Preview text:

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Contents lists available at ScienceDirect

Journal of the Taiwan Institute of Chemical Engineers

journal homepage: www.journals.elsevier.com/journal-of-the-taiwan-institute-of-chemical-engineers

Numerical analysis of lithium-ion battery performance with new

mini-channel configurations implementing hybrid nanofluid

M. Sheikholeslami a,b,*, Z. Esmaeili a,c, Ladan Momayez d

a Renewable energy systems and nanofluid applications in heat transfer Laboratory, Babol Noshirvani University of Technology, Babol, Iran

b Department of Mechanical Engineering, Babol Noshirvani University of Technology, Babol, Islamic Iran

c Department of Energy, Faculty of New Science and Technologies, Semnan University, Semnan, Iran

d Department of Engineering and Computer Science, University of Pittsburgh at Johnstown, Pennsylvania, USA A R T I C L E I N F O A B S T R A C T Keywords:

Background: The thermal management of lithium-ion battery packs was thoroughly investigated in the current Lithium-ion battery

study, aiming to enhance cooling efficiency through innovative design approaches. This research evaluates the Pin fins

performance of four distinct mini-channel configurations—Smooth (simple rectangular), Grooved, Tooth, and Hybrid nanofluid Pin Fin Mini-channel

—integrated with a hybrid nanofluid composed of water and Fe3O4-SWMCT nanoparticles. Numerical simulation

Methods: These advanced cooling channels are designed to improve thermal regulation by optimizing the thermal

characteristics of the system. The study employs a conduction-based model to simulate the unsteady heat source

conditions representative of battery discharge cycles. Validation against published data confirms the high ac-

curacy of the modeling approach.

Significant findings: Results demonstrate that the incorporation of nanoparticles in the cooling fluid contributes to

a slight reduction in battery temperature, with cells located near the cooling channels exhibiting more uniform

temperature distribution. Notably, the channel configuration with Pin fins proves to be the most effective,

achieving a Nusselt number 5.03 times greater than that of the Smooth rectangular duct, indicating significantly

improved heat transfer performance. Conversely, the channel design with Teeth showed the poorest hydraulic

performance, with performance value of 0.84, while the Pin Fin configuration achieved the highest performance

value of 2.62, signifying superior overall performance. This study highlights the crucial impact of channel ge-

ometry and cooling fluid composition on behavior of battery packs. By advancing the design and material use in

cooling systems, the research contributes valuable insights for enhancing battery safety, efficiency, and longevity. 1. Introduction

design to evaluate the thermal performance, focusing on cooling effi-

ciency and uniformity. Numerical analysis revealed that inadequate heat

Recently batteries have become crucial in advancing and expanding

conductivity between the cooling plate and the beneath of the cell stack

novel energy usages, including mobile robots and electric vehicles [1].

significantly hampers efficient heat dissipation. Additionally, tempera-

Among these, the desired choice for electric vehicle manufacturers is

ture uniformity declines with the asymmetric fin-cell arrangement.

LIBs (lithium-ion batteries). Their minimal self-discharge, reliable effi-

Satyanarayana et al. [11] evaluated the cooling performance of two

ciency and longevity make them an ideal option [2–4]. Nevertheless, the

kinds of fluids within the cold plate ducts. Their findings showed that

safety of such batteries is highly sensitive to temperature [5]. As a result,

liquid cooling led to effective heat dissipation from the cells. Chen et al.

numerous studies focus on either extending battery lifespan by

[12] investigated how modifying the locations of the outlet and inlet in

addressing thermal challenges or enhancing performance through

parallel microchannel cooling plates affects the maximum battery tem-

improved battery thermal management units [6–9]. Chung et al. [10]

perature. The outputs revealed that placing the outlet and inlet at

created a model for a pouch battery module equipped with liquid

opposite ends of the diagonal of the cooling duct yields the lowest

cooling. They used a conventional fin-cooled battery pack as a reference

maximum cell temperature. However, this configuration comes with * Corresponding author.

E-mail addresses: mohsen.sheikholeslami@nit.ac.ir, m.sheikholeslami1367@gmail.com (M. Sheikholeslami), z.esmaili.9473@gmail.com (Z. Esmaeili).

https://doi.org/10.1016/j.jtice.2025.106074

Received 4 September 2024; Received in revised form 11 February 2025; Accepted 2 March 2025

Available online 16 March 2025

1876-1070/© 2025 Taiwan Institute of Chemical Engineers. Published by Elsevier B.V. All rights are reserved, including those for text and data mining, AI training, and similar technologies.

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

higher costs. Dubey et al. [13] employed a dielectric coolant for battery

critical challenge of thermal management. This study introduces a novel

and showed that this method has the same uniformity as water cooling

approach by examining various mini-channel designs—Smooth,

approach. According to Ding et al. [14], while the number of ducts does

Grooved, Tooth, and Pin Fin—integrated with a hybrid fluid of water

affect the Tmax of cell, its impact is significant but limited when assessing

and Fe3O4-SWMCT nanoparticles. The use of such hybrid nanofluids is

the overall cooling performance of the model. With selecting channels

particularly innovative, as it aims to boost the heat transfer capabilities

with greater height of duct, the Tmax decreases and it keeps the tem-

of the cooling system, which has not been extensively explored in pre-

perature through a specific range.

vious research. Previous studies have primarily focused on conventional

Zhu et al. [15] performed an optimization on a hybrid cooling bat-

cooling techniques, such as single-channel or basic fin designs, and have

tery pack, achieving reductions in both the overall temperature. Guo

often used standard fluids without incorporating advanced nano-

[16] investigated how four different serpentine ducts to manage the

materials. These approaches have provided foundational insights but

temperature of battery cells. The optimization of channel structural

have not fully addressed the potential improvements in cooling effi-

parameters and flow rate was achieved using orthogonal test design.

ciency that can be achieved with advanced mini-channel designs and

This optimization led to a decrement in the system’s highest tempera-

hybrid nanofluids. Additionally, the impact of different channel geom-

ture difference by 0.10 % and a significant decrease in ΔP by 74.18 %.

etries on dynamic heat dissipation and temperature distribution during

Jiang et al. [17] incorporated rectangular channels filled with nano-

the discharge of high-capacity battery packs has not been thoroughly

particles into a battery pack that was also filled with phase change

investigated. The prominence of current research lies in its potential to

material (PCM). Their study revealed that augmenting the nanofluid

bridge these gaps by providing a comprehensive analysis of how various

velocity led to a decrement in the Tmax by 1.24 ◦C. Additionally, liquid

mini-channel configurations and advanced cooling fluids affect thermal

channels were embedded within these aluminum blocks to enhance heat

performance. By utilizing symmetric boundary conditions and unsteady

extraction. Additionally, Subhedar et al. [18] scrutinized the use of

three-dimensional simulations with ANSYS FLUENT, this study delivers

nanofluids in cooling cylindrical Li-ion cells within a module. Their

detailed insights into the hydrothermal behavior of the cooling system,

outputs demonstrated that temperature of cells maintains below 50 ◦C if

which has significant implications for battery safety, performance, and

Al2O3/EG-water nanofluid has been implemented. Xu et al. [19] scru-

longevity. This work not only enhances the thoughtful of thermal

tinized a simulation to investigate how minichannel cooling affects the

treatment in lithium-ion batteries but also offers practical solutions for

spread of thermal runaway (TR) in a module. They proved that the

optimizing cooling systems, which are crucial for the future great-

propagation of TR led to only a minor temperature rise—remaining

efficiency battery technologies.

below 130 ◦C—in neighboring batteries, and did not trigger further TR.

Mo et al. [20] developed an innovative cooling plate through topology

2. Modeling of battery pack in existence of mini-channel with

optimization techniques. To evaluate its performance, they compared hybrid nanofluid

the temperature, pressure, and speed of this optimized design with those

of a conventional structure. Angani et al. [21] enhanced the perfor-

2.1. Presentation of design

mance of module by incorporating zig-zag boards into their design.

