Preview text:

lOMoAR cPSD| 58707906

SOLAR THERMAL POWER PLANTS 1. Introduction.

Solar thermal power plants are not an innovation of the last few years. In 1878 when

a small solar power plant made up of a parabolic dish concentrator connected to an

engine was exhibited at the World's Fair in Paris. In 1913, the first parabolic trough solar

thermal power plant has been implemented in Egypt. After the energy crisis of 1970s,

nine parabolic trough power plants were installed during 1984–1991

Over the last twenty years, R&D efforts on solar thermal power plants have been growing

sharply particularly in the US, Spain, Germany, China, South Africa and Australia. As a

result significant solar power plants have been installed. The solar heat from the parabolic

trough solar field could be integrated into three power conversion cycles, i.e., Rankine

cycle, Brayton cycle or combined cycle.

The integration of parabolic trough technology into the Rankine cycle has been the first

applied technique since the 1980s in California. Compared with Rankine-based cycles,

the idea of integrating solar energy into the Brayton cycle (gas turbine) is very recent. In

this system, steam is injected directly into the combustion chamber or the gas flow of the

gas turbine to enhance efficiency and output power. A configuration of the solar parabolic

trough combined with a gas turbine (CC-GT) uses turbine exhaust gases to supplement

the thermal energy storage system.

The present study aimed at a detailed review and performance analysis of the integration

of solar heat from parabolic trough field into power conversion cycles including Brayton

cycle, Rankine cycle and combined cycle. After that, evaluate performance of fifteen

solar only, fossil only and hybrid solar-fossil power plants.

2. Modeling the components.

2.1 Solar Radiation Modeling

This section focuses on modeling solar radiation to assess the amount of energy that can

be captured. The ASHREA model is chosen for its high accuracy when measurement

stations are unavailable. The formula for calculating Direct Normal Irradiance (DNI) in the ASHREA model is: −Bash p DNIash=Aashexp(

cos (❑z) p0) lOMoAR cPSD| 58707906

where Aash ,Bash ,Cash are climate constants for each area. It helps determine the amount of

solar energy that can be collected, which is a crucial factor for the efficiency of a solar

thermal power plant. It’s applied to illustrate the method of modeling solar radiation under real-world conditions.

2.2 Parabolic Trough Solar Field Modeling

The solar field consists of parabolic trough collectors, piping, and HTF pumps. Key aspects include: •

2.2.1 Collector Model: The parabolic trough collector model determines solar

energy absorption, heat loss, and heat gain. The “H” field design optimizes

efficiency by minimizing pressure loss. •

2.2.2 Pressure Loss: The pressure loss in the piping system is calculated as follows: △P = p . g. h

This formula is applied to determine the pump power needed for HTF within the system.

