Preview text:

lOMoARcPSD|47207367

VIETNAM NATIONAL UNIVERSITY – HO CHI MINH CITY

INTERNATIONAL UNIVERSITY

SCHOOL OF INDUSTRIAL ENGINEERING & MANAGEMENT

Course: Inventory Management

Lecturer: Nguyen Van Hop

MULTI-ECHELON INVENTORY OPTIMIZATION

FOR FRESH PRODUCTS IN SUPPLY CHAINS GROUP 06 Student Full Name Student ID Contribution Phan Duy Thức IELSIU21385 100% Phạm Nguyễn Bảo Châu IELSIU21264 100% Hoàng Thị Quỳnh Dung IELSIU21278 100% Ngô Tôn Khánh Huyền IELSIU21307 100% ABSTRACT

Because fresh goods are perishable and delicate, proper inventory management planning

is necessary to avoid increased inventory expenses. Multi-echelon inventory control is

all fresh product supply chain systems. In this case, a multi-echelon inventory control

model for fresh products is designed and optimized based on the perishable

characteristics of the products and the combination of the deterioration rate with the

inventory control model. The optimal solution from the entire supply chain is then

obtained through the optimal fitness function using a genetic algorithm. The results of

this study can assist fresh product supply chain managers in making judgments about

inventory control and reducing expenses.

Keywords: Multi-echelon Supply Chain, Perishable Product, Deterioration Rate,

Optimal Inventory Replenishment Policy, Economic Order Quantity. TABLE OF CONTENTS

ABSTRACT ................................................................................................................... 0

TABLE OF CONTENTS .............................................................................................. 0

LIST OF TABLES ......................................................................................................... 1

LIST OF FIGURES ....................................................................................................... 1

CHAPTER 1 INTRODUCTION ................................................................................. 2

1.1 System Description ................................................................................................. 2

1.2 Problem Statement .................................................................................................. 3

1.3 Scope and Limitations ............................................................................................. 3

CHAPTER 2 METHODOLOGY ................................................................................ 4

2.1 Problem description ................................................................................................. 4

2.2 Model assumptions .................................................................................................. 5

2.3 Genetic Algorithm Development ............................................................................ 6

2.4 Preparation ............................................................................................................... 6

2.5 Objective function ................................................................................................... 7

2.6 Algorithm ................................................................................................................. 9

CHAPTER 3 RESULT ................................................................................................ 11

3.1 Result Presentation ................................................................................................ 11

3.2 Sensitivity Analysis ............................................................................................... 12

CHAPTER 4 DISCUSSION ....................................................................................... 13

4.1 Comparison of assigned paper and our work ........................................................ 13

4.2 Why the formulation of the paper assigned is not used in this matter? ................ 14

4.3 Limitation .............................................................................................................. 15

CHAPTER 5 CONCLUSION .................................................................................... 15

REFERENCES ............................................................................................................ 16

APPENDIX .................................................................................................................. 16 LIST OF TABLES

Table 2.1 Necessary data for solving case study ........................................................ 6

Table 3.2 Sensitivity analysis .................................................................................... 14

Table 4.1 The differences between the assigned paper and this report ..................... 16 LIST OF FIGURES

Figure 1.1 Multi-echelon system is considered ......................................................... 4

Figure 2.3 Genetic Algorithm Development ............................................................. 7

Figure 4.2 The weight of the processed inventory level at the processor and retailer 17 1 | P a g e lOMoARcPSD|47207367

CHAPTER 1 INTRODUCTION 1.1 System description

The system that this report applies is multi-echelon system, meaning this system will

take into consideration all inventory levels at each node. The system in this study will

consist of one supplier, one manufacturer, and one retailer.

Figure 1.1 Multi-echelon system is considered

With a multi-echelon fresh product inventory system, customer demand will start the

order from the retailer to the manufacturer, and the manufacturer based on the data

directly from manufacturer will start sending orders to a supplier. To avoid large

capacity and long inventory holding time of fresh goods at each level, the company will

need to design an inventory system to minimize inventory costs for the entire supply chain. 1.2 Problem statement

As customer demand for fresh food increases, factors such as deterioration (expiration

date) and fragility of fresh products become extremely important but at the same time

difficult to control in quantity and quality at each inventory level of the supply chain.

Furthermore, minimizing inventory costs for the entire supply chain is extremely

difficult to deal with. Numerous enterprises face the problem of high inventory to keep

fresh products but need help to control the expiration date of biodegradable goods with

high holding costs. If keeping the stock level low will result in a high risk of lost sales.

Thus, it is necessary to develop a system that controls the amount of inventory at each

level, by reducing inventory costs of the entire supply chain since then the company will

know how many orders to place, how many units each order has, and when to place that

order so that product quality is best and costs are minimized when each echelon is linked together.

1.3 Scope and Limitations 1.3.1 Scope

Our team looks at a case study including a manufacturer selection issue and profit

maximization in this investigation. It is believed that this network consists of a single

product that the manufacturers deliver to the demand within period t. In addition, we

need to determine the best order quantity in the network of one supplier. For a variety

of costs, including demand, farmer setup cost each cycle, and farmer feeding cost per

weight unit per unit time, we generate arbitrary demand data.

1.3.2 Limitation

The most urgent issue is computational complexity, particularly when it comes to

strategies for handling instability in certain circumstances. It may be essential to build

an agent but not an excessive number of scenarios if there is identifiable proof of the

appropriate underlying causes of such instability (such as economic events).

Furthermore, the scenario under examination presents a problem due to no mention of

transportation cost, discount policies, and no shortage that must be made within each

period and the variable demand for items, which impacts the appropriateness of the storage capacity. 3 | P a g e lOMoARcPSD|47207367 CHAPTER 2 METHODOLOGY

2.1 Problem Description

This case study considers the three-echelon inventory system of perishable products

having deterioration rates. The three-echelon inventory system consists of one supplier

at the first level at which the products are fed until they reach the specific weight; one

manufacturer at the second level where products are processed and packaged before

being delivered to other places; and one retailer at the third level, at which the products

are displayed to sell for customers.

The highlight of this work lies in the dependence of the three levels upon each other,

which means the order quantity of manufacturer to the supplier depends on the number

of products that retailer order from manufacturer. Similar to the cycle time of each

echelon, the supplier’s and manufacturer’s cycle times depend upon the retailer’s. The

idea that independent decisions should be avoided even though the decrease in cost for

one node can potentially increase the cost for another node due to the coordination in a

supply chain is also expressed in Zhang et al. (2021), but this paper used a genetic

algorithm to proved the optimization Centralized Strategy has over the Decentralized

Strategy without no details in how to come up with such results. The work in our report

proposes a detailed approach showing the dependence through a specific genetic algorithm.

The aim of this problem is based on the given data to find out the optimal number of

loads n that should be delivered to a retailer at one time, or in other words, to determine

the Economic Order Quantity (EOQ) that Processor should order from Supplier to fulfill

the demand of Retailer, and the retailer’s cycle time T should be to minimize the total

cost of this inventory system.

