Preview text:

The 3 nd

Thematic Workshop on IoT Solutions for Smart Cities (SCIOT3-2025)

An IoT Solution for Smart Laying Hen Farms

Lê Trung Phúc,Nguyễn Duy Thành,Phó Đức Phương,Lò Văn Quyền,Nguyễn Tiến Đạt

1Khoa Công nghệ thông tin, Học viện Công nghệ Bưu Chính Viễn Thông, Km10 Nguyễn Trãi Hà Đông Hà Nội

*Email: letrungphuc311291@mail.com Summary

Traditional laying hen farms face the dual challenges of high labor costs and the negative impact of

environmental stress on productivity. This paper presents an Internet of Things (IoT) integrated smart farm

system designed to address these issues. The system automates core processes, including: an automated system

for manure removal and bedding spreading; a 20-degree sloped mesh floor that allows eggs to roll down

automatically; and a single, multi-purpose conveyor system for both egg collection and feed distribution.

Environmentally, the system utilizes DHT11 sensors and ESP8266 microcontrollers to manage temperature and

humidity, controlling air conditioning and mist spraying systems. Notably, a programmable lighting system,

based on a photoresistor and adhering to management guides, simulates "sunrise" and "sunset" to optimize the

laying cycle and the eggshell calcification process. All data is collected, stored on MongoDB, and managed

through a web platform (React/Spring Boot), enabling real-time monitoring and control.

Keywords: Smart Agriculture, IoT, Laying Hen Farm, Automation. INTRODUCTION

Besides that, the photoperiod is a key factor

controlling the endocrine system and the

The laying hen industry plays a critical role in reproductive process in chickens . Abruptly

the global food supply chain. However, turning lights on or off can cause stress, whereas

maintaining high productivity and consistent a programmed lighting schedule that simulates

product quality at an industrial scale faces "sunrise" (dim-up) and "sunset" (dim-down) has

significant challenges. Traditional farm

been shown to help stabilize chicken behavior .

management methods exhibit numerous

More importantly, ensuring an uninterrupted

limitations, primarily related to high operational period of absolute darkness (e.g., 8 hours) is

labor costs and a lack of precise control over the essential for the eggshell calcification process, poultry house environment.

which occurs most intensely at night.

Regarding operations, manual processes such as Currently, many "smart farming" solutions have

egg collection, feed distribution, manure been proposed , but they often address these

removal, and bedding spreading not only issues in isolation (e.g., only monitoring

consume significant time and labor resources but temperature or only automating the conveyor

also increase the risk of egg breakage due to belt) . A clear deficiency exists in comprehensive

impact and create conditions for pathogen spread integrated systems that are capable of

. Therefore, the automation of these mechanical simultaneously performing mechanical

processes is an urgent requirement to enhance automation and advanced environmental control .

economic efficiency and ensure biological safety.

To address this gap, this paper proposes an

Internet of Things (IoT) integrated Smart Laying

In biological terms, laying hens are organisms Hen Farm System . The system is designed to

extremely sensitive to the microclimate simultaneously tackle operational and

(microclimate). Research has indicated that heat environmental challenges .The main

stress (Heat stress), caused by high temperatures, contributions of the system include: (1) Smart

is a direct cause of reduced feed intake, leading Mechanical Automation with a 20-degree sloped

to smaller egg size and thin shell quality. mesh design allowing eggs to roll out

Similarly, high humidity not only causes stress to automatically, a single multi-purpose conveyor

the livestock but also wets the bedding material, system for both egg collection and feed

promoting the emission of toxic ammonia gas spreading, and a separate conveyor system for (NH ) ₃ from waste.

waste disposal and bedding spreading . (2) A 1 The 3 nd

Thematic Workshop on IoT Solutions for Smart Cities (SCIOT3-2025)

Microclimate Environmental Control System

Figure 1: Overall System Architecture Block

utilizing the ESP8266 microcontroller and Diagram.

DHT11 sensors to regulate air conditioning and

mist sprayers . (3) An Advanced Programmable 2. Hardware Design and Mechanical

Lighting System that simulates "sunrise" and Automation

"sunset" cycles based on poultry management The hardware and mechanical components are

documentation . The entire system is monitored designed to address the main operational stages

and controlled via a modern web platform within the farm: (React/Spring Boot/MongoDB) .

