Preview text:

MINISTRY OF EDUCATION AND TRAINING HOA SEN UNIVERSITY

FACULTY OF ECONOMICS BUSINESS

------------- FINAL REPORT UNILEVER’S WAREHOUSE SYSTEM Subject: Sypply Chain Management Lecturer: Hồ Trung Thảo Group: 3

Members: Phạm Tuấn Minh – 22002278

Huỳnh Mạnh Khang – 22009641 Class: 0200 Ho Chi Minh, 11/2022

MINISTRY OF EDUCATION AND TRAINING HOA SEN UNIVERSITY

FACULTY OF ECONOMICS BUSINESS

------------- FINAL REPORT UNILEVER’S WAREHOUSE SYSTEM Subject: Sypply Chain Management Lecturer: Hồ Trung Thảo Group: 3 Members:

Phạm Tuấn Minh – 22002278

Huỳnh Mạnh Khang – 22009641 Class: 0200 Ho Chi Minh,11/2022 Blurred content of page 3 ACKNOWLEDGEMENT

First of all, we would like to thank Hoa Sen University for giving us the

opportunity to access the course Supply Chain Management. And we would like to

thank Mr. Ho Trung Thao, who has always accompanied and created conditions for us

to absorb the subject knowledge in the best way.

During the reporting period, he gave us a lot of useful advice and with his in-

depth knowledge, he helped us to complete this report. And in the report, there will be

errors due to lack of experience, hope you and everyone will sympathize and point out

mistakes so that we can learn from experience and complete the following reports better. We sincerely thank you. Best regards. ii TABLE OF CONTENTS

DECLARATION.......................................................................................................... i

ACKNOWLEDGEMENT..........................................................................................ii

TABLE OF CONTENTS...........................................................................................iii

IMAGE CATALOG....................................................................................................v

Chapter 1. Introduction of Unilever......................................................................1

Chapter 2. Warehouse operations of Unilever Vietnam Company......................2

2.1. Warehouse function of Unilever Vietnam Company.......................................2

2.2. Unilever's warehouse system............................................................................2

2.3. The preservation of goods with the warehouse of Unilever Vietnam.............7

2.4. Learn about preserving goods in warehouses of Unilever Vietnam...............8

2.4.1. a. Classification of preservation methods............................................8

2.4.2. b. Air conditioning, humidity in the warehouse..................................8

2.4.3. c. In addition, attention must be paid to goods care and warehouse

hygiene............................................................................................................. 8

2.4.4. d. Prevention of insects and rodents.....................................................8

2.4.5. e. Some notes with unilever...................................................................8

2.5. Warehouse management operations, warehouse management human

resources.................................................................................................................... 9

2.5.1. a. Warehouse and inventory management...........................................9

2.5.2. Methods and tools for inventory management....................................9

2.5.3. General model for distributor warehouse:..........................................9

2.5.4. Distribution center warehouse model................................................10

2.5.5. Human resources for warehouse management..................................10

2.6. Unilever's distribution system, transportation and warehousing services

Carriage................................................................................................................... 11

2.6.1. Warehouse service...............................................................................12

2.6.2. Distribution system..............................................................................13

Chapter 3. I. Packaging design at Unilever.........................................................14

3.1. Logo on all unilever packaging.......................................................................14

3.2. Product Protection...........................................................................................15 iii Blurred content of page 6 IMAGE CATALOG

FIgure 1.Logo and product of Unilever.....................................................................1