Their results demonstrated a reduction in the Tmax to below 35 ◦C, with

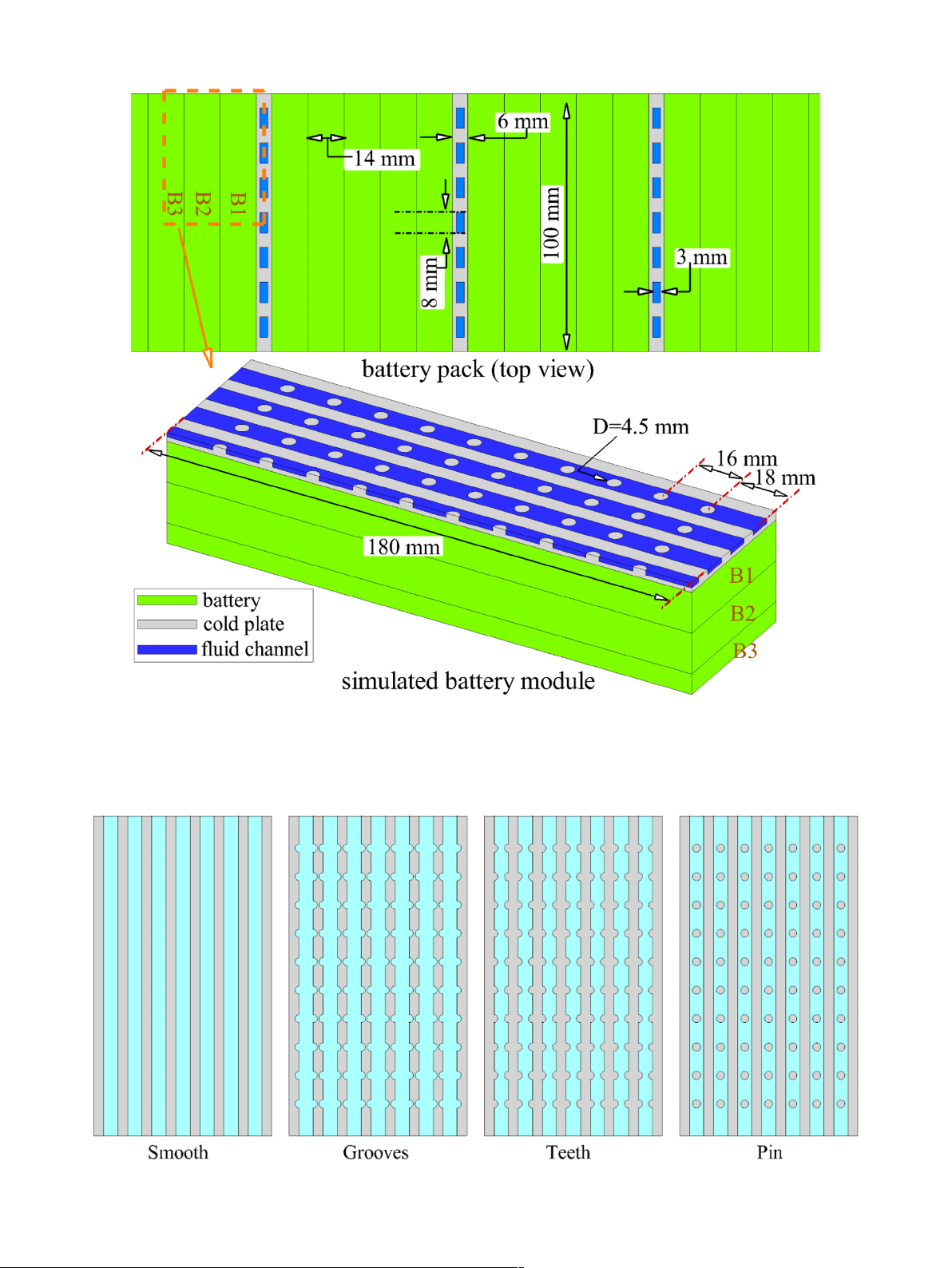

Creating a Li-ion battery pack involves carefully integrating multiple

the ΔT dropping to under 1.4 ◦C. This improvement led to a notable 28%

battery modules with cold plates that feature precisely engineered

increase in overall thermal performance. Gungor et al. [22] designed

cooling channels. The battery modules, composed of numerous indi-

new system for battery and showed that optimizing the flow path can

vidual cells, are arranged to form the core of the pack, while the cold

meaningfully enhance cooling efficiency while reducing the mass flow

plates are strategically placed between these modules to manage the

rate. Sheng et al. [23] scrutinized the comprehensive research on the

heat generated within operation. The cooling channels through the cold

thermal treatment of a serpentine channel used in conjunction with

plates are designed to optimize the flow of cooling fluid, ensuring effi-

battery cells. They demonstrated that the flow direction and duct width

cient heat transfer away from the modules. This arrangement not only

had a sensible influence on the power consumption ratio. Liu et al. [24]

maintains a uniform temperature, but also enhances the overall safety.

introduced a novel design featuring a honeycomb structure that com-

The combination of well-designed modules and effective cooling infra-

bines liquid cooling with PCM. Their system employs higher the overall

structure is essential for delivering reliable, high-performance energy

heat transfer efficiency. As a result, the new design provides a highly

storage solutions. The integration of hybrid nanomaterials into these

effective and dependable cooling solution for modules.

cooling fluids represents a significant advancement, enhancing thermal

Amalesh et al. [25] scrutinized an in-depth research on how different

conductivity and heat transfer efficiency. These nanomaterials, often

duct profiles impact the cooling efficiency. Among the profiles tested,

composed of metal oxides, carbon-based materials, or other conductive

the circular groove and zigzag designs provided the most effective

particles, can dramatically improve the fluid’s ability to absorb and

cooling and had the lowest pressure drop. Sarchami et al. [26] investi-

dissipate heat, thereby maintaining optimal battery temperatures even

gated a new cooling system for LIBs featuring stair and wavy ducts along

under demanding conditions. The design and geometry of the cooling

with a copper sheath. Their findings revealed that the stair channel

channels within the cold plates are equally important. Optimizing

significantly enhanced the cooling capacity. The safety issues in

channel geometry—whether through varying channel cross-sections,

lithium-ion battery packs and their associated impacts have been thor-

introducing turbulence promoters, or using branching patterns—maxi-

oughly discussed by Rana et al. [27], who proposed advancements in

mizes effective area. This precision in design helps prevent localized

both the internal and external battery materials to improve overall

overheating, reduces thermal gradients, and ultimately extends the

safety. Esmaeili and Khoshvaght-Aliabadi [28] investigated a channeled

battery’s operational life. Thus, the combined use of advanced cooling

liquid cooling unit integrated with twisted tapes for LIBs. Their findings

fluids and meticulously engineered cold plate geometries is crucial for

revealed that the modified twisted tapes effectively improved the tem-

achieving efficient thermal management in modern battery systems.

perature uniformity. A new hybrid liquid cooling technique for con-

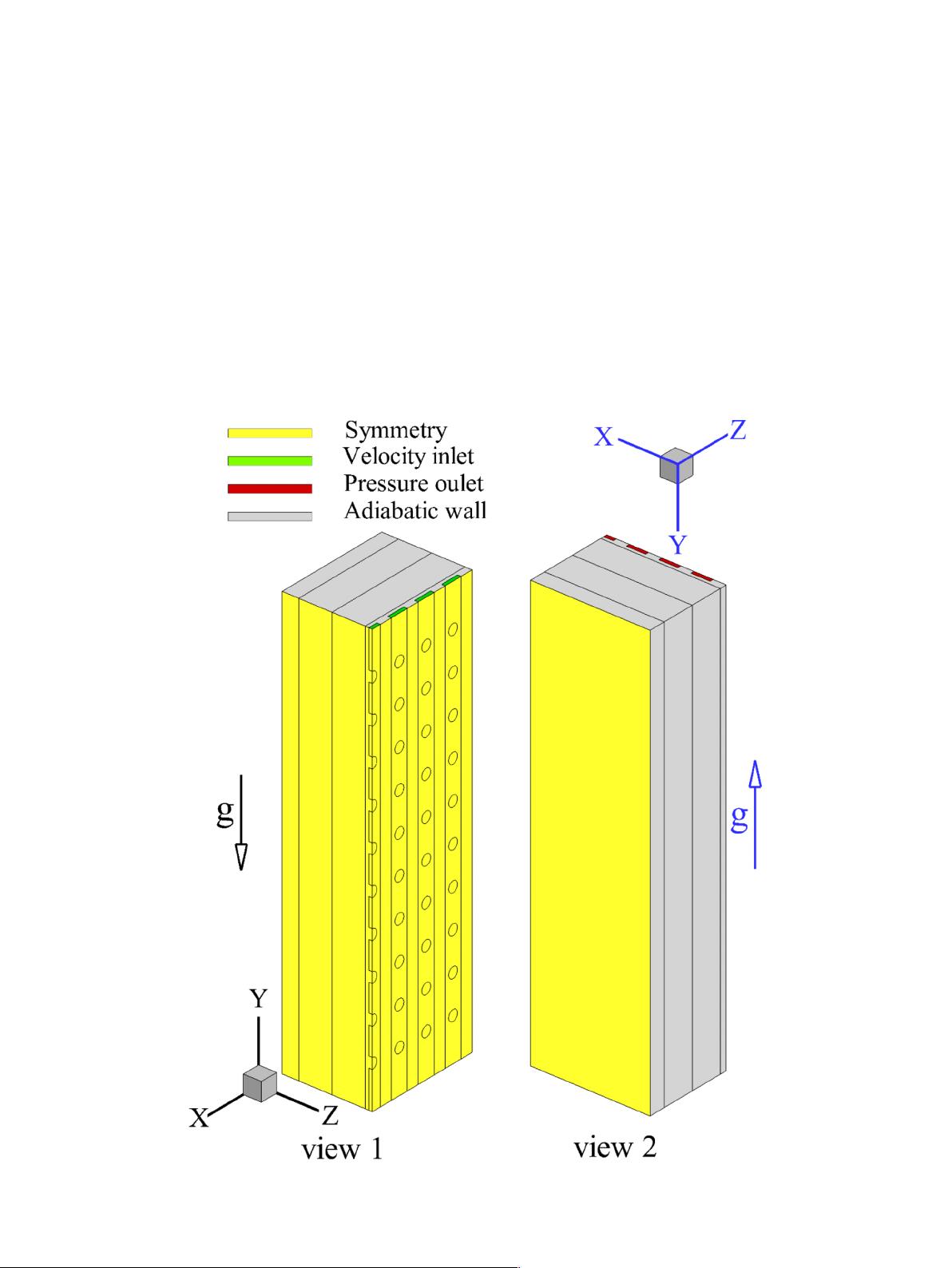

The battery pack under investigation involves of numerous prismatic

trolling temperature of LIBs was proposed by Sadeh et al. [29], who

lithium-ion cells, each with a capacity of 45 Ah. The cooling system for

applied it to 21,700-type Li-ion batteries under highway fuel-economy

this battery pack is designed with a mini-channel setup, as illustrated in

conditions. Their study demonstrated that employing an opposite flow

Fig. 1. This system sandwiches every 5 cells between two cold plates,

configuration between the direct and indirect approaches significantly

which are equipped with 7 mini-channels. To simplify the simulation

improves the thermal performance.

process and reduce computational costs, a simplified model of the

The investigation into advanced cooling strategies for lithium-ion

geometrically symmetrical battery module is utilized because overall

battery packs represents a significant step forward in addressing the

design is consistent and repetitive, allowing the assumption that the top, 2

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Fig. 1. Mini-channel within LIBs.

Fig. 2. Models of the mini-channels. 3

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

bottom, and right surfaces can be treated as symmetry planes. This

2.2. Modeling the battery components

approach is deemed reasonable given the large number of LIBs present

in the pack, which makes detailed modeling of every individual cell and

The equation for the LIBs is as following [30]:

component unnecessary. This reduction in complexity facilitates a more ( ) ( ) ( )

efficient analysis while still providing a representative understanding of ∂T ∂ ∂T ∂ ∂T ∂ ∂T ρCp λz + λy + λx (5) the cooling system

∂t = ˙Qgen + ∂z ∂z ∂y ∂y ∂x ∂x ’s performance.

In this study, three innovative designs for mini-channel cooling

In this equation, ρ, represents the bulk density, and, Cp denotes the

plates (MCPs) have been proposed, each featuring distinct channel specific heat capacity.

profiles. These new designs build upon the battery module analyzed in

For the cold plate, the equation is [30]:

the research by Liu et al. [30]. Fig. 2 provides a detailed illustration of ( )

these proposed designs. The novel channel profiles are developed to ∂T ∂2T ρCp (6)

intensify the cooling rate by optimizing heat transfer within the ∂t = λ ∂xi2

mini-channels. Each design introduces unique geometrical modifica-

tions aimed at enhancing the thermal management of LIBs, thereby

2.3. Modeling fluid flow within the mini-channel

addressing limitations observed in traditional cooling systems. By

incorporating these new channel configurations, the study seeks to

The flow within the channel is described by below equations [30]:

advance the understanding of how different cooling plate designs impact

the thermal regulation of LIBs. ∂ρ ∂

In current work, the battery cells are modeled as solid blocks (ρu ∂t + ∂x i) = 0 (7) i

composed of a material with orthotropic thermal conductivity. The cold ( )

plates, made of aluminum, are treated as having isotropic thermal ∂ ∂ ( ) ∂P ∂ ∂u ρu i = − + μ + ρ g → (8)

properties. Heat generation within the battery cells is simulated as a

∂t (ρui) + ∂x iuj j ∂xi ∂xi ∂xi

conduction process, where thermal energy is conducted through the ( ) ( )

solid material of the cell and subsequently transferred to the cold plates ( ) ∂T ∂ ( ) ∂ ∂T ρCp Tuj = λ (9)

which conduct this heat to the surrounding liquid coolant flowing ∂t + ∂xj ∂xj ∂xj

through the mini-ducts. The coolant, which absorbs and carries away a

significant portion of the thermal energy, is responsible for removing

heat from the system via convection. As the heat is dissipated, the

2.4. Deriving the heat generation source term in battery pack

temperature of cell increases owing to the accumulated thermal energy within the cells.

