Preview text:

lOMoARcPSD| 36991220 ABSTRACT

During the research and study process to complete our group assignment report, we

received a lot of guidance from our teacher as well as help from our classmates to ensure the best completion of this report.

We would like to express special thanks to Assoc.Prof Ph.D Lê Ngọc Quỳnh Lam for her

detailed guidance and explanations regarding the knowledge of Management Business Logistics.

Thanks to her instructions, our group was able to better understand the project topic and

complete this assignment on time.

Although we have tried our best to complete this report, there are still some shortcomings

in terms of assuming data due to our limited practical experience. We sincerely hope for

understanding and constructive feedback from our teacher and peers so that we can improve the

report and gain experience for future assignments. We would like to express our sincere gratitude. TABLE OF CONTENTS

CHAPTER 1: OVERVIEW OF THE SAIGON BEER – ALCOHOL – BEVERAGE

CORPORATION – SABECO ..................................................................................................3

1.1 General Information .........................................................................................................4

1.2 Outstanding Achievements ...............................................................................................5

1.3 Vision – Mission .................................................................................................................6

1.4 Oriented Development .......................................................................................................7

CHAPTER 2: THE SUPPLY CHAIN OF SAIGON BEER CORPORATION IN ......9

VIETNAM ....................................................................................................................................9

2.1 Introduction about the supply chain ..............................................................................9

2.1.1 Definition .........................................................................................................................9

2.1.2 Supply chain components ................................................................................................9

2.1.3 Supply chain management .............................................................................................10

2.2 Demand management and planning ............................................................................11

2.3 Procurement of the supply chain ..................................................................................12

2.3.1 Main ingredient .............................................................................................................12

2.3.2 Production process ........................................................................................................13 lOMoARcPSD| 36991220

2.3.3 Quality control ..............................................................................................................15

2.4 Managing inventory flow ...............................................................................................16

2.4.1 Goods characteristics ....................................................................................................16

2.4.2 Warehouse .....................................................................................................................17

2.4.3 Types of inventory .........................................................................................................18

2.4.4 Inventory management ..................................................................................................20

2.4.5 Good characteristics .....................................................................................................22

2.4.6 Warehouse of SABECO .................................................................................................22

2.5 Transportation system .....................................................................................................23

2.5.1 Overview of Saigon Beer Transportation and Logistics Joint Stock Company ...........23

(Sabetranjsc) ..........................................................................................................................23

2.5.2 Transportation system roles ..........................................................................................24

2.5.3 Modes of transport ........................................................................................................25

2.5.4 Advantages and disadvantages for the Saigon Beer transportation system .................26

2.6 Distribution channel .......................................................................................................27

2.6.1 Distribution channel ......................................................................................................27

2.6.2 Members in the Distribution Channel of Saigon Beer ..................................................29

2.6.3. Distribution Channel Structure ....................................................................................30

2.6.4 Distribution Channel Design Process ...........................................................................31

2.6.5 Distribution Channel Management ...............................................................................33

2.6.6 Distribution Channel flows ...........................................................................................33

2.6.7 Saigon Beer distribution channel system ......................................................................35

CHAPTER 3: PROBLEM AND SOLUTION ....................................................................37

3.1. Problems in Distribution Network ...............................................................................37

3.1.1. Imbalanced Distribution Market ..................................................................................37

3.1.2. Inaccurate Order Fulfillment .......................................................................................38

3.1.3. Exchange and Return ...................................................................................................39

3.2. Problems in Inventory Management ...........................................................................40

3.2.1. Inefficient product storage managing ..........................................................................40

3.2.2. Excessive or Insufficient Inventory ..............................................................................41

3.3. Problems in Transportation Process ...........................................................................43

3.3.1. Compliance and Regulatory Issues ..............................................................................43 1 lOMoARcPSD| 36991220

3.3.2. Insufficient Transportation Infrastructure System .......................................................45

3.3.3. Abnormal Weather Conditions .....................................................................................47

3.3.4. Inefficient Transportation Process ...............................................................................49

3.3.5. Loss of Goods during Transportation ..........................................................................50

3.3.6. Fluctuate Transportation Costs ...................................................................................52

CHAPTER 4: CONCLUSION ...............................................................................................54

REFERENCES ......................................................................................................................55 LIST OF TABLES

Table 2. 1: Beer parameters for storage..............................................................................22

Table 2. 2: Size of the unit of goods 28 2 lOMoARcPSD| 36991220 LIST OF FIGURES

Figure 1. 1: Products of Saigon Beer Corporation – SABECO..............................................8

Figure 1. 2: The Saigon Beer – Alcohol – Beverage Corporation located in Nguyen Chi

Thanh Street, Ward 5, HCMC............................................................................................13

Figure 2. 1: Model of supply chain components 14

Figure 2. 2: Supply Chain Management.............................................................................16

Figure 2. 3: Beer production process at SABECO...............................................................19

Figure 2. 4: Production of glass bottles Saigon Beer...........................................................21

Figure 2. 5: SABECO’s warehouse....................................................................................23

Figure 2. 6: Types of products of Saigon beer.....................................................................28

Figure 2. 7: Transport SABECO’s beers by truck................................................................32

Figure 2. 8: Flow in distribution channels..........................................................................40

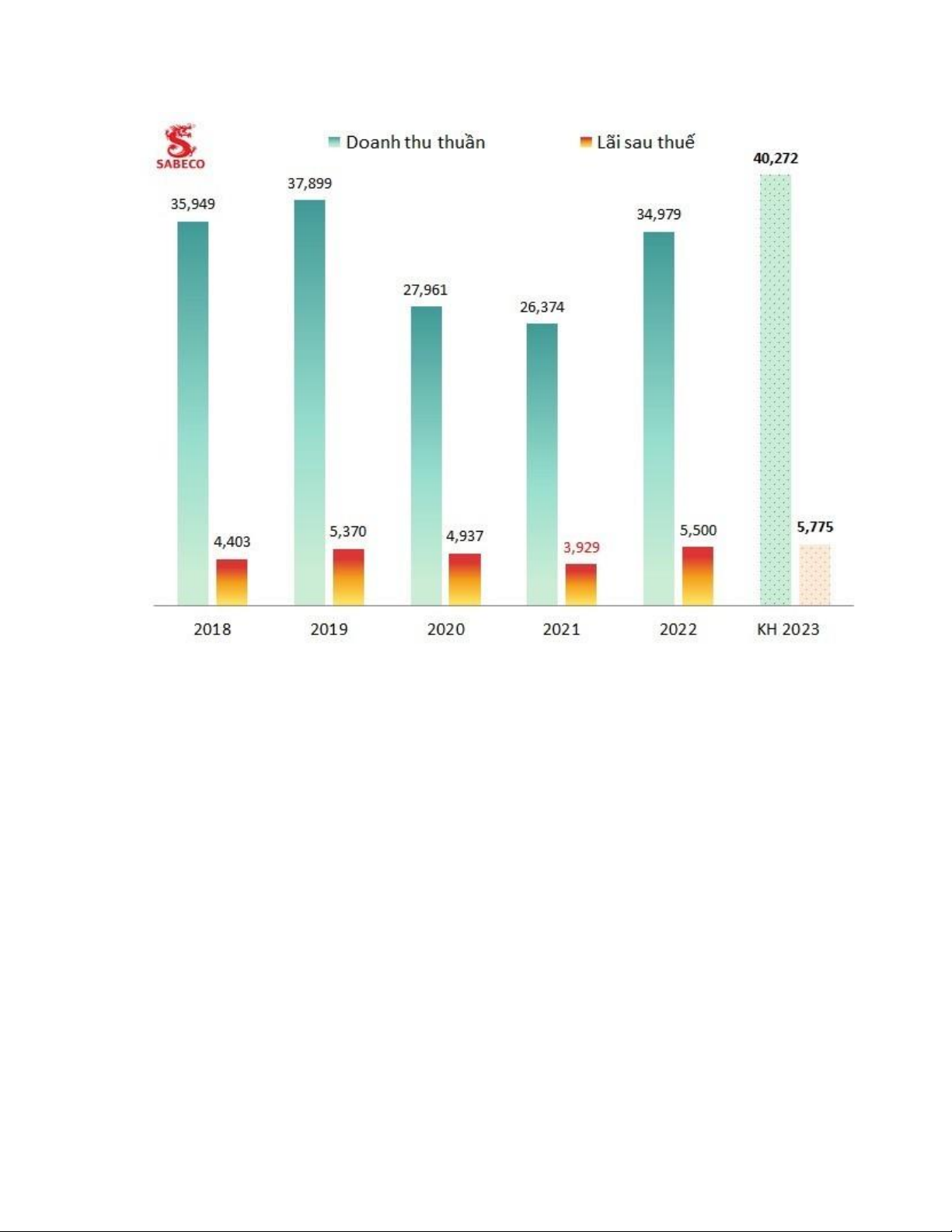

Figure 3. 1: Sales result over the years since 2018 and plan for 2023 of SABECO

CHAPTER 1: OVERVIEW OF THE SAIGON BEER – ALCOHOL –

BEVERAGE CORPORATION – SABECO

Vietnamese consumers have long been familiar with the Saigon Beer brand of Saigon Beer

