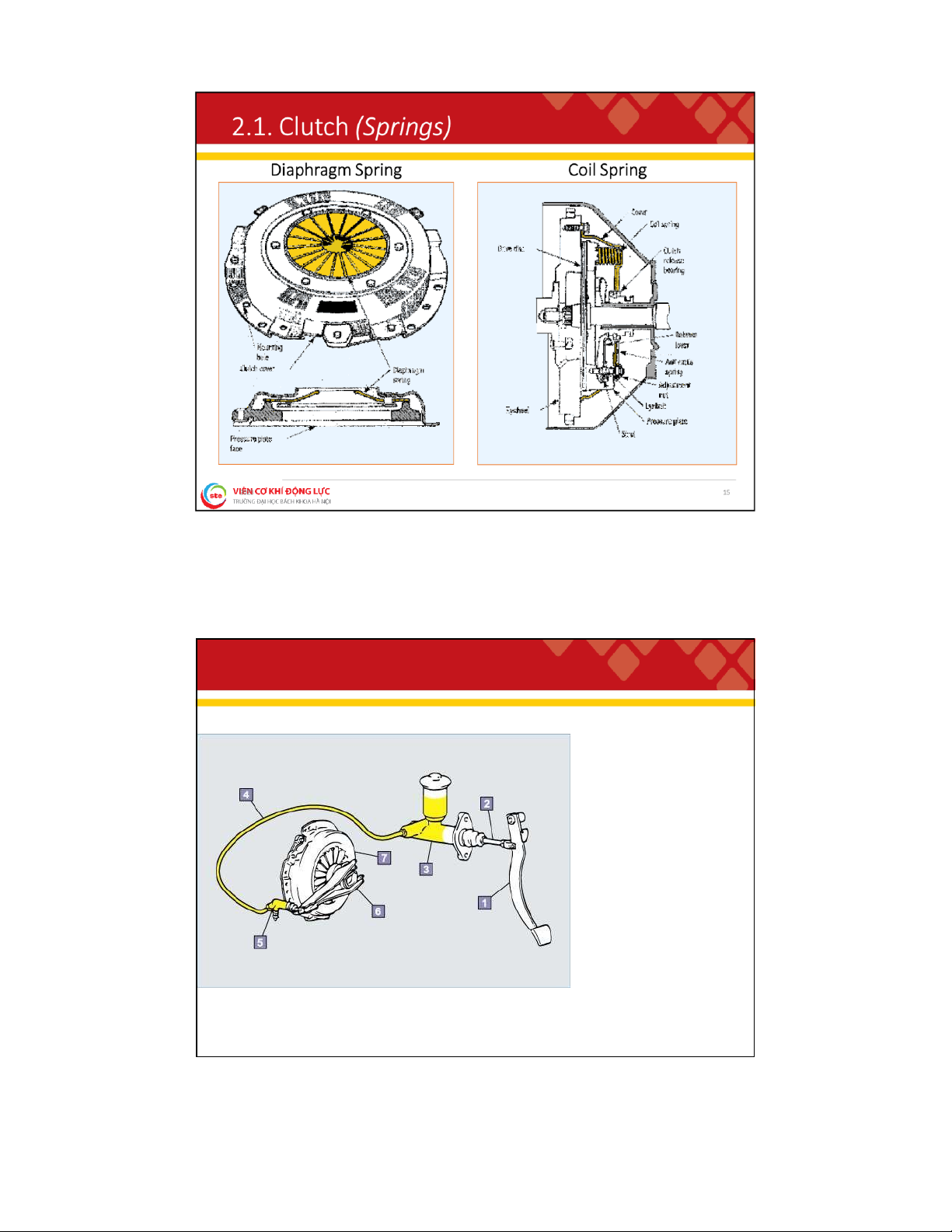

. 1 . C l u t c h ( H y d r a u l i c R e l e a s e M e c h a n i s m ) ❑ Uses a simple hydraulic circuit to transfer clutch pedal action to the clutch fork. ❑ Components: • clutch pedal • clutch cylinder • hydraulic line • slave cylinder • release fork/level 16 lOMoAR cPSD| 59595715 2