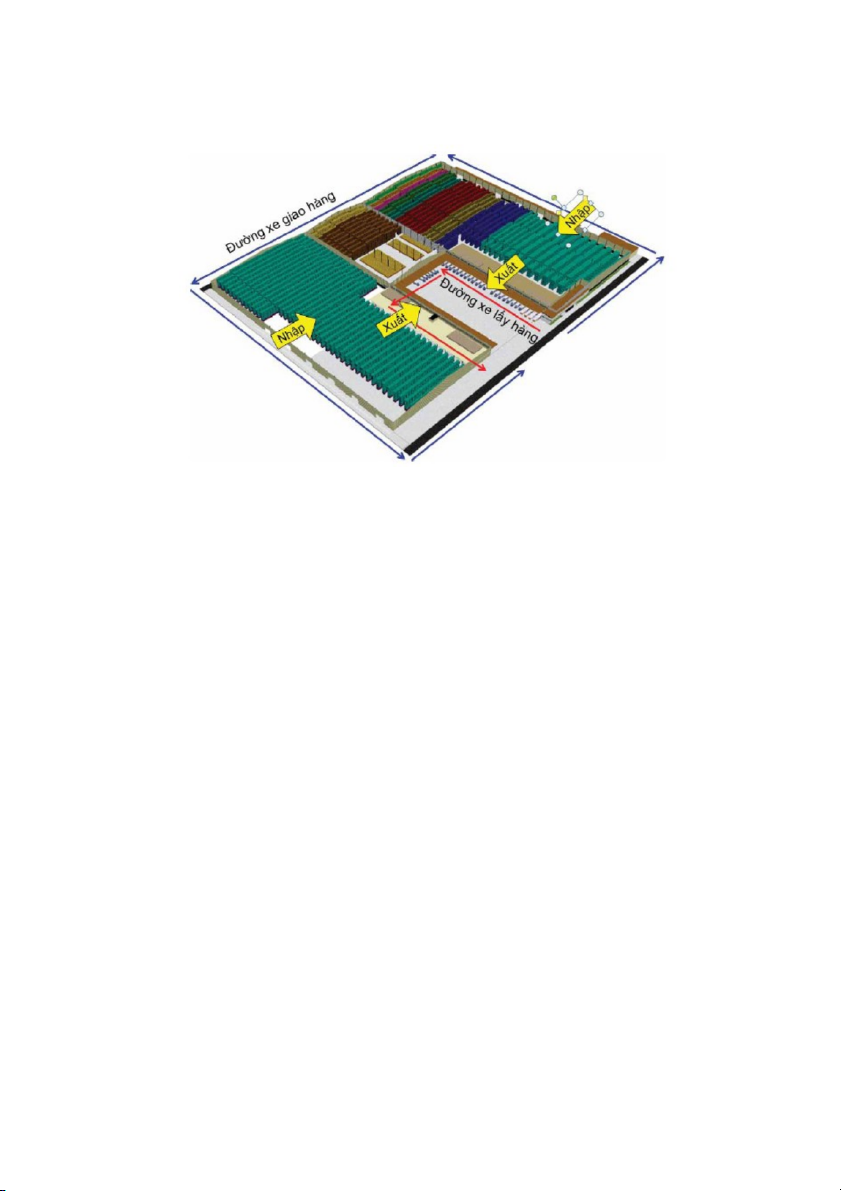

FIgure 2. Cross-sectional image of VSIP area warehouse........................................3

FIgure 3.VSIP is modernly designed in the shape of a U.........................................4