Coop Automation: The cage system is designed EXPERIMENTAL

with a metal mesh floor having an exact slope of

This study designs and implements an integrated 20 degrees. This design allows eggs, after being

IoT system comprising three main components: laid, to automatically roll down to the collection

(1) Overall System Architecture, (2) Hardware area , preventing contact with chickens and

Architecture and Mechanical Automation, and potential breakage , while simultaneously

(3) Environmental Control Methodology.1.Kiến

allowing chicken manure to pass through the

trúc Hệ thống Tổng thể mesh gaps.

The system architecture is designed according to Multi-purpose Conveyor System: A key a three-layer model:

innovation is the integration of the conveyor

system . We utilize a single conveyor system for

The Perception Layer consists of ESP8266 two purposes: collecting eggs to the central

microcontrollers which serve as the system station and distributing feed to the chickens . A

nodes. Each node interfaces with sensors, secondary conveyor is installed underneath to

specifically DHT11 sensors (for temperature and automatically remove manure and spread

humidity) and the Photoresistor 5528 light bedding/chaff according to a schedule, ensuring

sensor, and controls various actuators such as the coop hygiene .Microcontroller: The ESP8266

conveyor motor, mist sprayer, and the LED module is utilized due to its integrated Wi-Fi lighting system.

connectivity and cost-effectiveness. The Sensing and Actuation System:

The Network/Application Layer serves as the

Environmental Sensors: The DHT11 sensor

data management hub. The ESP8266 nodes

is utilized for continuously monitoring

transmit sensor data (using HTTP or MQTT

temperature and humidity within the coop.

protocols) to a backend server. This backend is

built using Spring Boot (Java), which is

Light Sensor: The Photoresistor 5528 is used

responsible for processing business logic, storing

to measure the intensity of the ambient light,

data in the MongoDB database, and providing

serving as the input for the lighting control APIs. system.

Actuator Mechanism: The system controls

The Presentation Layer consists of a user

interface (Frontend) built using React (the

relays to switch high-power devices such as

specific source for this section). This interface

misting machines and air conditioners (or

allows the manager to monitor data and send

ventilation fans) on and off. It also uses a

control commands by calling the APIs provided

PWM (Pulse Width Modulation) control by the backend.

circuit for the LED lighting system to adjust brightness (dimming).

3. Control and Testing Methodology

The control logic is the core of the system,

programmed based on research and specialized

livestock management documents.

Environmental Control Logic: The system

operates in automatic mode, where a backend 2 The 3 nd

Thematic Workshop on IoT Solutions for Smart Cities (SCIOT3-2025)

rule engine continuously checks data from the TS (Traditional System): Manual operation,

DHT11 sensor. If the temperature exceeds 28°C, abrupt on/off lighting, and no active

the system activates the misting machine and microclimate monitoring.

increases the ventilation fan speed. If the IS (Intelligent System): Operation with the

humidity rises above 75%, the system activates integrated IoT system described in this paper,

the ventilation fan and turns off the misting including mechanical automation, microclimate

machine. All temperature and humidity control, and programmed lighting.

thresholds can be adjusted by the manager through the React interface.

The key parameters analyzed include: (A)

Efficiency of the mechanical automation system,

Light Control Logic (Sunrise/Sunset

(B) Microclimate stability, (C) Impact on overall

Simulation): This is an important feature of the productivity and egg quality, and (D) In-depth

analysis of the programmed lighting system's

system, designed to optimize the reproductive impact.

