Preview text:

lOMoARcPSD| 36782889 Lecture MANAGI NG 7a I NVENTORI ES I NTHE SUPPLY CHAI N (i) lOMoARcPSD| 36782889 12 MANAGING UNCERTAINTY IN THE SUPPLY CHAIN lOMoARcPSD| 36782889 Introduction lOMoARcPSD| 36782889 • What is maybe the biggest hinder inmanaging the supply chain?

• What are the risks if you do notmanage the supply chain well?

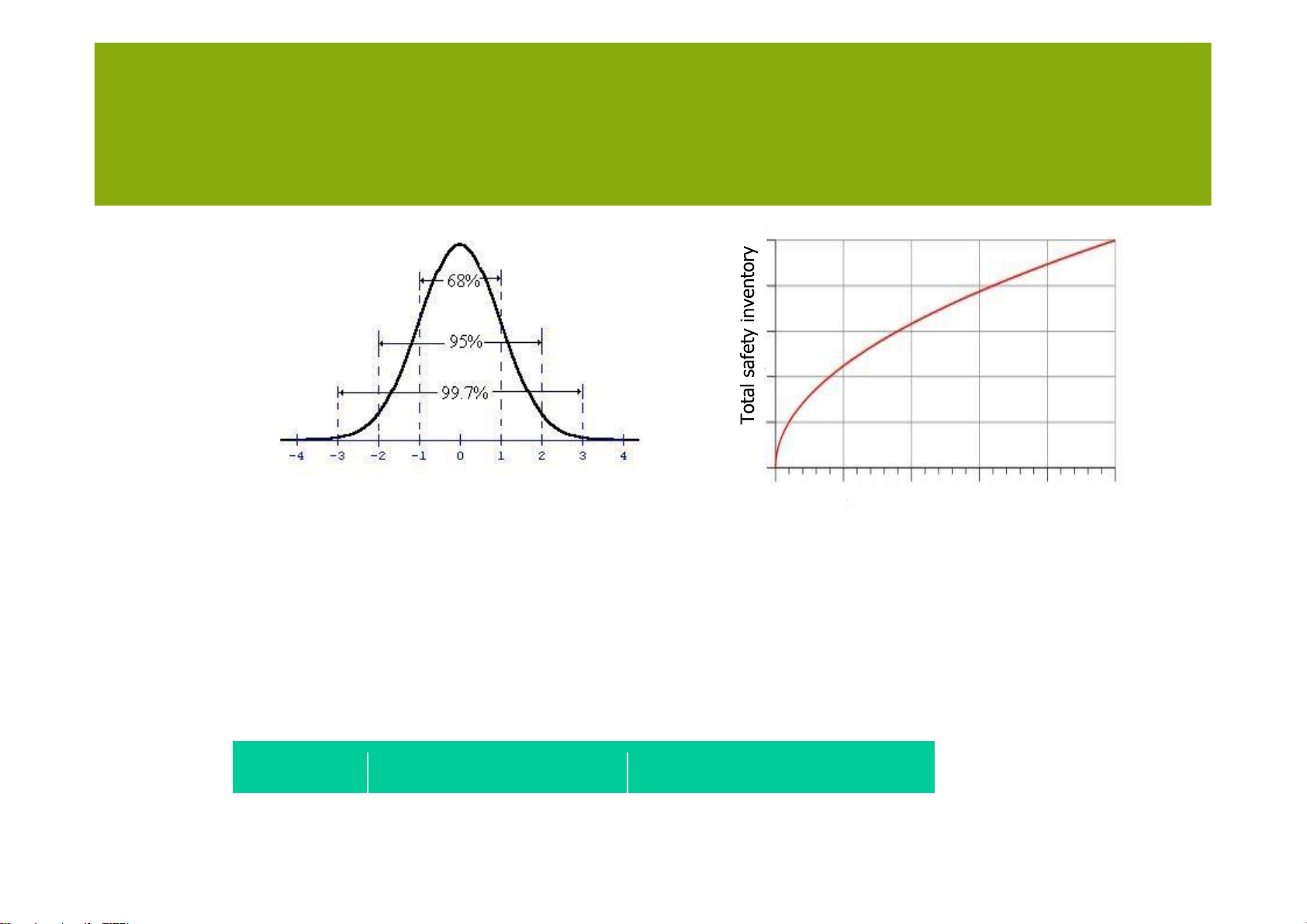

• How can you cover for this risk? lOMoARcPSD| 36782889 MANAGING UNCERTAINTY Safety inventory