Li [33] derived expressions for battery heat generation over time as below:

To provide a detailed understanding of the thermal dynamics, the

governing equations include the pure conduction equation within the ˙

Qgen = A1t6 + A2t5 + A3t4 + A4t3 + A5t2 + A6t + A7,

LIBs and the cold plates, and convective heat transfer equations for the

A1 = 4.9132 × 10(− 16), A2 = − 3.7742 × 10(− 12), A3 = 1.0679 × 10(− 8),

coolant. The effects of the thermophysical properties of the module and

A4 = − 1.3417 × 10(− 5), A5 = 0.0076 A6 = − 2.2208

the nanoparticles used in water are crucial for accurately simulating the A7 = 17151.7482

thermal behavior of the system. These properties are summarized in (10)

Table 1 [25,31], which provides essential data on relevant characteris-

tics of the materials and nanofluids employed in this study.

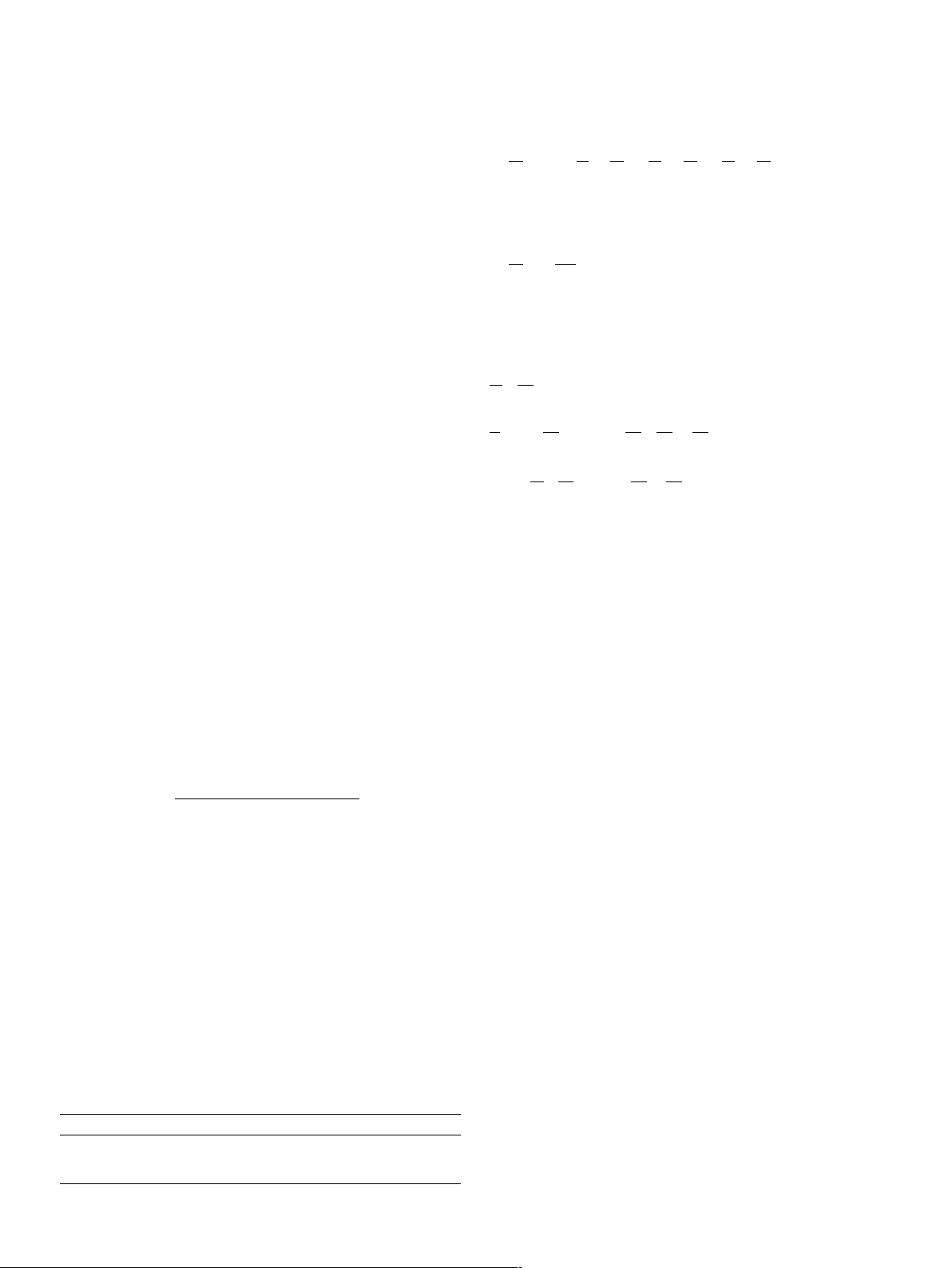

Fig. 3 illustrates the heat generation rate, providing a visual repre-

Additionally, the study accounts for the temperature-dependent

sentation of the thermal dynamics under this discharge condition. This

thermo physical properties of water, following the relationships out-

data is vital for assessment of the thermal treatment of the module lined in Eqs. (1

during operation and informs the design of effective cooling strategies. –4) from [32].

Within the discharge of a 45 Ah battery pack at a 1C rate, the heat ( ) (T

generation initially remains relatively constant due to stable internal ρ w − 4.0)2 w = 1000 × 1.0 − (1) 119000

resistance and consistent electrochemical reactions. However, after

+ 1365 × Tw − 4 × (Tw)2

3000 s (or 50 min), a sharp increase in heat generation is often detected.

This surge is primarily due to the battery nearing full discharge, where

λw = 0.56112 − 6.08803 × 10− 8 × (Tw)3 − 2.60152749 × 10− 6 × (Tw)2

internal resistance rises as electrolyte conductivity decreases and elec- + 0.00193 × Tw

trode materials change. Additionally, as the battery depletes, electro- (2)

chemical efficiency drops, resulting in more heat production. Localized

areas within the cells may experience increased current density, further μ 3 2

w = 0.00169 − 2.09935 × 10− 9 × Tw + 4.9255 × 10− 7 × Tw

exacerbating heat buildup. This final phase is critical, as excessive heat

− 4.25263 × 10− 5 × Tw (3)

can risk thermal runaway. Therefore, managing the thermal profile of

the battery pack through effective cooling systems and monitoring is Cp

crucial, especially towards the end of the discharge cycle, to prevent

,w = 0.09503 × (Tw)2 −

3.20888 × Tw + 9.415 × 10− 6 × (Tw)4 (4)

− 0.00132 × (Tw)3 − 2.5479 × 10− 8 × (Tw)5 + 4217.629

overheating and ensure safe operation.

In these equations, Tw represents the temperature of the water in ( ◦ C).

2.5. Applied assumptions in modeling

For the purpose of modeling and ensuring consistency across all

designs studied, the following assumptions have been made: Table 1

Thermo-physical properties of materials [25,31].

• The coolant is considered incompressible and exhibits isotropic Material /Features ρ(kg.m− 3)

Cp(J.kg− 1.K− 1)

λ(Wm− 1K− 1) properties throughout. Battery 3000 1005.91

λx = λy = 0.302, λz = 22.48

• The lithium-ion battery materials are assumed to have isotropic SWCNT 2600 425 6600

properties, except for their thermal conductivities, which are treated

Fe3O4 5200 670 6 as orthotropic. 4

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Fig. 3. Battery heat generation during time.

• Heat transfer is presumed to happen solely through the coolant, ( ) 1 [( )( ) ( ) ( ) ]

which extracts thermal energy from the walls of the mini-channel Cp 1 (13) hnf = − φ ρC φρC φρC ρ hnf p bf + p SWCNT + p Fe3O4 plates. hnf

• Heat source through the batteries is modeled as a transient process, [{ }( ) ( ) 1 1 ]

reflecting the time-dependent nature of thermal production during (φλ)

+ 2φhnf + 2λbf φhnf − φhnf λ

SWCNT + (φλ)Fe3O4 hnf = { }( ) ( ) λbf discharge.

(φλ)SWCNT + (φλ)Fe 1 − φ + 2λ 1 − φ 3O4 hnf bf φhnf hnf

• All wall boundaries within the system are considered adiabatic, (14)

meaning no heat is transferred through these surfaces.

In the above correlations, the values of φSWCNT and φFe are 0.01. 3O4

• Contact resistances between LIBs and the cold plates are ignored.

• The effects of buoyancy forces due to temperature-induced density

variations are included in the model.

2.7. The definition of important factors

These assumptions help in focusing on the primary mechanisms of

The definitions of Re (Reynolds number) [36], h (heat transfer co-

heat transfer and cooling efficiency, while simplifying the complex in-

efficient) [22], Nu (Nusselt number) [37], f (Darcy factor) [38], and,

teractions that might otherwise complicate the analysis.

PEC (hydrothermal performance) [39], are ρVDh

2.6. Formulation for properties of hybrid nanofluid Re = (15) μ

In current study, it is assumed that the treatment of the hybrid h qʹ = ( ) (16)

nanofluid as a single-phase fluid, simplifying the analysis. Consequently, Tw,ave − Tb

the thermo-physical features of the hybrid nanofluid are represented by

operative amounts that account for both the base fluid and the nano- Nu hD (17)

particles. These effective properties are derived from the characteristics = λ

of the components, as specified by the formulas detailed in [34–35]. This

approach enables a more accurate representation of the nanofluid 2ΔPD ’s f h =

behavior within the cooling system, facilitating better predictions of ρu2L (18)

thermal performance and efficiency. Nu ( ) PEC Nu0 (19) ρ =

hnf = 1 − φhnf ρbf + (φρ)SWCNT + (φρ)Fe (11) ( )1 3O4 f 3 [{ ( )} f0 μ − 2.5] hnf =

1 − φSWCNT + φFe μ 3O4 bf (12) 5

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

2.8. The utilized initial and boundary condition for modeling

improved thermal conductivity and heat dissipation. Using symmetry in

the model allows engineers to effectively test various cooling channel

At the duct outlet, constant gauge pressure of 0 Pa is applied. The

designs and nanofluid configurations without the need for full-pack

constant inlet velocity (Vin=0.1 m/s) is applied to the coolant entering

simulations. This approach enables efficient optimization of cooling

the mini-channels, which also starts at 25 ◦C. The boundary conditions

systems, ensuring better thermal management and safety in the battery

for the computational domain are illustrated from two different per-

pack. In essence, symmetric boundary conditions streamline the simu- spectives in Fig. 4.

lation process, making it feasible to accurately model and optimize the

In modeling a battery pack, symmetric boundary conditions are

thermal performance of battery packs, particularly when using

utilized to simplify the simulation of complex thermal processes and

advanced cooling technologies like hybrid nanofluids.