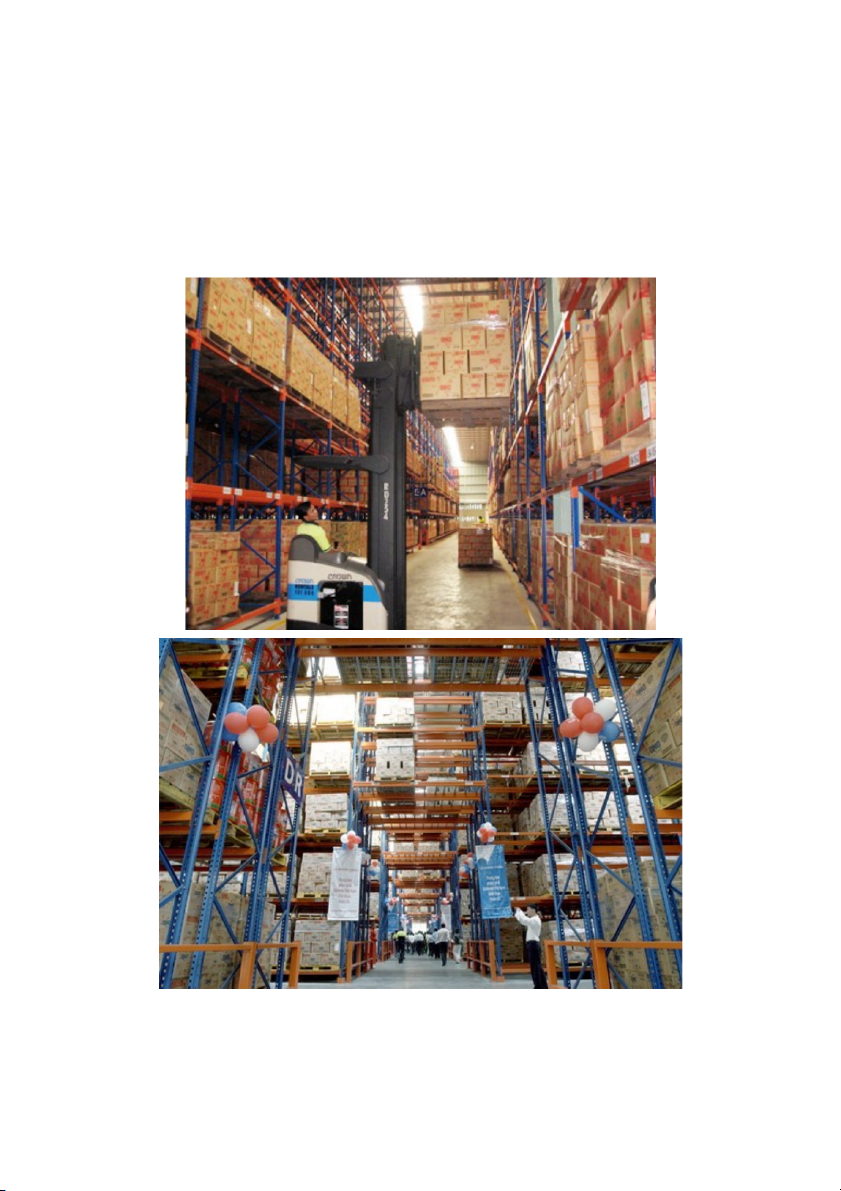

FIgure 4.Some pictures inside the warehouse in VSIP area.....................................6

FIgure 5.Costs for activities related to transportation...........................................11

FIgure 6.One of the company's delivery..................................................................12

FIgure 7.Logo of Unilever........................................................................................14 v

1. Introduction of Unilever

Unilever is a multinational firm with British and Dutch roots that is well-known

for producing fast-moving consumer goods like food, tea, and other beverages, as well

as items for personal and home cleanliness. The typical brands of Unilever, such

Lipton, Knorr, Cornetto, Omo, Lux, Vim, Lifebuoy, Dove, Close-Up, Sunsilk, Clear,

Pond's, Hazeline, Vaseline,... are well-known and widely used throughout the world.

Unilever is proving to be one of the most successful businesses in the world in the

consumer healthcare sector, with revenues of over millions of dollars per brand.

Currently, Unilever and Proctol & Gambel (P&G) control the global market for these goods.

One of Unilever's objectives as a multinational corporation is to grow its

clientele and establish numerous branches all over the world to seize market share. A

milestone in Unilever's overall plan was taken in 1995 with the establishment of Unilever Vietnam.

Lever Vietnam Joint Venture in Hanoi, Elida P/S in Ho Chi Minh City, and Best

Food Company, also in that city, make up Unilever Vietnam. Together, they operate as

one company. About 120 million USD have been invested by Unilever in these 3 companies since 1995.

FIgure 1.Logo and product of Unilever P a g e of 1 Blurred content of page 9

FIgure 2. Cross-sectional image of VSIP area warehouse

Basic specifications of Unilever VSIP regional warehouse:

Land area: 100,000 square meters.

Warehouse area: 65,000 square meters.

Can hold up to 70 thousand pallets.

