Preview text:

lOMoAR cPSD| 58950985

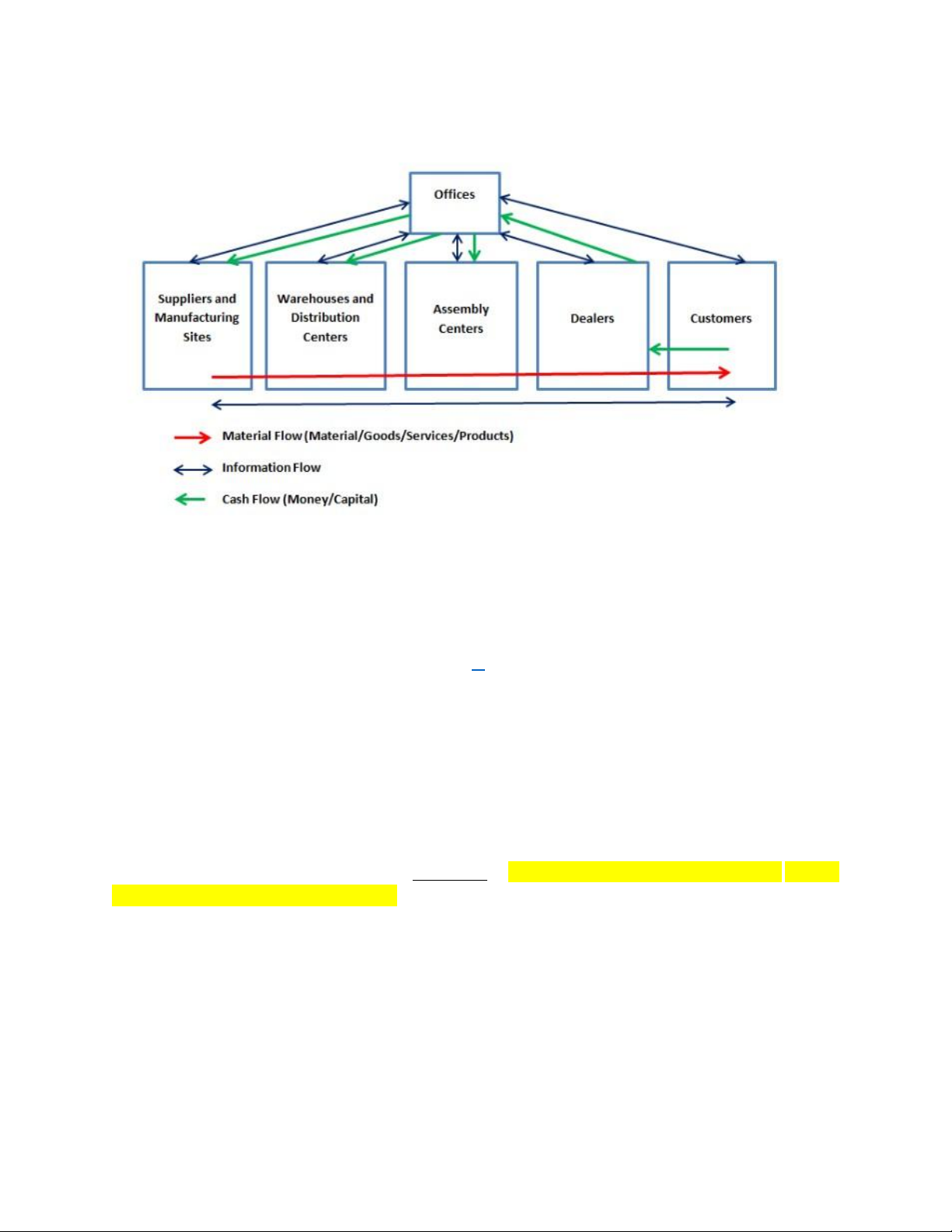

Mô hình tổng quan về ccu của FORD?

Raw materials and parts are delivered from suppliers to warehouses. From there, they are sent to

assembly centers for vehicle production. Once assembled, vehicles are distributed to dealers, who then sell them to customers.

Còn check lại 2022 (khả năng vẫn là thế này vì) 1. Planning Process

Ford’s supply chain planning is supported by advanced digital tools that enhance production flexibility.