enhance computational efficiency. This approach is especially important

The conjugate transient heat transfer presented in this study has been

for accurately predicting heat generation and transfer during unsteady

addressed by ANSYS FLUENT. For all simulations, the flow within the

states, such as during charging and discharging cycles. By applying

mini-channel coolant was modeled under laminar conditions, as the

symmetric boundary conditions, the simulation focuses on a represen-

calculated inlet Reynolds number for all coolant flows in this investi-

tative section of the battery pack, reducing the computational domain

gation was <100, indicating laminar flow characteristics. The SIMPLE

and speeding up the analysis. For simulations involving hybrid nano-

algorithm, coupled with 2nd order upwind approach. To ensure accu-

fluids in cooling channels, symmetric boundary conditions are critical

rate solutions, stringent convergence criteria were set: iteration re-

for evaluating the enhanced heat transfer properties of these fluids.

siduals needed to drop below 10− 5 for the flow equations and 10− 7for

Hybrid nanofluids, which combine base fluids with nanoparticles, offer

the energy equations. The value of Δt of 1 second was chosen for the

Fig. 4. Boundary conditions used in the present simulations. 6

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

calculations. Additionally, the heat generation within the module, longevity.

calculated using the correlation in Eq. (5), along with the thermophys-

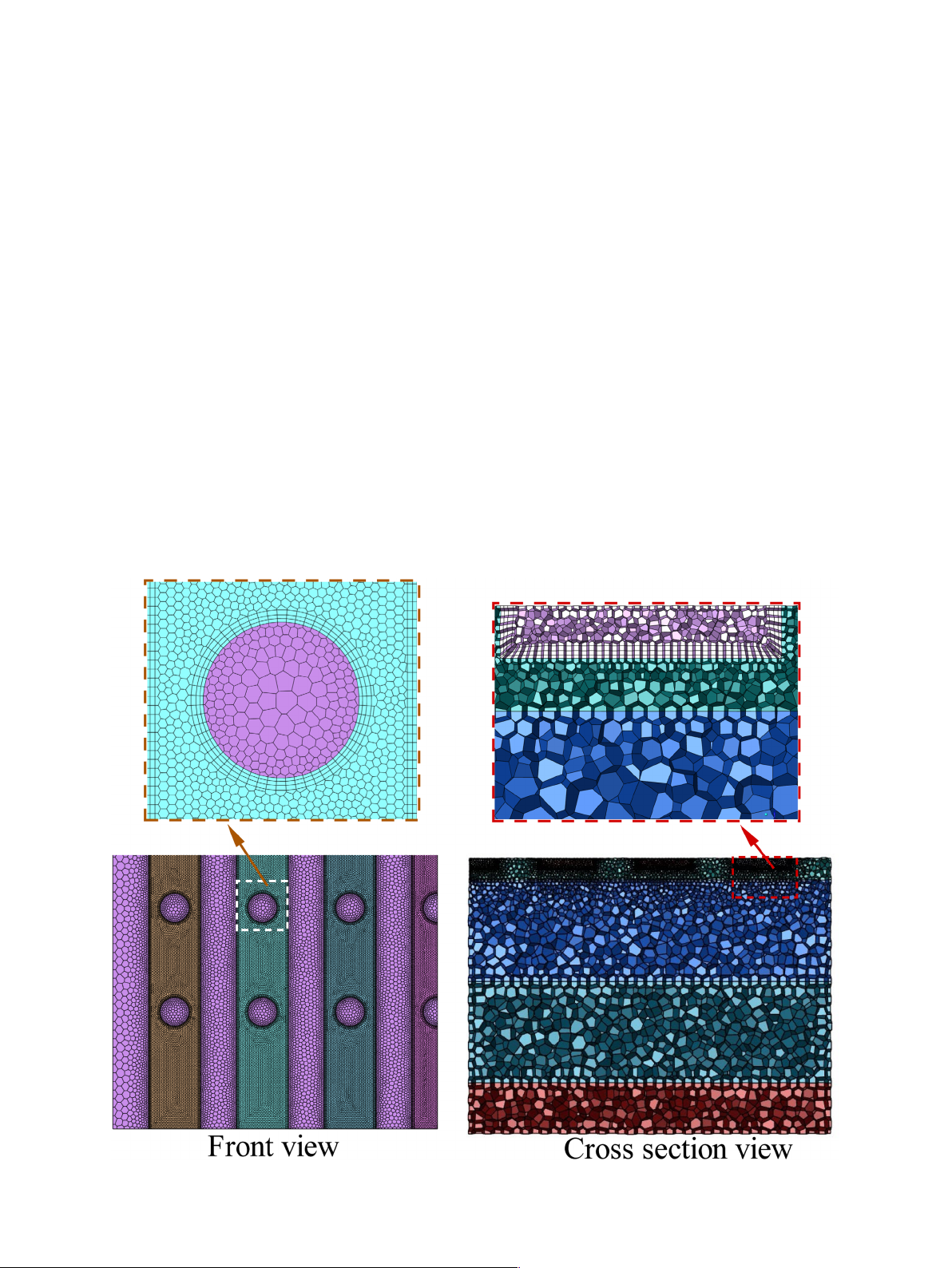

The unstructured polyhedral grid, depicted in Fig. 5, was created

ical features of the fluids, was integrated into the simulation through

using FLUENT MESHING software. To enhance simulation accuracy, the

User-Defined Functions (UDFs). This meticulous approach ensures that

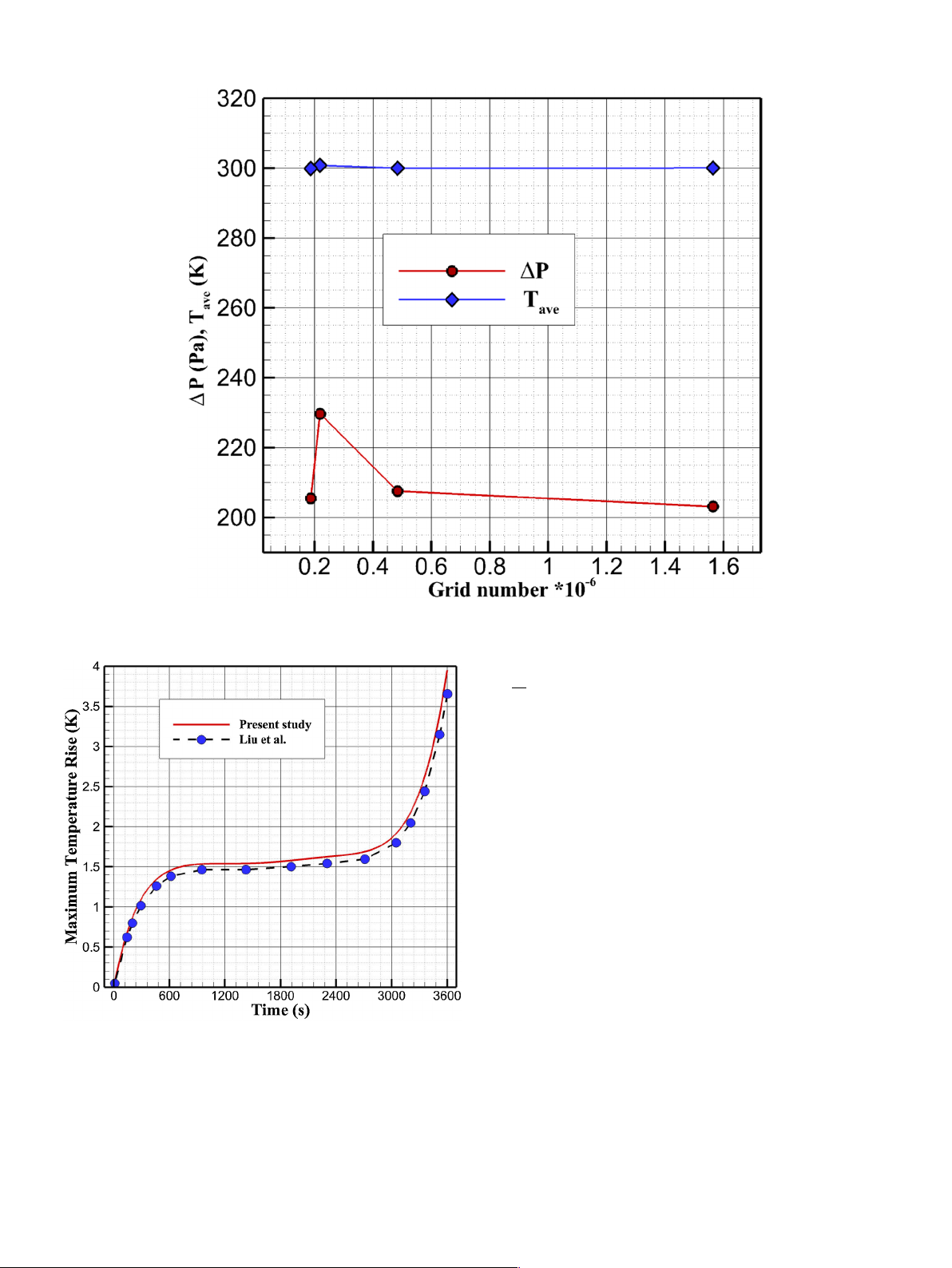

mesh density in the fluid zone was amplified. Various mesh configura-

the simulation accurately captures the complex interactions hydro-

tions, ranging from 186,718 to 1564,884 grid cells, were applied to

thermal behavior, providing reliable data for analyzing the thermal

model the battery. The scenario involved nanofluid flowing within the behavior of module.

mini-channels with pin fins. The value of Tmax of battery and the fluid

pressure drop across the ducts were compared across different meshes to

3. Results and discussion

verify mesh independence. The examined results, as depicted in Fig. 6,

indicated that when the grid size reached 484,278 cells, the computa-

Current research explores advancements in cooling units for lithium-

tional results achieved sufficient accuracy. Thus, the mesh with 484,278

ion battery packs, focusing on enhancing cooling rates during discharge

grid cells was selected for all simulations in this study, balancing pre-

to improve battery performance and longevity. Each module in the

cision and computational cost. Establishing mesh independence is

battery pack contains five 45 Ah lithium-ion cells, with cold plates

crucial in computational simulations to ensure that the outputs are not

inserted between packs to facilitate effective thermal management. The

significantly affected by the mesh size, thereby providing reliable and

research emphasizes the prominence of temperature distribution for

accurate predictions of the physical phenomena being modeled.