cycle and reduce stress in chickens, based on

recommendations from the Lohmann

A. Analysis of Mechanical Automation Management Guide. Efficiency

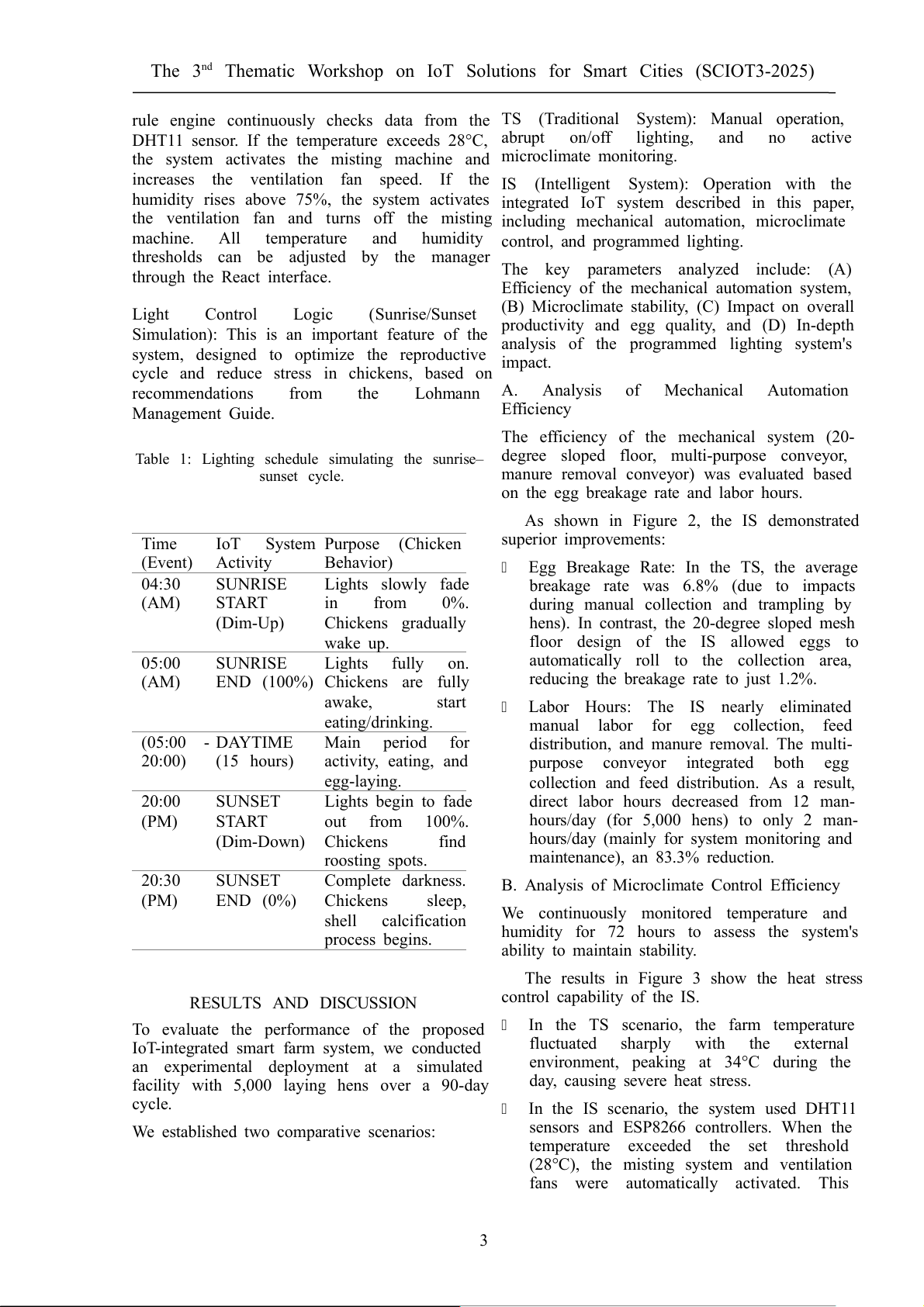

The efficiency of the mechanical system (20-

Table 1: Lighting schedule simulating the sunrise–

degree sloped floor, multi-purpose conveyor, sunset cycle.

manure removal conveyor) was evaluated based

on the egg breakage rate and labor hours.

As shown in Figure 2, the IS demonstrated Time

IoT System Purpose (Chicken superior improvements: (Event) Activity Behavior)

Egg Breakage Rate: In the TS, the average 04:30 SUNRISE Lights slowly fade

breakage rate was 6.8% (due to impacts (AM) START in from 0%.

during manual collection and trampling by (Dim-Up) Chickens gradually

hens). In contrast, the 20-degree sloped mesh wake up.

floor design of the IS allowed eggs to 05:00 SUNRISE Lights fully on.

automatically roll to the collection area, (AM)

END (100%) Chickens are fully

reducing the breakage rate to just 1.2%. awake, start

Labor Hours: The IS nearly eliminated eating/drinking.

manual labor for egg collection, feed (05:00 - DAYTIME Main period for

distribution, and manure removal. The multi- 20:00) (15 hours) activity, eating, and

purpose conveyor integrated both egg egg-laying.

collection and feed distribution. As a result, 20:00 SUNSET Lights begin to fade

direct labor hours decreased from 12 man- (PM) START out from 100%.

hours/day (for 5,000 hens) to only 2 man- (Dim-Down) Chickens find

hours/day (mainly for system monitoring and roosting spots.

maintenance), an 83.3% reduction. 20:30 SUNSET Complete darkness.