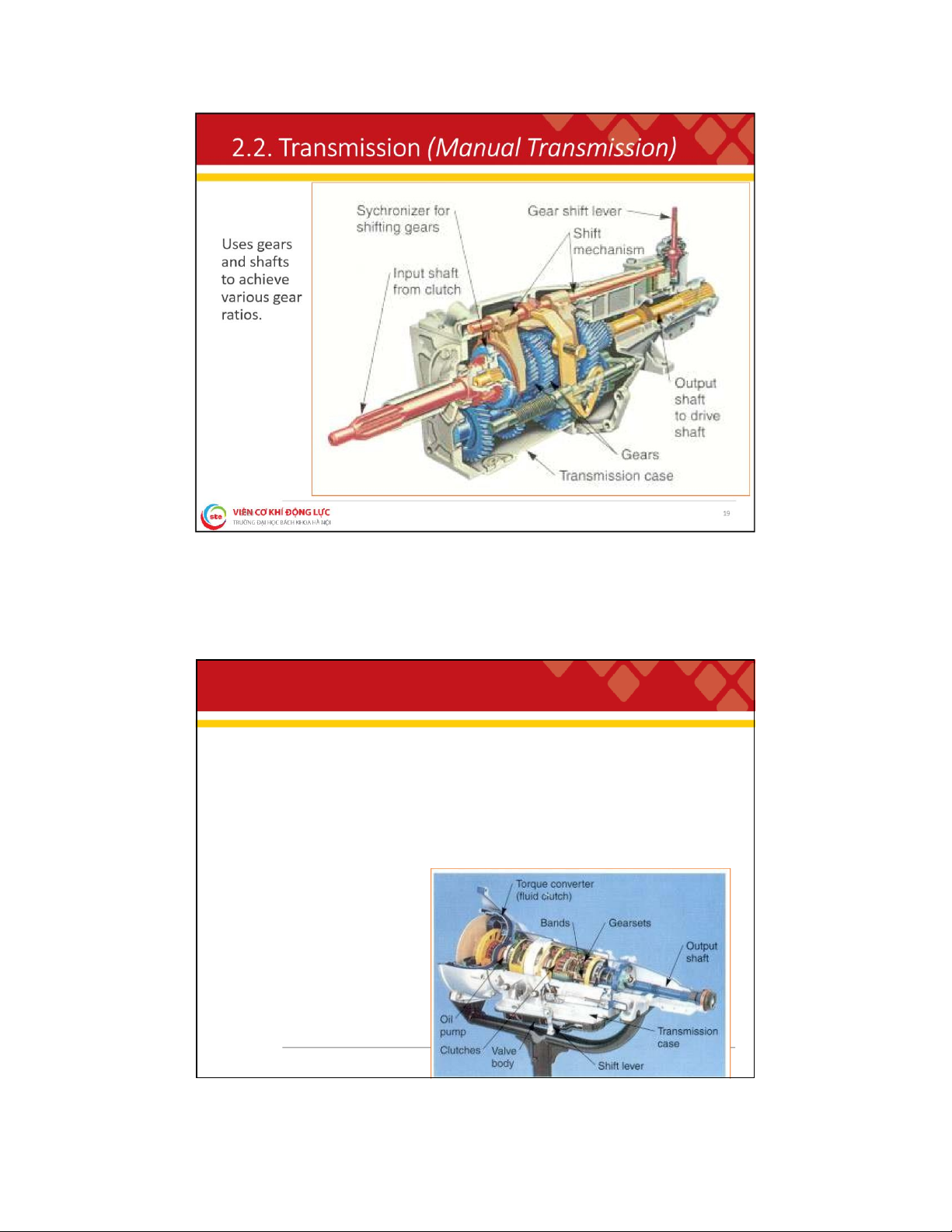

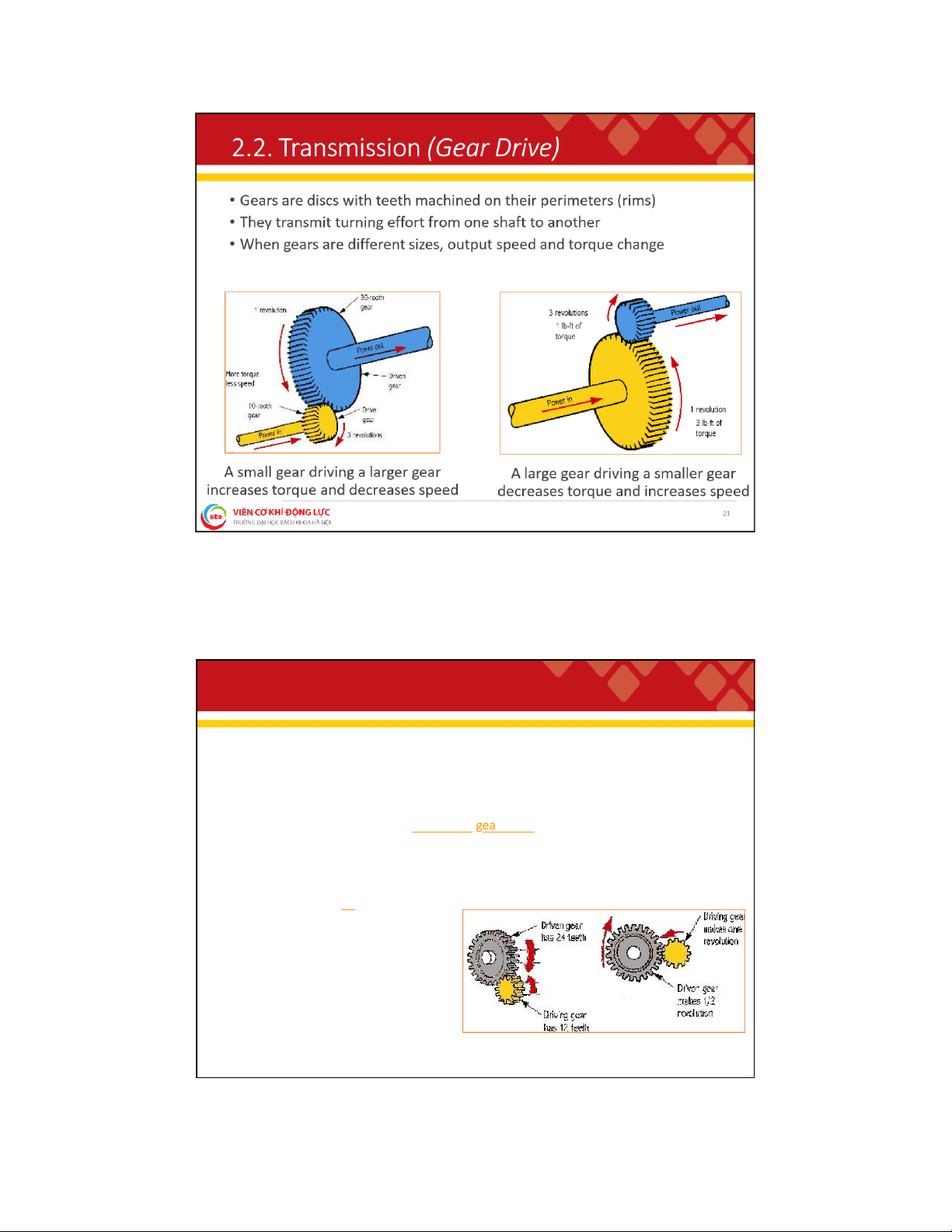

. 2 . T r a n s m i s s i o n Functions:

❑ Uses various gear combinations (ratios), to multiply engine speed

and torque to accommodate driving conditions;

❑ To uncouple power transmission when needed;

❑ To provide a reverse gear. Classify: ❑ Manual Transmission (MT)

❑ Automotive Transmission (AT) 18 lOMoAR cPSD| 59595715 2

. 2 . T r a n s m i s s i o n ( A u t o m a t i c T r a n s m i s s i o n )

❑ Does not have to be shifted by the driver;

❑ Uses an internal hydraulic system and, in most cases, electronic controls to shift gears;