Information technology system: SAP WMS.

Rack system: 7 floors, selective & double deep. Vendor: SCHAEFER.

Internal transportation system: Folk lift, Pallet mover, Reach truck. Vendor: CROWN. Number of outlets: 51 Number of doors: 21

Light and ventilation system: get light and wind (energy saving).

Automatic fire alarm and extinguishing system.

Security camera system monitors the entire warehouse area.

There is a separate promotion (mezzanine) area.

There is a separate waste treatment area, warehouse and recovered goods handling area. There is a modern office area. P a g e of 3

There is a dining area, canteen, staff motel, waiting room for drivers, medical room. Regarding advantages:

The first advantage of this distribution center is that it can hold up to 70,000

pallets. This will help Unilever meet the needs of the market in the coming years.

In addition, this distribution center is also equipped with modern equipment to

serve the job such as: SCHAEFER's 7-storey shelves, CROWN's fleet of high-lift

forklifts (forklift prices are equal to the price of each vehicle). Reach trucks are equal).

Toyota Camry), SAP WMS warehouse management system. This is an investment that

shows the class of Unilever Vietnam.

The third advantage is that the distribution center is designed according to

energy saving criteria and makes the most of light and wind. This is Unilever's global policy "Green Supply Chain".

Fourth, the distribution centers are equipped with the most modern automatic

fire extinguishing system today. Besides, the Distribution Center can also take on the

function of a processing factory, serving the needs of doing business. promotional

products, packaging, labeling, this helps save costs in the long run as well as

proactively provide timely quantities when needed.

Finally, this Distribution Center has full facilities for more than 700 employees working 24/7.

FIgure 3.VSIP is modernly designed in the shape of a U P a g e of 4 Blurred content of page 12

Secondly, the layout of the doors seems to be unreasonable: usually in the

distribution center, the number of pickup trucks and trucks waiting to pick up

goods is many times higher than in the import area. The reason is that imported

vehicles are usually large trucks carrying one or several items, including pallets.

Meanwhile, pickup trucks are usually pickup trucks (because customers tend to

FIgure 4.Some pictures inside the warehouse in VSIP area P a g e of 6

order very little and because areas like the inner city prohibit large loads). Picking

up goods is also much more complicated than importing goods to the warehouse,

so trucks often have to wait. Looking at the layout of the distribution center, it is

easy to see that the export area is too small compared to the import area. This has

the potential to cause traffic jams and limit returns at delivery areas. .

2.3. The preservation of goods with the warehouse of Unilever Vietnam

Storage of goods is one of the main functions of a warehouse. Preservation and

storage of goods is: ensuring the integrity of the quantity and quality of goods during

the operation, taking advantage of the area and capacity of the warehouse, preserving

and preserving the goods in the warehouse.

Goods preservation is the formulation and implementation of a system of

technical, organizational and economic measures to combat the harmful effects of the

environment on the quality of goods in order to keep the goods intact in quantity.

2.4. Learn about preserving goods in warehouses of Unilever Vietnam.

2.4.1. Classification of preservation methods.

Unilever's main goods preservation wings

• Stacking method: is the method used with goods in the form of packages or

pieces, there are 2 ways of stacking: cube and pyramid. P a g e of 7 Blurred content of page 15

2.5.2. Methods and tools for inventory management Book and record mode. Material liability regime. Inspection and inventory mode.

Types of inventory management in the supply chain : Finished goods inventory management

2.5.3. General model for distributor warehouse:

1. Warehouse type: this is a closed warehouse with only one door. This door is

used for both import and export. Each warehouse will be controlled by a storekeeper.

2. Warehouse structure: A simple warehouse has four surrounding walls and roof (corrugated iron or concrete).

3. Equipment operating in the warehouse: The transportation equipment in the

warehouse such as forklifts, pallet trucks ... has fire protection systems, humidity and temperature control systems...

4. Inventory management system: Using advanced warehouse management

software such as SAP, Oracle, or People Soft, Unilever's DMS software to control

goods as well as print import and export documents.