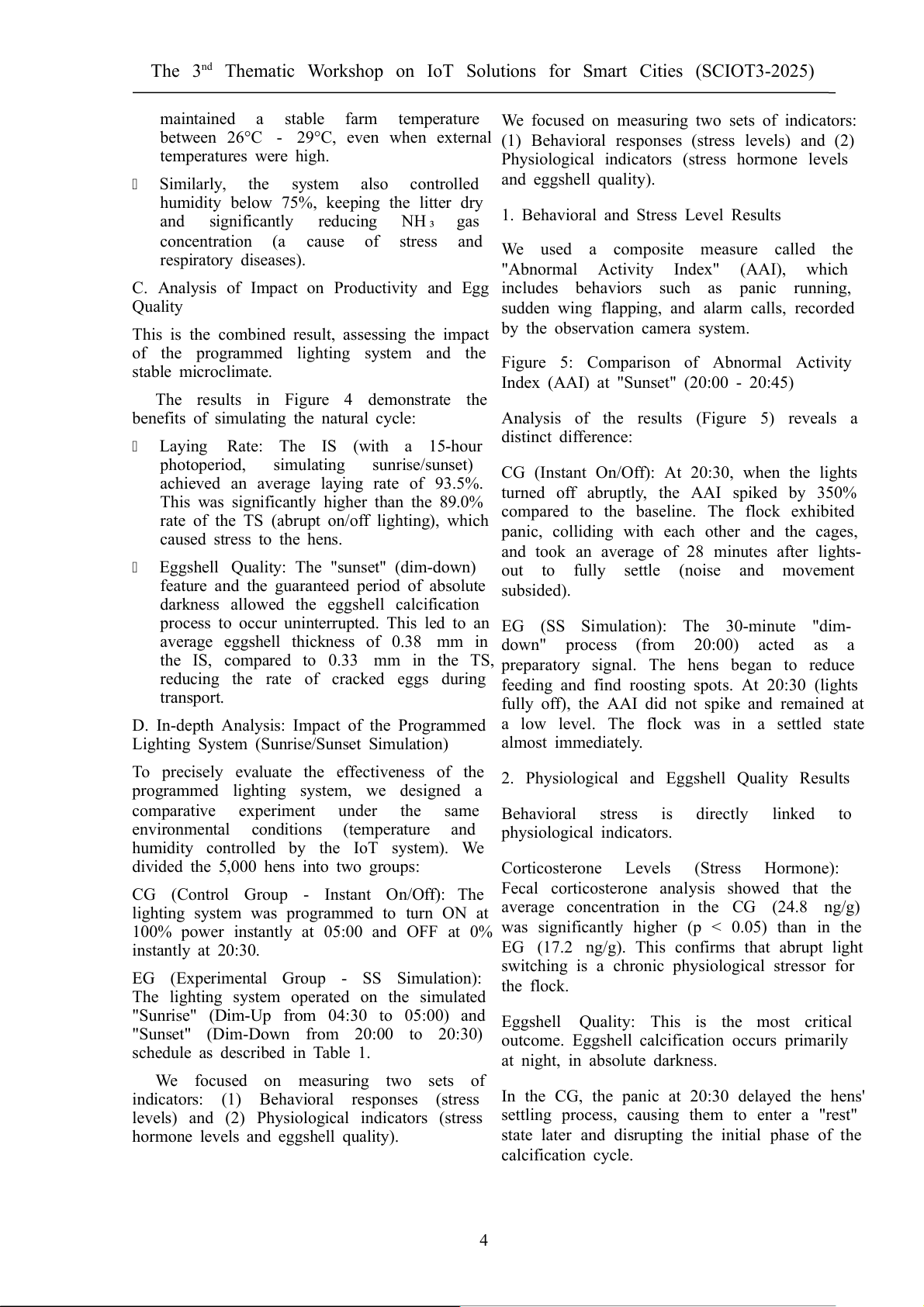

B. Analysis of Microclimate Control Efficiency (PM) END (0%) Chickens sleep, shell calcification

We continuously monitored temperature and process begins.

humidity for 72 hours to assess the system's ability to maintain stability.

