Preview text:

lOMoARcPSD| 36782889 AGGREGATE PLANNING Lecture PLANNI NG AND COORDI NATI ON 5 I N THE SUPPLY CHAI N lOMoARcPSD| 36782889 AGGREGATE PLANNING AGGREGATE lOMoARcPSD| 36782889 AGGREGATE PLANNING PLANNING IN A SUPPLY CHAIN 8Introduction lOMoARcPSD| 36782889 AGGREGATE PLANNING

• Why is it interesting to look from lOMoARcPSD| 36782889 AGGREGATE PLANNING

asupply chain perspective to the planning?

• What solutions do organisations

haveto upscale (or down scale) capacity?

• What is the role of ICT related to theplanning issue? lOMoARcPSD| 36782889 AGGREGATE PLANNING Example

• Paper is seasonal product, in spring

more paper is consumed because of

printing the annual year reports.

Running a mill is costly. To optimize

revenues the industry uses aggregate

planning to determine production and inventory levels. lOMoARcPSD| 36782889 AGGREGATE PLANNING Introduction

• Aggregate planning is the process where a company determines planned levels of: – Capacity – Production – Sub-contraction lOMoARcPSD| 36782889 AGGREGATE PLANNING – Inventory – Stock-outs – Pricing Objectives

• Main objectives of aggregate planning are to identify

following operational parameters: lOMoARcPSD| 36782889 AGGREGATE PLANNING

– Production rate –units to produce per time unit – Workforce – Overtime – Machine capacity level – Sub contracting – Backlog – Inventory on hand lOMoARcPSD| 36782889 AGGREGATE PLANIING The planning challenge • Forecast • Production costs

• LabourProduction quantities • Subcontractingfrom:

• Changing capacity• Regular time • Labor/machine hours•

Overtime required per unit• Subcontracting

• Inventory holding costsInventory held

• Stock-out costsBacklog/Stock-outs

• ConstraintsWorkforce hired/laid off

• Limits on overtimeMachine capacity

• Limits on layoffsincrease/decrease • Limits on capital lOMoARcPSD| 36782889 AGGREGATE PLANNING • Limits on stock- outs • Constraints from suppliers Aggregate • Planning • • • • Profitability lOMoARcPSD| 36782889 AGGREGATE PLANNING Aggregate strategies

• Aggregate planning is focusing on three costs:

– Capacity (regular, overtime, subcontracting) – Inventory – Backlog • Three strategies:

– Chase strategy – using capacity as the lever lOMoARcPSD| 36782889 AGGREGATE PLANNING