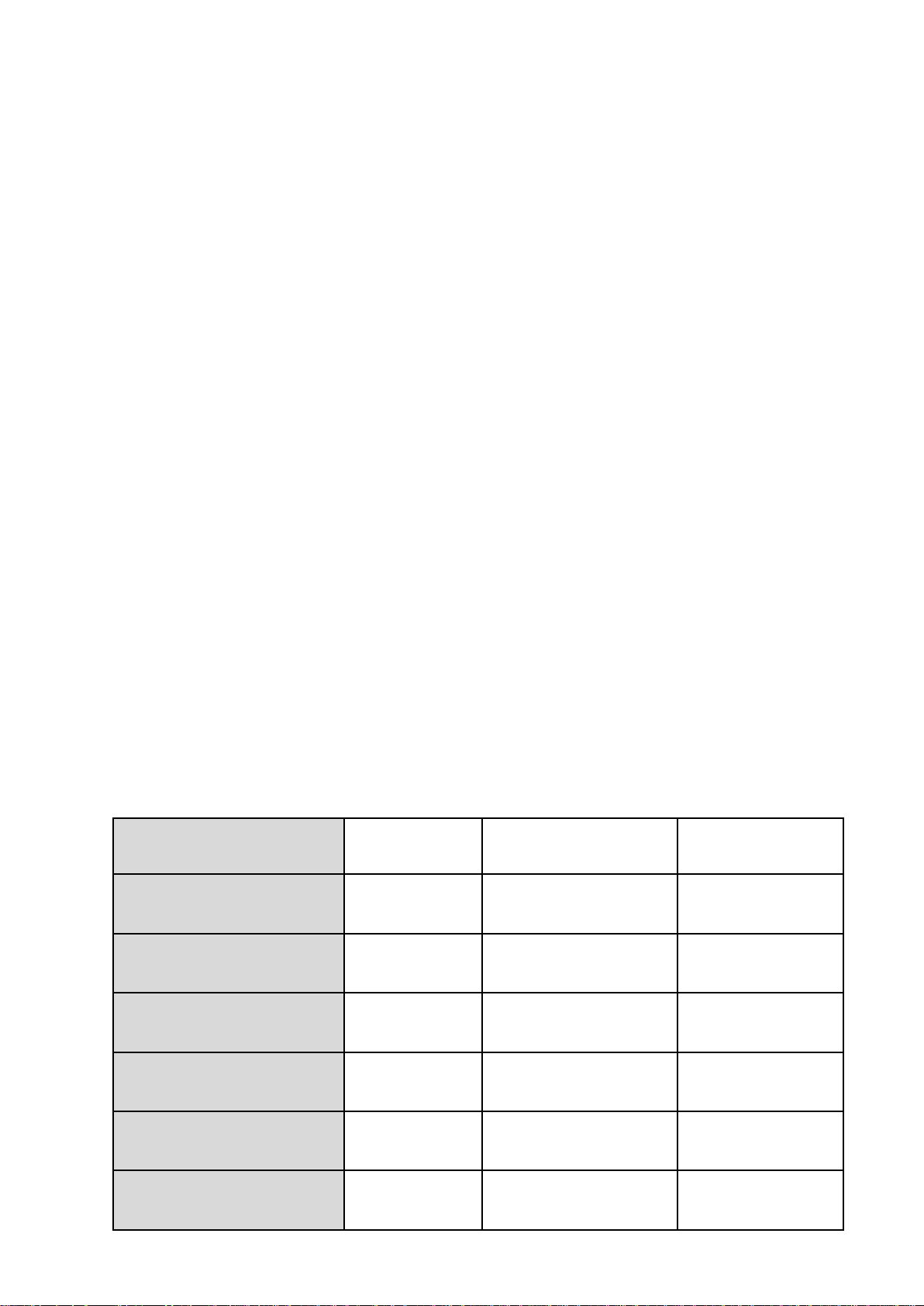

The necessary data for solving this case is given in the table below:

RETAILER MANUFACTURER SUPPLIER Demand (kg) 200 w0 0.5 0.5 0.5 w1 3 3 3 P 300 Kf ($) 400 cf ($/kg/day) 0.5 mf ($/kg/day) 0.1 Kp ($) 320 hp ($/kg/day) 0.2 L (days) 10 10 10 Kr ($) 200 hr ($/kg/day) 0.5 α 6.52 6.52 6.52 β 100 100 100 𝝺 (w1/w0/70 days) 0.09

Table 2.1 Necessary data for solving case study 2.2 Model assumptions:

- Dealing with a three-echelon supply chain model: 1 vendor - 1 processor - 1 retailer.

- Dealing with a single type of perishable product.

- The processing rate is greater than the demand rate.

- Deterioration is taken into consideration under the form of the expiration date of the finished product.

- Beyond the expiration date, the utility of products is over.

- The next shipment from processor to retailer is conducted once the previous shipment is depleted. 5 | P a g e lOMoARcPSD|47207367