battery life and aims to optimize this factor. Various mini-channel de-

Before conducting main simulations, the current model was verified

signs have been tested, including Smooth (simple rectangular), Grooved,

against the findings of Liu et al. [30], which scrutinized the discharging

Tooth, and Pin Fin channels, with a working fluid composed of water

behavior of a 45 Ah Li-ion battery at a 1C rate. The comparison of results

mixed with hybrid nanoparticles (Fe3O4-SWMCT). These configurations

is illustrated in Fig. 7. The data indicate that the model’s predictions for

were modeled using symmetric boundary conditions and unsteady

the performance of the mini-channel plate (MCP) align very closely with

three-dimensional simulations in ANSYS FLUENT, capturing the dy-

the outputs obtained by Liu et al. [30]. Specifically, the model accu-

namic heat transfer during discharge. The study presents temperature

rately captured the thermal and electrical behavior of the battery during

distribution data for each channel design and analyzes the hydrothermal

discharging, demonstrating consistent results in terms of temperature

behavior, reporting on Nusselt numbers and pressure drop. By

distribution and heat dissipation. This close agreement not only con-

comparing these configurations, the study identifies the most efficient

firms the validity of the current model but also highlights its reliability

cooling system. This research is vital as it addresses the critical need for

for simulating the thermal controlling of modules with various MCP

improved cooling solutions to ensure battery safety, performance, and

designs. The validation process illustrated that the temperature profiles

Fig. 5. Unstructured grid of the current domain. 7

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

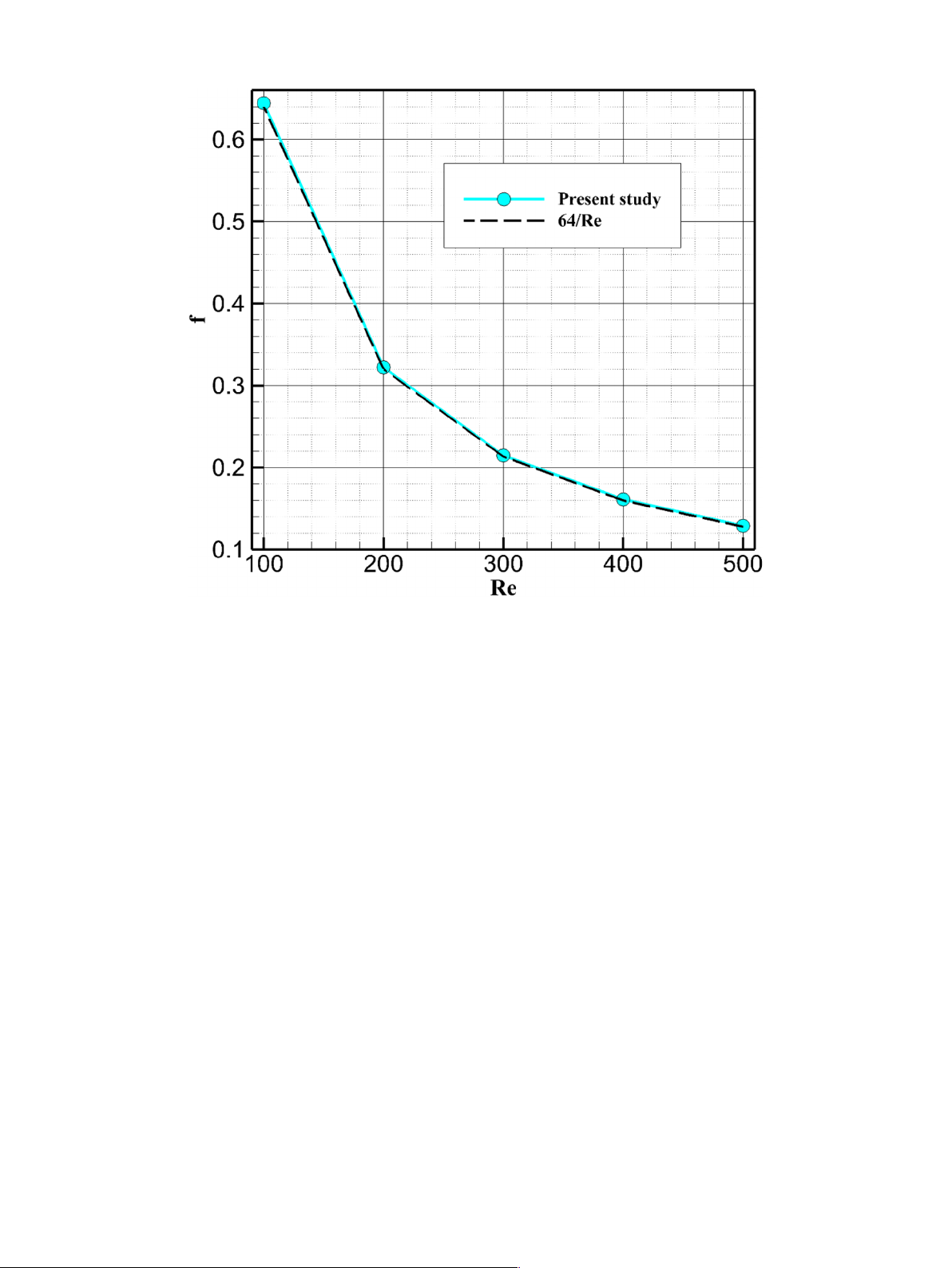

Fig. 6. Mesh assessment. 100–500 [37,40]. f 64 = Re (20)

The estimation of the Darcy factor in the current study shows

excellent agreement with this equation.

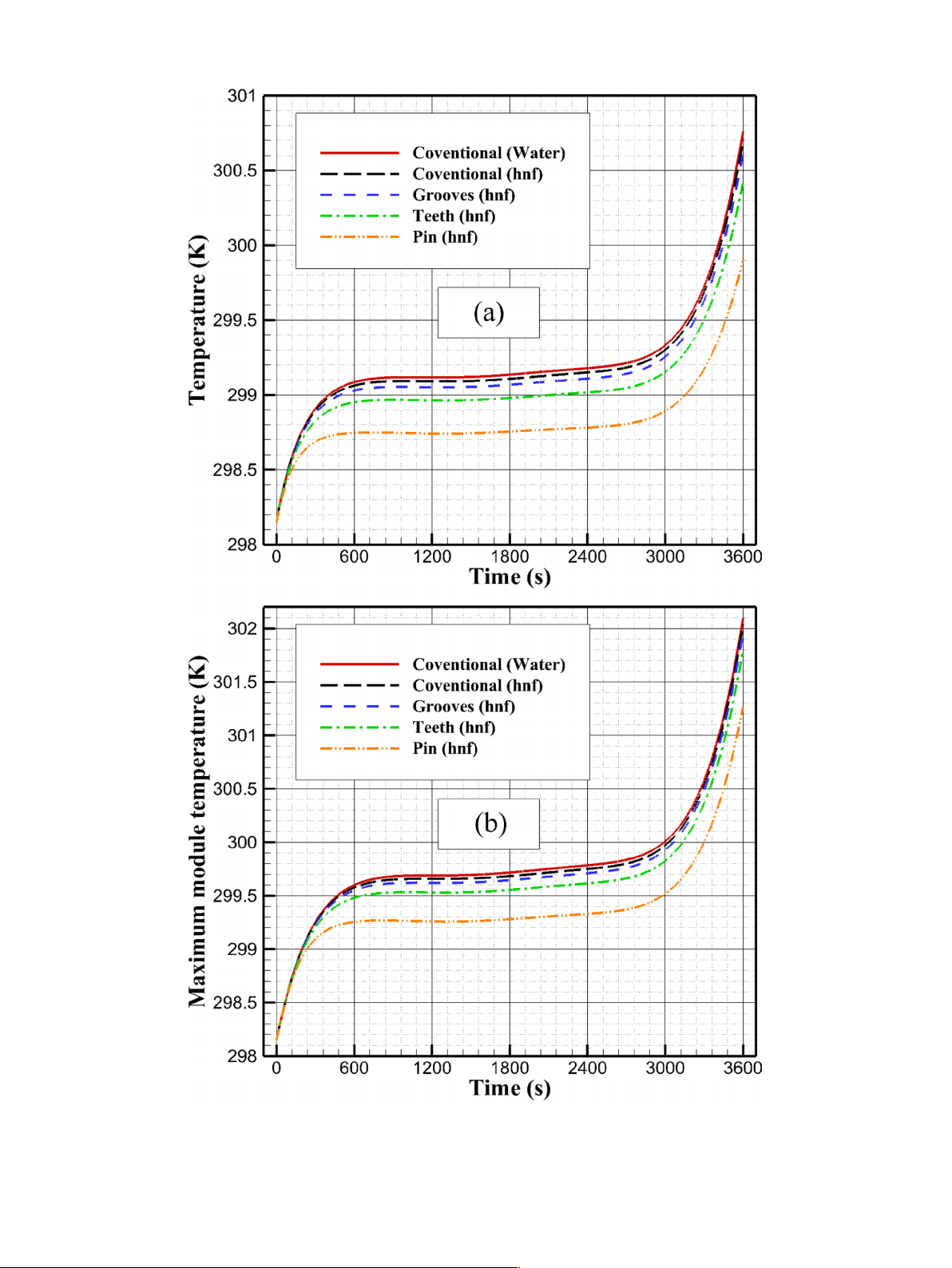

Fig. 9 illustrates the variations in the average value of T for the first

battery (B1) and the Tmax of the module for all the designs studied at 1C

discharge rate. The battery module experienced rapid heating during the

initial phase (the first 150 s), followed by a gradual increase (up to

around 600 s). Between 900 and 1800 s, the alter in the maximum

temperature were minimal, but the rate of temperature increase became

steeper afterward. This behavior can be associated to the heat genera-

tion profile, where the heat generation remains relatively uniform up to

approximately 1500 s. However, after this point, the slope of heat

generation increases. The augment in heat generation rate becomes very

pronounced in the time interval from 2750 s until the end of process. The

obtained Tmax of the cell at the end of process was around 302.1 K for the

base smooth design, while it decreased to approximately 301.2 K with

the pin-fin design. Furthermore, it is observed that all proposed designs

performed superior than the conventional case. The case with cylindri-

cal pins demonstrated good cooling capability. The loading hybrid nano-

powders into the coolant can successfully lower the battery’s tempera-

ture. Additionally, equipping the cooling channels with pin fins further

Fig. 7. Verification of the current code with Liu et al. [30] at 1C for first cell including water cooling.

enhances this cooling effect, resulting in a significant reduction in temperature.

predicted by the model closely matched the outputs reported by Liu

Cells located near the cooling channels benefit from this design by

et al. [30]. Consequently, the model is deemed suitable for further nu-

experiencing a more non-uniform temperature distribution. The

merical testing of the proposed MCP designs. Additionally, in Fig. 8, the

enhanced thermal management provided by hybrid nanoparticles and

friction factor in the fully developed region within a mini-channel is

pin fins ensures a more efficient and safe operation, extending the bat-

compared with the well-known Darcy equation for laminar flow in a

tery’s lifespan and improving its overall performance. Studying the cells

fully developed region (Eq. (20)) over a Reynolds number range of

close to the cold plate channel is important for several reasons, and 8

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Fig. 8. Comparison of the friction factor between present study and Darcy’s expression.

understanding why these cells might experience different temperature

the cooling source. The cooling channels facilitate the direct

behavior compared to other cells is crucial for effective thermal

removal of heat from these cells, resulting in lower temperatures. management.

• Improved Cooling Efficiency: The cooling unit is planned to

The following note should be mentioned about the importance of

manage the temperature of the entire modules, but cells near the

studying cells near cold plate channels:

cold plates benefit more directly from the cooling effect.