- Alcohol - Beverage Corporation - SABECO. In 2020, SABECO has gone through 145 years of

history and 43 years of building and developing the brand. From the 145-year milestone, the golden

flow of Beer has and will always be preserved by efforts to continue into the future, always existing

in the emotions of Vietnamese people proud of Vietnamese products.

The unique flavor of Saigon Beer is the crystallization of the products of the rich Southern

land and the generous spirit of Saigon people, becoming an indispensable part of daily happy and 3 lOMoARcPSD| 36991220

sad life. With 2 types of Larue bottled beer with a capacity of 610 ml and 333 bottled beer with a

capacity of 330ml at the beginning of the takeover, up to now, SABECO has developed 10 product

lines: Saigon Lager 450 bottled beer, Saigon Export bottled beer, and Saigon Special bottled beer.

, Saigon Lager 355 bottled beer, 333 Premium bottled beer, Lac Viet bottled beer, 333 canned beer,

Saigon Special canned beer, Saigon Lager canned beer, Lac Viet canned beer are fully present in the market.

After 145 years of establishment and development, with many difficulties and challenges,

up to now, although there have been many famous beer brands in the world, Saigon Beer and Beer

333 are still the leading brands. Vietnamese brand leads the Vietnamese beer market and is on its

way to conquering demanding markets such as Germany, the US, Japan, the Netherlands, etc.

Figure 1. 1: Products of Saigon Beer Corporation – SABECO

1.1 General Information

- Name: SAIGON BEER – ALCOHOL – BEVERAGE CORPORATION - Abbreviated name: SABECO

- Charter capital: 6,412,811,860,000 VND

- Legal representative – Chairman of the Board of Directors: Mr. Koh Poh Tiong

- General Director: Mr. Lester Tan Teck Chuan

- Registered office: 187 Nguyen Chi Thanh, Ward 12, District 5, City. Ho Chi Minh, Vietnam

- Head office: 5th Floor, Vincom Center Building, 72 Le Thanh Ton, Ben Nghe Ward, District 1,City. Ho Chi Minh, Vietnam

- Phone: (+84) 28 3829 4081 - 3829 4083 - 3829 6342 4 lOMoARcPSD| 36991220 - Fax: (+84) 028 3829 6856

- Email: Website: https://www.sabeco.com.vn

- Business license: 0300583659 issued by the Ho Chi Minh City Department of Planning and

Investment on April 17, 2008, adjusted for the 11th time on October 13, 2023

- Business lines: Producing and trading Beer, Alcohol and Beverage.

1.2 Outstanding Achievements

- LACVIET BEER, SAIGON LAGER BEER, SAIGON EXPORT BEER, SAIGON

GOLDBEER: Gold Medal “2023 World Beer Championships in USA”, from Chicago’s Beverage Testing Institute.

- BEER 333, SAIGON CHILL BEER, SAIGON SPECIAL BEER, SAIGON COFFEE -

INFUSED BEER: Silver Medal “2023 World Beer Championships in USA”, from Chicago’s Beverage Testing Institute.

- SAIGON SPECIAL BEER, SAIGON EXPORT BEER: Silver Medal “2022 World BeerAwards

in UK”, from World Beer Award Publication.

- BEER 333, SAIGON LAGER BEER: Gold Medal “2022 World Beer Awards in UK”,

fromWorld Beer Award Publication.

- SAIGON SPECIAL BEER: Silver Medal “2022 Brussels Beer Challenge in Belgium” fromBeer Communications & Events.

- SAIGON CHILL BEER: Gold Medal “2022 Asia Beer Championship in Singapore” from AsiaBrewers Network.

- BEER 333, SAIGON GOLD BEER, LACVIET BEER: Silver Medal “Pilsen type”, 60th World

Selection 2021 of Beers, Waters and Soft Drinks 2022, from Monde Selection International Quality Institute, Belgium.

- BEER 333: Silver Medal “Pilsen type”, 60th World Selection 2021 of Beers, Waters and Soft

Drinks 2021, from Monde Selection International Quality Institute, Belgium.

- SAIGON EXPORT BEER: Silver Medal “Pilsen type”, 60th World Selection 2021 of Beers,

Waters and Soft Drinks 2021, from Monde Selection International Quality Institute, Belgium.

- SAIGON CHILL BEER: Silver Medal “Other International Style Lager”, AIBA 2021, fromThe

Royal Agricultural Society of Victoria, Australia. 5 lOMoARcPSD| 36991220

- SAIGON LAGER BEER: Silver Medal “ Special or Regional beers”, 60th World Selection 2021

of Beers, Waters and Soft Drinks 2021, from Monde Selection International Quality Institute, Belgium.

- SAIGON LAGER BEER: Silver Medal “Other International Style Lager”, AIBA 2021, fromThe

Royal Agricultural Society of Victoria, Australia.

- SAIGON SPECIAL BEER: Gold Medal “Pilsen type”, 60th World Selection 2021 of Beers,

Waters and Soft Drinks 2021, from Monde Selection International Quality Institute, Belgium.

- SAIGON GOLD BEER: Gold Medal “Australian Style Lager”, Australian International

BeerAwards 2021, from The Royal Agricultural Society of Victoria, Australia.

- BEER 333: Silver Medal "International Style Pilsener Runner - up", The International BeerCup

2019, from The Craft Beer Association, Japan.

- SAIGON SPECIAL BEER: Gold Medal “International Style Pilsener”, The International

BeerCup 2019, from The Craft Beer Association, Japan.

- SAIGON LAGER BEER: Champion “German Heritage”, The International Beer Cup

2019,from The Craft Beer Association, Japan.

- SAIGON LAGER BEER: Gold Medal “Light Lager”, The International Beer Cup 2019,

fromThe Craft Beer Association, Japan.

- SAIGON LAGER BEER: Gold Medal “International Small pack Lager Competition”, Class

1,The International Brewing Awards 2019, from The National Brewery Center, UK.

- BEER 333 PREMIUM EXPORT: AIBA International Rhyme Prize in Australia 2015. 1.3 Vision – Mission Vision to 2025:

Develop SABECO into Vietnam's leading beverage industry corporation, with a position in the region and internationally. Mission:

- Contribute to the development of Vietnam's Beverage industry on a world-class level.

- Promote Vietnamese culinary culture. 6 lOMoARcPSD| 36991220

- Improve quality of life through providing high quality, safe and nutritious beverage products.

- Bring practical benefits to shareholders, customers, partners, employees and society.

- Satisfy and meet beverage needs according to international food safety and hygiene

standards"Food hygiene and safety and environmental protection".

- Fulfill all obligations to the State on the basis of transparency in business.

- Actively participate in community activities.

- Ensuring development towards international integration.

1.4 Oriented Development

SABECO continues to promote business activities towards effective and sustainable development

to affirm its leading position in the market. Main issues: - Sells:

• Focus on maintaining its domestic position, promoting exports and penetrating new markets.

• Diversify distribution channels, improve capacity and operational efficiency of the distributionsystem. - Trademark: • Review brand positioning.

• Develop brand architecture.

• Develop brand architecture. - Manufacture:

• Ensure and improve product quality.