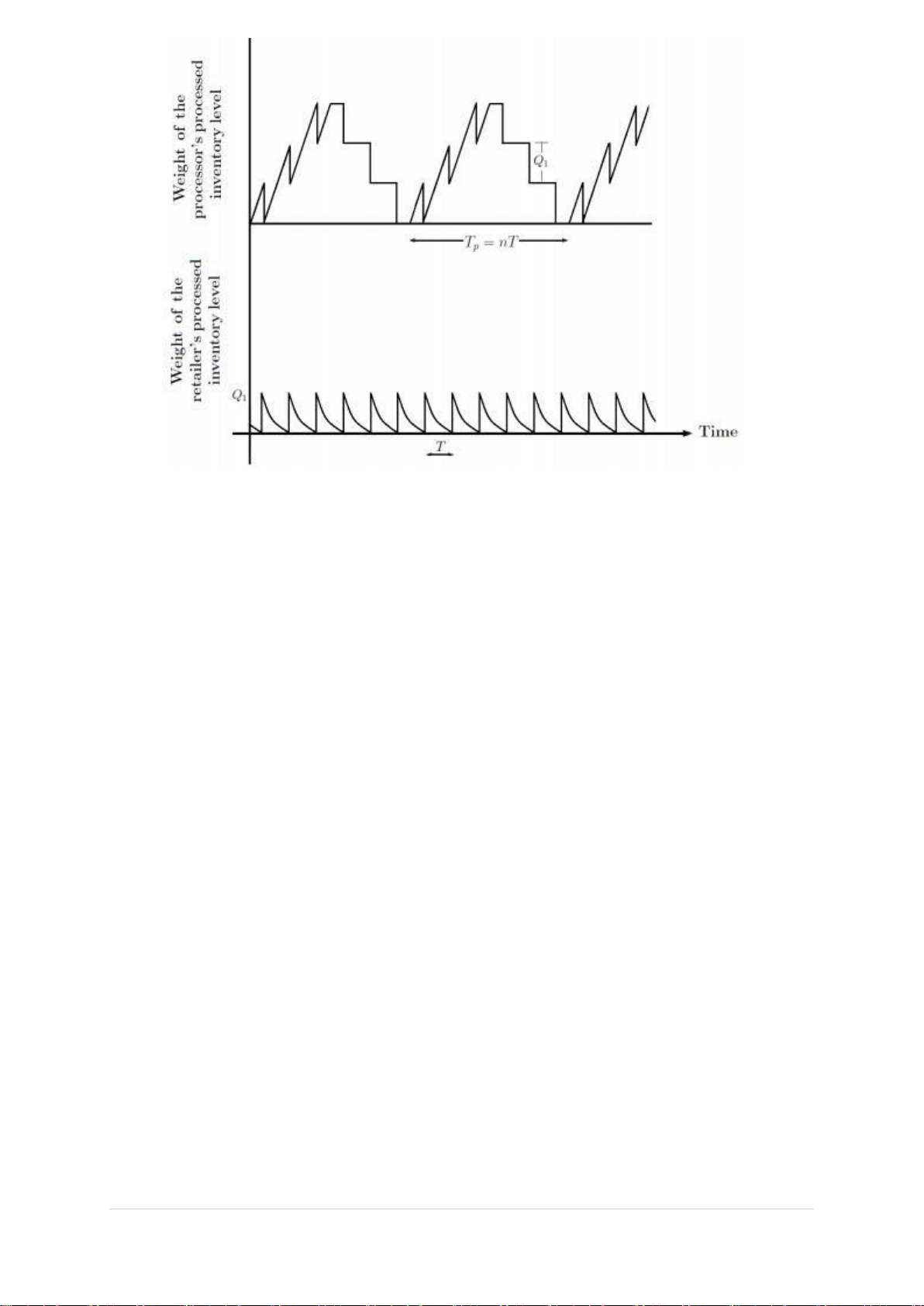

2.3 Genetic Algorithm Development

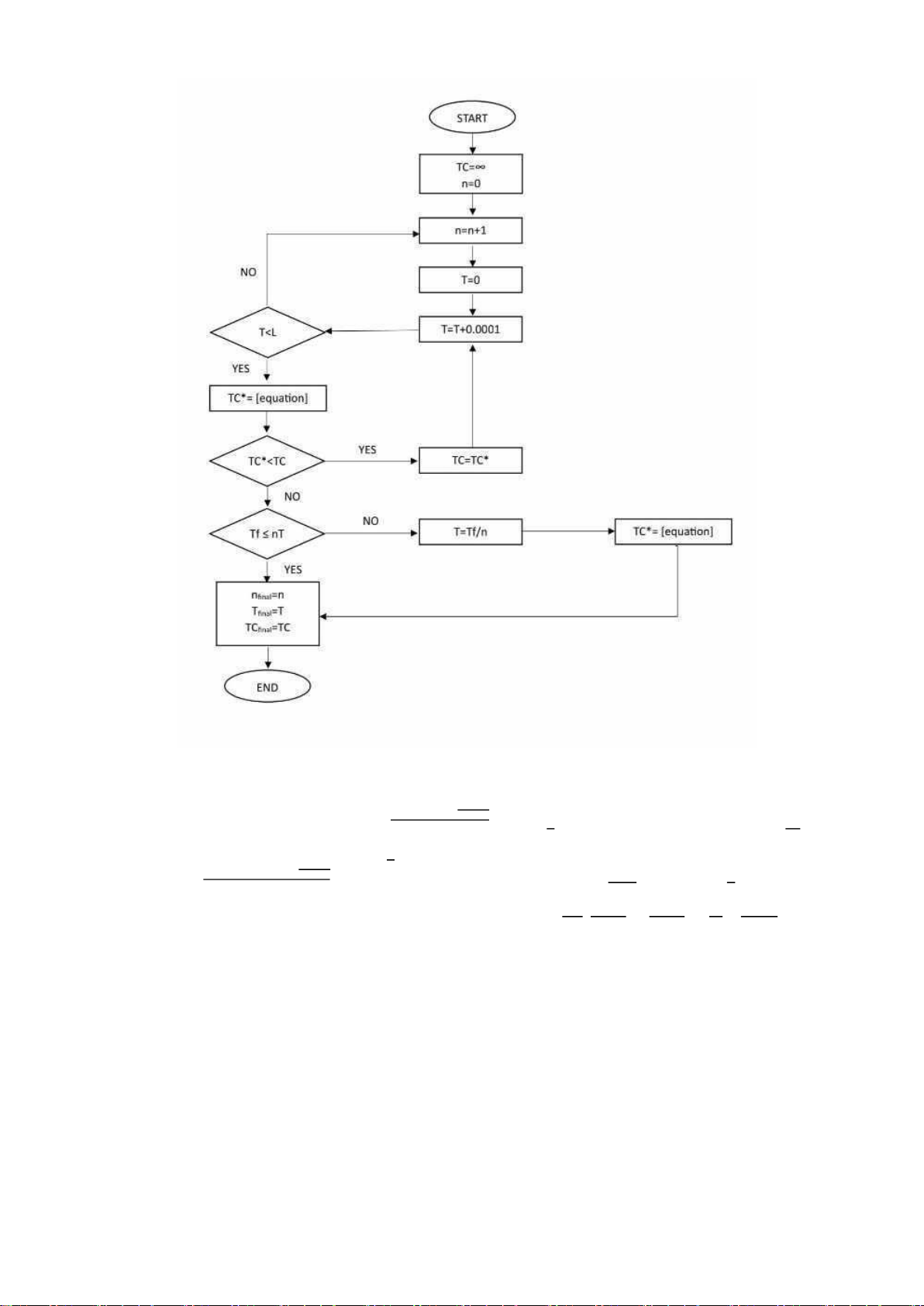

Figure 2.3 Genetic Algorithm Development 1+𝐿

** [equation]= 𝑐𝑓𝑥𝐷(1+𝐿)𝑙𝑛1+𝐿−𝑇 {𝛼𝑇𝑓 + 𝛼 [𝑙𝑛(1 + 𝛽𝑒−𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽)]} + 𝐾𝑓 + 𝑇𝑥(𝑤1) 𝜆 𝑛𝑇 1+𝐿

𝑚𝑓(1−𝑥)𝐷(1+𝐿)𝑙𝑛1+𝐿−𝑇 {αTf + 𝛼 −𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽]} + ℎ𝑝𝑇𝐷 [(𝑛 − 1)(1 − 𝐷)+𝐷] + 𝐾𝑝 + [𝑙𝑛(1 + 𝛽𝑒 𝑇𝑥(𝑤1) 𝜆 2 𝑃 𝑃 𝑛𝑇 ℎ𝑟𝐷 (1+𝐿)2 1+𝐿 𝑇2 (1+𝐿)𝑇 𝐾𝑟 [ 𝑙𝑛( ) + − ] + 𝑇 2 1+𝐿−𝑇 4 2 𝑇

2.4 Preparation

2.4.1 Parameters W1 Weight of maturity item

x Fraction of the live items that survive throughout the growth period. This factor

determines that x*100 % of the initially ordered items will survive after the growth period ends

D Demand rate for processed items from processor to retailer in weight units per unit time

P Processing rate in weight units per unit time Kf

Farmer’s setup cost per cycle cf Farmer’s feeding cost

per weight unit per unit time Tf Duration of the farmer’s

growth period mf Farmer’s mortality cost per weight

unit per unit time Kp Processor’s setup cost per cycle hp

Processor’s holding cost per weight unit per unit time

L The maximum lifetime (i.e. expiration date) of the processed inventory

Kr Retailer’s ordering cost per cycle hr Retailer’s holding cost per

weight unit per unit time α The items’ asymptotic weight β Constant

of integration λ Growth rate (exponential) of the items

2.4.2 Decision Variables

n Number of shipments from the processor to the retailer per unit cycle of the processor T Retailer’s cycle time

2.4.3 Constraints (1) Tf - n*T ≤ 0

(2) n is an integer: the number of shipments from the processors to the retailers per processing setup (n).