❑ Internal clutches or bands control gearsets to provide various gear ratios;

❑ Input shaft is connected to the engine crankshaft through a torque converter. 20 lOMoAR cPSD| 59595715 2

. 2 . T r a n s m i s s i o n ( G e a r R a t i o )

• The number of revolutions a drive gear must turn before the driven gear completes one revolution

• Calculated by dividing the number of teeth on the driven gear by the

number of teeth on the drive gear Gear Ratio = # of driven g ear teeth # of drive gear teeth

Example: If the drive gear has 12 teeth and the driven gear has 24

teeth, the gear ratio is two-to-one Gear Ratio = 24 = 2, written 2:1 12 22 lOMoAR cPSD| 59595715 2

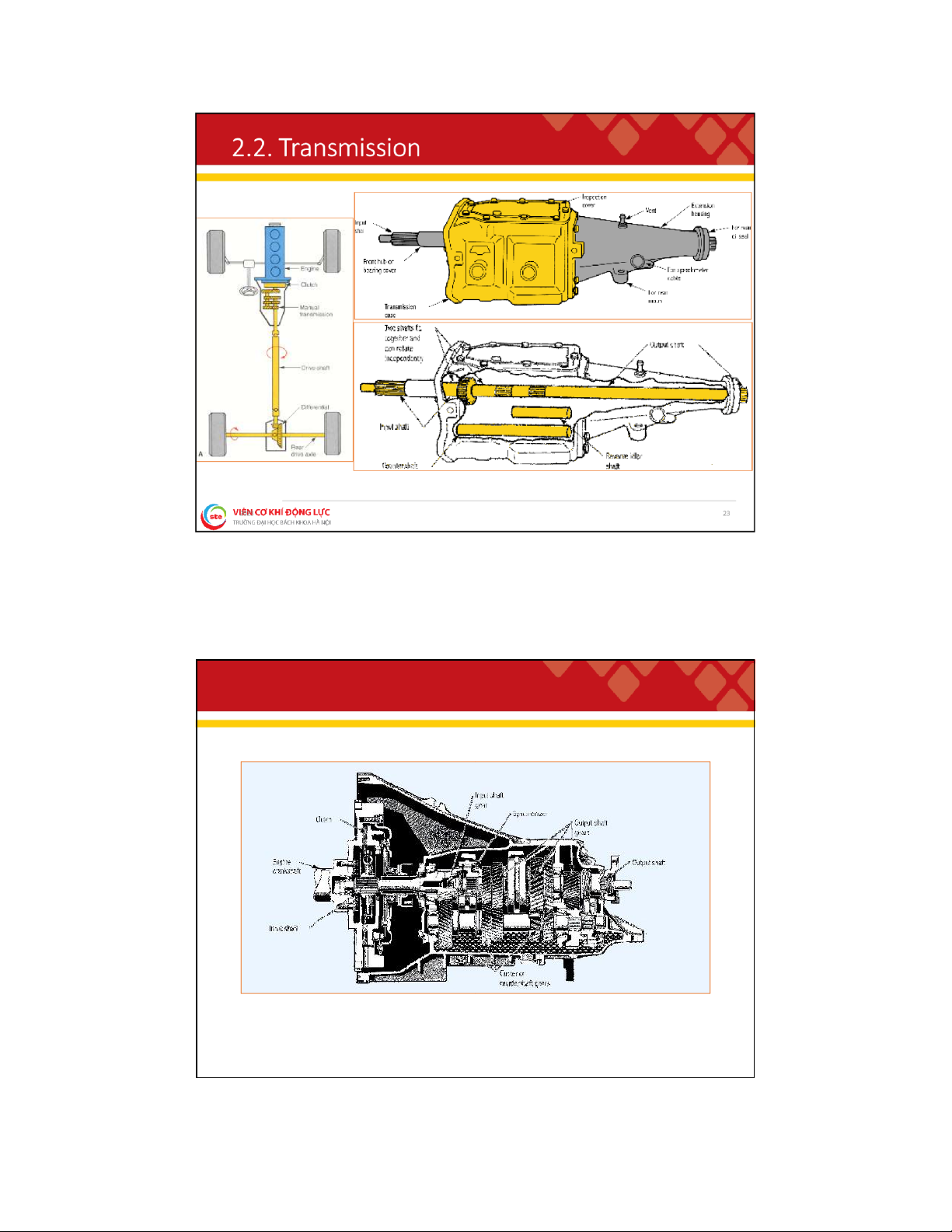

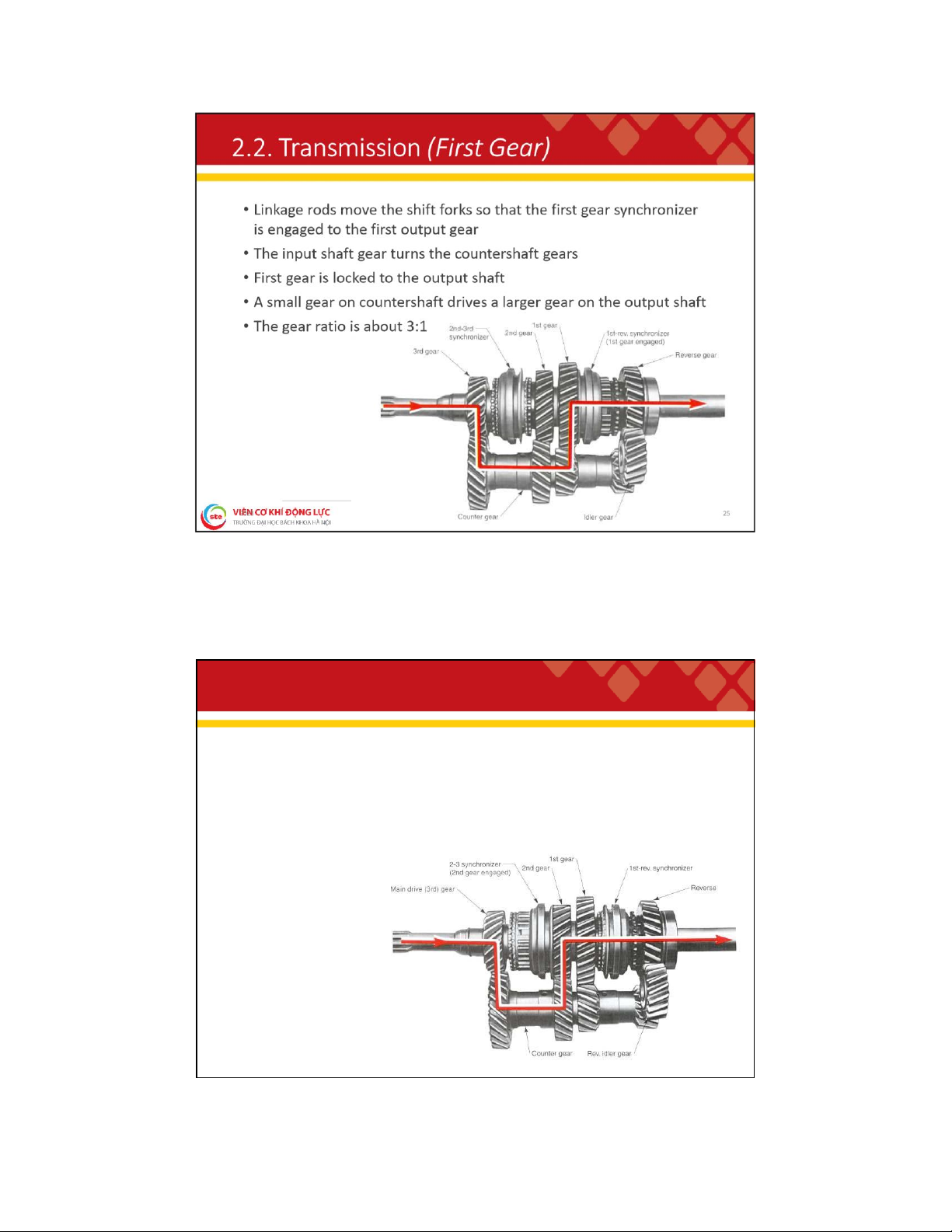

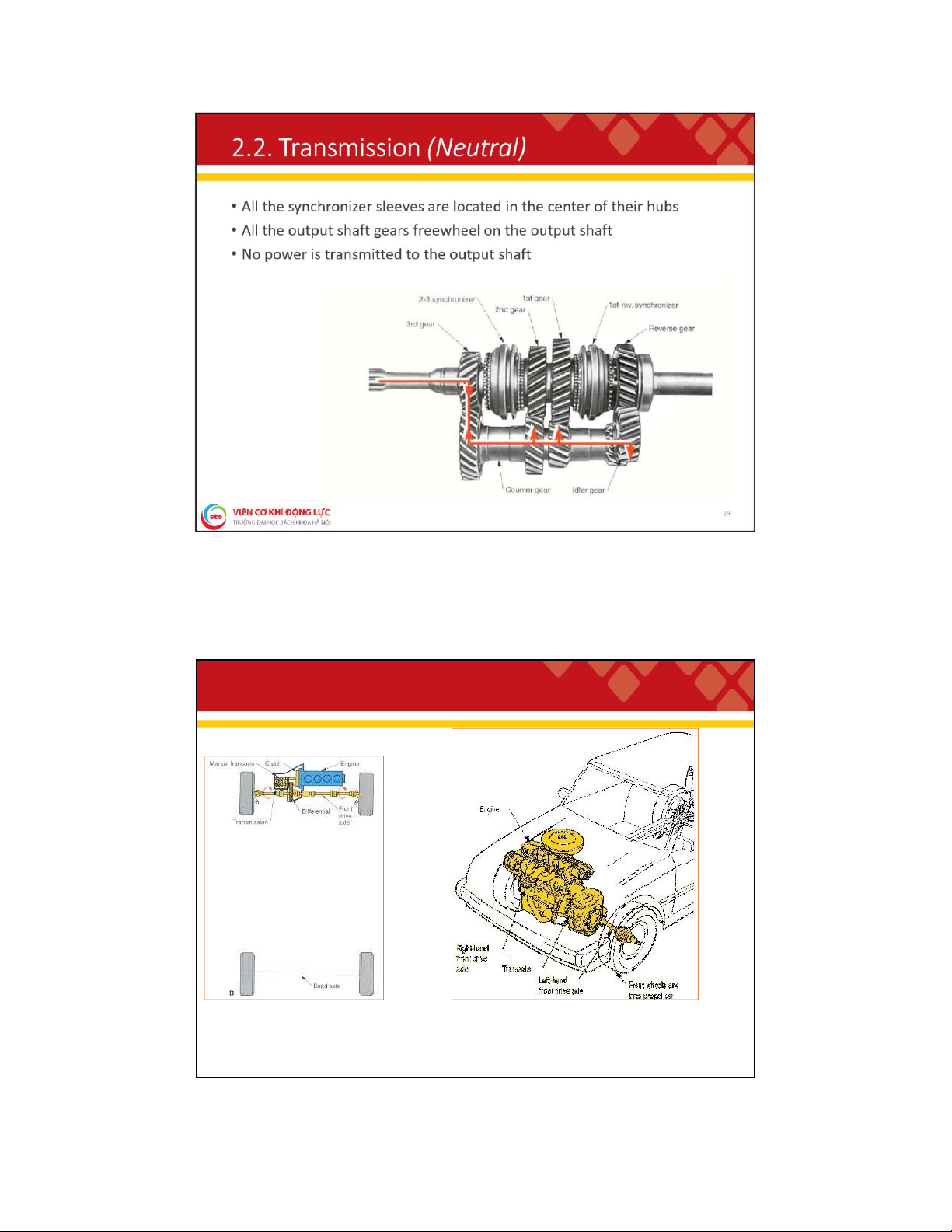

. 2 . T r a n s m i s s i o n ( T r a n s m i s s i o n G e a r s )

The input shaft gear turns the countershaft gears, which then turn the output shaft gears 24 lOMoAR cPSD| 59595715 2