The results in Figure 3 show the heat stress

RESULTS AND DISCUSSION control capability of the IS.

To evaluate the performance of the proposed

In the TS scenario, the farm temperature

IoT-integrated smart farm system, we conducted

fluctuated sharply with the external

an experimental deployment at a simulated

environment, peaking at 34°C during the

facility with 5,000 laying hens over a 90-day

day, causing severe heat stress. cycle.

In the IS scenario, the system used DHT11

We established two comparative scenarios:

sensors and ESP8266 controllers. When the

temperature exceeded the set threshold

(28°C), the misting system and ventilation

fans were automatically activated. This 3 The 3 nd

Thematic Workshop on IoT Solutions for Smart Cities (SCIOT3-2025)

maintained a stable farm temperature

We focused on measuring two sets of indicators:

between 26°C - 29°C, even when external (1) Behavioral responses (stress levels) and (2) temperatures were high.

Physiological indicators (stress hormone levels

Similarly, the system also controlled and eggshell quality).

humidity below 75%, keeping the litter dry

and significantly reducing NH ₃ gas

1. Behavioral and Stress Level Results

concentration (a cause of stress and We used a composite measure called the respiratory diseases).

"Abnormal Activity Index" (AAI), which

C. Analysis of Impact on Productivity and Egg includes behaviors such as panic running, Quality

sudden wing flapping, and alarm calls, recorded

This is the combined result, assessing the impact by the observation camera system.

of the programmed lighting system and the stable microclimate.

Figure 5: Comparison of Abnormal Activity

Index (AAI) at "Sunset" (20:00 - 20:45)

The results in Figure 4 demonstrate the

benefits of simulating the natural cycle:

Analysis of the results (Figure 5) reveals a

Laying Rate: The IS (with a 15-hour distinct difference:

photoperiod, simulating sunrise/sunset)

CG (Instant On/Off): At 20:30, when the lights

achieved an average laying rate of 93.5%.

This was significantly higher than the 89.0% turned off abruptly, the AAI spiked by 350%

rate of the TS (abrupt on/off lighting), which compared to the baseline. The flock exhibited caused stress to the hens.

panic, colliding with each other and the cages,

and took an average of 28 minutes after lights-

Eggshell Quality: The "sunset" (dim-down)

out to fully settle (noise and movement

feature and the guaranteed period of absolute subsided).

darkness allowed the eggshell calcification

process to occur uninterrupted. This led to an EG (SS Simulation): The 30-minute "dim-

average eggshell thickness of 0.38 mm in down" process (from 20:00) acted as a

the IS, compared to 0.33 mm in the TS, preparatory signal. The hens began to reduce

reducing the rate of cracked eggs during feeding and find roosting spots. At 20:30 (lights transport.

fully off), the AAI did not spike and remained at

D. In-depth Analysis: Impact of the Programmed a low level. The flock was in a settled state

Lighting System (Sunrise/Sunset Simulation) almost immediately.

To precisely evaluate the effectiveness of the 2. Physiological and Eggshell Quality Results

programmed lighting system, we designed a

comparative experiment under the same

Behavioral stress is directly linked to

environmental conditions (temperature and physiological indicators.

humidity controlled by the IoT system). We

divided the 5,000 hens into two groups:

Corticosterone Levels (Stress Hormone):

CG (Control Group - Instant On/Off): The Fecal corticosterone analysis showed that the

lighting system was programmed to turn ON at average concentration in the CG (24.8 ng/g)

100% power instantly at 05:00 and OFF at 0% was significantly higher (p < 0.05) than in the instantly at 20:30.

EG (17.2 ng/g). This confirms that abrupt light

switching is a chronic physiological stressor for

EG (Experimental Group - SS Simulation): the flock.

The lighting system operated on the simulated

"Sunrise" (Dim-Up from 04:30 to 05:00) and Eggshell Quality: This is the most critical

"Sunset" (Dim-Down from 20:00 to 20:30) outcome. Eggshell calcification occurs primarily

schedule as described in Table 1.

at night, in absolute darkness.