• Increase the operating efficiency of factories.

• Increase production management capacity and rationalize production and consumption areas. - Supply chain: 7 lOMoARcPSD| 36991220

• Streamline warehousing and transportation.

• Optimize dispatch planning.

• Improve transportation services

- Activities of the Board of Directors and Executive Board:

• Internationalize operating activities by applying a management model according to

international practices, in which the Board of Directors plays the role of strategic direction and

the Executive Board is in charge of production, business and operating activities. - Personnel:

• Strengthen employee engagement and make people a core competitive factor.

• Enhance open and transparent dialogue.

• Develop management policies and evaluate work performance.

• Increase employee work efficiency through annual training programs.

• Implement a salary structure based on capacity.

- Information Technology:

• Transforming the way of working by applying IT - SABECO 4.0.

Figure 1. 2: The Saigon Beer – Alcohol – Beverage Corporation located in Nguyen Chi

Thanh Street, Ward 5, HCMC 8 lOMoARcPSD| 36991220

CHAPTER 2: THE SUPPLY CHAIN OF SAIGON BEER CORPORATION IN VIETNAM

2.1 Introduction about the supply chain

2.1.1 Definition

A supply chain is the network of all the individuals, organizations, resources, activities and

technology involved in the creation and sale of a product. A supply chain encompasses everything

from the delivery of source materials from the supplier to the manufacturer through to its eventual

delivery to the end user. The supply chain segment involved with getting the finished product from

the manufacturer to the consumer is known as the distribution channel.

During the production process, necessary planning is required to ensure the supply chain

operates at optimal efficiency. The concept of Supply Chain Management is the integration of key

business processes from the initial suppliers to the final link of the supply chain, that is, the

customer to provide products, services and information to create added value for customers and

shareholders of the business. The purpose of supply chain management is to maximize customer

value, deliver optimal efficiency, and achieve sustainable competitive advantage.

2.1.2 Supply chain components

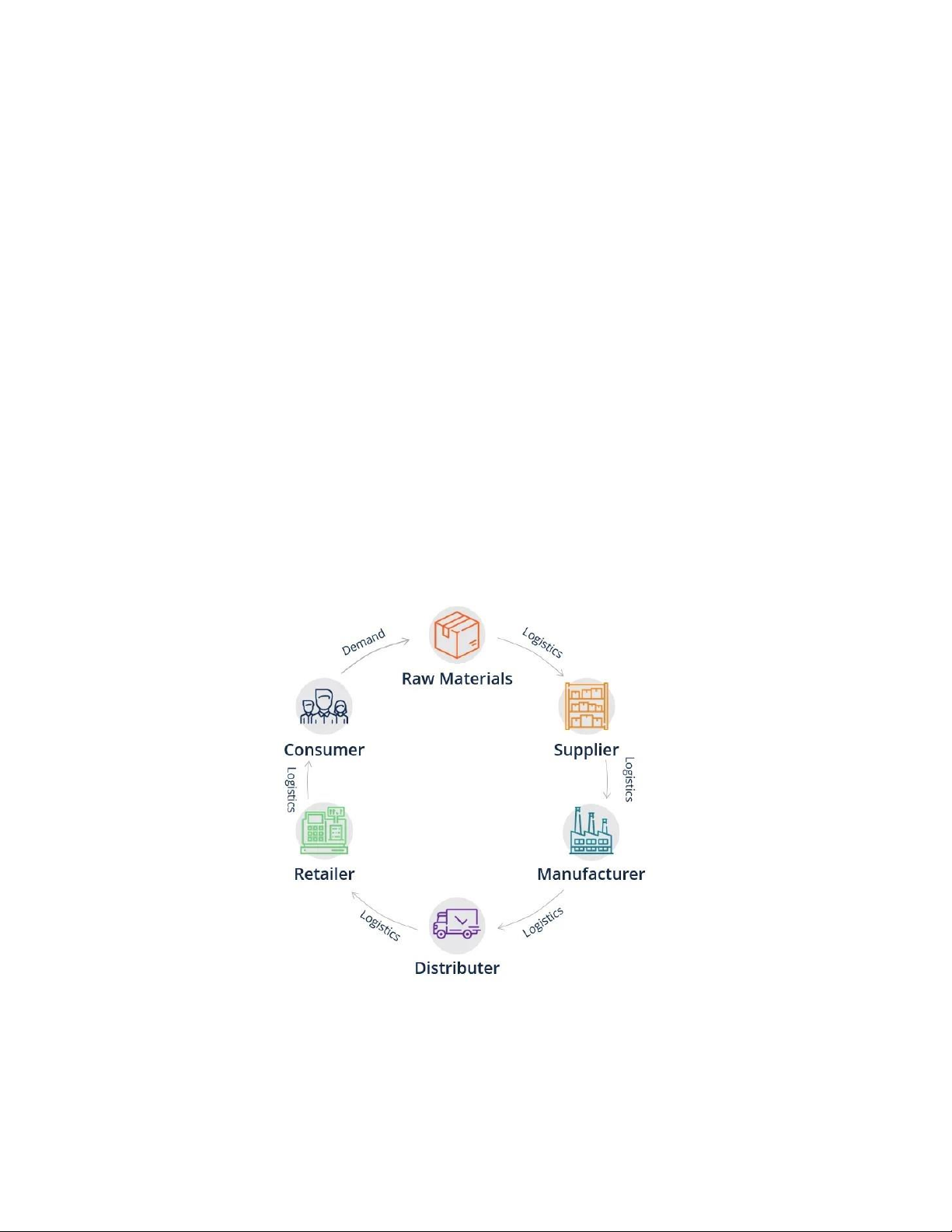

Figure 2. 1: Model of supply chain components

The components of a supply chain include 5 main components: 9 lOMoARcPSD| 36991220 -

Raw material supply: This is the first component and plays an important role in the

supplychain. Input materials are a key factor that determines product quality. If raw material

supplies are interrupted, production plans and supply chains will face problems. -

Producers: The producers will take on the role of processing raw materials to create

productsthat meet customer needs. Producers are components that directly affect the quality of finished products. -

Distribution centers: are assigned the task of bringing products to customers.

However,distribution centers often ship large quantities of products, primarily sending products to

retail outlets rather than directly to the end consumer. -

Retailers: are grocery stores, supermarkets, convenience stores,... intermediaries

betweendistributors and consumers. -

Customers: are people who directly consume and use products and goods. This is also the

finalcomponent and the end of the supply chain.

2.1.3 Supply chain management

Supply chain management (SCM) is the oversight of materials, information and finances

as they move in a process from supplier to manufacturer to wholesaler to retailer and then to the

consumer. The three main flows of the supply chain are the product flow, the information flow and

the finances flow. These occur across three main stages: strategy, planning and operation.

SCM involves coordinating and integrating these flows both within and among companies. 10 lOMoARcPSD| 36991220

Figure 2. 2: Supply Chain Management

2.2 Demand management and planning

In the ever-evolving landscape of the global market, businesses face the imperative

challenge of not only meeting current demand but also strategically planning for future growth.

Demand management and planning play pivotal roles in ensuring a company's sustainability,

competitiveness, and resilience.

Sales, being the lifeblood of any successful enterprise, demand meticulous attention to both

domestic and export market dynamics. Saigon Beer, recognizing the need for sustained growth, is

actively boosting its presence in both arenas. Diversification of distribution channels, especially

through the expansion of e-commerce platforms, is a strategic move to meet the evolving

preferences of modern consumers. Simultaneously, improving the capacity and operational

efficiency of the distribution system ensures that products reach consumers in a timely and cost-

effective manner. Investing in the enhancement of salesforce competencies further fortifies the

company's ability to understand and respond to market demands dynamically.

On the production front, Saigon Beer is embracing a forward-looking approach by focusing

on brand expansion and innovations. This not only caters to the diverse preferences of consumers 11 lOMoARcPSD| 36991220

but also ensures the company remains at the forefront of the industry. Beyond profitability, there

is a keen emphasis on corporate sustainability development, aligning production processes with

environmental and social responsibility.