Ford has announced a plan to invest a total of $29 billion globally in the stage of 5 years (2021 to 2025).

The goal of this investment is to strengthen Ford's competitiveness in the global electric and autonomous

vehicle market. Part of this strategy focused on expanding Ford's presence in China, establishing it as a key

market alongside EU and the United States.

The company utilizes tools like Teradata and Planisware to support collaborative planning between product

developers and manufacturing engineers. These software tools allow Ford to manage complex assembly

lines that can accommodate multiple vehicle models, improving flexibility and reducing costs. For instance,

Ford can quickly adapt its assembly lines to incorporate new production needs, such as adding a battery

insertion station for electric vehicle production. This capability is essential in maintaining production

efficiency as the company expands its lineup of electric vehicles.

R&D: Ford’s decentralized Research and Development (R&D) structure involves spreading R&D activities

across multiple locations, allowing various teams to innovate and collaborate based on regional and global

needs. Decentralized R&D allows Ford to tailor innovations to different regional markets. This flexibility lOMoAR cPSD| 58950985

is crucial because automotive needs can vary based on geography, consumer preferences, regulations, and

infrastructure. For instance, fuel efficiency technologies may be more prominent in Europe, while electric

vehicle (EV) development could be a priority in markets like North America and China.

The decentralized approach fosters collaboration across various teams with specialized knowledge.

Engineers and designers working on specific technologies can quickly exchange information and innovate