. 2 . T r a n s m i s s i o n ( S e c o n d G e a r )

• The first gear synchronizer is slid away from the first gear

• The second-third synchronizer is then engaged

• Power flow is through the second gear on the output shaft

• The gear ratio is about 2:1 26 lOMoAR cPSD| 59595715 2

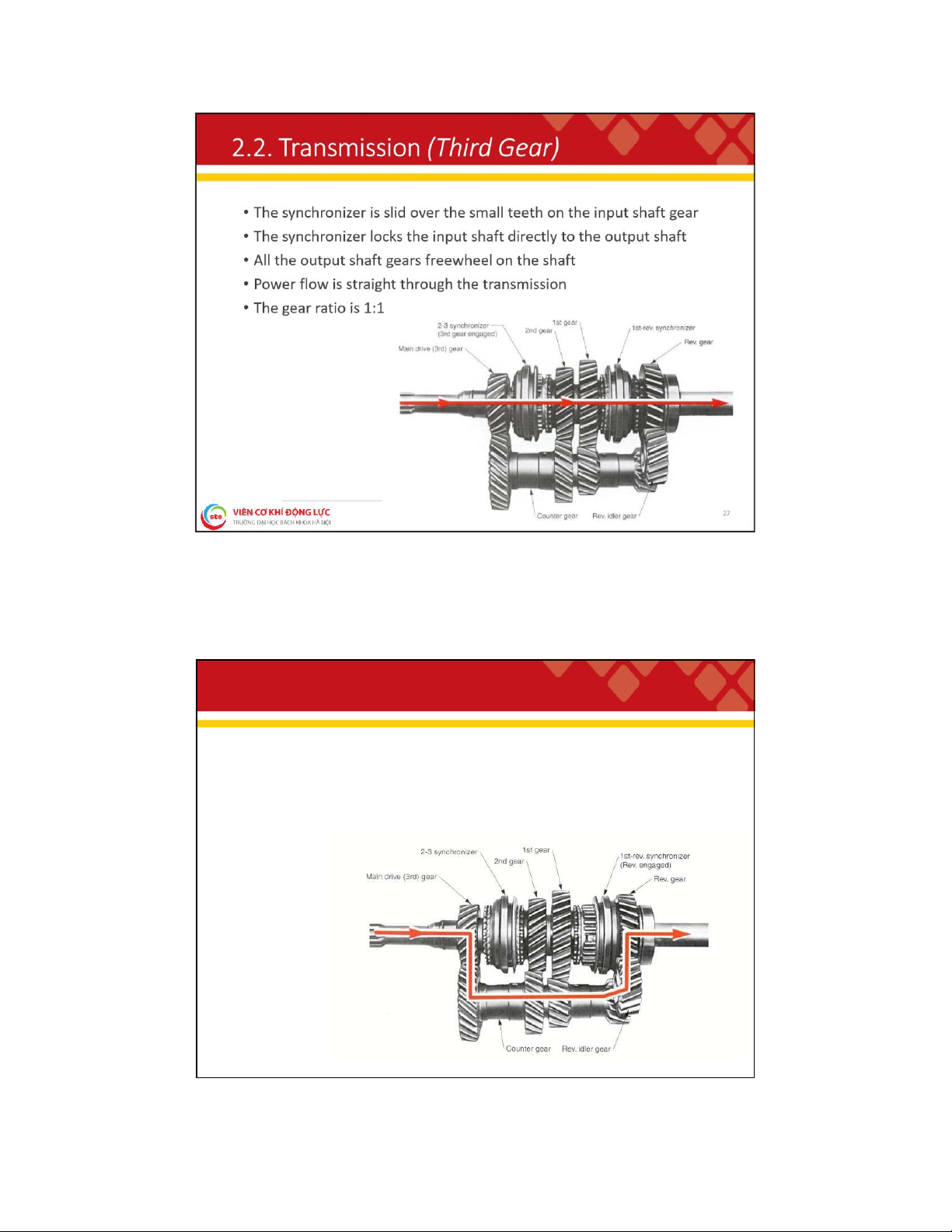

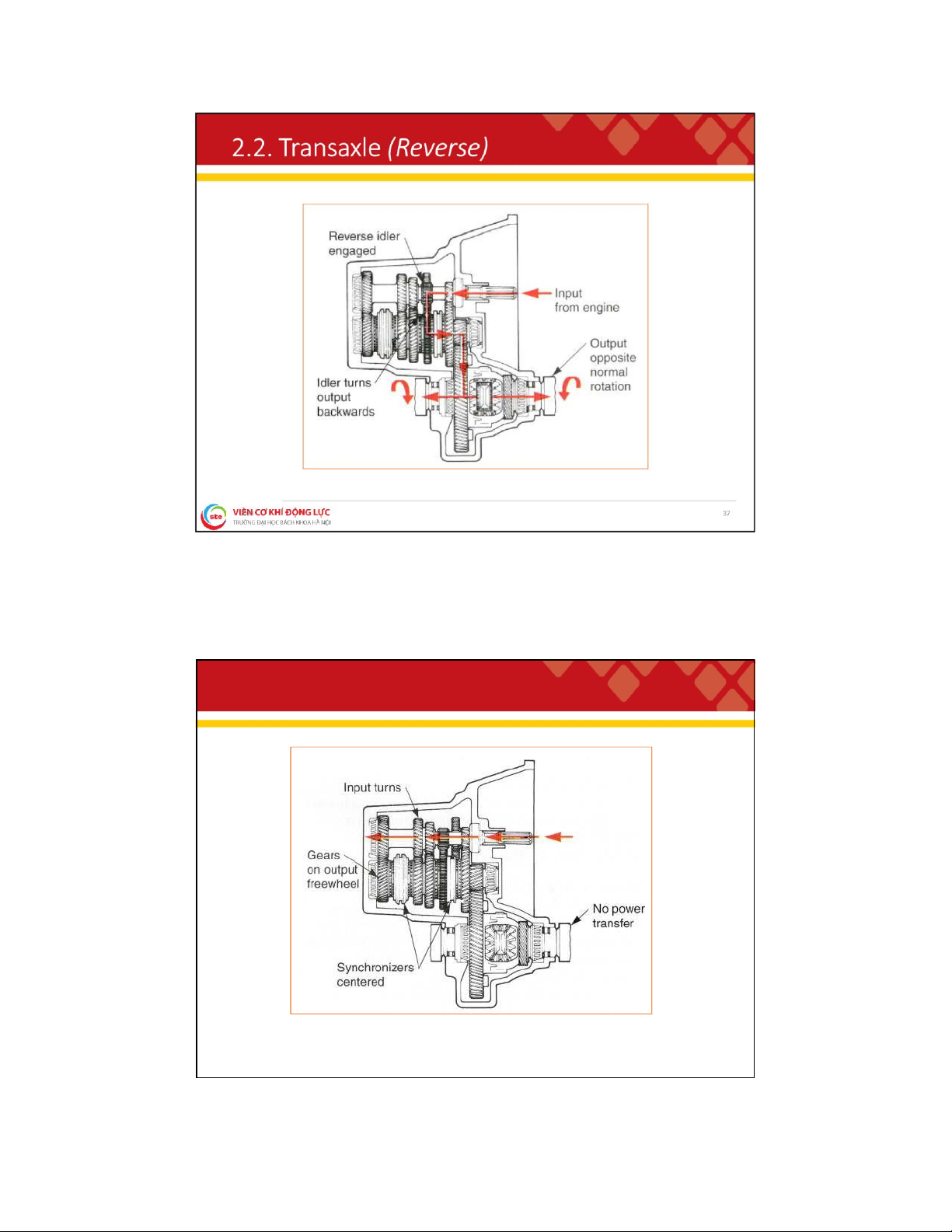