(3) P > D : The demand rate of a retailer should be less than the processing rate to

ensure enough quantity being shipped to the retailer.

(4) L > T : The retailer’s replenishment cycle, T, cannot exceed the expiration date of the processed inventory. 2.5 Objective function

2.5.1 Formulation

The 1st supply chain echelon: Vendor 7 | P a g e lOMoARcPSD|47207367 (i) Feeding Cost: 1+𝐿

FCf = 𝑐𝑓𝑥𝐷(1+𝐿)𝑙𝑛 𝛼

−𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽)]}

1+𝐿−𝑇 {𝛼𝑇𝑓 + [𝑙𝑛(1 + 𝛽𝑒 𝑇𝑥(𝑤1) 𝜆 (ii) Set up Cost: 𝐾𝑓 KCf = 𝑛𝑇 (iii) Mortality Cost: 1+𝐿

𝑚𝑓(1−𝑥)𝐷(1+𝐿)𝑙𝑛 𝛼

−𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽]} MCf =

1+𝐿−𝑇 {αTf + [𝑙𝑛(1 + 𝛽𝑒 𝑇𝑥(𝑤1) 𝜆

→Total Cost vendor = (i) + (ii) + (iii) 1+𝐿 𝛼

𝑐𝑓𝑥𝐷(1+𝐿)𝑙𝑛

−𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽)]} + 𝐾𝑓 + =

1+𝐿−𝑇 {𝛼𝑇𝑓 + [𝑙𝑛(1 + 𝛽𝑒 𝑇𝑥(𝑤1) 𝜆 𝑛𝑇 1+𝐿

𝑚𝑓(1−𝑥)𝐷(1+𝐿)𝑙𝑛1+𝐿−𝑇 {αTf + 𝛼

−𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽]} (I) [𝑙𝑛(1 + 𝛽𝑒 𝑇𝑥(𝑤1) 𝜆

The 2nd echelon supply chain: Processor (i) Holding Cost: ℎ𝑝𝑇𝐷 𝐷 𝐷 HCp = [(𝑛 − 1)(1 − )+ ] 2 𝑃 𝑃 (ii) Set up Cost: 𝐾𝑝 KCp = 𝑛𝑇

→Total Cost processor = (i) + (ii) ℎ𝑝𝑇𝐷 𝐷 𝐷 𝐾𝑝 = [(𝑛 − 1)(1 − )+ ]+ (II) 2 𝑃 𝑃 𝑛𝑇

The 3rd echelon supply chain: Retailer (i) Holding Cost: ℎ𝑟𝐷 (1+𝐿)2 1+𝐿 𝑇2 (1+𝐿)𝑇 HCr = [ 𝑙𝑛( ) + − ] 𝑇 2 1+𝐿−𝑇 4 2 (ii) Set up Cost: KCr = 𝐾𝑟 𝑇

→Total Cost retailer = (i) + (ii) ℎ𝑟𝐷 (1+𝐿)2 1+𝐿 𝑇2 (1+𝐿)𝑇 𝐾𝑟 = [𝑙𝑛( ) + − ] + (III) 𝑇 2 1+𝐿−𝑇 4 2 𝑇

2.5.2 Objective function Min z = (I) + (II) + (III) 1+𝐿

= 𝑐𝑓𝑥𝐷(1+𝐿)𝑙𝑛1+𝐿−𝑇 {𝛼𝑇𝑓 + 𝛼 −𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽)]} + 𝐾𝑓 + [𝑙𝑛(1 + 𝛽𝑒 𝑇𝑥(𝑤1) 𝜆 𝑛𝑇 1+𝐿