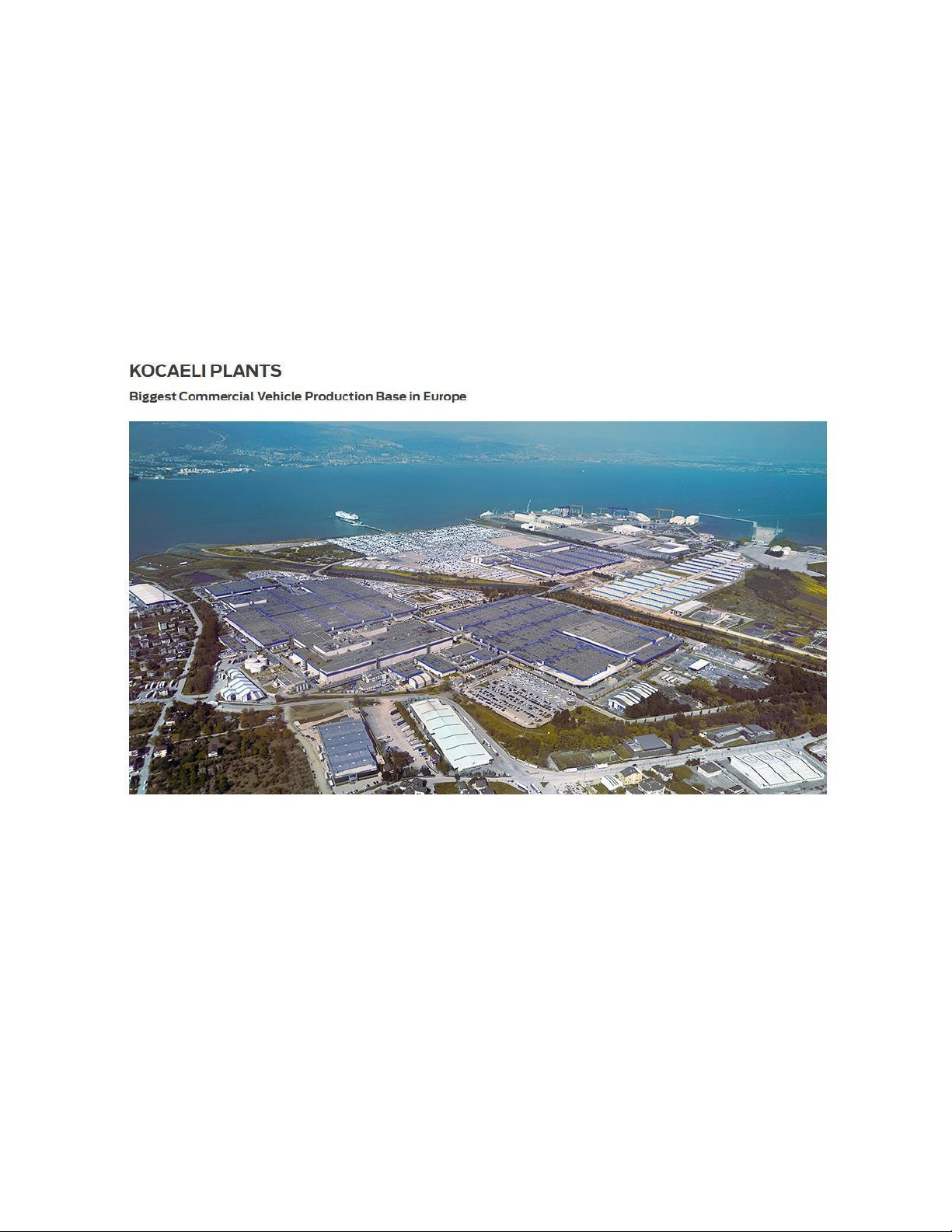

without being constrained by a centralized structure. Ford Otosan Golcuk Plant, Turkey lOMoAR cPSD| 58950985 CRAIOVA PLANT , Romania Atlanta R&D Center lOMoAR cPSD| 58950985

Ford's decentralized R&D model, the company uses a combination of both in-house teams and

outsourced partnerships.

- Ford’s in-house teams are instrumental in driving long-term innovations and creating

foundational technologies that support its global product lines. By centralizing some areas

of expertise, Ford ensures consistency and alignment with their strategic vision across the organization.

- While Ford relies on its internal teams for many R&D activities, it also outsources certain

functions and forms partnerships with external entities to access specialized skills, new

technologies, or faster innovation cycles. Examples include:

Tech companies and startups: Ford partners with technology firms, especially in the fields

of artificial intelligence (AI), machine learning, and advanced software. For instance, Ford

has collaborated with companies like Google for AI integration and Argo AI for

autonomous driving technology. 2. Purchasing lOMoAR cPSD| 58950985

Ford’s supply chain can be characterized as a multitier supplier network where thousands of suppliers

provide raw materials and parts of vehicles, as well as services and resources. Currently, Ford Motor

Company cooperates with about 1,500 Tier 1 suppliers that produce the most important vehicle parts.

These suppliers are located in more than 60 countries, where over 4,000 sites are involved in the

production processes (Ford Motor Company, 2017a; Ford Motor Company, 2017b). There are 10 tiers of

suppliers that provide vehicle components and raw materials.

Tier 1: direct suppliers to Ford and supply the major vehicle components such as engines, transmissions,

and advanced systems that are integral to vehicle assembly (close and strategic partnership with Ford,

often providing high-quality and complex parts that are essential to the finished product) using

frameworks like the Aligned Business Framework (ABF), which helps ensure that sustainability and

business conduct are aligned across the supply chain

Tier 2 Suppliers provide subcomponents or raw materials to the Tier 1 suppliers. For instance, if Tier 1 is

providing engine systems, Tier 2 might be responsible for providing components like sensors, fuel injectors,

or raw materials like steel or aluminum that are essential to building the final product.

Tier 3 Suppliers might be responsible for even more basic components or materials such as metals,

plastics, or electronics that are used by Tier 2 suppliers. In some cases, Tier 3 could be involved in providing

raw materials like specific types of plastic that are then molded into smaller components by Tier 2 suppliers.

Tier 4 and Below can be further down the supply chain, providing basic raw materials such as chemicals,

metals, or even energy, which are crucial for the manufacturing of products in higher tiers.

- => There is a flow of parts and materials between these tiers. Tier 1 suppliers receive their key

components from lower tiers (Tier 2, Tier 3, etc.), integrate them into larger, more complex

systems, and then deliver those systems to Ford.

Essentially, Tier 1 suppliers are integrators that take parts or materials from lower tiers and

assemble them into the final product that Ford uses in its vehicle production. lOMoAR cPSD| 58950985

- Searching and selecting suppliers: It is important to find suppliers with strategic locations

that are convenient for assembly plants.

- Maintaining effectiveness and flexibility: Ensuring the balance of efficiency and flexibility

in both mass production and mass customization models.