Supply chain optimization forms another critical pillar of Saigon Beer's demand

management strategy. Rationalizing warehouses and transportation, alongside optimizing route

planning, minimizes operational inefficiencies and contributes to a more streamlined and

costeffective supply chain. Improved delivery services further enhance customer satisfaction and loyalty.

Recognizing that a company is only as strong as its people, Saigon Beer places a premium

on employee engagement and transparent communication. Open and transparent communication

channels foster a culture of collaboration and innovation. Policies aimed at managing and

evaluating work effectiveness provide employees with clear expectations, promoting

accountability and productivity. The company's commitment to employees' continuous

development is evident in the implementation of annual training programs, strengthening their

skills and knowledge base. Furthermore, a performance-based salary structure ensures that

employees are recognized and rewarded based on their contributions, fostering a culture of excellence.

2.3 Procurement of the supply chain

2.3.1 Main ingredient - Water:

Play the role of the main components make up a large proportion of beer, water usually account

for about 90-95% of the weight of a beer bottle. Water is a solvent that dissolves chemical

compounds (such as starch, sugar, protein, fat ...). Enzymes participate in the hydrolysis process

of breaking down high-molecular-weight compounds into simpler ones for yeast consumption.

Subsequently, the yeast continues to live and thrive in a water environment. - Malt:

Malt, typically delivered from barley, is a crucial ingredient. It provides the sugar necessary for

fermentation, as well as the malty flavors and aromas that contribute to the beer’s profile. At the

brewing stage, the starch in malt is hydrolyzed by the amylase enzyme system into fermentable sugars. 12 lOMoARcPSD| 36991220 - Hops:

Houblon hops are a fundamental ingredient after malt in beer production. They impart a pleasantly

mild bitterness, a highly distinctive aroma, enhance the ability to create and maintain foam,

increase adhesive strength, and stabilize the biological components of the product. In beer

production technology, only unpalliated female hop cones are utilized.

In some recent years, Yakima hops are replacing Houblon in some special flavor, make “Saigon

Special” much more special, go along with a new technology “dry-hopping”, Yakima hops bring

a mild bitterness accompanied by a distinctive aroma. - Yeast:

Yeast plays a role in converting fermentable compounds in wort into alcohol and CO2 during

fermentation. In the fermentation process, yeast produces compounds that contribute aroma and

flavor to the beer. Different yeast strains yield distinctive beer flavors. Various breweries own

proprietary yeast strains, which are closely guarded and protected.

2.3.2 Production process

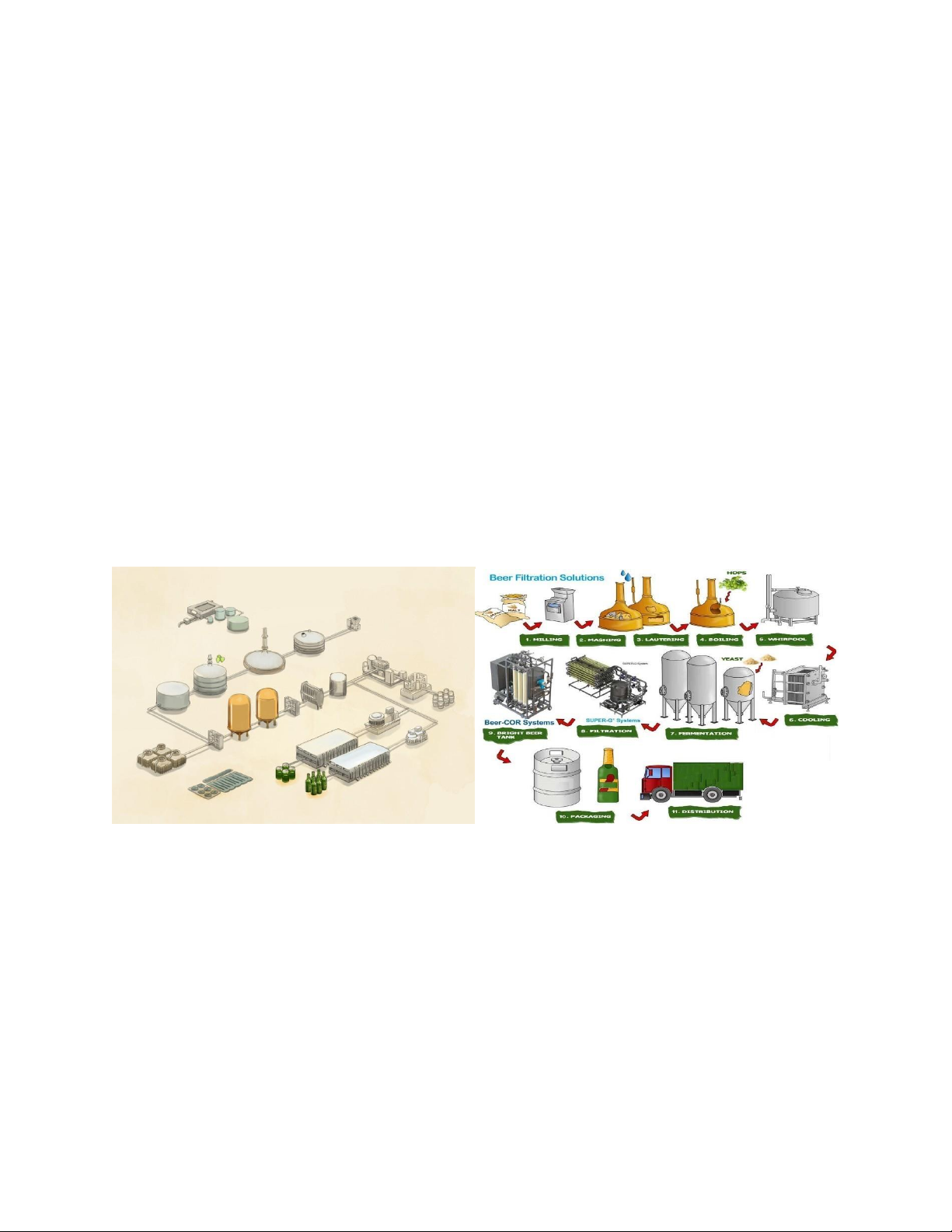

Figure 2. 3: Beer production process at SABECO - Grinding mill

Grind small the malt into the particles size (or rice grain) to the required size so that the

ingredients in the material can be dissolved into water and release the enzyme to catalyze the hydrolysis process. - Malt cooker 13 lOMoAR cPSD| 36991220

Hydrolysis of polymeric compounds such as starch, protein into fermentable compounds such as

maltose, glucose, amino acids, etc. At the end of the malt process, sweeteners are obtained and

this process called “Glucosinolation”. - Filter pot

It is the process of removing ground paddy husk of malt seed from sugar solution. - Boiling pot

The clear sugar is boiled with hops to produce a characteristic bitterness, while the boiling process

also evaporates and precipitates unwanted compounds and sterilizes the solution. - Scale separator

Remove ingredients such as petal berry, the precipitate formed during boiling. - Quick heat

0The boiled water (10 C) is brought to the appropriate temperature for the yeast to operate as 100̊

- 15oC. This temperature depends on the type of yeast and the type of beer. - Fermentation tank

Refrigerated yeast and yeast are put into the fermenting tank for fermentation. Yeast along with

sugar is formed during cooking to form alcohol and CO2. Smell compounds for beer are also

produced by yeast in this period. At the end of fermentation, the yeast will be removed from the

fermenting tank for reuse for the next fermentation. The fermentation after fermentation will be

transferred to the brewing tank to start the secondary fermentation process. - Beer brewing tank

The process of metabolizing or removing unwanted compounds formed during fermentation such

as diacetyl. The brewing process ends when the contents of the beer are reduced to the desired

level and reach the desired time of the beer. - Long cooling

Beer pre-filtered will be cooled down to -1 and-2°C to form cold residue. These scales will be

removed during filtration in the later. - Filter in beer

Yeast, cold residue, etc. will be removed to make the beer transparent. 14 lOMoARcPSD| 36991220 - Bright Beer Tank

The filtered beer is stored in the beer tank pending for the extract brewing and packaging process. - Beer brew

In extract brewing, beer is extracted into different packaging to meet the needs of customers. Keg

beer has 2 liters capacity, 5 liters, 20 liters, 30 liters or 50 liters. Beer is extracted into a cans of

330ml, 500ml. Beer bottles have a capacity of 330ml, 450ml, 500ml, 750ml. Capacity of beer

bottles, beer can depends on the market strategy and consumer tastes of each country.