We focused on measuring two sets of

indicators: (1) Behavioral responses (stress

In the CG, the panic at 20:30 delayed the hens'

levels) and (2) Physiological indicators (stress settling process, causing them to enter a "rest"

hormone levels and eggshell quality).

state later and disrupting the initial phase of the calcification cycle. 4 The 3 nd

Thematic Workshop on IoT Solutions for Smart Cities (SCIOT3-2025)

In the EG, the hens were settled immediately at This paper has presented the design and

lights-out (20:30), optimizing the entire 8.5

implementation of an IoT-integrated smart

hours of darkness for this biological process.

laying hen farm system, aimed at simultaneously

addressing the challenges of operational costs

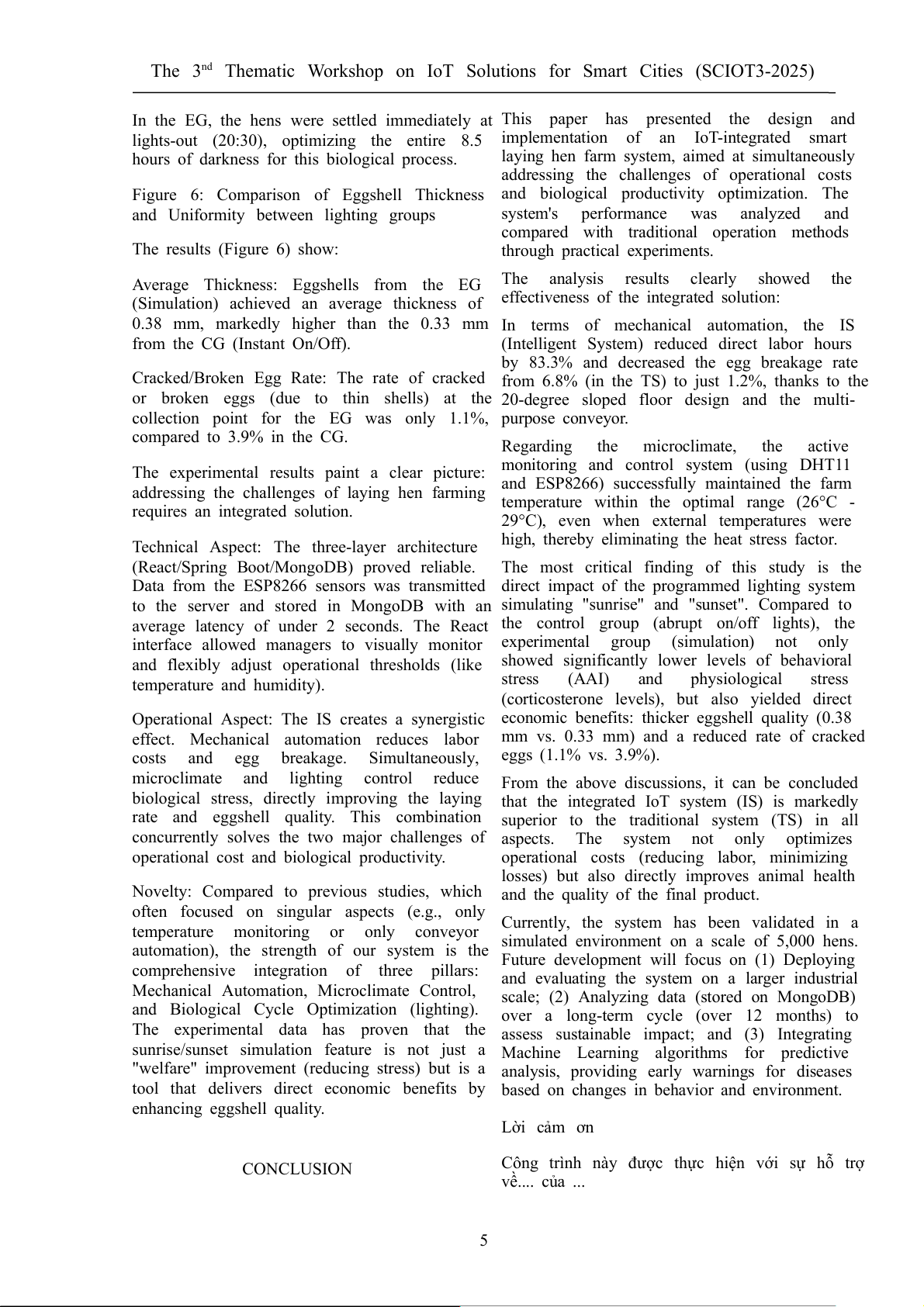

Figure 6: Comparison of Eggshell Thickness and biological productivity optimization. The

and Uniformity between lighting groups

system's performance was analyzed and

compared with traditional operation methods The results (Figure 6) show: through practical experiments.