Ford Vietnam has implemented a strategy of assembling the Ranger pickup truck at the

Hai Duong plant to optimize efficiency and flexibility in production, also established a

network of material and auto parts suppliers throughout the country to ensure product

and service quality. These suppliers are often located near assembly plants and

Fordauthorized dealerships, making it easier to provide and service vehicles. (Dana Ford –

Da Nang, Binh Duong Ford – Binh Duong

- Restraint criterias of choosing suppliers:

+ Quality Assurance: Suppliers must adhere to Ford's rigorous quality standards, demonstrating a

commitment to delivering products that meet or exceed specifications.

This includes compliance with recognized quality management systems such as ISO/TS 16949 +

Collaboration and Continuous Improvement: Ford seeks suppliers willing to collaborate on

product development and continuous improvement initiatives. Participation in industry

standards and guidelines, such as those provided by the Automotive Industry Action Group (AIAG), is encouraged

+ Besides, they evaluate suppliers based on their ability to manage risks, ensure timely deliveries,

and maintain financial and operational stability, which are followed by Ethical & Legal

Compliance, Environmental Responsibility, and Human Rights and Labor Practices

Programs and initiatives to identify and develop suppliers: Widening the Inclusion Network (WIN)

program (in 2020, focused on increasing Tier 2 suppliers), MentorWE( woman program), and some others 3. Operations lOMoAR cPSD| 58950985

Autonomous assembly line:

Ford uses technology from a startup called Symbio Robotics that looks at the past few hundred attempts

to determine which approaches and motions appeared to work best. A computer sitting just outside the

cage shows Symbio’s technology sensing and controlling the arms. Toyota and Nissan are using the same

tech to improve the efficiency of their production lines.

This technology allows this part of the assembly line to run 15 percent faster, a significant improvement in

automotive manufacturing where thin profit margins depend heavily on manufacturing efficiencies.

-> Improvement in Product Quality

Error Reduction in Manufacturing: The use of robots and AI systems helps reduce errors and

improve product quality. At Ford's Super Duty plant, the installation of vision-guided robots has

improved both quality and efficiency in handling large metal parts, reducing costs and increasing accuracy.

Labor Cost Savings and Increased Productivity: The implementation of autonomous

assembly lines has helped Ford reduce labor costs and increase productivity. Specifically,

the use of robots and automation systems has helped lower production costs and increase

efficiency, while reducing dependence on manual labor.

Ford’s Lean Manufacturing:

Concept: Lean manufacturing is a systematic, continuous improvement method focused

on adding value for customers while eliminating waste in the production process or service

delivery within an organization. This approach helps reduce costs (increase profits),

optimize resource usage, shorten production/service delivery times, and increase

flexibility in responding to the ever-changing, increasingly stringent customer requirements. lOMoAR cPSD| 58950985 Benefits:

Improves productivity and quality (Ford improved its assembly productivity by

36% since 1980 through the implementation of Lean Manufacturing principles. )

Shortens production times and service delivery cycles ( At Daman Products, the

adoption of Lean Manufacturing led to a 97% reduction in cycle times, a 50% reduction

in setup times, and a 90% reduction in flow distance.)

Minimizes both tangible and intangible waste due to inventory

Enhances the efficiency of equipment and facility utilization Increases responsiveness

Lean manufacturing brings efficiency to the supply chain by avoiding bottlenecks. The

principles of Lean aim to make the production process as efficient as possible. It focuses on

improving product quality and costs by removing waste from the production process and

the value chain. Ford learned this approach from Toyota. Flexibility:

Mass Production Features:

Mass production is characterized by the standardization of products, where items

are produced in large volumes with minimal customization. It emphasizes

efficiency through automation, reducing labor costs, increasing productivity and

cost reduction rather than personalized preferences.