. 2 . T r a n s m i s s i o n ( R e v e r s e G e a r )

• The synchronizer is moved into the reverse gear on the output shaft,

locking the gear to the output shaft

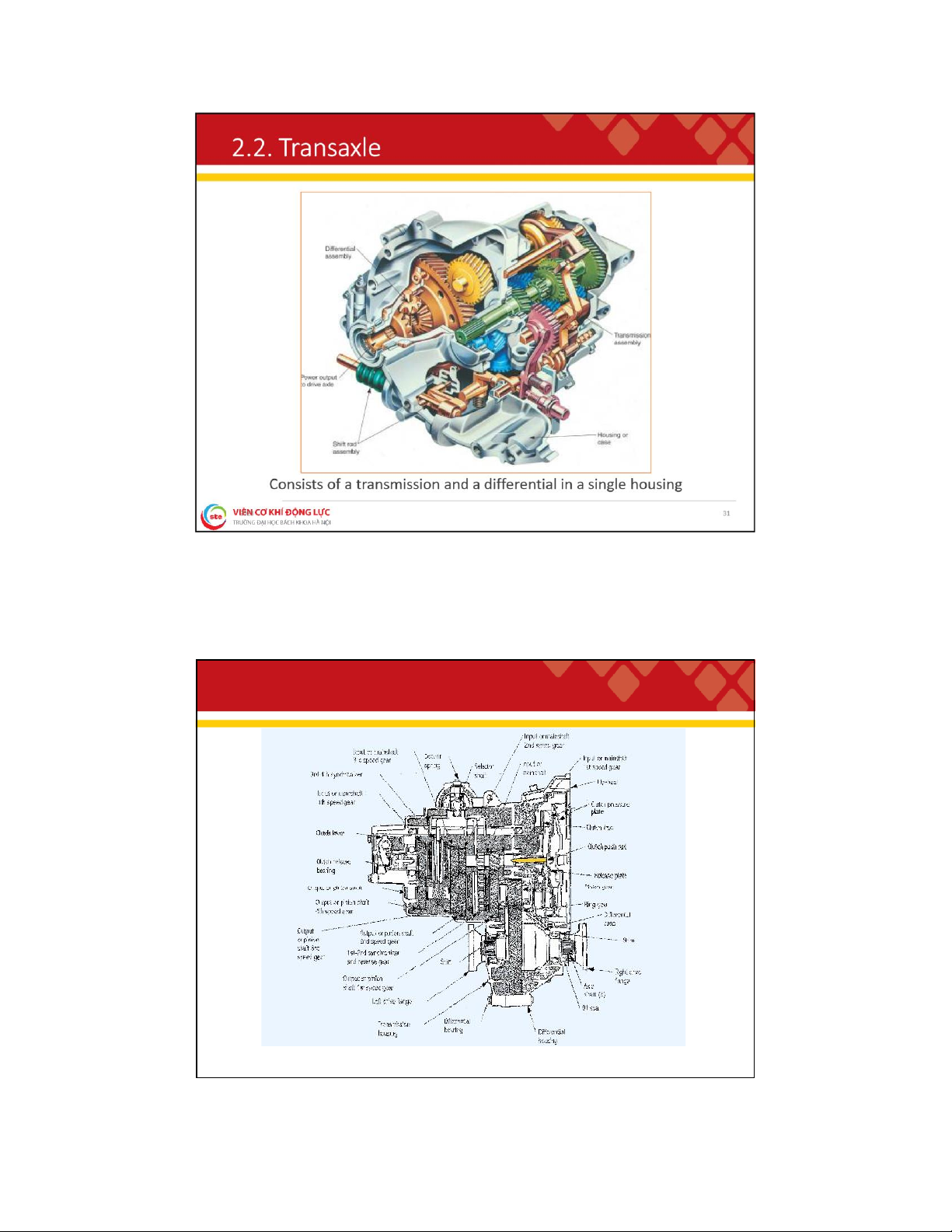

• Power flows through the countershaft, reverse idler gear, reverse gear, and to the output shaft 28 lOMoAR cPSD| 59595715 2 . 2 . T r a n s a x l e