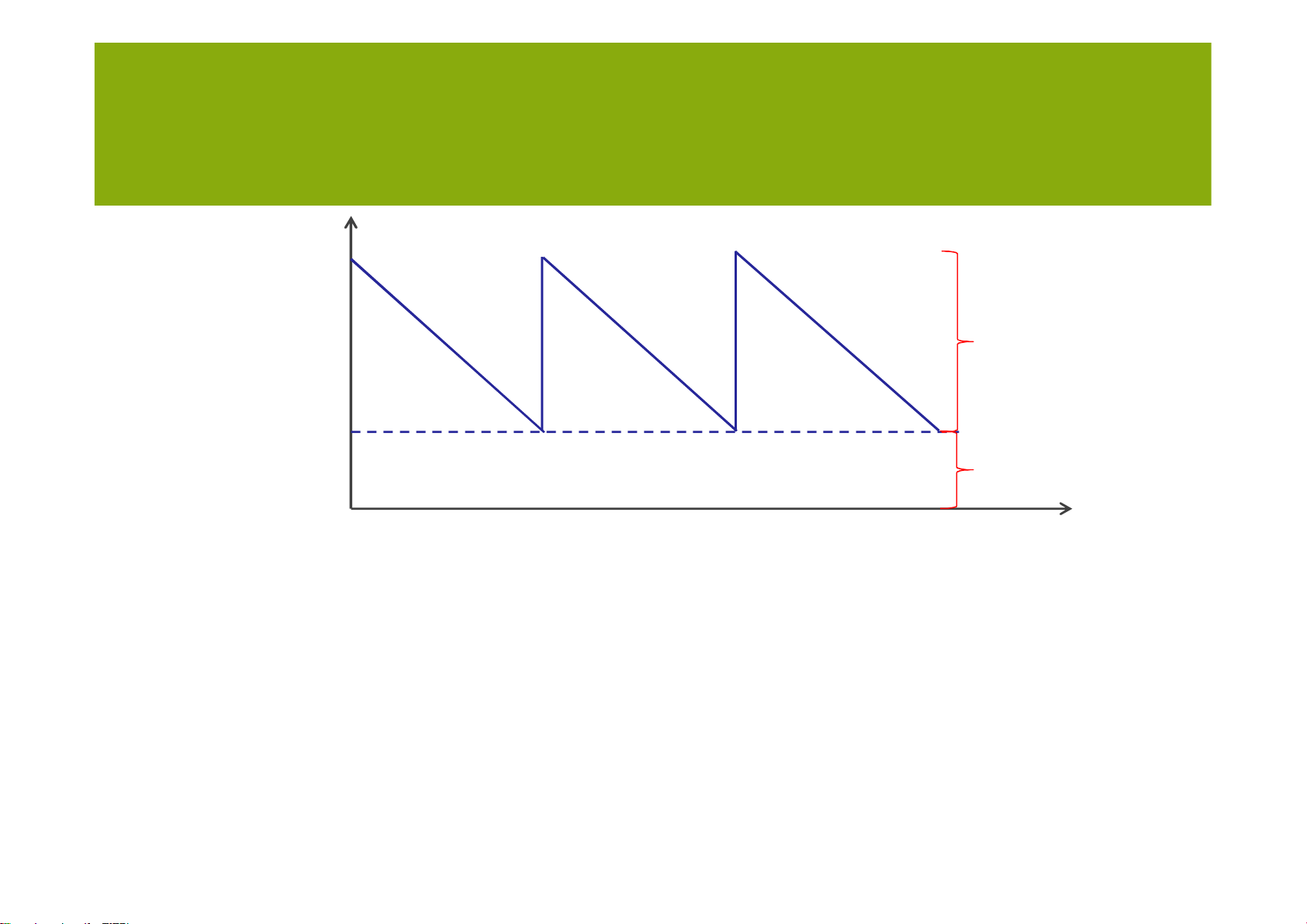

• Safety inventory is inventory carried to satisfy

demand that exceeds the amount forecasted for a given period. lOMoARcPSD| 36782889 MANAGING UNCERTAINTY Inventory Cycle inventory Safety inventory Time lOMoARcPSD| 36782889 MANAGING UNCERTAINTY

Example importance of availability lOMoARcPSD| 36782889 MANAGING UNCERTAINTY lOMoARcPSD| 36782889 MANAGING UNCERTAINTY Trade-off of safety stock

• A supply chain manager has to balance:

– Pro: Increase of product availability

– Con: cost of holding (safety) inventory

• Higher pressure on product availability, because:

– Internet increases the ease of searching

– Increased variability and customization

– Shorter product life cycle lOMoARcPSD| 36782889 MANAGING UNCERTAINTY

• High pressure on reduced inventory because: – Need to reduce costs

Safety inventory and demand uncertainty

• Key questions for planning safety stock:

– What is the appropriate level of product availability

– How much safety inventory is needed – What actions can be taken to improve

productavailability while reducing safety inventory?

• Demand has a systematic and a random component lOMoARcPSD| 36782889 MANAGING UNCERTAINTY

• Goal is of forecasting is:

– Predict the systematic component

– Estimate the random component

Measuring product availability

• Product availability can be measured by:

– Product fill rate (fr): is the fraction of product

demandthat is satisfied from product in inventory

– Order fill rate: is the fraction of orders that are

filledfrom available inventory lOMoARcPSD| 36782889 MANAGING UNCERTAINTY

– Cycle service level (CSL): is the fraction ofreplenishment

cycles that end with all the customer demand being met. Replenishment policies • Replenishment policies is the process of

regardingwhen to order and how much to order. • Two main approaches: lOMoARcPSD| 36782889 MANAGING UNCERTAINTY

– Continuous review: Inventory is continuously

checkedand when at Reorder point (ROP) a lot size Q is ordered.

– Periodic review: Inventory is checked at a

regularinterval and the order is placed to raise the

inventory to a certain threshold.

Impact uncertainty on safety stock

• The safety stock level is influenced by:

– Uncertainty in lead-time (of supplier, production) – Uncertainty in demand

– Number of independent stocking locations lOMoARcPSD| 36782889 MANAGING UNCERTAINTY Number of independent Stocking locations