• Temperature Gradient: Cells close to the channels are kept cooler

• Temperature Distribution: Cells close to the cold plate channels

due to the direct influence of the cooling system, while cells further

often exhibit different thermal characteristics compared to those

away might not receive as much cooling, resulting in higher

further away. Studying these cells helps in understanding how well temperatures.

the cooling system is distributing thermal energy and identifying any

• Flow Distribution: The configuration of the ducts affects how

potential issues in temperature uniformity.

uniformly the cooling fluid flows through the system. If the flow is

• Heat Dissipation Efficiency: Cells near the cooling channels are

not well-distributed, cells near the channels might be cooler due to

expected to benefit directly from the cooling system. This can help in

direct contact with the cooling fluid, while cells farther away could

optimizing the cooling design for better performance. be less effectively cooled.

• Risk of Localized Hotspots: Even though cells close to the cooling

channels are expected to have lower temperatures, localized hotspots

Therefore, studying the temperature behavior of cells close to the

can still occur if there are issues with the cooling design or uneven

cold plate channels is essential for assessing and optimizing the effi-

flow distribution. Studying these cells helps in identifying and ciency of system. mitigating such risks.

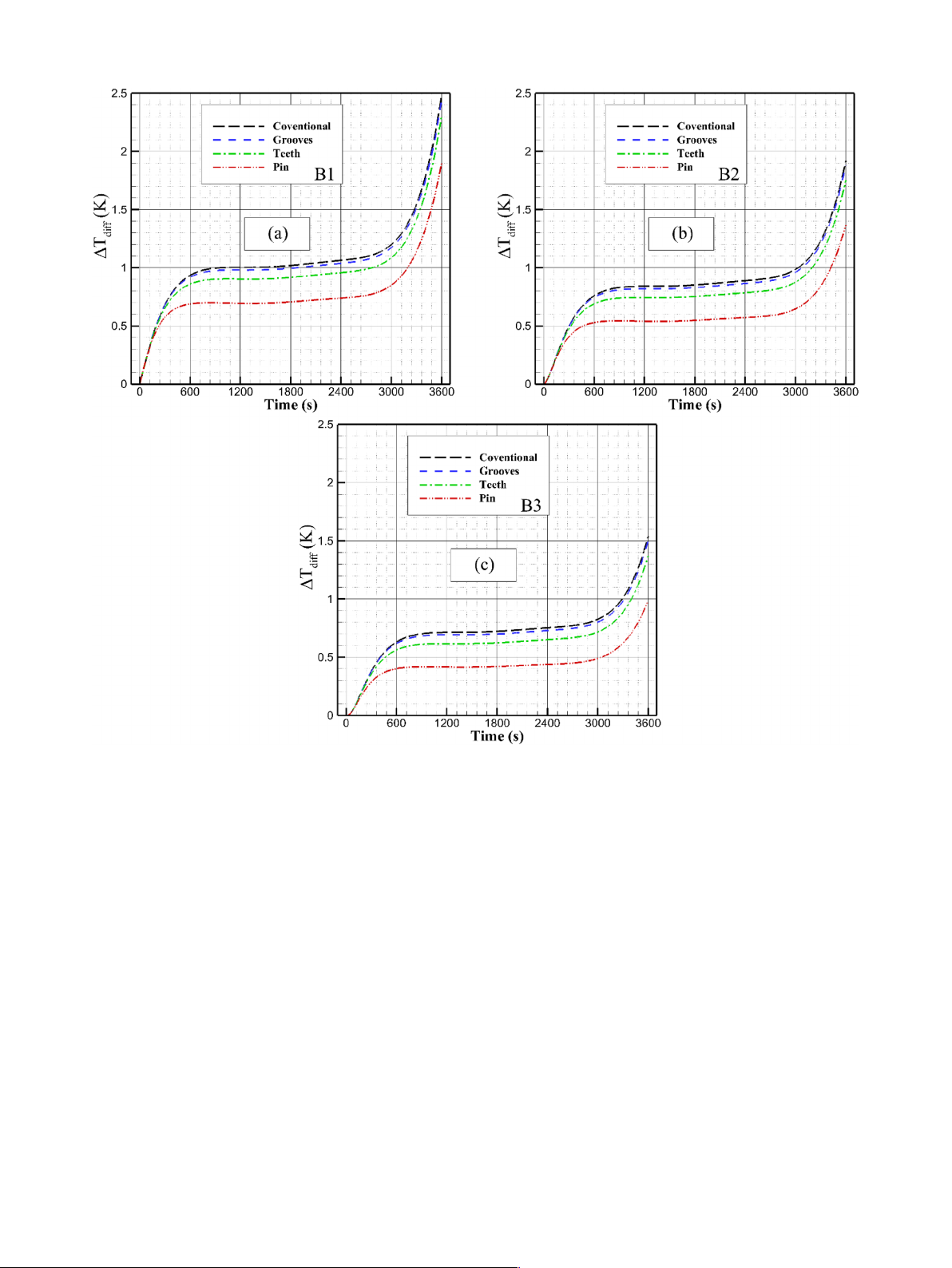

Fig. 10 shows the time-dependent variations of the temperature

• Thermal Management Optimization: Insights gained from study-

difference (ΔTdiff) within cells for the baseline and pin-fin designs

ing these cells can guide improvements in cooling channel design,

studied. ΔTdiffis a crucial parameter indicating the temperature unifor-

flow distribution, and overall thermal management strategies. This

mity within a cell. Publications have indicated that a thermal non-

helps in ensuring that all cells, including those furthest from the

uniformity exceeding 5 K in lithium-ion batteries can reduce their life-

cooling system, maintain uniform and safe operating temperatures.

span [25]. The cell B1, which is closer to cooling plate, experiences

moderately larger thermal non-uniformity than other cells. Further-

Temperature difference for cells near cold plate channels is greater

more, the ΔTdiffin battery B1 is relatively lower in the pin-fin design

than other cells because of following notes:

compared to the case 1. Consequently, in all cases, the side of battery B1

closest to the coolant remains relatively cooler than the other side.

Comparing the pin-fin case with the baseline design shows that better

• Effective Heat Transfer: Cells close to the cold plate channels

mini-channel designs can somewhat mitigate this phenomenon.

experience more effective heat transfer due to their proximity to

Additionally, to better compare the thermal efficiency of the baseline

case with the pin-fin case, the Tave distribution of cells 1, 2, and 3 for 9

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Fig. 9. Temporal variation of (a) Tave of B1,(b) Tmax. 10

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Fig. 10. The amount of (ΔTdiff) for various geometries.

both cases is shown in Fig. 11. It is observed that equipping the rect-

The velocity distribution (as shown in Fig. 12) indicates that the coolant

angular channels with cylindrical pins reduces the temperature of all

flow pattern varies significantly depending on the mini-channel char-

three batteries. Notably, the third battery in the pin-fin case has an

acteristics. For case1, the velocity profile remains uniform along the

average temperature nearly equal to that of the first battery in the

duct, resulting in a (ΔP) of approximately 37.7 Pa. As the boundary layer

baseline case. This indicates that by equipping the mini-channels with

grows along the duct, the maximum velocity increases to maintain flow

cylindrical fins, the number of cooling units required in the battery pack

continuity. For the channels equipped with grooves, the pressure drop can potentially be reduced.

across the coolant is not significantly different from the baseline case. A

Incorporating pin fins into the mini channels of a cold plate signifi-

close examination of the velocity magnitude contours at the groove lo-

cantly enhances cooling efficiency by expanding the effective area and

cations reveals that the mixing of the nanofluid in mentioned design is

promoting fluid flow, which improves convective heat transfer. As a

not principally strong, leading to noticeable transverse velocity gradi-

result, the module can safely operate at higher power densities and

ents. Interestingly, in the case featuring teeth, the flow does not expand

discharge rates without risking excessive heat buildup, thereby

after passing the first row of teeth but continues through a space equal to

extending its lifespan. Efficient cooling minimizes thermal stress on the

the gap between the teeth, resulting in a relatively high ΔP of around

cells, reduces the risk of thermal runaway, and helps maintain consistent

100 Pa. On the other hand, the channel with cylindrical pins creates

performance over time. However, while pin fins improve cooling per-

vortexes which increase mixing rate. The maximum fluid velocity is

formance, they also add complexity and cost to the cooling system and

found near the channel walls, which is approximately twice that of the

can increase fluid flow resistance, which requires careful consideration

baseline and grooved cases. The presence of pins in the flow path leads

to balance the overall benefits.

to a comparatively higher ΔP of around 152 Pa. The swirl the flow en-

In the strategy of effective units, it is vital to consider both thermal

hances the thermal productivity of the pin-fin design compared to other

and hydraulic performance. The previous discussions have thoroughly

cases. This conclusion aligns with earlier discussions where the pin-fin

examined the hydrothermal performance of various configurations. In

case demonstrated superior thermal performance. Additionally, it can

the following paragraphs, the hydraulic performance will be addressed

be noted that the ΔP induced by the presence of pins is greater than that

by focusing on fluid flow features and pressure drop (ΔP) (see Fig. 12).

caused by the teeth on the walls. Fig. 13 illustrates the isotherm over the 11

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Fig. 11. Comparing the temperature of different batteries in two different cases, conventional and equipped with a pin.

Fig. 12. Pressure-velocity contours for the various mini-channel cold plates designs.