Short drive axle assemblies connect the

transaxle output to the hubs and wheels 30 lOMoAR cPSD| 59595715 2

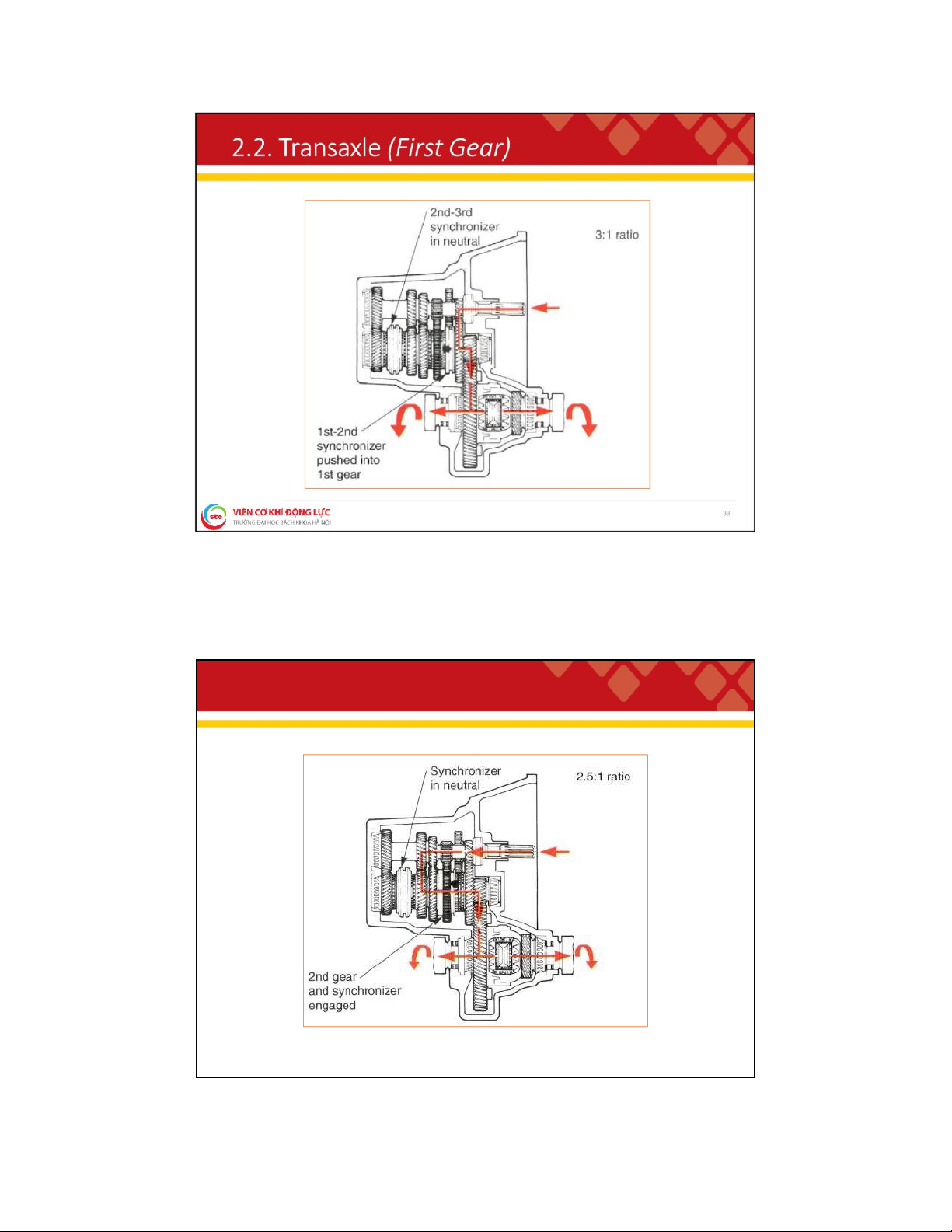

. 2 . T r a n s a x l e ( M a n u a l T r a n s a x l e ) 32 lOMoAR cPSD| 59595715 2