Mass Customization Features:

Mass customization allows for a wide variety of personalized products, offering

customers the opportunity to tailor items to their preferences, which adapt

efficiently to diverse demands without compromising productivity. The approach

aims to keep costs similar to mass production by leveraging flexible manufacturing

systems. Additionally, customers are more involved in the design or selection

process, resulting in a product that better meets individual needs. lOMoAR cPSD| 58950985 4. Logistics Logistics: lOMoAR cPSD| 58950985 Xuôi:

Inbound Supply Chain (Left side of the diagram):

1. 1st Tier Suppliers:

The process begins with the first-tier suppliers, who provide parts and materials

that are directly used in the production of vehicles.The materials and parts from

the suppliers are then delivered to the inbound distribution centers. These centers

serve as storage hubs before the parts are moved to the assembly plants. Then,

the parts from the distribution centers are sent to the assembly plants, where they

are used to manufacture the final products (vehicles). This stage involves the core

activity of assembling the components into finished vehicles.

The inbound supply chain focuses on the flow of raw materials and components, ensuring

that assembly plants are supplied with the right materials in a timely manner.

(first-tier supplier provide parts and materials -> delivered to the inbound distribution

centers (storage hubs) -> sent parts to assembly plants, where final products are manufactured lOMoAR cPSD| 58950985

* This stage involves the core activity of assembling the components into finished vehicles.

Outbound Supply Chain (Right side of the diagram):

1. Outbound Distribution Centres:

After assembly, finished vehicles are sent to the outbound distribution

centers. These centers act as holding areas for the cars before they are

shipped to dealers or directly to customers.

Finally, the vehicles are sent to car dealers, who serve as the point of

contact for the customers (buyers). Dealers sell the cars to customers,

completing the outbound supply chain.

The outbound supply chain focuses on the distribution of finished products from

assembly plants to the final customers, ensuring timely delivery to car dealers and, ultimately, to end consumers.

Finished vehicles -> outbound distribution centers (holding areas, wait to be shipped to

dealers or directly to customers) -> sent to car dealers (customers), completing the outbound supply chain Logistics management

Ford Motor Company is focusing on using warehouses that are the property of third-party providers

because of the necessity to utilize large spaces associated with warehousing facilities in more than 60

countries (Ford Motor Company, 2017a). Therefore, warehouses, which are used by the company for

storing its products, are usually leased under certain service contracts (Ford Motor Company, 2017a; Ford

Motor Company, 2017b). Still, it is also important to note that Ford’s plants and assembly centers that are

owned by the company have additional warehousing space to store the limited number of products and components.

RTLS: In its manufacturing facilities, Ford employs RTLS technology to enhance efficiency and precision. lOMoAR cPSD| 58950985

For example, Ford has implemented RFID-based Just-In-Time (JIT) delivery systems to streamline parts

delivery to its manufacturing plants. This system ensures that parts arrive within hours of being needed,

optimizing inventory management and production timelines.

WMS: Ford Motor Company utilizes Warehouse Management Systems (WMS) to enhance the efficiency

of its supply chain and distribution operations. These systems automate and optimize various warehouse

processes, including inventory management, order fulfillment, and parts distribution.

JIT: Ford often uses a “just-in-time” inventory system. This means they get parts from suppliers exactly

when they need them. It helps reduce storage costs and ensures fresh components for assembly. Ngược:

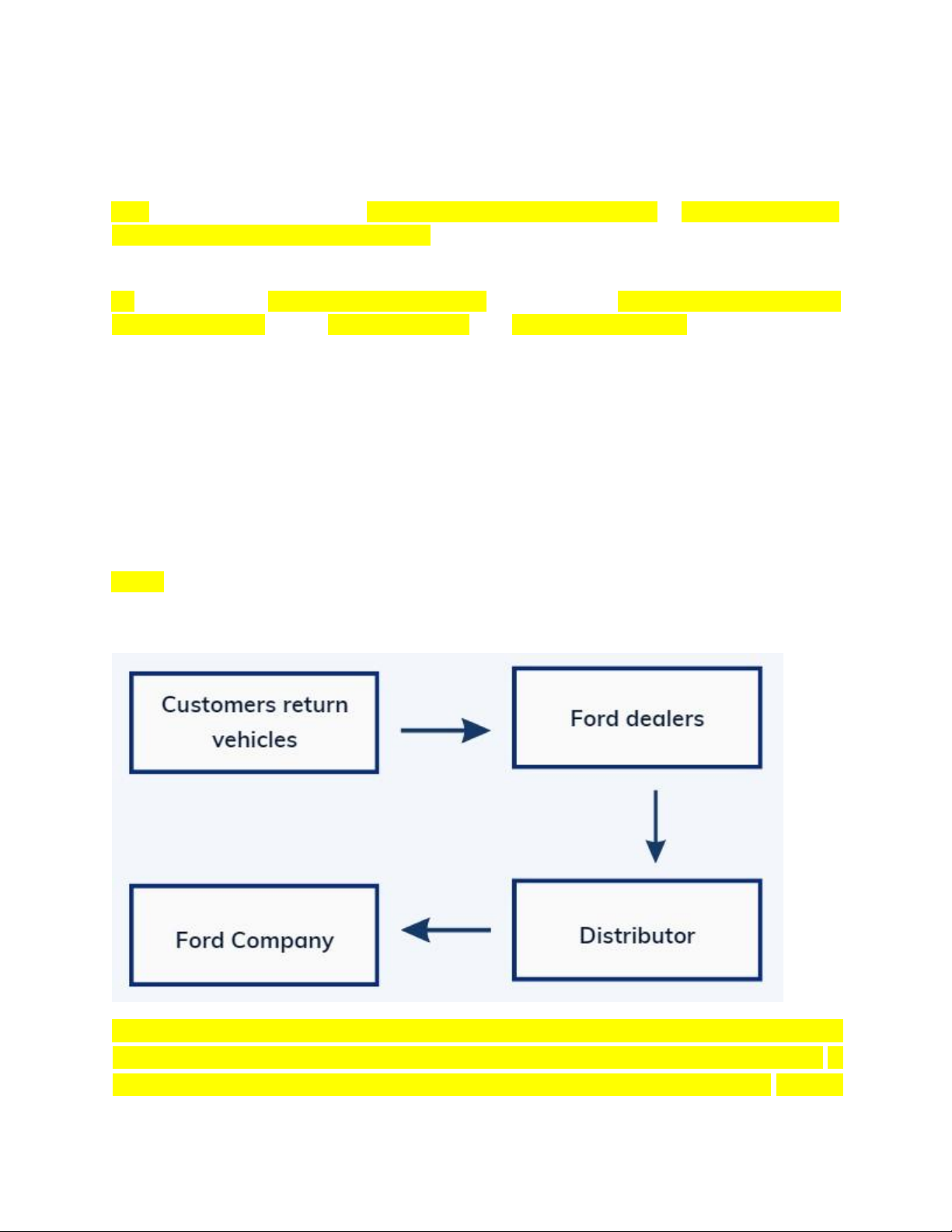

Ford's reverse logistics process begins when customers return vehicles due to defects,

dissatisfaction, or recalls. The returned cars are sent to Ford dealers, where they are inspected to

determine if they need repair, reselling, or recycling. Ford then evaluates the returned products lOMoAR cPSD| 58950985

and decides whether to repair, refurbish, or recycle them. If the vehicle is suitable for resale, it is

sent to a distribution center for further processing; if not, it may be dismantled or recycled. 5. Distribution -