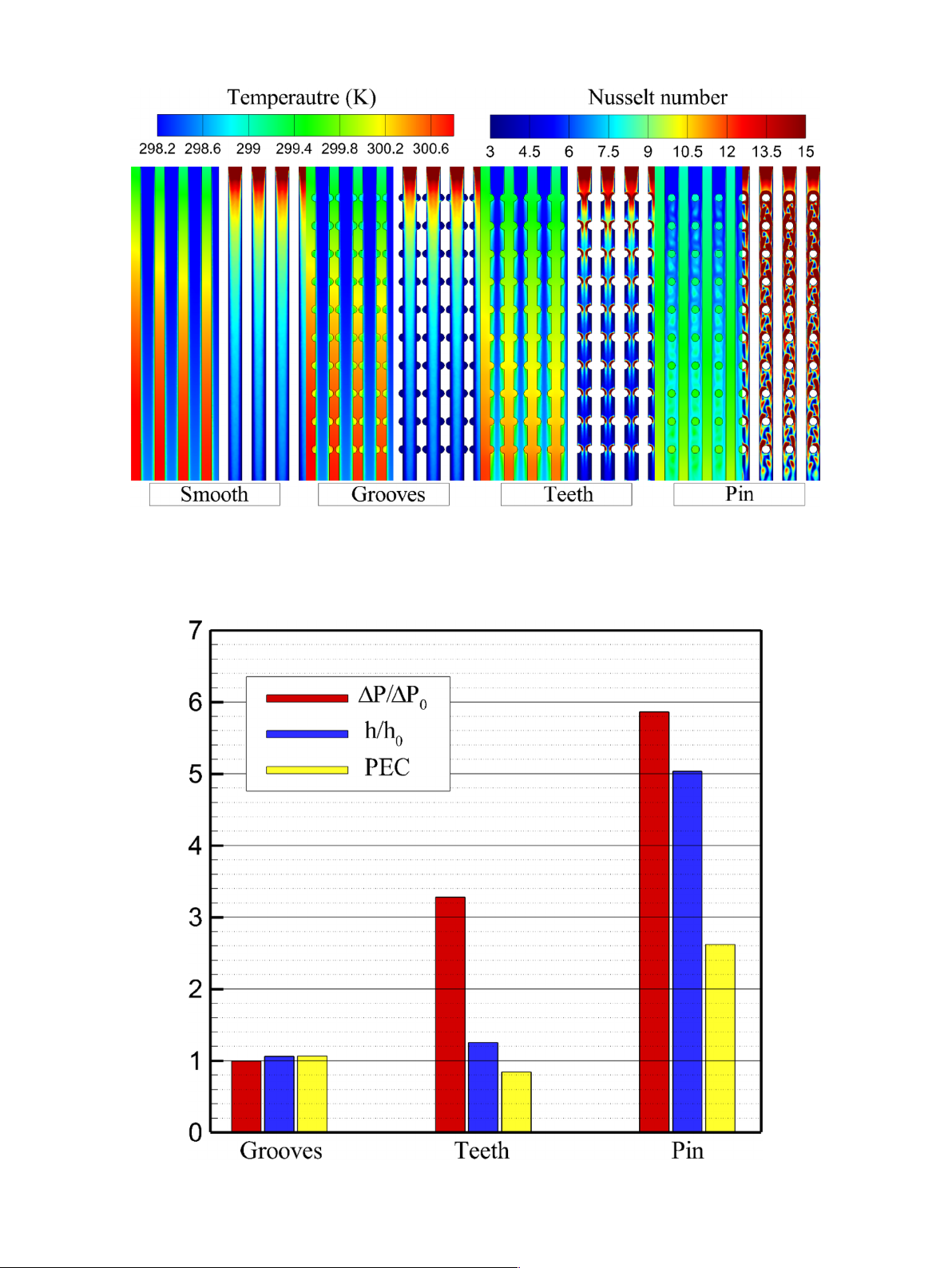

mid-plane and Nusselt number on the bottom of the mini-channels at t =

number contours indicate a great rate of heat transfer near the inlet of

3600s. As observed, the Tmax in the pin-fin case is significantly smaller

the mini-channels across all cases. Additionally, the baseline and

than in the other cases. This can enhance their lifespan. The Nusselt

grooved cases show a similar distribution of the Nu. Near the teeth in the 12

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

Fig. 13. Temperature-Nusselt number contour for different minichannel cold plates designs.

Fig. 14. Comparison of pressure drop ratio, heat transfer coefficient ratio and PEC for different cases when t = 1800s. 13

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074

toothed case, the Nu increases locally. However, in the pin-fin case, the

design. This research emphasizes the importance of optimizing thermal

local Nusselt number remains high throughout the mini-channel sec-

behavior of battery to improve their safety, efficiency, and longevity.

tions, indicating significant mixing of the coolant flow in this configu-

The study effectively validates the productivity of the mini-channel

ration. This enhanced mixing contributes to the superior thermal

plate (MCP) model, demonstrating that its predictions closely align

management performance observed in the pin-fin design. When tran-

with previous research findings. The model accurately simulated the

sitioning from the Smooth case to the Grooves case, the Nusselt number

thermal and electrical behavior of the module during discharging,

(Nu), which measures convective heat transfer efficiency, increases by

particularly in terms of temperature distribution and heat dissipation.

approximately 6.37 %. The value of (ΔP), indicating the resistance to

This accuracy underscores the model’s reliability for simulating dis-

fluid flow, decreases by about 0.25 %. For the Teeth case, the Nu is found

charging of battery. The choice of a computational mesh with 484,278

to be 1.25 times higher than in the case 1, while the ΔP increases

grid cells strikes a balance between simulation precision and computa-

significantly, being 3.27 times greater. This suggests that while the

tional efficiency, ensuring accurate results without excessive computa-

Teeth design enhances heat transfer, it also introduces a substantial

tional cost. One of the critical observations is the temperature non-

resistance to flow, which could lead to higher pumping costs and energy

uniformity within the cells. This non-uniformity arises due to the de-

consumption. In the Pin case, the Nusselt number and pressure drop

gree of coolant heating. Specifically, firs cell B1, being closer to the

both see considerable increases, with Nu being 5.03 times and ΔP being

coolant, experiences more direct cooling, leading to cooler temperatures

5.86 times bigger than those of case 1. This indicates a significant

on the side closest to the coolant compared to the opposite side. Un-

improvement in heat transfer performance, but also a much larger

derstanding the temperature behavior of cells next to the ducts is crucial

pressure drop, reflecting a high degree of flow resistance. The data

for optimizing the thermal management system, as it helps prevent hot

suggest that while the Pin case offers superior cooling performance, it

spots and ensures uniform isotherms. This uniformity is significant for

requires careful consideration of the associated pressure drop to ensure

preventing uneven aging and potential safety issues, thereby extending

efficient operation. Fig. 14 depicts the values of convective coefficient,

the battery pack’s lifespan and enhancing overall performance. The

ΔP, and hydrothermal performance (PEC). As indicated in the figure, the

study reveals that while the toothed design significantly increases the

toothed design, despite having a noteworthy augment in the convective

convective heat transfer coefficient, it also leads to a substantial pressure

coefficient, also experiences a high pressure drop. This results in a PEC

drop, resulting in a PEC value of less than one. This indicates suboptimal

value of less than one, indicating suboptimal performance. In contrast,

performance. In contrast, the grooved and cylindrical pin-fin cases

both the grooved and cylindrical pin-fin cases exhibit PEC values greater

exhibit PEC values greater than one, indicating more efficient thermal

than one, suggesting more efficient thermal management. Considering

management. The pin-fin case, in particular, shows the highest (h/h0)

both thermal and hydraulic performance, the cylindrical pin-fin design

which is 4.73 times superior than that of the grooves case. However, this

was identified as the best option among the studied cases. The base case,

design also experiences the highest pressure drop (ΔP/ΔP0), which is

which utilizes a smooth rectangular channel, serves as the reference for

5.87 times higher than that of the grooves case. The pin-fin design stands

calculating the PEC. In comparison to this base case, the ratio of pressure

out with the highest Nusselt number throughout the mini-channel sec-

drop (ΔP/ΔP0) for the Grooves case is significantly lower than for the

tions, indicating effective coolant mixing and enhanced heat transfer.

other cases, with the Pin case exhibiting the highest ratio. Specifically,

The values of Nu and ΔP for the pin-fin case are 5.03 and 5.86 times

the pressure drop ratio for the Pin case is 5.87 times higher than that for

greater, respectively, than those for the smooth case. The grooved case

the Grooves case. Regarding the ratio of heat transfer coefficients (h/h0),

shows a modest increase in Nu by 6.37 % and a slight decrease in ΔP by

the maximum and minimum values are observed in the Pin and Grooves

0.25 %, compared to case 1. The PEC value for the pin-fin design is 3.1

cases, respectively. The value of (h/h0) for the Pin case is 4.73 times

times greater than the teeth design and 2.64 times greater than the

greater than that for the Grooves case, indicating a substantial

grooved design, making it the best performing option among the studied

augmentation in heat transfer capability with the installing pins. In

cases. The minor swirl and wavy nature of the flow in the pin-fin design

terms of PEC, which balances thermal and hydraulic performance, the

contribute to its superior thermal performance. In conclusion, the

Teeth case performs the worst, with a PEC value of 0.84. This low value

incorporation of hybrid nanoparticles and pin fins into the cooling sys-

indicates that the increased heat transfer does not sufficiently compen-

tem significantly enhances thermal management. The hybrid nano-

sate for the increased flow resistance, resulting in inefficient overall

particles help to reduce the Tave. This combination results in more

performance. Conversely, the Pin case achieves the best PEC value of

uniform isotherms across the cells, diminishing temperature gradients.

2.62, reflecting a strong balance between improved heat transfer and

Consequently, the battery pack can safely operate without excessive

manageable ΔP. The PEC value for the Pin case is 3.1 times higher than

heat buildup, thereby extending its operational life. Efficient cooling

that of the Teeth case and 2.64 times higher than the Grooves case,

reduces thermal stress on the cells, mitigates the risk of thermal

highlighting its superior performance. This analysis underscores the

runaway, and maintains consistent performance over time.

importance of considering both thermal and hydraulic factors when

designing thermal management systems.

CRediT authorship contribution statement 4. Conclusion

M. Sheikholeslami: Writing – review & editing, Writing – original

draft, Validation, Supervision, Software, Conceptualization, Methodol-

In this study, advancements in cooling strategies for lithium-ion

ogy. Z. Esmaeili: Writing – original draft, Visualization, Validation,

battery packs have been explored by investigating various mini-

Software, Investigation, Data curation, Conceptualization. Ladan

channel designs to optimize cooling rates during discharge. The sys-

Momayez: Writing – review & editing, Visualization, Validation,

tem was equipped with cold plates inserted between the modules to

Methodology, Data curation, Conceptualization.

improve thermal management. The temperature distribution has vital

role in extending battery life. Several channel configurations—including

Declaration of competing interest

Smooth, Grooved, Tooth, and Pin Fin—were evaluated with a hybrid

fluid composed of water and nanoparticles (Fe3O4-SWMCT). Through

The authors declare that they have no known competing financial

the application of symmetric boundary conditions and unsteady three-

interests or personal relationships that could have appeared to influence

dimensional simulations using ANSYS FLUENT, dynamic heat dissipa-

the work reported in this paper.

tion during discharge was accurately captured. Insights into tempera-

ture distribution, hydrothermal performance, and flow characteristics

were obtained, leading to the identification of the most effective cooling 14

M. Sheikholeslami et al.

Journal of the Taiwan Institute of Chemical Engineers 171 (2025) 106074 Supplementary materials

[20] Mo X, Zhi H, Xiao Y, Hua H, He L. Topology optimization of cooling plates for

battery thermal management. Int J Heat Mass Transf 2021;178:121612. https://

Supplementary material associated with this article can be found, in

doi.org/10.1016/j.ijheatmasstransfer.2021.121612.

[21] Angani A, Kim HW, Hwang MH, Kim E, Kim KM, Cha HR. A comparison between

the online version, at doi:10.1016/j.jtice.2025.106074.

Zig-Zag plated hybrid parallel pipe and liquid cooling battery thermal management

systems for lithium-ion battery module. Appl Therm Eng 2023 25;219:119599. References

https://doi.org/10.1016/j.applthermaleng.2022.119599.

[22] Gungor S, Cetkin E, Lorente S. Canopy-to-canopy liquid cooling for the thermal

management of lithium-ion batteries, a constructal approach. Int J Heat Mass

[1] Xu Z, Xu J, Guo Z, Wang H, Sun Z, Mei X. Design and optimization of a novel

Transf 2022;182:121918. https://doi.org/10.1016/j.

microchannel battery thermal management system based on digital twin. Energies

ijheatmasstransfer.2021.121918.

2022;15(4):1421. https://doi.org/10.3390/en15041421.