2.3.3 Quality control

Deployment and successful implementation:

• ISO 9001:2008 Quality Management System (quality management).

• ISO 14001 Quality Management System (environmental management).

• HACCP Quality Management System to control the quality, ensuring the taste, quality, andsafety

of the product when purchased.

• CIP (Cleaning in Place) and COP (Cleaning out of Place) sanitation systems. Quality inspection:

• Microbiological testing in fermentation rooms.

• Chemical testing in a shared laboratory.

• Multiple quality checkpoints in the production process entirely operated by machinery,addressing

any detected errors immediately.

• Checking the cleanliness of bottle shells, identifying defects on bottles, and assessing qualityafter washing. 15 lOMoARcPSD| 36991220

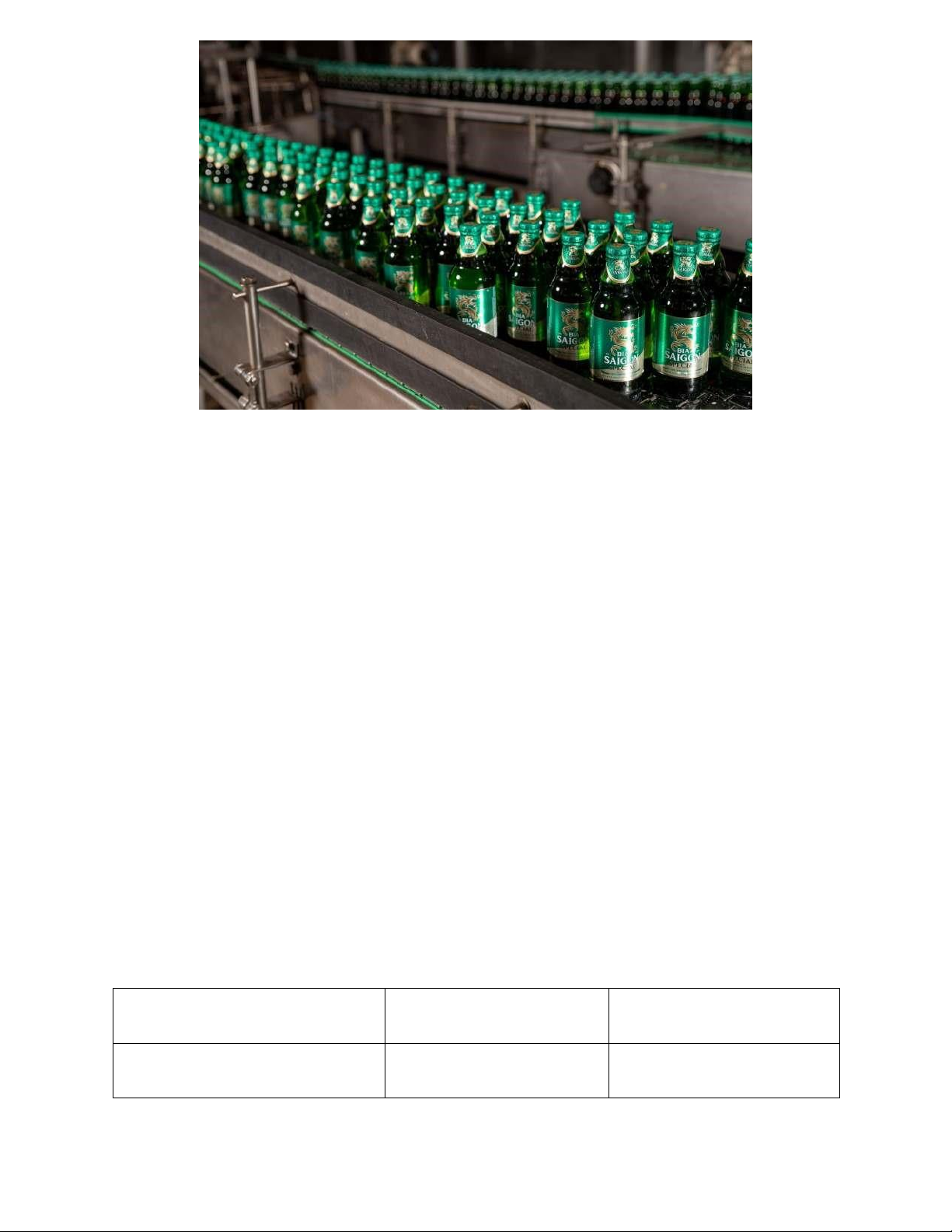

Figure 2. 4: Production of glass bottles Saigon Beer

2.4 Managing inventory flow

2.4.1 Goods characteristics -

Saigon Beer is the main product of Saigon Beer - Alcohol - Beverage Corporation

(SABECO),with two main packaging forms: cans and glass bottles. In this report, the team will

only analyze Saigon Beer products from a packaging perspective, not in-depth analysis of product

designs (green Saigon Beer, red Saigon Beer...) -

Aluminum can: Capacity 330ml. This is a popular form of Saigon Beer product because if

youwant to buy beer to take home or transport it far away, aluminum cans are the most suitable

option. In addition, Saigon Beer's aluminum can design also applies Ergonomics as the height is

not too high, helping drinkers not have to tilt their head too high when drinking, or has a larger

radius than other products other aluminum can products, to fit the hand of male customers (who

are the main customers of Saigon Beer). -

Glass bottle: Capacity 330ml. Saigon Beer has many types of glass bottles with

differentheights, serving many different customer groups, but they all use the same type of tank