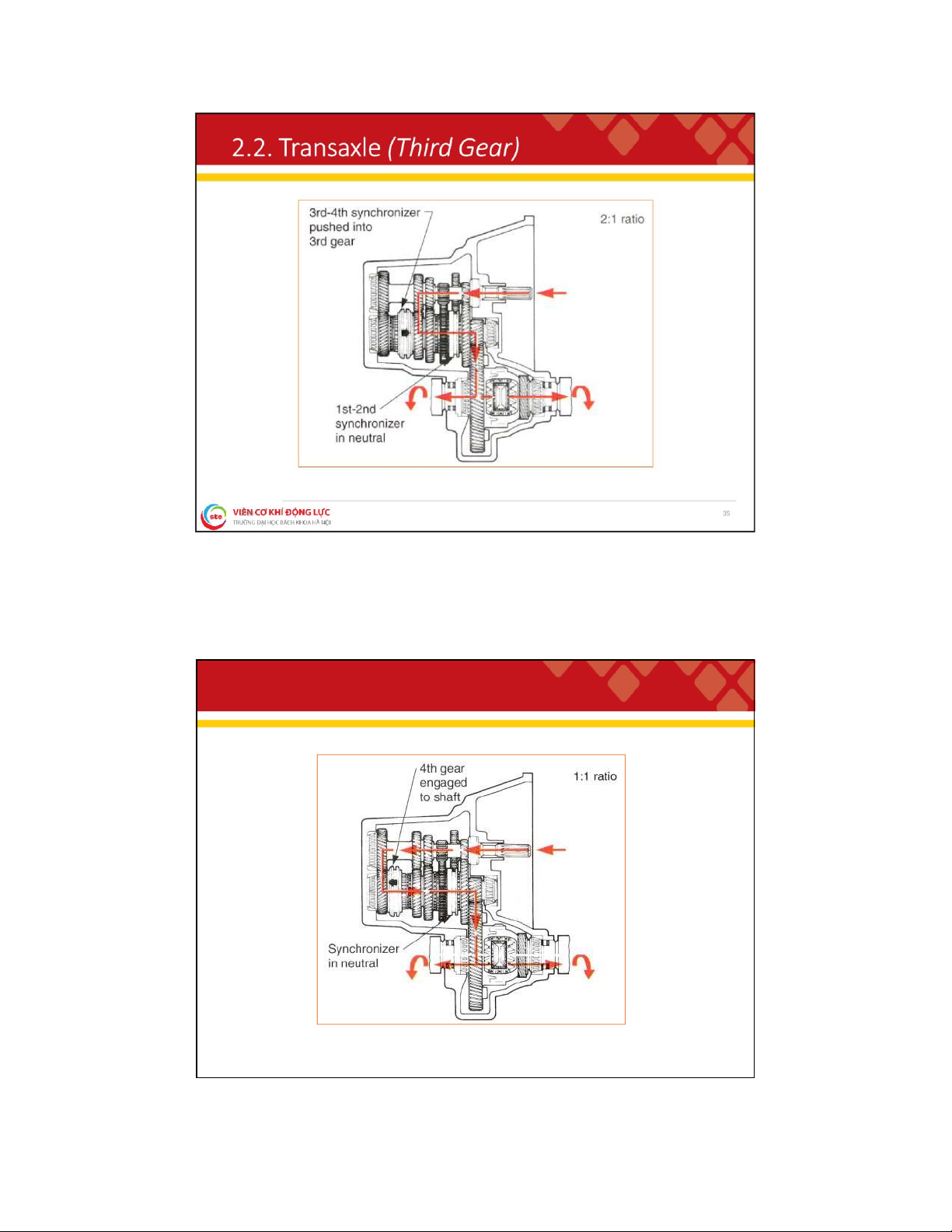

. 2 . T r a n s a x l e ( S e c o n d G e a r ) 34 lOMoAR cPSD| 59595715 2

. 2 . T r a n s a x l e ( F o u r t h G e a r ) 36 lOMoAR cPSD| 59595715 2

. 2 . T r a n s a x l e ( N e u t r a l ) 38 lOMoAR cPSD| 59595715 2

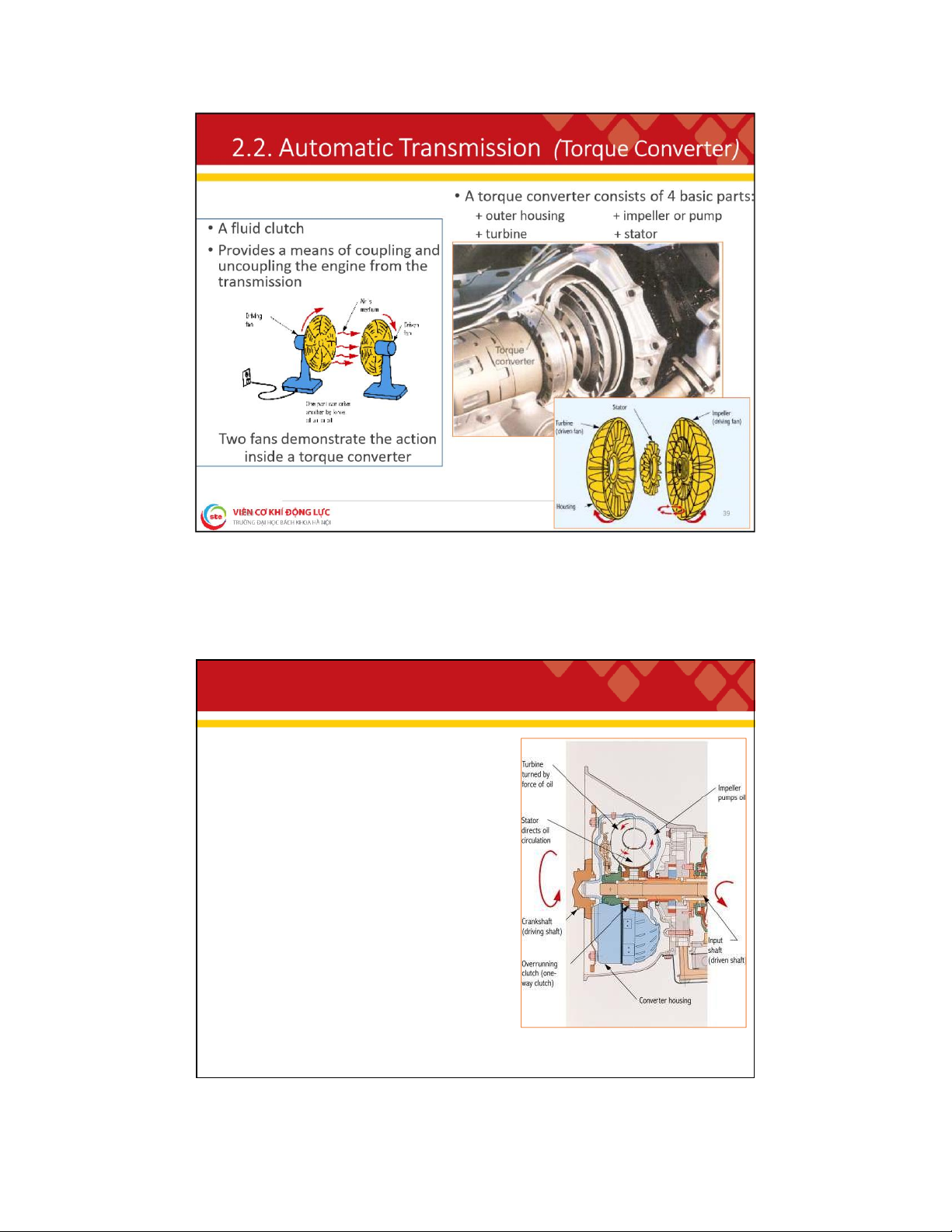

. 2 . A ut o m a t i c T r a n s m i s s i o n ( T o r q u e C o n v e r t e r ) ❑ Impeller • Driven by the engine

• Integral part of the housing

• Produces oil movement within the converter ❑ Turbine • Driven by the impeller

• Splined to the transmission input shaft

• Fits in the front of the housing

• Oil is the only connection between the impeller and the turbine ❑ Stator • Improves oil circulation

• Increases efficiency and torque by directing the oil flow toward the turbine

• Helps make use of nearly all the force produced by the moving oil

• Located between the impeller and the turbine, mounted on a one-way clutch 40