[23] Sheng L, Su L, Zhang H, Li K, Fang Y, Ye W, Fang Y. Numerical investigation on a

[2] Feng X, Zheng S, Ren D, He X, Wang L, Cui H, Liu X, Jin C, Zhang F, Xu C, Hsu H.

lithium ion battery thermal management utilizing a serpentine-channel liquid

Investigating the thermal runaway mechanisms of lithium-ion batteries based on

cooling plate exchanger. Int J Heat Mass Transf 2019;141:658–68. https://doi.org/

thermal analysis database. Appl Energy 2019;246:53–64. https://doi.org/10.1016/

10.1016/j.ijheatmasstransfer.2019.07.033. j.apenergy.2019.04.009.

[24] Liu Z, Xu G, Xia Y, Tian S. Numerical study of thermal management of pouch

[3] Chen J, Kang S, Jiaqiang E, Huang Z, Wei K, Zhang B, Zhu H, Deng Y, Zhang F,

lithium-ion battery based on composite liquid-cooled phase change materials with

Liao G. Effects of different phase change material thermal management strategies

honeycomb structure. J Energy Storage 2023;70:108001. https://doi.org/

on the cooling performance of the power lithium ion batteries: a review. J Power 10.1016/j.est.2023.108001.

Sources 2019;442:227228. https://doi.org/10.1016/j.jpowsour.2019.227228.

[25] Amalesh T, Narasimhan NL. Introducing new designs of minichannel cold plates for

[4] Zheng C. Examining the benefits of using boron compounds in lithium batteries: a

the cooling of Lithium-ion batteries. J Power Sources 2020;479:228775. https://

comprehensive review of literature. Batteries 2022;8(10):187. https://doi.org/

doi.org/10.1016/j.jpowsour.2020.228775. 10.3390/batteries8100187.

[26] Sarchami A, Tousi M, Kiani M, Arshadi Amir, Najafi M, Darab M, Houshfar Ehsan.

[5] Bandhauer TM, Garimella S, Fuller TF. A critical review of thermal issues in

A novel nanofluid cooling system for modular lithium-ion battery thermal

lithium-ion batteries. J Electrochem Soc 2011;158(3):R1. https://doi.org/

management based on wavy/stair channels. Int J Thermal Sci 2022;182:107823. 10.1149/1.3515880.

https://doi.org/10.1016/j.ijthermalsci.2022.107823.

[6] Lin X, Kerler M, Birke KP, Lienkamp M. Optimal battery cell design for electric

[27] Rana Suraj, Kumar Rajan. Rabinder Singh Bharj, current trends, challenges, and

vehicles–A holistic method with consideration of ageing due to electrothermal

prospects in material advances for improving the overall safety of lithium-ion

gradients. In: 2019 8th International Conference on Power Science and Engineering

battery pack. Chem Eng J 2023;463:142336. https://doi.org/10.1016/j.

(ICPSE). IEEE; 2019. p. 55–62. https://doi.org/10.1109/ cej.2023.142336. ICPSE49633.2019.9041061.

[28] Esmaeili Z, Khoshvaght-Aliabadi M. Thermal management and temperature

[7] Li Q, Yang C, Santhanagopalan S, Smith K, Lamb J, Steele LA, Torres-Castro L.

uniformity enhancement of cylindrical lithium-ion battery pack based on liquid

Numerical investigation of thermal runaway mitigation through a passive thermal

cooling equipped with twisted tapes. J Taiwan Inst Chem Eng July 2023;148:

management system. J Power Sources 2019;429:80–8. https://doi.org/10.1016/j.

104671. https://doi.org/10.1016/j.jtice.2023.104671. jpowsour.2019.04.091.

[29] Sadeh M, Tousi M, Sarchami A, Sanaie R, Kiani M, Ashjaee M, Houshfar E. A novel

[8] Xu J, Mei X, Wang H, Wang J. A hybrid self-heating method for batteries used at

hybrid liquid-cooled battery thermal management system for electric vehicles in

low temperature. IEEE Trans Industr Inform 2020;17(7):4714–23. https://doi.org/

highway fuel-economy condition. J Energy Storage 2024;86(Part A):111195. 10.1109/TII.2020.3020302.

https://doi.org/10.1016/j.est.2024.111195.

[9] Xie Y, Li B, Hu X, Lin X, Zhang Y, Zheng J. Improving the air-cooling performance

[30] Liu H, Chika E, Zhao J. Investigation into the effectiveness of nanofluids on the

for battery packs via electrothermal modeling and particle swarm optimization.

mini-channel thermal management for high power lithium ion battery. Appl Therm

IEEE Trans Transp Electrif 2020;7(3):1285–302. https://doi.org/10.1109/

Eng 2018;142:511–23. https://doi.org/10.1016/j.applthermaleng.2018.07.037. TTE.2020.3046735.

[31] Saba F, Ahmed N, Khan U, Mohyud-Din ST. A novel coupling of (CNT-Fe3O4/H2O)

[10] Chung Y, Kim MS. Thermal analysis and pack level design of battery thermal

hybrid nanofluid for improvements in heat transfer for flow in an asymmetric

management system with liquid cooling for electric vehicles. Energy Convers

channel with dilating/squeezing walls. Int J Heat Mass Transf 2019;136:186–95.

Manag 2019;196:105–16. https://doi.org/10.1016/j.enconman.2019.05.083.

https://doi.org/10.1016/j.ijheatmasstransfer.2019.02.097.

[11] Satyanarayana G, Sudhakar DR, Goud VM, Ramesh J, Pathanjali GA. Experimental

[32] Azmi WH, Sharma KV, Mamat R, Alias AB, Misnon II. Correlations for thermal

investigation and comparative analysis of immersion cooling of lithium-ion

conductivity and viscosity of water based nanofluids. In: IOP Conference Series:

batteries using mineral and therminol oil. Appl Therm Eng 2023;225:120187.

Materials Science and Engineering. 36. IOP Publishing; 2012, 012029. https://doi.

https://doi.org/10.1016/j.applthermaleng.2023.120187.

org/10.1088/1757-899X/36/1/012029.

[12] Chen K, Chen Y, Song M, Wang S. Multi-parameter structure design of parallel

[33] Tao L. Study on thermal effects of lithium-ion battery in electric vehicle and

mini-channel cold plate for battery thermal management. Int J Energy Res 2020;44

battery package dissipation structural optimization. Chongqing University; 2013.

(6):4321–34. https://doi.org/10.1002/er.5200. p. 13–47.

[13] Dubey P, Pulugundla G, Srouji AK. Direct comparison of immersion and cold-plate

[34] Gupta AK, Gupta B, Bhalavi J, Baredar P, Parmar H, Senthil R. CFD study on heat

based cooling for automotive Li-ion battery modules. Energies 2021;14(5):1259.

transfer and pressure drop of nanofluids (SiO2/H2O, Al2O3/H2O, CNTs/H2O) in a

https://doi.org/10.3390/en14051259.

concentric tube heat exchanger. Int J Ambient Energy 2022;43(1):4578–93.

[14] Ding Y, Wei M, Liu R. Channel parameters for the temperature distribution of a

https://doi.org/10.1080/01430750.2021.1913222.

battery thermal management system with liquid cooling. Appl Therm Eng 2021;

[35] Susa D, Lehtonen M, Nordman H. Dynamic thermal modelling of power

186:116494. https://doi.org/10.1016/j.applthermaleng.2020.116494.

transformers. IEEE Trans Power Del 2005;20(1):197–204. https://doi.org/

[15] Zhu Z, Wu X, Zhang H, Guo Y, Wu G. Multi-objective optimization of a liquid 10.1109/TPWRD.2004.835255.

cooled battery module with collaborative heat dissipation in both axial and radial

[36] Xiao H, Jiaqiang E, Tian S, Huang Y, Song X. Effect of composite cooling strategy

directions. Int J Heat Mass Transf 2020;155:119701. https://doi.org/10.1016/j.

including phase change material and liquid cooling on the thermal safety

ijheatmasstransfer.2020.119701.

performance of a lithium-ion battery pack under thermal runaway propagation.

[16] Guo R, Li L. Heat dissipation analysis and optimization of lithium-ion batteries

Energy 2024;295:131093. https://doi.org/10.1016/j.energy.2024.131093.

with a novel parallel-spiral serpentine channel liquid cooling plate. Int J Heat Mass

[37] Bergman TL, Lavine AS, Incropera FP, DeWitt DP. Introduction to heat transfer.

Transf 2022;189:122706. https://doi.org/10.1016/j. John Wiley & Sons; 2011.

ijheatmasstransfer.2022.122706.

[38] Duffie JA, Beckman WA. Solar engineering of thermal process, 2. A Wiley-

[17] Jiang Y, Smaisim GF, Mahmoud MZ, Li Z, Aybar HS¸, Abed AM. Simultaneous

Interscience Publicaytion, Estados Unidos da Am´erica; 2013 Apr. https://doi.org/

numerical investigation of the passive use of phase-change materials and the active 10.1002/9781118671603.

use of a nanofluid inside a rectangular duct in the thermal management of lithium-

[39] Fuqiang W, Zhexiang T, Xiangtao G, Jianyu T, Huaizhi H, Bingxi L. Heat transfer

ion batteries. J Power Sources 2022;541:231610. https://doi.org/10.1016/j.

performance enhancement and thermal strain restrain of tube receiver for jpowsour.2022.231610.

parabolic trough solar collector by using asymmetric outward convex corrugated

[18] Subhedar D, Chauhan KV, Panchal S, Bais A. Numerical investigation of

tube. Energy 2016;114:275–92. https://doi.org/10.1016/j.energy.2016.08.013.

performance for liquid-cooled cylindrical electrical vehicle battery pack using

[40] Avci AT, Karagoz I. A new explicit friction factor formula for laminar, transition

Al2O3/EG-water nano coolant. In: Materials Today: Proceedings; 2023. https://doi.

and turbulent flows in smooth and rough pipes. Eur J Mech B/Fluids 2019;78:

org/10.1016/j.matpr.2023.08.055.

182–7. https://doi.org/10.1016/j.euromechflu.2019.07.007.

[19] Xu J, Lan C, Qiao Y, Ma Y. Prevent thermal runaway of lithium-ion batteries with

minichannel cooling. Appl Therm Eng 2017;110:883–90. https://doi.org/10.1016/ j.applthermaleng.2016.08.151. 15

Document Outline

- Numerical analysis of lithium-ion battery performance with new mini-channel configurations implementing hybrid nanofluid

- 1 Introduction

- 2 Modeling of battery pack in existence of mini-channel with hybrid nanofluid

- 2.1 Presentation of design

- 2.2 Modeling the battery components

- 2.3 Modeling fluid flow within the mini-channel

- 2.4 Deriving the heat generation source term in battery pack

- 2.5 Applied assumptions in modeling

- 2.6 Formulation for properties of hybrid nanofluid

- 2.7 The definition of important factors

- 2.8 The utilized initial and boundary condition for modeling

- 3 Results and discussion

- 4 Conclusion

- CRediT authorship contribution statement

- Declaration of competing interest

- Supplementary materials

- References