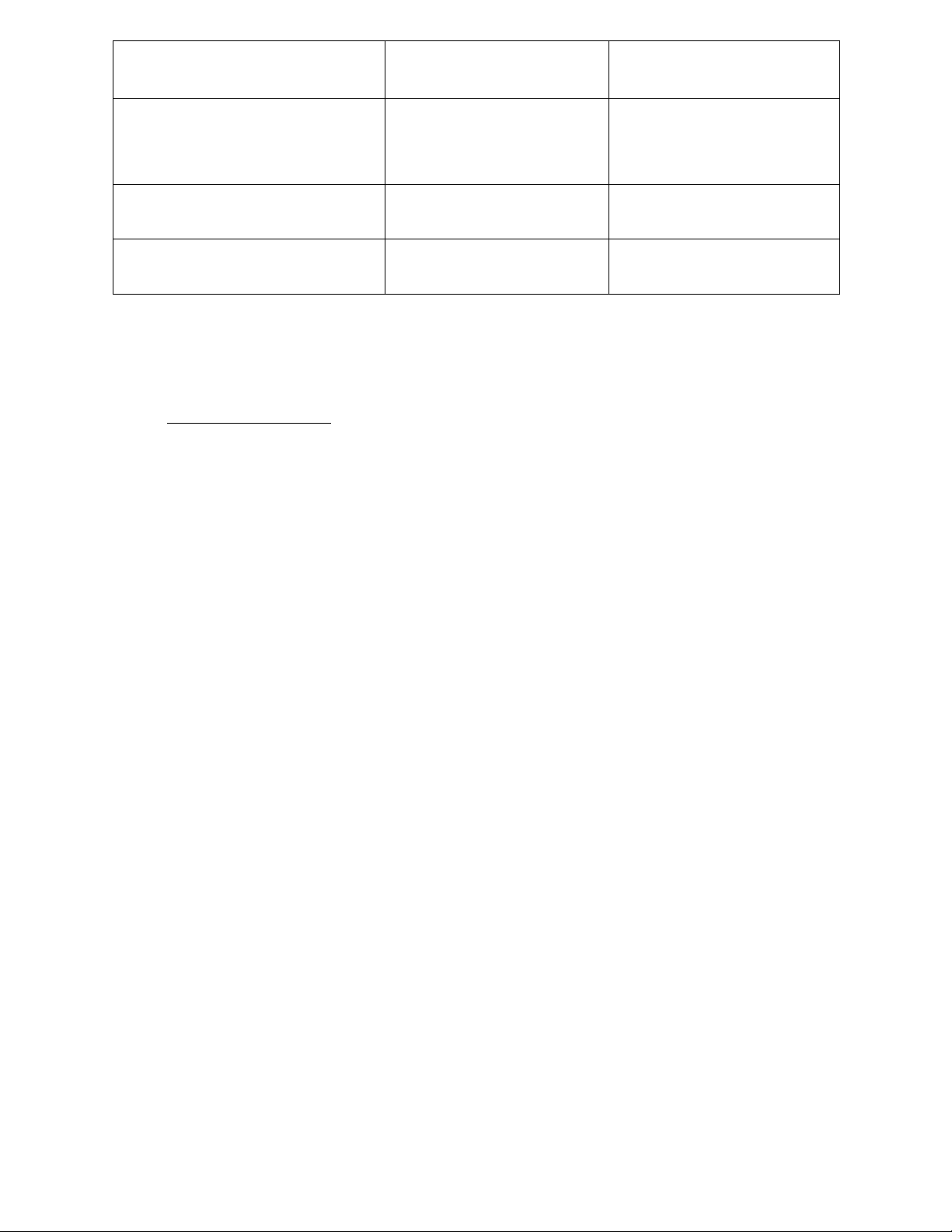

for storage. In addition, the glass bottle design also applies Ergonomics in some points. Aluminum cans (barrels) Glass bottles (tanks) Dimensions (cm) 18 x 12 x 24 30 x 25 x 24 16 lOMoARcPSD| 36991220 Number of products/ storage 24 cans 24 bottles units 4 6 The highest number of floors allowed Number of units on each floor 9 6 Total units/pallet 36 36

Table 2. 1: Beer parameters for storage 2.4.2 Warehouse 2.4.2.1 Characteristic

Some warehouse characteristics:

- Built with a large area and in spacious, flat locations, with airy space to help facilitatethe

transportation process as well as improve the efficiency of preserving finished products.

- Warehouses are built in a closed architectural style to store and store raw materials, products

or goods for a certain period of time to protect goods from environmental

impact or loss or wastage deficit...

- Have an effective space suitable for its function, providing a safe and comfortable working

environment for workers with the goal of increasing productivity and control, reducing

operating costs as well as increasing productivity customer service level.

- The company's distribution warehouse in Vietnam is a level 1 distribution warehouse(i.e.

from factory ⇒ warehouse). Products after being produced from the factory are transferred to

this warehouse and further distributed to level 1 agents,... distributed to retail stores (levels

2,3,4,...) and final consumer. 17 lOMoARcPSD| 36991220

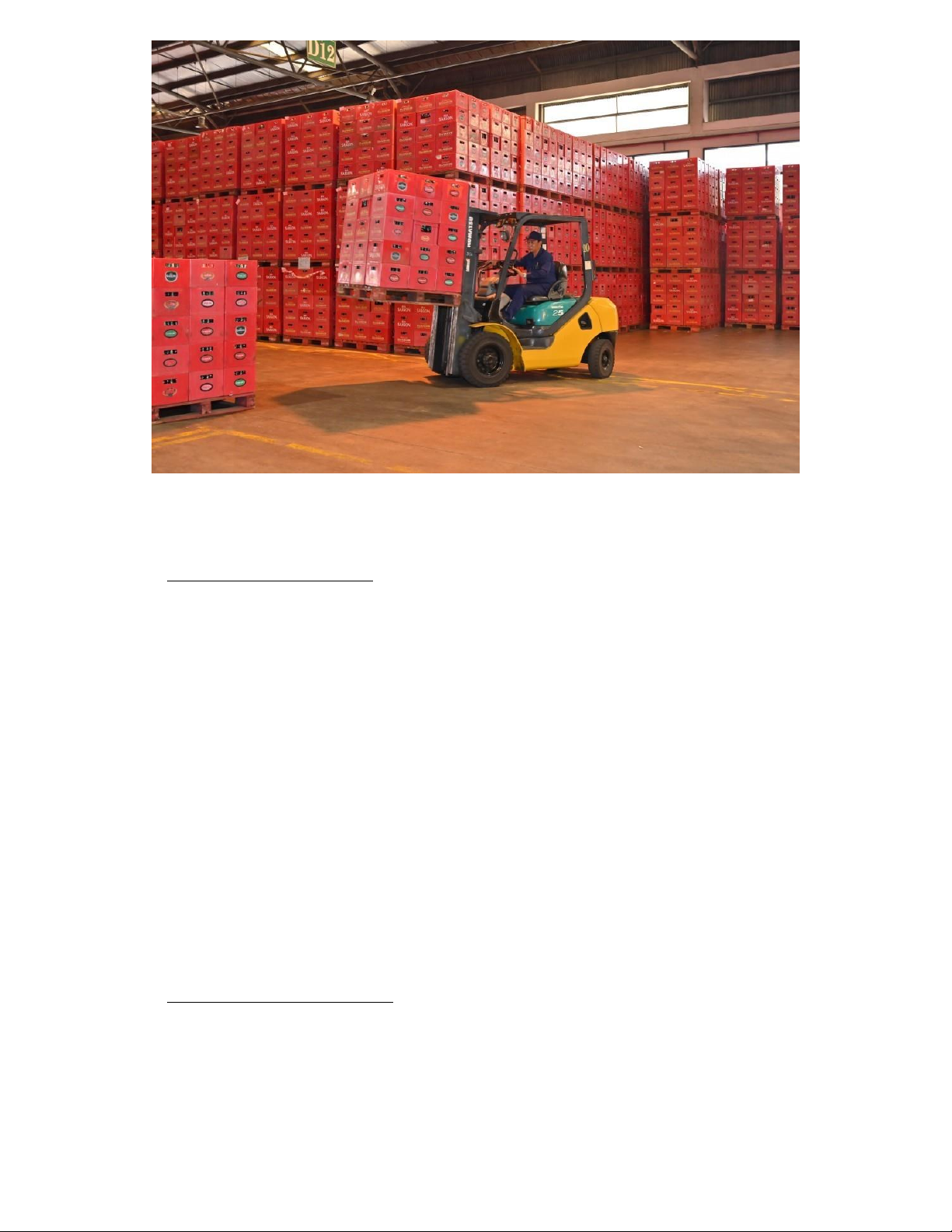

Figure 2. 5: SABECO’s warehouse

2.4.2.2 Warehouse location

- Saigon Beer - Alcohol - Beverage Corporation is a long-standing company, with asystem of

factories, warehouses, companies, offices,... stretching from North to South, plus hundreds of

Partners from large to small have created an extremely large logistics network with extremely

strong, seamless links. To analyze the effectiveness of that logistics network, the team will

analyze the warehouse system of Saigon - Cu Chi Brewery, located on the outskirts of Ho Chi Minh City.

- The warehouse is about 20km from the center of Ho Chi Minh City, a large industrial park

with full facilities such as roads, landscapes, electricity and water systems, waste treatment

systems. At the same time, this area has easy access to an abundant unskilled labor force, as

well as being close to a major highway, creating a strong advantage for development.

2.4.3 Types of inventory

2.4.3.1 Definition of inventory

Inventory, or inventory, is a list of materials and products or the materials and products

themselves that are kept in stock by a business. If inventory management is done properly,

it can reduce costs and increase profits for the company. 18 lOMoAR cPSD| 36991220

2.4.3.2 Inventory in Saigon Beer production - Raw material inventory:

These are the raw materials needed for the product creation process, including: • Danish malt • Hops • Yeast • Materials

• High quality bottles, high quality cartons and paper boxes • Processing additives • Devices

These are the main raw materials that the company purchases for use in the production

process. Maintaining an appropriate amount of inventory will bring advantages to the

company in purchasing materials and production activities. In particular, the material

supply department will benefit when it can buy in large quantities and enjoy discounted

prices from suppliers. In addition, when a company predicts that in the future the price of

raw materials will increase or that a certain type of raw material will be scarce, or both,

keeping a large amount of inventory will ensure that the company is always fully supplied

in a timely manner at a stable cost. Semi-finished product inventory (unfinished products):

raw materials are in the production stage but not yet completed (not yet finished products).