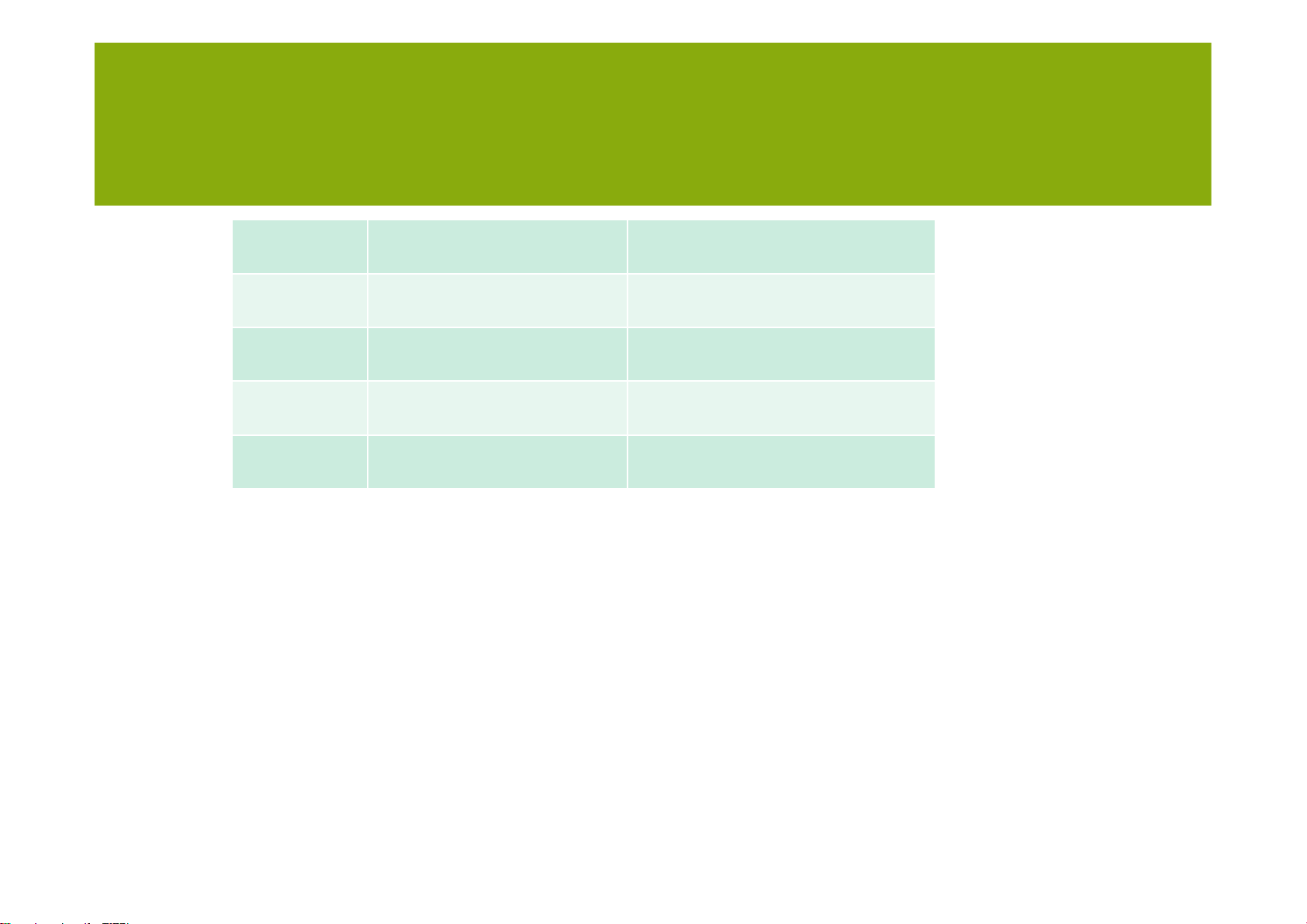

Impact uncertainty on safety stock • This could lead to the following mathematicaloutcomes: Fill rate Safety inventory Costs lOMoARcPSD| 36782889 MANAGING UNCERTAINTY 97.5% 67 + 98.0% 183 ++ 98.5% 321 ++++ 99.0% 499 +++++++++ 99.5% 767 +++++++++++++++

• How to balance or to improve?

Impact uncertainty on safety stock

• The impact on safety stock can be improved by: – Reducing the lead-time

– Reducing the uncertainty in demand lOMoARcPSD| 36782889 MANAGING UNCERTAINTY

– Reducing the number of independent stockinglocations

The role of IT in inventory management

• IT can support inventory management by: – Improved visibility:

• To see how much is available

• To see where this is available (store, warehouse, other stores)–

Better coordination of the supply chain: • Using RFID systems

• Integrating different stages (collaborative planning, etc) lOMoARcPSD| 36782889 MANAGING UNCERTAINTY

• It is important to recognize that

informationaccuracy important (garbage in -> garbage out!)