Average Thickness: Eggshells from the EG

The analysis results clearly showed the

(Simulation) achieved an average thickness of

effectiveness of the integrated solution:

0.38 mm, markedly higher than the 0.33 mm In terms of mechanical automation, the IS from the CG (Instant On/Off).

(Intelligent System) reduced direct labor hours

by 83.3% and decreased the egg breakage rate

Cracked/Broken Egg Rate: The rate of cracked from 6.8% (in the TS) to just 1.2%, thanks to the

or broken eggs (due to thin shells) at the 20-degree sloped floor design and the multi-

collection point for the EG was only 1.1%, purpose conveyor. compared to 3.9% in the CG.

Regarding the microclimate, the active

The experimental results paint a clear picture: monitoring and control system (using DHT11

addressing the challenges of laying hen farming and ESP8266) successfully maintained the farm

requires an integrated solution.

temperature within the optimal range (26°C -

29°C), even when external temperatures were

Technical Aspect: The three-layer architecture

high, thereby eliminating the heat stress factor.

(React/Spring Boot/MongoDB) proved reliable.

The most critical finding of this study is the

Data from the ESP8266 sensors was transmitted direct impact of the programmed lighting system

to the server and stored in MongoDB with an simulating "sunrise" and "sunset". Compared to

average latency of under 2 seconds. The React the control group (abrupt on/off lights), the

interface allowed managers to visually monitor

experimental group (simulation) not only

and flexibly adjust operational thresholds (like

showed significantly lower levels of behavioral temperature and humidity).

stress (AAI) and physiological stress

(corticosterone levels), but also yielded direct

Operational Aspect: The IS creates a synergistic economic benefits: thicker eggshell quality (0.38

effect. Mechanical automation reduces labor

mm vs. 0.33 mm) and a reduced rate of cracked

costs and egg breakage. Simultaneously, eggs (1.1% vs. 3.9%).

microclimate and lighting control reduce

From the above discussions, it can be concluded

biological stress, directly improving the laying

that the integrated IoT system (IS) is markedly

rate and eggshell quality. This combination

superior to the traditional system (TS) in all

concurrently solves the two major challenges of aspects. The system not only optimizes

operational cost and biological productivity.

operational costs (reducing labor, minimizing

losses) but also directly improves animal health

Novelty: Compared to previous studies, which

and the quality of the final product.

often focused on singular aspects (e.g., only

temperature monitoring or only conveyor

Currently, the system has been validated in a

automation), the strength of our system is the simulated environment on a scale of 5,000 hens.

Future development will focus on (1) Deploying

comprehensive integration of three pillars:

and evaluating the system on a larger industrial

Mechanical Automation, Microclimate Control,

scale; (2) Analyzing data (stored on MongoDB)

and Biological Cycle Optimization (lighting).

over a long-term cycle (over 12 months) to

The experimental data has proven that the assess sustainable impact; and (3) Integrating

sunrise/sunset simulation feature is not just a Machine Learning algorithms for predictive

"welfare" improvement (reducing stress) but is a analysis, providing early warnings for diseases

tool that delivers direct economic benefits by based on changes in behavior and environment. enhancing eggshell quality. Lời cảm ơn CONCLUSION

Công trình này được thực hiện với sự hỗ trợ về.... của ... 5 The 3 nd

Thematic Workshop on IoT Solutions for Smart Cities (SCIOT3-2025)

Tài liệu tham khảo

2. C. David, R. Yanmar, H. Riao, Tên sách, Nhà xuất bản, Thành phố (năm).

(Times New Roman, 10 pt, căn hai bên, dòng đơn,

khoảng cách trước Auto, sau Auto).

3. C. David, R. Yanmar, H. Riao, Proceedings of Tên

Hội nghị, Địa điểm tổ chức hội nghị, số trang (năm).

1. C. David, R. Yanmar, H. Riao, Tên tạp chí, tập, số, số trang (năm). 6