- Inventory of semi-finished products:

Semi-finished product inventory includes all items that are currently at a stage (such as

unlabeled products, semi-finished products in transit warehouses between stages).

Semi-finished product inventory is an essential part of the production system. Thanks to

semi-finished product inventory, each stage in the production process will reduce

dependence on each other, causing disruption to other departments. In addition,

semifinished products help to effectively plan production for each stage and minimize costs

arising from production delays or free time.

- Inventory of finished products: 19 lOMoARcPSD| 36991220

It is the final product of the manufacturing process. Finished goods inventory includes

products that have completed the production process and are awaiting consumption. Except

for large-scale equipment, consumer goods and industrial products are mass produced and

stored in warehouses to meet expected future consumption.

2.4.4 Inventory management

Inventory management includes 3 main tasks: - Manage product codes - Manage warehoused goods

- Manage the warehouse delivery process

2.4.4.1 Manage product codes

- Receive new or changed information

• A product's product code may have to be added, changed or canceled.

• Management levels will send information to the warehouse manager.

• The warehouse manager will add, edit or delete.

- Check and compare with the product code in the warehouse

• Warehouse staff need to check and compare the actual status of products in the warehouse. - Update information

• Update product code information on the system

• Include information such as: date of modification, request document with validsignature

as well as the signature of the person who edited.

• To ensure if any unexpected incidents arise.

2.4.4.2 Manage warehoused goods

Warehouse goods management has the following operating procedures:

- Notice of warehouse import plan 20 lOMoAR cPSD| 36991220

• Before each warehousing activity, a plan is made and discussed to find the most optimalwarehousing direction.

- Check and compare actual goods

• Check and compare goods in the warehouse

• After the goods arrive at the warehouse, staff must check all information about the

shipment such as name, code, quantity and quality. As well as the standards specified in

the warehouse management process of materials and goods.

• The purpose of solving problems if there are defective goods from the supplier.

- Complete warehouse import procedures

• Warehouse management staff imports goods into the warehouse

• Then prepare stamped warehouse receipt documents as well as update information into the system.

• This information is transferred to relevant departments such as accounting andproduction for checking and comparison.

2.4.4.3 Manage the warehouse delivery process

For warehousing activities, the operating process is as follows:

- Receive warehouse delivery requests

• Staff will process the validity of the request and then continue processing such as

releasing the warehouse for sale, releasing the warehouse for production, assembling or

releasing the warehouse to move to another place. - Check inventory

• Warehouse staff will check that product code at the warehouse. To know whether the

actual quantity is enough to export or not.

- Prepare delivery notes and invoices

• Staff prepare warehouse receipts and invoices for the company and customers to compare

and handle when problems arise.

- Export warehouse and update information

• Warehouse management staff will update information on the system 21 lOMoARcPSD| 36991220

• Report to relevant parties to proceed with warehouse release

2.4.5 Good characteristics

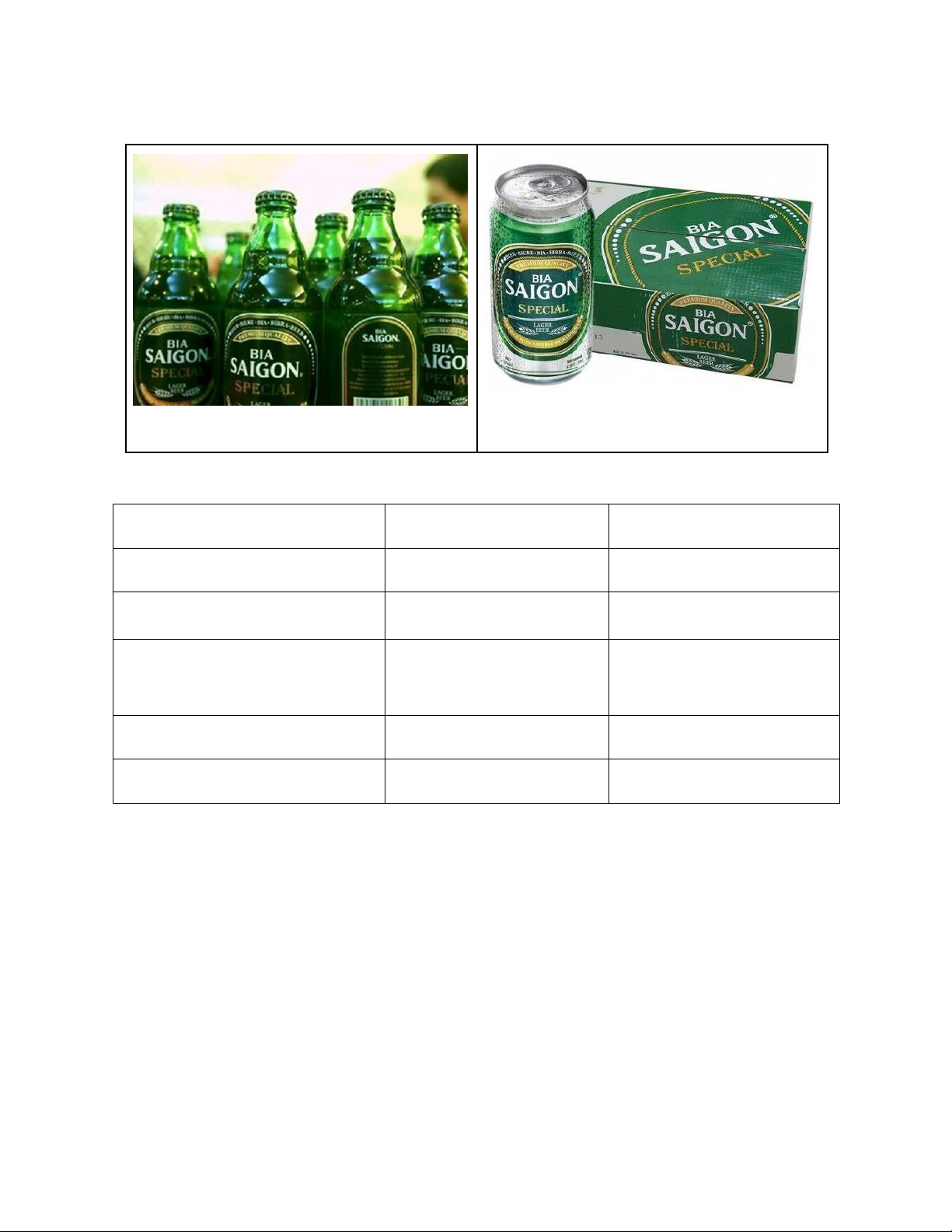

There are two types of Saigon beer sold in the market: glass bottle beer and canned beer.

Figure 2. 6: Types of products of Saigon beer Aluminum cans (barrels) Glass bottles (tanks) Dimensions (cm) 30 x 25 x 12 30 x 25 x 24 Number of products/ storage 24 cans 24 bottles units 10 6 The highest number of floors allowed Number of units on each floor 6 6 Total units/pallet 60 36

Table 2. 2: Size of the unit of goods

2.4.6 Warehouse of SABECO

- Warehouses are divided into 2 types: • Dry material storage

• Warehouse for storing materials and finished products

- Regarding dry material storage: 22 lOMoARcPSD| 36991220 •

Raw materials are the main materials that a company purchases to use in its production

process.Is where input materials are stored to produce beer (final product). Maintaining the

appropriate amount of raw materials will bring the company convenience in purchasing materials

and production activities. Such as: barley, Houblon flowers, rice, water, yeast •

Because of the nature of the materials, appropriate conditions and space are needed.

Likepulses, flowers, and rice, they need a dry, cool place to avoid mold. As for yeast, the right

temperature is needed so that the yeast does not get damaged.

- About finished product warehouse:

• Saigon Beer's finished product inventory includes products that have completed their production

cycle and are waiting to be shipped for consumption. Except for large-scale equipment, consumer

products and industrial products are mass produced and stored in warehouses to meet expected

future consumption. Specifically: bottles and cans (Hanacans Joint Stock Company, TCB Ball

Vietnam Beverage Can Company Limited...); label (Krones

Company, San Miguel Yamamura Phu Tho...); lid (Hercules VN Co., Ltd., Hanaka Co., Ltd....)