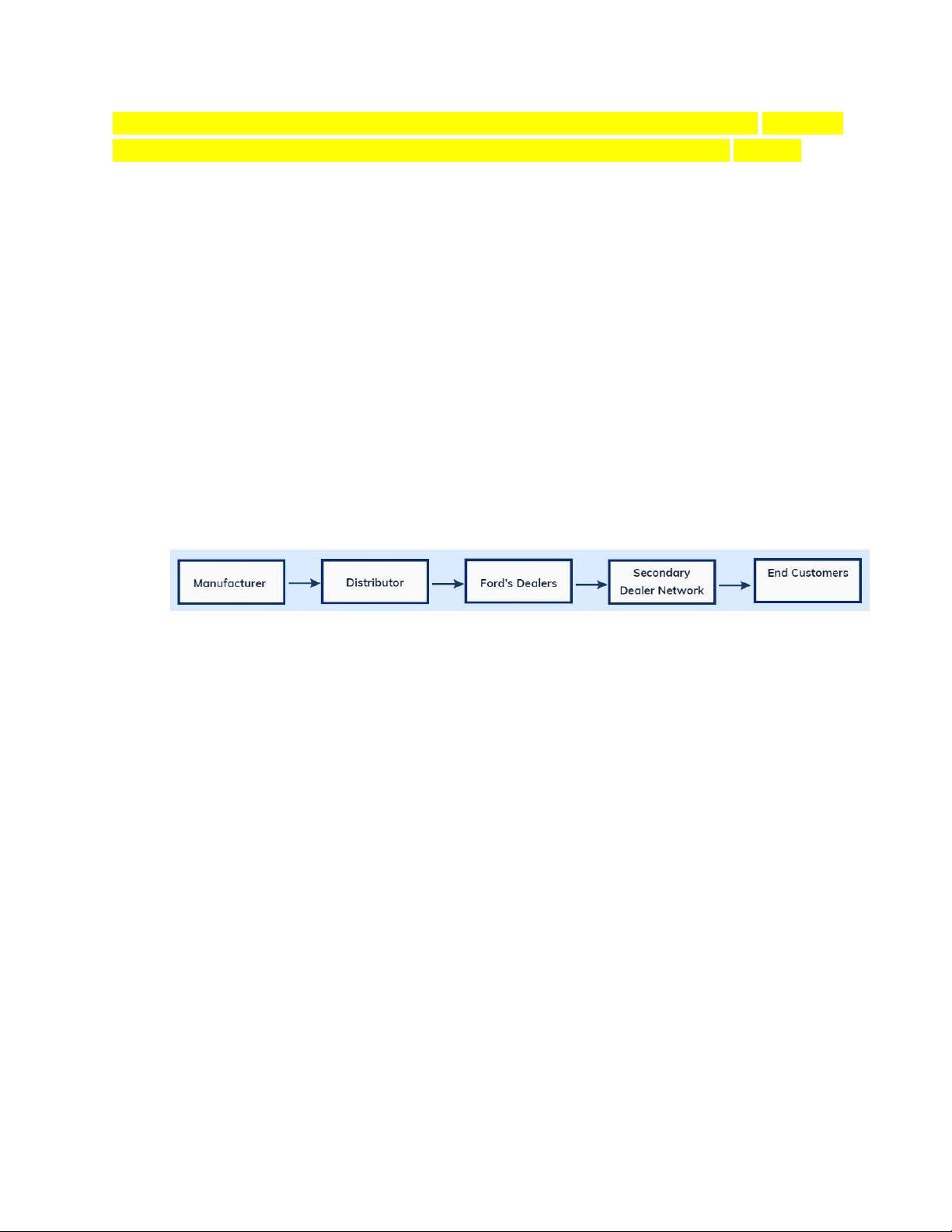

The Ford distribution process begins at the manufacturing plant, where vehicles are produced.

After production, the vehicles are sent to the distribution center, which acts as a hub for

distributing vehicles to various authorized dealers or regional distribution points - which serve as

the direct intermediary between Ford and the customers. These dealerships are responsible for

marketing the vehicles, managing customer relationships, and offering after-sales services. In

addition to the primary dealership network, Ford also relies on a secondary dealer network,

which includes smaller dealers or agents who have agreements to sell Ford products but are not

directly owned by the company. This secondary network helps expand Ford's reach, especially in

less accessible areas. Ultimately, the process culminates with end customers, who purchase the

vehicles through the dealership network, completing the distribution journey. lOMoAR cPSD| 58950985