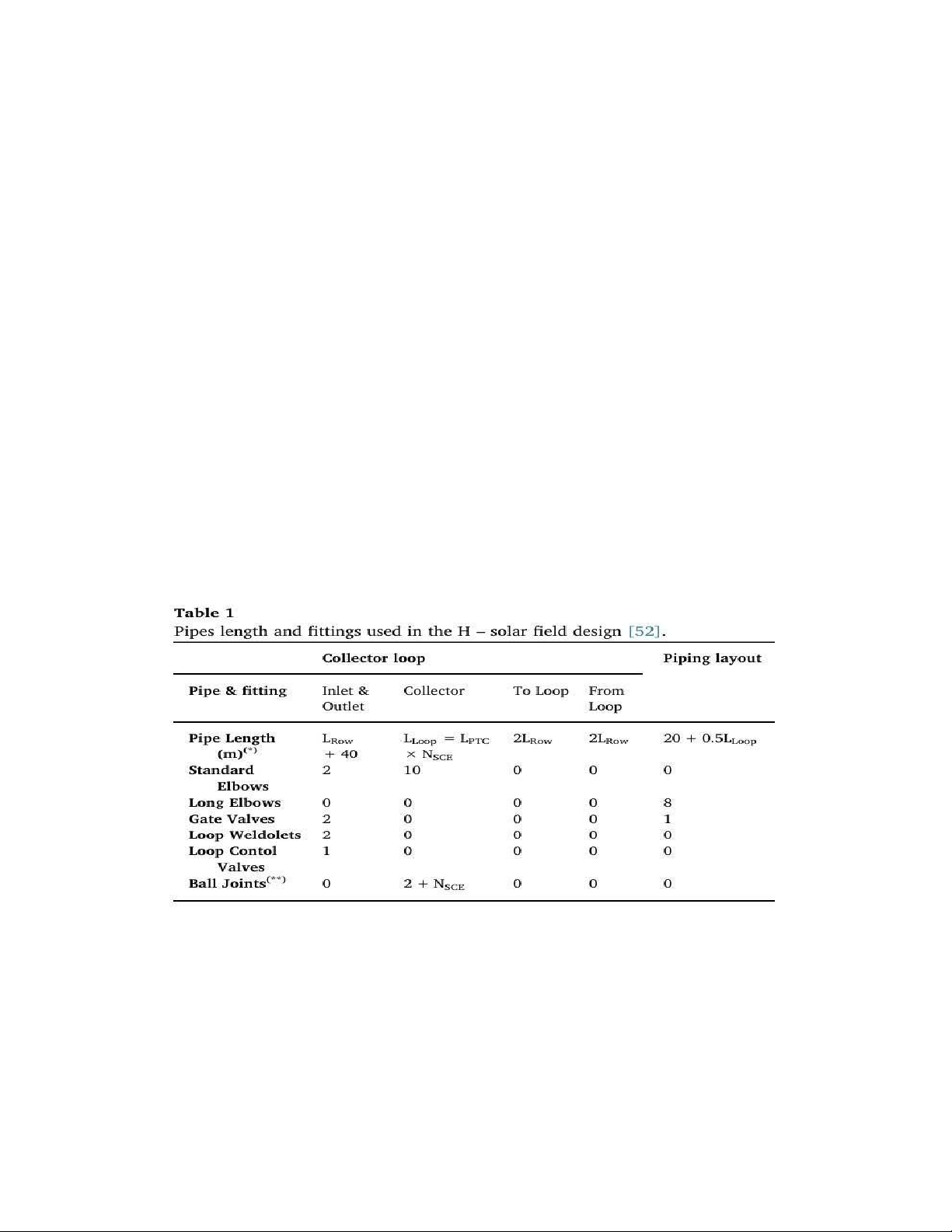

The pipe length, type of fittings, and details of the collector loop significantly impact

pressure loss and overall system efficiency.

Figure 1: Pipes length and fittings used in the H – solar field design

A table listing the pipe lengths, necessary fittings, and typical design for the piping

system. The piping system is where pressure loss occurs, impacting heat transfer

efficiency in the solar field. Including this table in the description of the solar field design

helps clarify the structure and factors affecting the system. lOMoAR cPSD| 58707906

2.3 Gas Turbine Modeling

This section discusses the Brayton cycle model, considering environmental factors and

pressure loss through each turbine component. Important factors include: •

Isentropic Efficiency of the Compressor: Compressor efficiency is calculated

based on inlet and outlet pressure ratios, average temperature, and polytropic efficiency. •

Actual Turbine Power Output: The formula for calculating the actual power

output of the gas turbine is: W ¿=WT−WC

W : Power generated at the turbine T

W : Power consumption at the compressor C

This formula allows evaluating the efficiency of the gas turbine when combined with

solar heat, helping to determine the effectiveness of converting solar heat into electricity.

2.4 Regenerative Rankine Cycle Modeling

The regenerative Rankine cycle uses heat from the HRSG (Heat Recovery Steam

Generator) to improve efficiency, including:

Heat Exchange Steps in HRSG: The amount of heat gained in the economizer is

calculated as: QwaterECO=mwater((1+BDF ) (Hwater5−Hwater4 )) QwaterECO: the heat gained in the economizer.

mwater: the mass of water

Hwater 5, Hwater 4: the enthalpy (internal heat) of the water at the point exit from the economizer

BDF: Blow down Factor. "This coefficient typically has a small value (e.g., 0.01 - 0.02)

and is calculated to ensure that the water in the system has good quality, preventing issues

such as scaling or corrosion of the pipes.

(1+BDF) reflects that the total mass flow rate of water includes not only the heated water

but also the water being drained. Therefore, multiplying by (1+BDF) helps accurately

calculate the amount of heat needed to heat both the circulating water and the drained water in the system." lOMoAR cPSD| 58707906

This part describes the heat exchange process within the HRSG, where steam is heated

from a saturated to a superheated state and then reheated between the high and lowpressure turbines.