5. Control goods automatically by barcode or RFID.

6. The smallest sales unit can be cartons or packages, bottles, boxes, bags, ... to export the whole pallet.

7. Goods in the warehouse must not be in direct contact with the soil, lined with

a layer of wood. It is best to immediately use wooden pallets spread on the warehouse

floor to store goods. The pallet considered is a standard pallet, size 1.2 x 1m, which is

the most commonly used type of pallet today.

8. The boxes are stacked on the pallet.. Number of layers on the pallet according

to the manufacturer's instructions. More layers can be stacked, but considering the

strength of the carton, usually 3 layers should not be exceeded than specified by the manufacturer.

2.5.4. Distribution center warehouse model

The distribution center of Unilever Vietnam is equipped with modern and

scientific equipment and arrangement. Operated by Australian logistics company

Linfox (famous for logistics and logistics management systems) with Warehouse

Management System control system, most of the activities in the warehouse are P a g e of 9

controlled and managed by microcomputer. Therefore, the cargo handling capacity can reach 2,000 tons/day.

2.5.5. Human resources for warehouse management

College degree or higher, proficient in office computers, careful, accurate,

excellent staff, able to communicate and negotiate with outsourcing units, suppliers

and suppliers other. Internal department, supporting the team with good coordination

ability, ability to analyze and solve situations. Work:

Receiving raw materials and packaging from suppliers to the factory after

checking valid documents: purchase orders, delivery notes, invoices... to ensure the

correct quantity, type, and quality goods...

Arrange warehouse for raw materials and packaging, export packing materials to

the workshop, ensure compliance with factory regulations: 5S, safety, quality, accuracy, timeliness,...

Receive and respond to export requests from workshops and other departments on a LIFO and FIFO basis.

Conduct regular warehouse checks: explain when there are deviations and

maintain the area according to 5S standards.

Monitor and report nonconforming quality materials to the hungry warehouse manager.

Comply with the "Quality and Safety Policy for Customers and Consumers" as

well as the warehouse management system applied at the company: ISO 9001, ISO 14001, ISO 18001, GMP, HACCP. P a g e of 10 Blurred content of page 18

FIgure 6.One of the company's delivery

2.6.1. Warehouse service Concept

A warehouse is where the supply chain stores raw materials and goods.

Warehouses provide space and time benefits for materials and products and

allow the company to use customer service as a competitive tool to create flexible added value. Function.

Gather goods for transportation. Mixing goods. Transfer goods within the day. Service. Avoid risk. Air conditioning. P a g e of 12

The role of adding value of the warehouse. Value-adding role Rally Mixing goods Service Risk prevention Production conditioning Balance field Transport Order processing

Waiting time for goods, out of stock When out of stock Manufacturing

2.6.2. Distribution system

About warehouse sing and distribution

Unilever chooses the direction of outsourcing its distribution system with its

partner, Australia's Linfox corporation. To mark the cooperation is the transfer of all

factories and labor force at Unilever's 3 main distribution locations: Bac Ninh, Da Nang, VSIP Binh Duong.

The main distribution center in the south at VSIP Binh Duong with a total

warehouse area of up to 10ha is the largest distribution center in Vietnam, in which the

warehouse area is 33,000 m2, with a capacity of 20,000 tons. Production capacity can be up to 2000 tons/day.

The distribution center has 3 main functions: Delivering goods to agents in the

Central, Western and Southern regions; transshipping goods from Ho Chi Minh City

to 2 Unilever's distribution centers in Bac Ninh and Da Nang; export goods to 18

countries around the world: Hong Kong, Malaysia, Thailand….

Distribution center in Binh Duong not only has the largest area but also has the

most modern layout, arrangement and operation in Vietnam and other developing

countries in the region to meet the needs of storage and distribution. Unilever VN's

growing size helps products reach customers quickly and when it comes into

operation, Unilever's distribution center will also create jobs for 1000 workers

(according to Mr. Greg Sullivan Unilever supply chain PCT in Vietnam) ). P a g e of 13