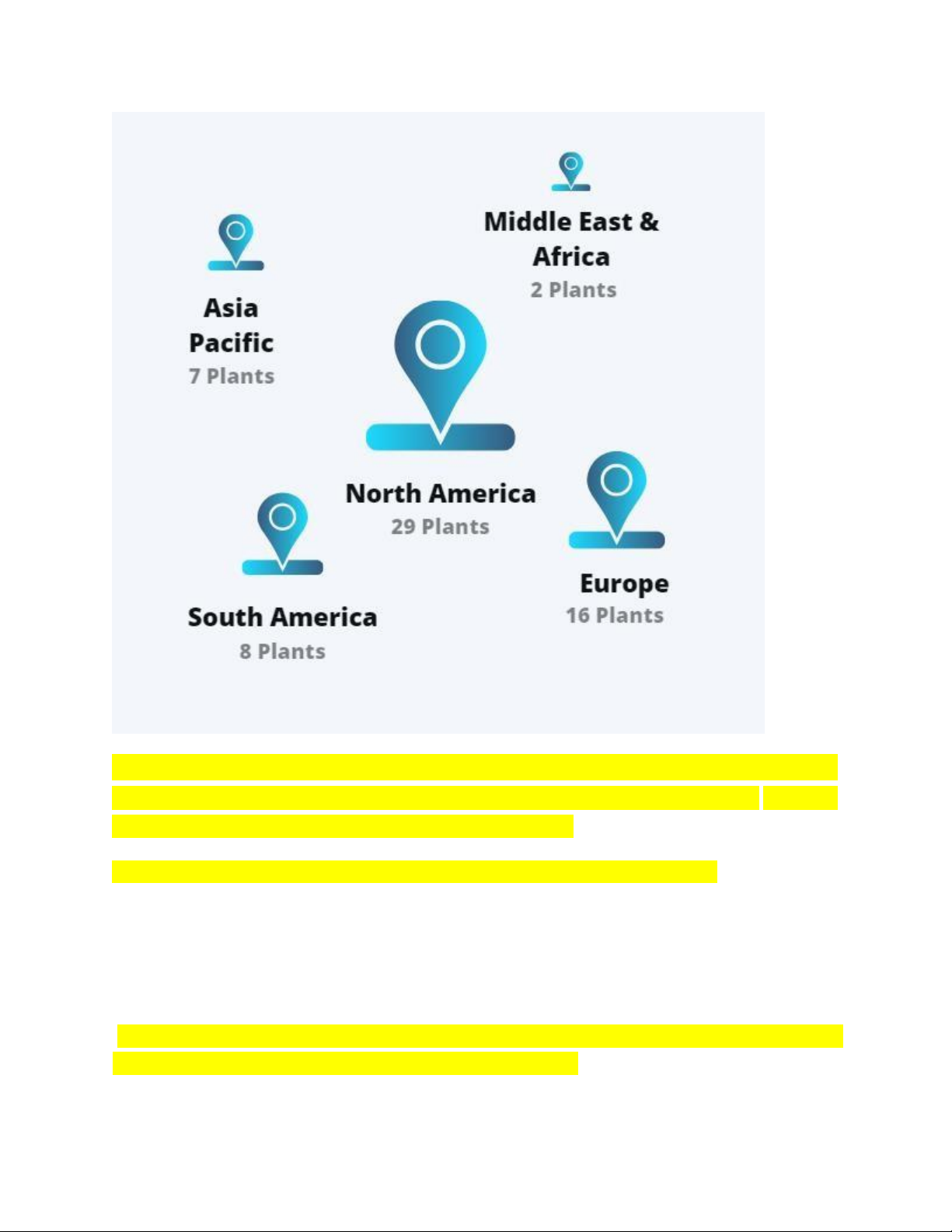

*Ford combines a strategy of globalization and localization, provides a wide range

of global products with a strong focus on regional adaptations to cater to specific consumer

preferences, regulatory requirements, and market conditions.

Ford operates in over 100 countries worldwide, making it a truly global brand. - Ford strives for

brand consistency across all its markets. This means that while product offerings might be

tailored, the brand message (e.g., “Built Ford Tough”) and core values of durability, reliability, and

innovation remain the same worldwide.

-> Optimizing transportation costs, reducing import taxes, leveraging local labor, cutting

operational costs, and quickly responding to market demands. lOMoAR cPSD| 58950985

- Each region focuses on producing different vehicle models to serve the local market's needs.

For example, Ford offers a broad lineup of vehicles that includes cars, trucks, SUVs, and

electric vehicles (EVs) across all global markets. While the overall product strategy is global, some

models are designed specifically for certain regions (e.g., the Ford F-150 for North America or the Ford Focus for Europe) TWO MAIN Channels:

Direct Distribution via Authorized Dealers

Distribution via Secondary Dealers

- Training, Marketing, and Financial Support: Ford provides training and marketing support

for dealers to ensure they can effectively sell Ford products and stay competitive. Financial

support programs can help dealers with working capital and loan facilitation.

- Flexible Pricing and Promotional Programs: Ford uses flexible pricing strategies and

promotions to attract customers and increase sales. These programs can include discounts,

limited-time offers, and financing options tailored to different customer needs.