𝑚𝑓(1−𝑥)𝐷(1+𝐿)𝑙𝑛1+𝐿−𝑇 {αTf + 𝛼 [𝑙𝑛(1 + 𝛽𝑒−𝜆𝑇𝑓) − 𝑙𝑛(1 + 𝛽]} + ℎ𝑝𝑇𝐷

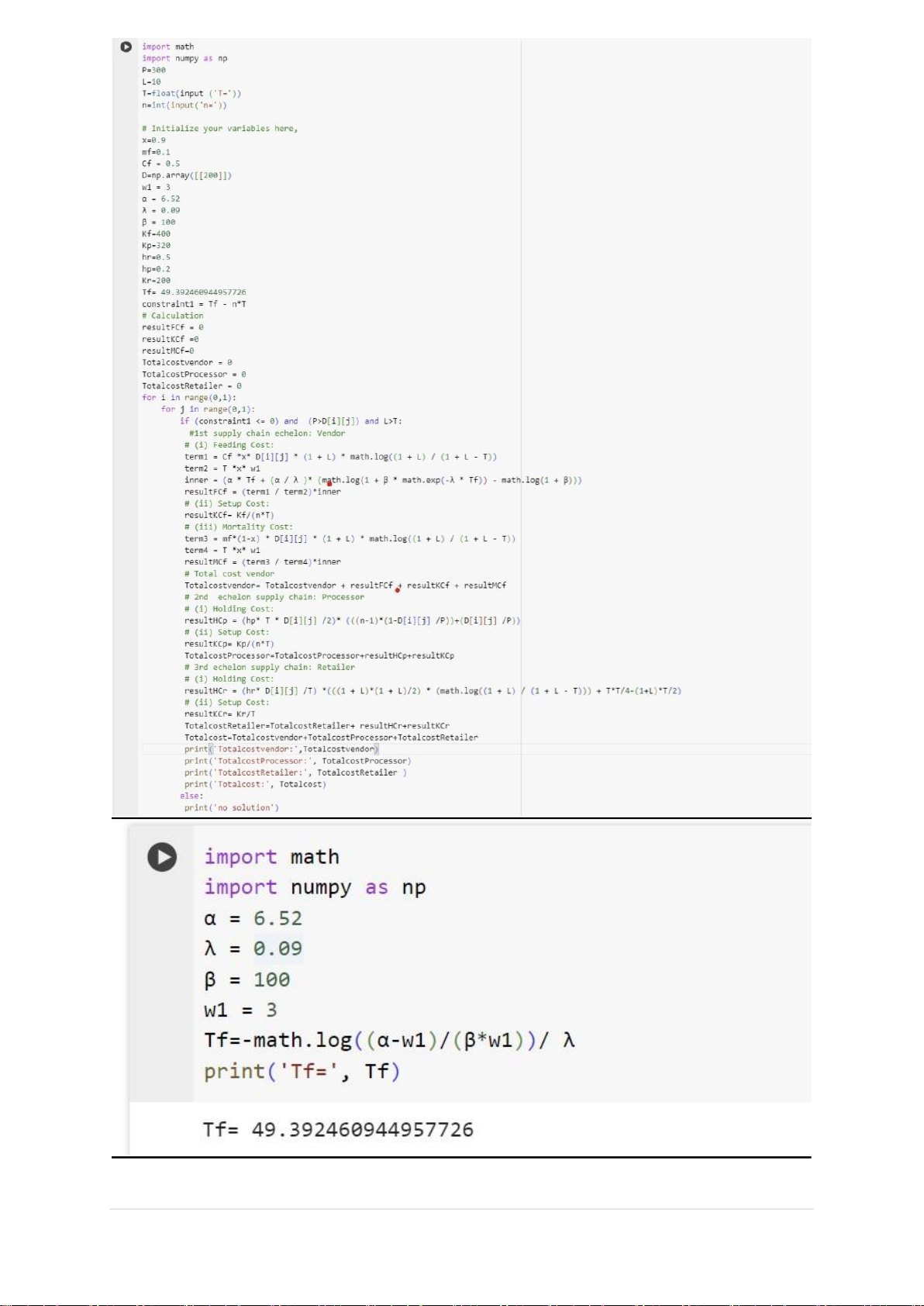

[(𝑛 − 1)(1 − 𝐷 )+𝐷] 𝑇𝑥(𝑤1) 𝜆 2 𝑃 𝑃 𝐾𝑝 ℎ𝑟𝐷 (1+𝐿)2 1+𝐿 𝑇2 (1+𝐿)𝑇 𝐾𝑟 + + [ 𝑙𝑛( ) + − ] + 𝑛𝑇 𝑇 2 1+𝐿−𝑇 4 2 𝑇 2.6 Algorithm STEP 1 import math import numpy as np α = 6.52 λ = 0.09 β = 100 w1 = 3

Tf=-math.log((α-w1)/(β*w1))/ λ print(’Tf=’, Tf) STEP 2 import math import numpy as np P=300 L=10 T=float(input (’T=’)) n=int(input(’n=’)) # Initialize variables x=0.9 mf=0.1 9 | P a g e lOMoARcPSD|47207367 Cf = 0.5 D=np.array([[200]]) w1 = 3 α = 6.52 λ = 0.09 β = 100 Kf=400 Kp=320 hr=0.5 hp=0.2 Kr=60

Tf= 49.392460944957726 constraint1 = Tf - n*T # Calculation resultFCf = 0 resultKCf =0 resultMCf=0 TotalcostVendor = 0

TotalcostProcessor = 0 TotalcostRetailer = 0 for i in range(0,1):

for j in range(0,1): if (constraint1 <= 0) and (P>D[i][j]) and

L>T: #1st supply chain echelon: Vendor # (i) Feeding

Cost: term1 = Cf *x* D[i][j] * (1 + L) * math.log((1 + L) / (1 + L - T)) term2 = T *x* w1

inner = (α * Tf + (α / λ )* (math.log(1 + β * math.exp(-λ * Tf)) - math.log(1 + β)))

resultFCf = (term1 / term2)*inner # (ii) Setup Cost: resultKCf= Kf/(n*T) # (iii) Mortality Cost:

term3 = mf*(1-x) * D[i][j] * (1 + L) * math.log((1 + L) / (1 + L - T)) term4 = T *x* w1

resultMCf = (term3 / term4)*inner # Total cost vendor

TotalcostVendor= TotalcostVendor + resultFCf + resultKCf + resultMCf

# 2nd echelon supply chain: Processor # (i) Holding Cost:

resultHCp = (hp* T * D[i][j] /2)* (((n-1)*(1-D[i][j] /P))+(D[i][j] /P)) # (ii) Setup Cost: resultKCp= Kp/(n*T)

TotalcostProcessor=TotalcostProcessor+resultHCp+resultKCp

# 3rd echelon supply chain: Retailer # (i) Holding Cost:

resultHCr = (hr* D[i][j] /T) *(((1 + L)*(1 + L)/2) * (math.log((1 + L) / (1 + L - T))) + T*T/4-(1+L)*T/2) # (ii) Setup Cost: resultKCr= Kr/T

TotalcostRetailer=TotalcostRetailer+ resultHCr+resultKCr

Totalcost=TotalcostVendor+TotalcostProcessor+TotalcostRetailer

print(’TotalcostVendor:’, Totalcostvendor)

print(’TotalcostProcessor:’, TotalcostProcessor)

print(’TotalcostRetailer:’, TotalcostRetailer )