– Flexibility strategy – using utilization as the lever

– Level strategy – using inventory as the lever

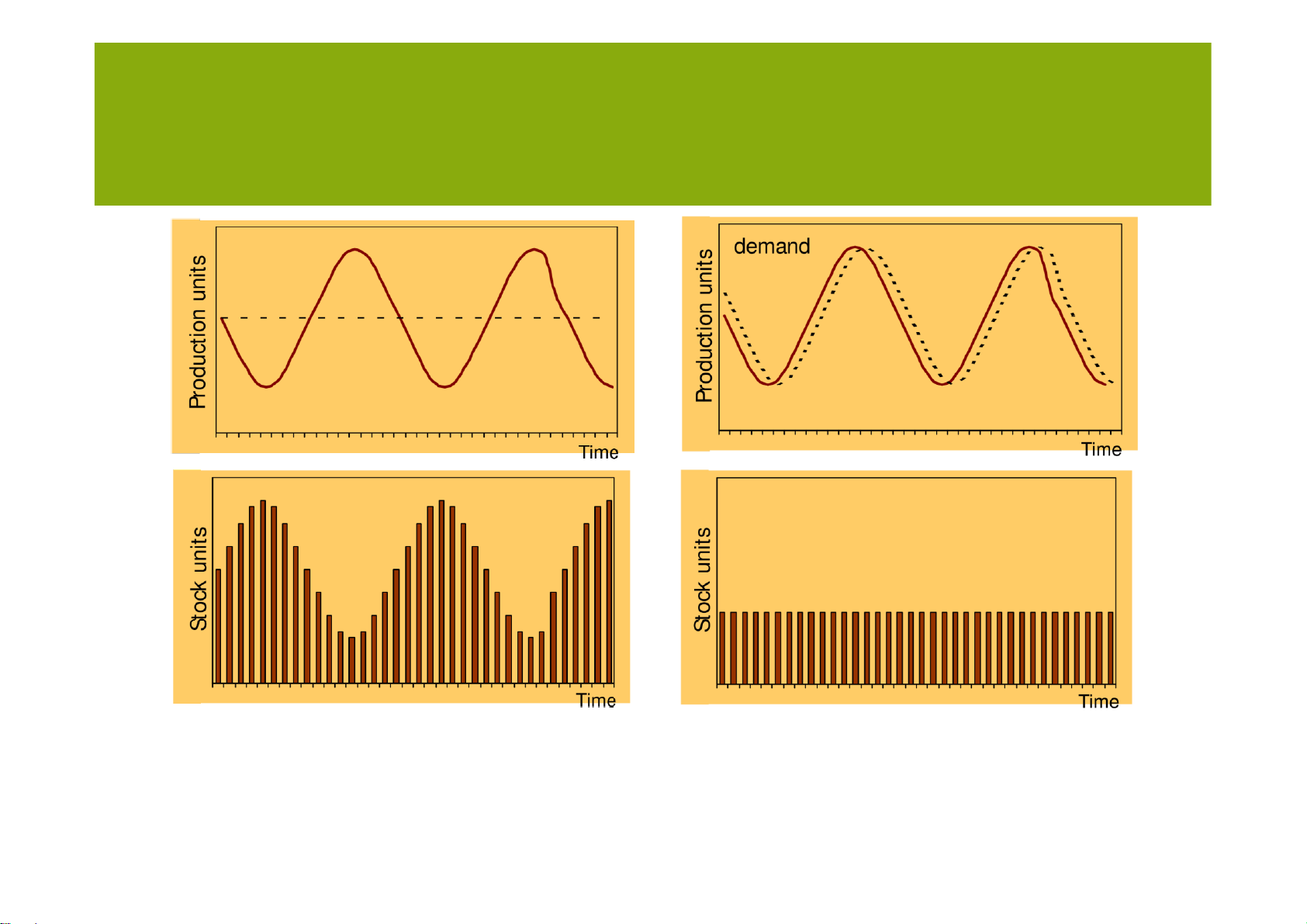

Leveling and chasing demand Level

production Chase demand lOMoARcPSD| 36782889 AGGREGATE PLANNING lOMoARcPSD| 36782889 AGGREGATE PLANNING Constraints

• Workforce, hiring and layoff constraints • Capacity constraints

• Inventory balance constraints

• Overtime limit constraints lOMoARcPSD| 36782889 AGGREGATE PLANNING

Building a master production schedule

• Master Production Schedule (MPS) identifies

allbatches which needs to be produced in each period. • Example: Family Set-up Batch Prod. Prod. Numb. Set-up Prod. time size time quant. set-ups time time A 8 50 5.60 256 5 40 1,433.6 B 6 150 3.00 640 4 24 1,920.0 C 8 100 3.80 512 5 40 1,945.6 lOMoARcPSD| 36782889 AGGREGATE PLANNING D 10 50 4.80 256 5 50 1,228.8 E 6 100 3.60 512 5 30 1.843.2 F 5 75 4.30 384 5 25 1,651,2 The role of IT

• The most early IT supply chain products

wereaggregate planning modules • Advantages of using IT:

– Can go beyond linear programming to solve theproblem lOMoARcPSD| 36782889 AGGREGATE PLANNING

– Possibility to combine with production planning andinventory planning

Implementing aggregate planning

• Today aggregate planning modules are part of ERPpackages.

• Important aspects related to implementation:

– Think beyond the enterprise, focus on supply chain lOMoARcPSD| 36782889 AGGREGATE PLANNING

– Make plans flexible, forecasts are never accurate

– Rerun planning when new data emerges

– Use aggregate planning as capacity increases lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING 9 lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING Introduction lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING •

What can you tell about demand anddemand patterns? • How does demand connect

sales tooperations and the supply chain? •

What solutions do organizations

haveto influence the capacity and/or demand? lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING Example

• Red Tomato Tools is selling

gardenproducts which is seasonal, concentrated in spring.

• Two strategies for managinginventory: – Producing only during season,leaving plant capacity unused lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING

– Producing flat during year

absorbingsales fluctuation via stock Predictable variability

• Predictable variability is change in demand that canbe forecasted.

• Objective: balance supply with demand maximizingprofitability by: lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING

– Manage supply using capacity, inventory,subcontracting

– Manage demand using short-term price discounts andpromotions Managing supply

• A firm can manage supply by following factors: – Production capacity lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING –Inventory Customer Inventory Capacity lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING Managing capacity

• Firms can manage capacity by using a combination of:

– Time flexibility from workforce – Use of seasonal workforce – Use of subcontracting – Use of dual facilities

– Design product flexibility in the process lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING Managing inventory

• Firms can manage capacity by using a combination of:

– Using common components across multiple products

– Build inventory of high-demand or predictable- demandproducts lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING Managing demand

• Supply chains can manage demand by using acombination of: – Pricing – Promotion lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING

• Note: Promotion decisions are mostly made byretailers

without taking into account the impact on the rest of the supply chain.

Factors influencing timing of promotion

• Four key factors influencing promotion:

– Impact of the promotion on demand – Cost of holding inventory

– Cost of changing the capacity level – Product margins lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING

• The increase in demand comes from: – Market growth – Stealing share – Forward buying

Implementing sales & operations planning

• Important aspects related to implementation:

– Coordinate planning across enterprises in the supplychain

– Take predictable variability into account when makingstrategic decisions lOMoARcPSD| 36782889 SALES AND OPERATIONS PLANNING

– Design S&OP to understand and manage the drivers ofdemand usage

– Ensure that S&OP process modifies plans as the realityof forecasts changes