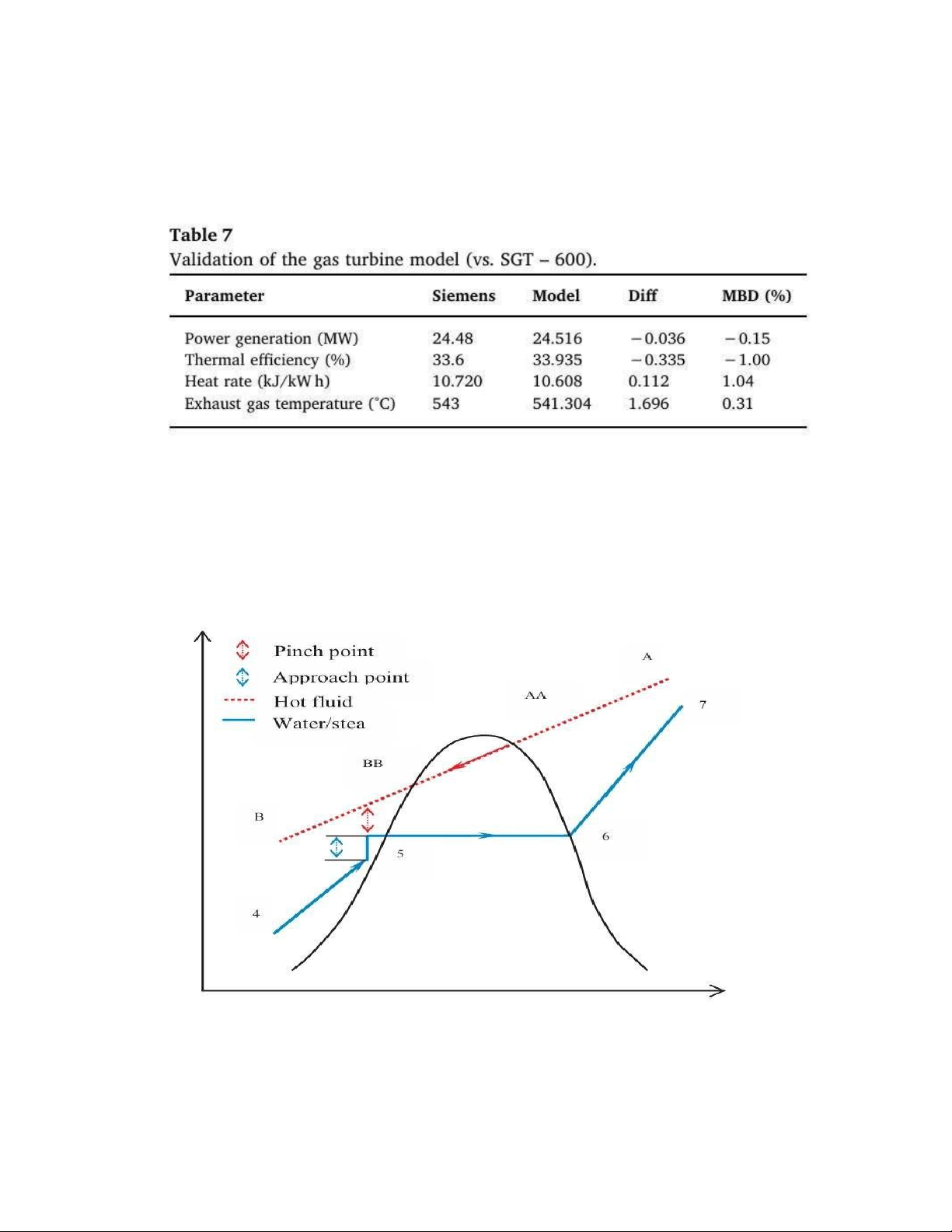

Figure 2: Validation of the gas turbine model

The table shows minor deviations between the model and actual values, indicating a good

fit between the model and real-world data, with a mean bias difference (MBD) of less

than 1.04% across parameters. This demonstrates the reliability of the gas turbine

simulation in the context of hybrid configurations with solar energy. lOMoAR cPSD| 58707906

Figure 3: Heat Transfer in the HRSG

This diagram represents a temperature-entropy (T-s diagram) or temperature-heat

diagram in the system of a solar thermal power plant. It illustrates key points and lines in

the heat exchange process between the hot fluid and water (or steam) for power generation. Specifically:

1. The red dashed line represents the hot fluid flow used to heat the water or steam

during the heat exchange process.

2. The blue line represents the water/steam flow through various stages from liquid

to steam, marked by points 4 to 7:

o Point 4 to 5: The initial heating process of water.

o Point 5: Reaches the approach point, where the water temperature is close to the hot fluid temperature.

o Point 6: Reaches the pinch point, where the temperature gap between the

two fluids is the smallest in the heat exchange process.

o Point 7: The water/steam reaches its highest temperature after the heating process.

3. The pinch point and approach point are two important points in the heat

exchanger design of the solar thermal power plant. The pinch point indicates the

smallest temperature difference between the hot fluid and water, optimizing

thermal efficiency. The approach point represents the temperature point before the

water reaches the pinch point.

Model Validation: A comparison table between the model and IAPWS IF-97

standard data ensures accuracy in predicting thermodynamic parameters. This is

crucial for assessing the overall efficiency of the Rankine cycle when integrated with solar energy