print(’Totalcost:’, Totalcost) else: print(’no solution’) CHAPTER 3 RESULT

3.1 Result presentation

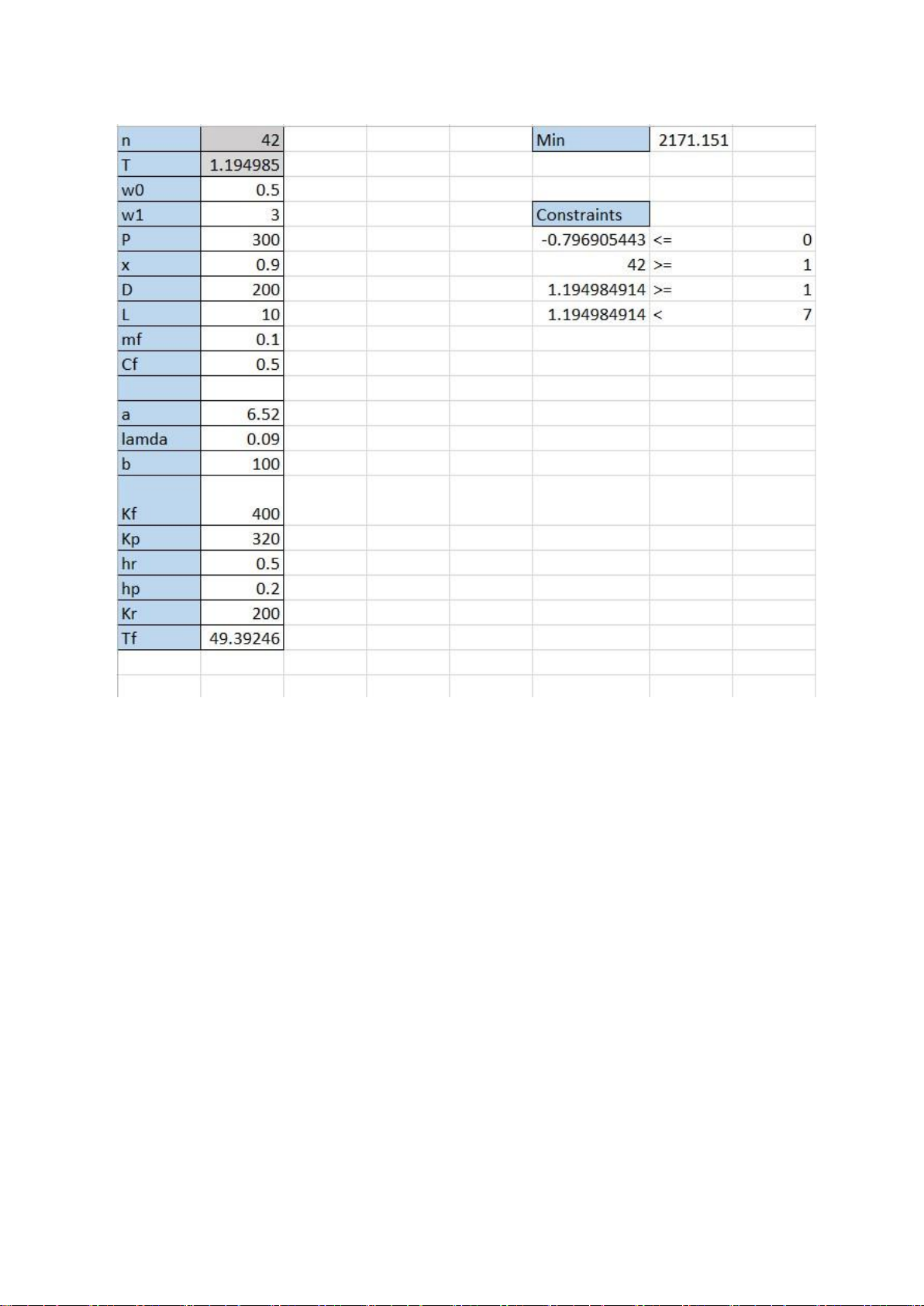

3.1.1 Result of Decision variables and Objective function

The results obtained are the optimal quantity of shipments delivered from the processor

to the retailer per unit processor cycle time and the retailer’s cycle time. + T = 1.195 + n = 42

Here, the minimized total cost is also calculated:

+ The minimized total cost of supplier is $1,592.7415457665797

+ The minimized total cost of processor is $348.94243873281533

+ The minimized total cost of retailer is $229.47083226599898

+ The minimized total cost of a system is $2,171.154816765394

3.1.2 Result Analysis

From the result, inventory replenishment and shipment strategies are calculated and summarized as follows:

(1) An order of (ny) 3935.244 live newborn items should be placed to fulfill the demand of a retailer.

(2) The total weight of the shipments delivered from the supplier to the processor in

the weight unit is (nQ1) 10,625.1589 kg.

(3) During the whole of a single processor’s cycle, n= 42 shipments to the retailer

within each shipment weights 𝑄1 = 𝐷(1 + 𝐿)ln(

1+1+𝐿−𝑇𝐿 ) = 252.98 kg

(4) The safe interval of time for inventory replenishment is T= 1.195 days to avoid

surplus damaged inventory due to reaching the expiration date.

(5) The new cycle for growing and processing should be conducted every nT= 50.19 days.

(6) Finally, the total inventory cost is minimized to $2,171.1548/day within the

retailer cycle time, T=1.195 days, and n=42 shipments. 11 | P a g e lOMoARcPSD|47207367

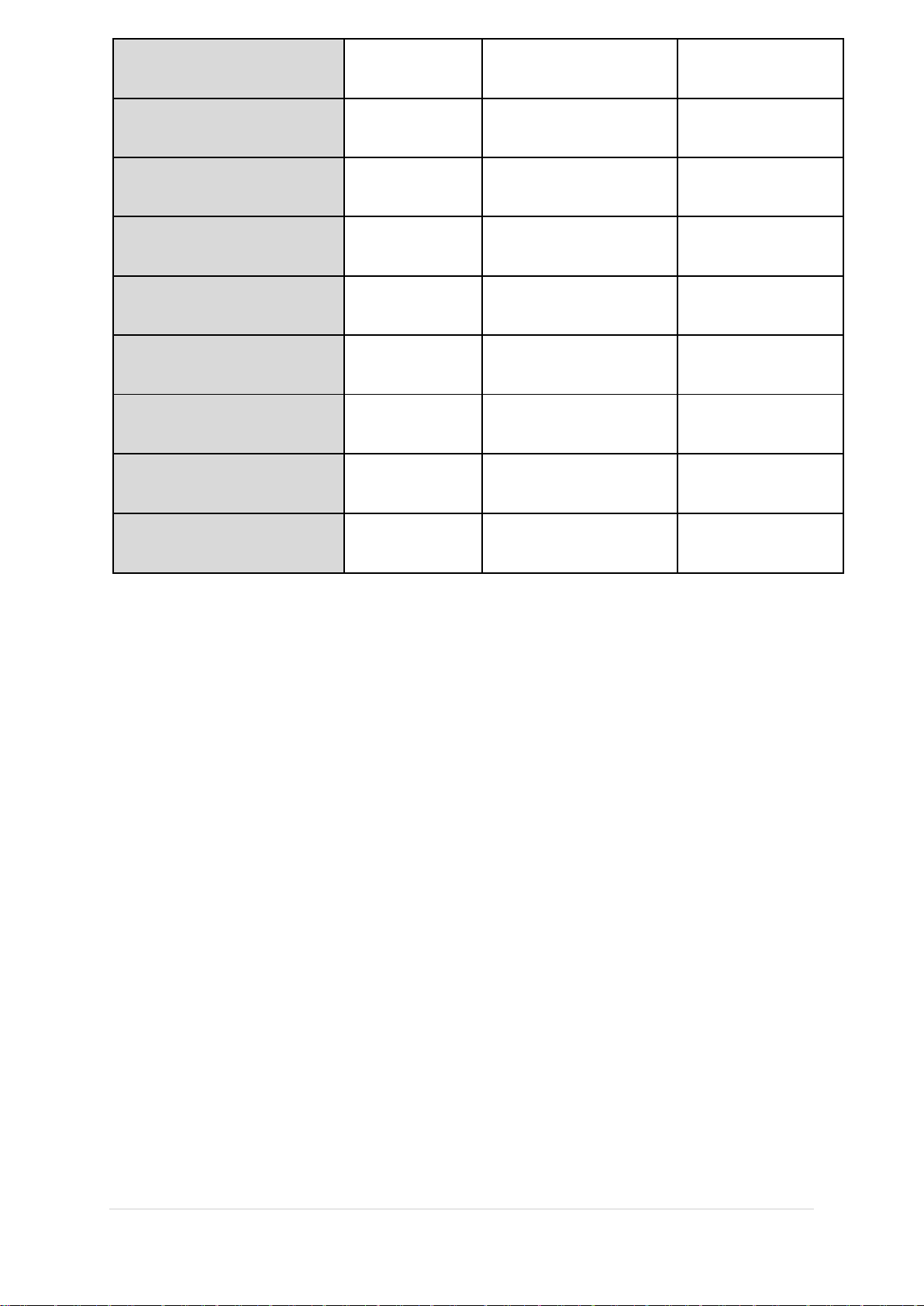

3.2 Sensitivity Analysis

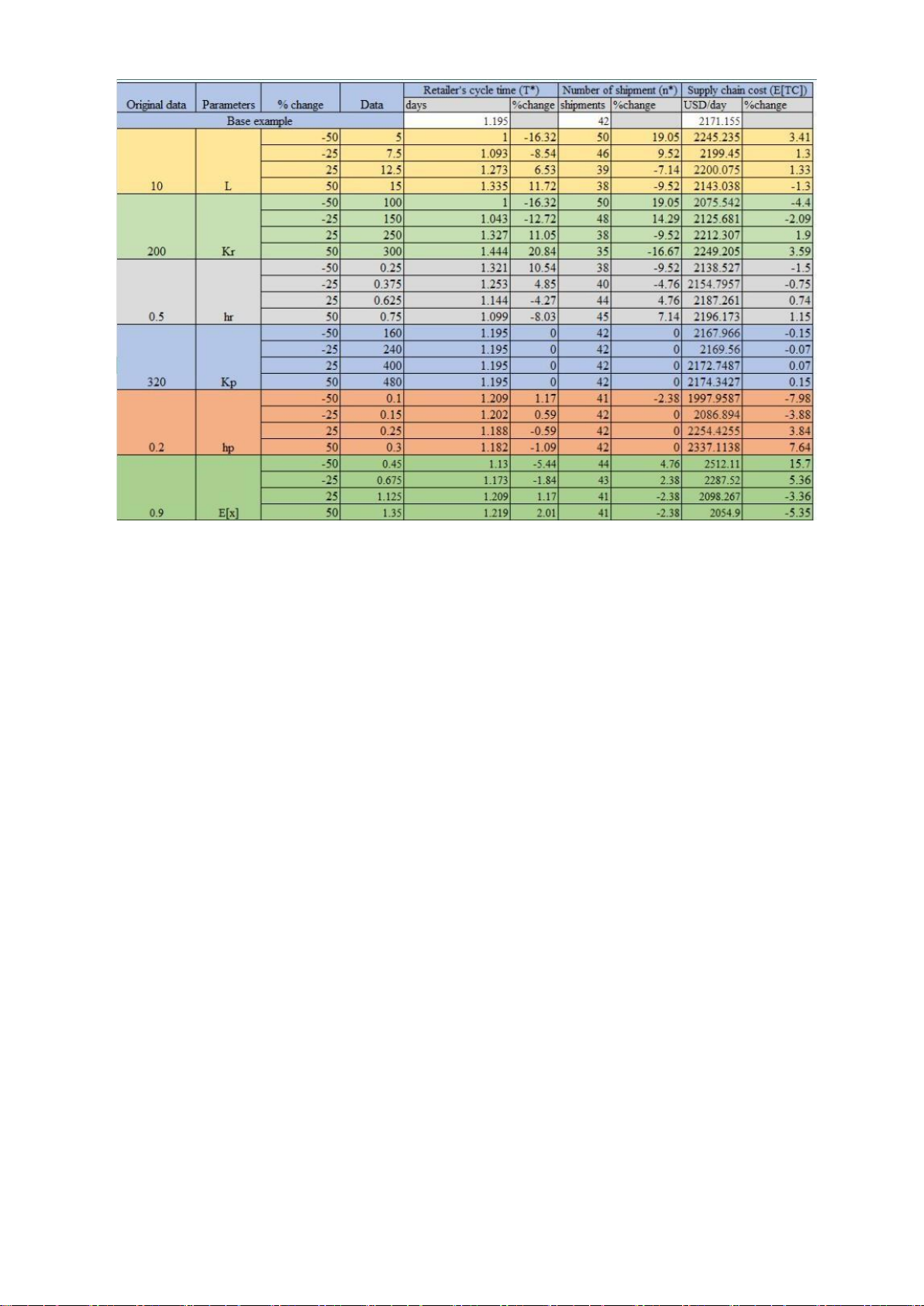

Table 3.2 Sensitivity analysis result

To see how adjustments (increases and decreases of 25% and 50%) to the key input

parameters in the base example affected the objective function (E[TCsc]) and the two

decision variables (T and n), a sensitivity analysis was conducted on those parameters

using Excel Solver. The findings are displayed in the above table, and it is important to

notice the following observations:

For the shelf life (or expiration date) of the processed items affecting the cost of the

supply chain when a 50% loss in shelf life resulted in a roughly 3.5% rise in cost, a

roughly 19% increase in shipments, and about 17% reduction in the retailer's cycle time.

Since the store does not wish to keep the products past their expiration dates. Thus, the

model's optimal solution suggests ordering for relatively smaller lot sizes more

frequently as the product's shelf life is shortened.

Modifications to the retailer's ordering cost when rising order costs is to allow the

retailer to place fewer orders. However, because of the higher holding expenses brought

on by the bigger lot size, this can have a negative impact on the overall cost. For instance,

a 50% increase in ordering costs results in a 20% increase in cycle time. This raises the overall cost by about 4%.

The model's optimal solution reacts to an increase in the retailer's holding costs by

suggesting the retailer order more shipments with smaller lot sizes. The primary

advantage of ordering smaller lot sizes is that they have relatively lower holding costs.

This is because smaller lots require fewer items to be stored, and smaller lots also result

in a shorter cycle time for the retailer, which lowers the amount of time the processed

inventory is stored and, ultimately, the holding costs. For instance, a 50% rise in the

retailer's holding costs led to an 8% decrease in cycle time and a 7% increase in shipments.

Modifications to the processor's setup indicate that the ideal number of cycle times and

shipments to the merchant will not alter, even if the processor's setup costs drop. This

demonstrates that altering the setup cost of the processor has little effect on the overall cost.

The model's optimal solution reacts to a rise in the processor's holding costs by

shortening the cycle time. This shortens the amount of time the processed inventory is

stored, which lowers the holding costs. For instance, a 50% increase in holding costs

results in a 1% reduction in cycle time and raises the overall cost by about 7.7%.

When the fraction of live things that survive during the growing cycle rises, the number

of shipments and the overall cost drop as the cycle time grows. The best solution of the

model reacts in this way because the enhanced survival rate allows a smaller lot size of

newborn items to meet the given demand rate for processed goods. Because there are a

smaller number of shipments to the retailer, this lowers the overall supply chain cost. CHAPTER 4 DISCUSSION

4.1 Comparison of assigned paper and our work (1) Similarities:

Both of them consider the three-echelon system and enhance the inventory management

of a multi-echelon supply chain of perishable products. The outcome of them is to

minimize the total inventory cost of the system. (2) Differences: ASSIGNED PAPER THIS REPORT In consideration Non Transportation cost and reorder point 13 | P a g e lOMoARcPSD|47207367 Output Compare decentralized strategy and centralized Mainly determine the strategy and end up stock cycle of the retailer

concluding the centralized (3rd level) to give insight one result in the optimal regarding how long the inventory management perishable product should be kept in the final level of a multi-echelon supply chain to avoid potential inventory risks (overstock, etc.) No Yes Genetic Algorithm Proposal

Table 4.1 The differences between the assigned paper and this report

4.2. Why the formulation of the paper assigned is not used in this matter?

The assigned paper solved the problem, minimizing the total inventory cost. In the

context of lacking the impact that echelons have on each other, our work is based on the

research of considering this effect and giving the idea of making the order quantity

decisions jointly with the members in a supply chain.

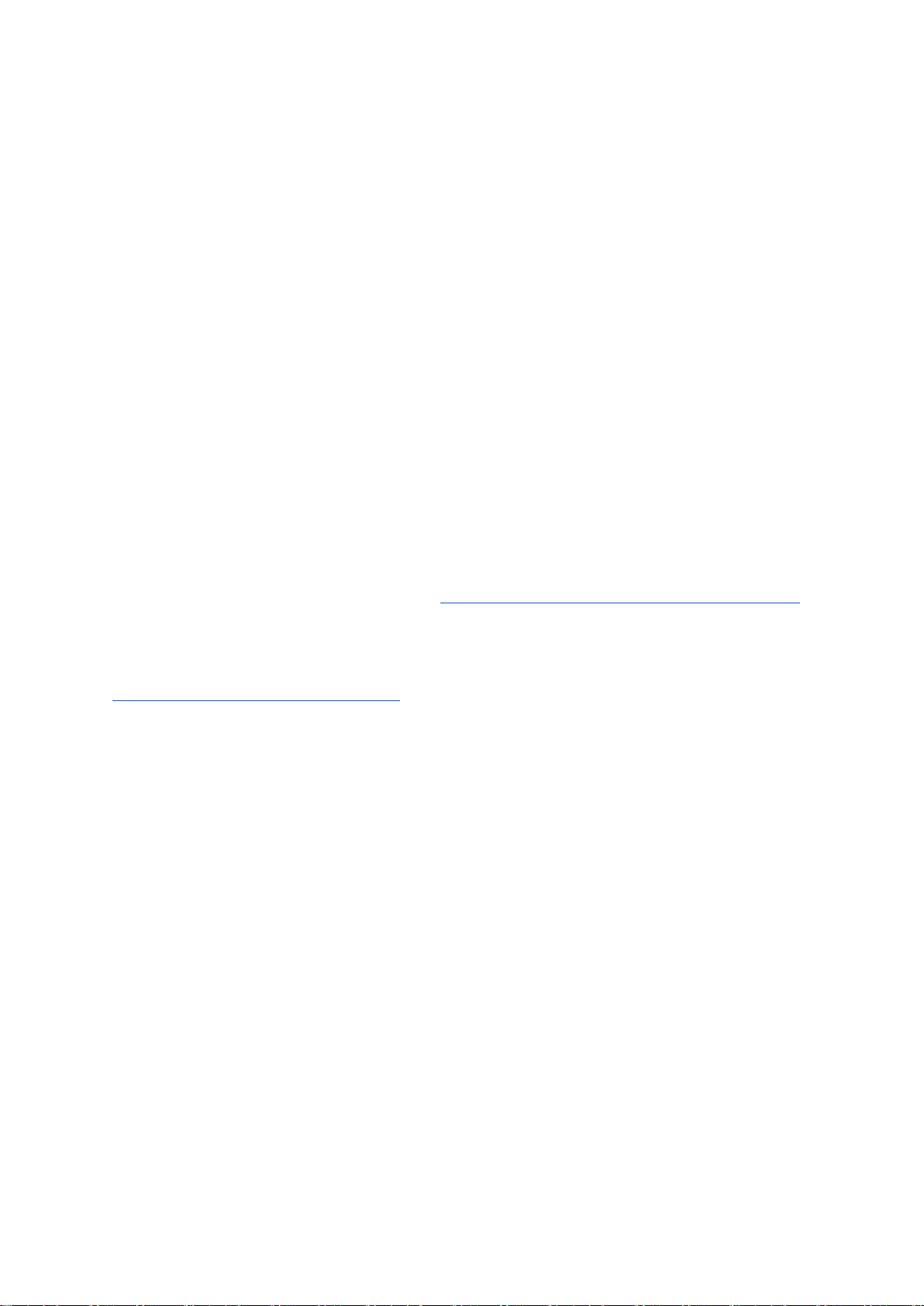

This point can be verified through the difference in the Holding Cost Formula between the processor and retailer: ℎ𝑝𝑇𝐷𝑖𝑗 𝐷 𝐷 + Processor: HCp 2 𝑃 𝑃 2 2 + Retailer: HCr i=1 𝑗=1 𝑇 2 1+𝐿−𝑇 4 2 ]

These two formulas are formulated based on the characteristics of a multi-echelon

supply chain, are multiplications of the areas under the graphs, which show the impact

supply chain levels have on each other, and the time interval T.

Figure 4.2 The weight of the processed inventory level at the processor and the retailer

Whereas the assigned paper uses the same Holding Cost formula for every node in every

level of the multi-echelon model when applying Decentralized strategy, and no detailed

approach was mentioned for Centralized strategy.

4.3 Limitation

(1) The used data was collected based on Sebatjane et al. (2022) paper since we lack

deep knowledge about the deterioration and relevant factors, namely the growth

rate, fraction of the live items, constant of integration, and the items’ asymptotic

weight. More understanding and scientific applied data will result in more applicability of the model.

(2) The simplification of the model in the number of nodes in each echelon

(3) Lack of comparison with the assigned paper regarding its methodology to clarify

that our optimal results have the same effectiveness due to the difference in the

type of multi-echelon model (1-1-1 and 1-2-3) and the difference in genetic algorithm. CHAPTER 5 CONCLUSION

Delivery of perishable products from supplier to customer is always one of the most

difficult issues currently. The managers need to think of how to control the deterioration

rate of this kind of product, how to reduce the number of damaged items during a long 15 | P a g e lOMoARcPSD|47207367

delivery time, and how to optimize the cycle time when transferring them. They must

decide the appropriate policies to satisfy conditions and solve those problems.

This research is carried out to determine the optimal solution for perishable products in

a multi-echelon system. By involving deterioration rate in formulas, it could calculate

and give a more accurate result that helps to achieve the more optimal policy for the

whole system. Specifically, the research considers the three-echelon system which

includes one supplier, one manufacturer, and one retailer. The objective is to show the

optimal number of shipments from manufacturer to retailer in a unit cycle time of the

processor and the retailer’s cycle time so that the inventory cost of this system is minimized.

Although there are some limitations to computational complexity, assuming no mention

of transportation cost, discount policies, or no shortage, it could be a premise for other

research later so that people can reach nearer to the most optimal solution. REFERENCES [1]

Sebatjane, M., Adetunji, O. (2022) Optimal inventory replenishment and

shipment policies in a three-echelon supply chain for growing items with expiration

dates. OPSEARCH 59, 809–838 (2022). https://doi.org/10.1007/s12597-022-00572-6 [2]

Zhang, Y., Chai, Y., & Ma, L. (2021). Research on Multi-Echelon Inventory

Optimization for Fresh Products in Supply Chains. Sustainability, 13(11), 6309.

https://doi.org/10.3390/su13116309 APPENDIX 1. Python code

The results were obtained using Python software 17 | P a g e lOMoARcPSD|47207367

2. Sensitivity Analysis

The results are obtained using Excel Solver.