2.5 Transportation system

2.5.1 Overview of Saigon Beer Transportation and Logistics Joint Stock Company (Sabetranjsc)

- Address: 8th Floor, No. 8 Nam Ky Khoi Nghia, Nguyen Thai Binh Ward, District 1, Ho Chi Minh City.

- The predecessor was a fleet of vehicles taken over from BGI Company in 1977 under the Union

of Alcohol - Beer - Beverage Enterprises II. In 2005, the Company was equitized into Saigon

Beer Transportation and Delivery Joint Stock Company.

- Saigon Beer Transportation and Forwarding Joint Stock Company - Sabetranjsc is an

enterprisespecializing in transportation services serving Saigon Alcohol - Beer - Beverage Joint

Stock Corporation, playing an important role in the channel. Distribution and circulation of

goods is a link in Sabeco's system. 23 lOMoARcPSD| 36991220

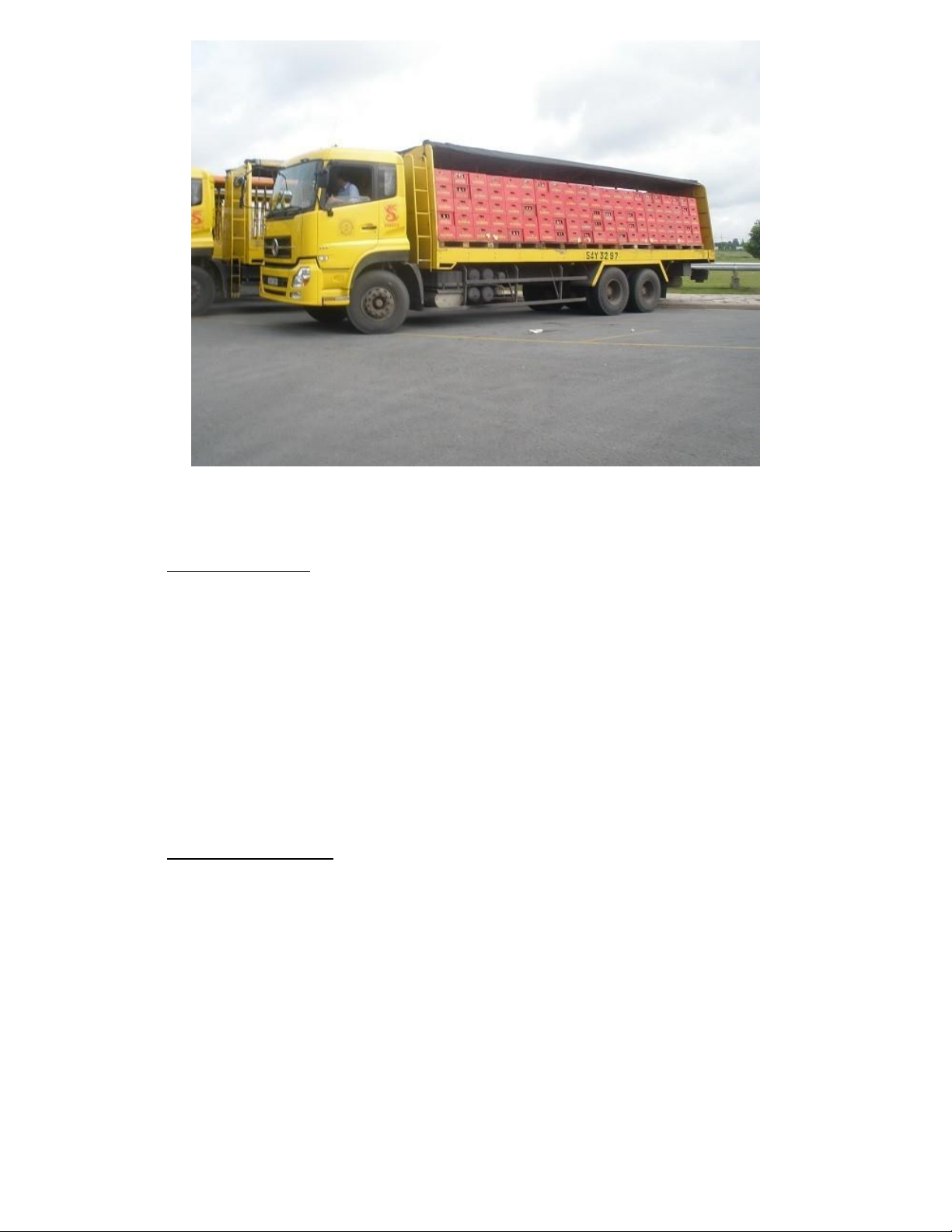

- Sabeco's transportation system is two-way, from transporting finished goods (beer, wine, soft

drinks...) to transporting materials (cases, beer tanks...) to maximize energy. transportation efficiency and cost savings.

- Currently, road transport accounts for the majority of the proportion in Sabeco's domestic

transport system. In addition, Sabeco also uses a variety of other types of transport such as

waterway and railway for its units. domestic and foreign suppliers.

2.5.2 Transportation system roles -

Transportation facilitates the movement of goods from suppliers to customers, which is

critical in logistics. Several transportation roles help to ensure a smooth logistical operation: -

Freight Transportation: The transportation of goods via various modes such as trucks, trains,

ships, and planes based on factors such as speed, cost, and the nature of the goods. -

Warehousing and Distribution Centers: These facilities serve as hubs for goods storage,

sorting,and distribution, and are frequently linked to transportation networks for easy access. -

Supply Chain Management: Coordination of transportation schedules, route optimization,

and timely delivery while minimizing costs and disruptions. -

Inventory Control: Maintaining stock levels in order to ensure that goods are available when

needed while avoiding overstocking, which affects transportation volume. -

Carrier and Freight Services: Transportation companies such as carriers, freight forwarders,

and brokers.play vital roles in executing logistics plans and ensuring goods reach their destinations. -

Last-Mile Delivery: Finishing the final phase of delivery to the customer's door, which

frequently involves local transportation methods such as vans, bikes, or even walking. -

Technology Integration: Using technology to improve transportation efficiency and

visibility, such as GPS, route optimization software, and real-time tracking. -

Regulatory Compliance: Knowing and following transportation regulations, such as permits,

safety standards, and international trade laws. 24 lOMoARcPSD| 36991220 -

Risk Management: Identifying potential transportation risks (for example, weather,

accidents, and delays) and putting strategies in place to mitigate their impact on logistics

operations. - Customer Service: Providing updates, answering questions, and ensuring a positive

customer experience throughout the transportation process.

Each of these roles is critical to establishing a seamless and efficient transportation system within

logistics, ensuring that goods are delivered reliably, on time, and at a reasonable cost.

2.5.3 Modes of transport

- Saigon beer is used in many forms of transportation: by sea, by air, by train or by road. It also

hires many third-party logistics companies for shipping. In particular, road transport is

considered the most flexible method developed by the road system.

- Shipping by air is the fastest way. However, the cost is also the highest.

- Shipping by sea: can transport large amounts of products at the same time at a lower cost but

also takes more time than other shipping methods.

- Besides, containers can also be used to continue transport by road or train at the customs

clearance location. Saigon Beer is considering choosing the shipping method by sea, including

the cost of loading goods onto the ship, related licenses,...

- Transport by train: economical and effective for transporting goods from one place to another.

Countries with high-speed train systems such as Europe, Japan or China will benefit from this method. 25 lOMoARcPSD| 36991220

Figure 2. 7: Transport SABECO’s beers by truck

2.5.4 Advantages and disadvantages for the Saigon Beer transportation system 2.5.4.1 Advantages

- Vietnam's geographical location is extremely favorable

- More than 3000 km of coastline

- Located at the international maritime intersection

- Favorable terrain to develop strategic ports

- Convenient for sea transportation (low cost, large volume of goods). 2.5.4.2 Disadvantages

- Law: There are quite a few documents, but specific policies detailing those policies have

not been implemented or are overlapping, leading to long immigration processing times.

- Natural environment: On average each year, Vietnam has 10 - 12 storms hitting the

mainland and on average, Coca-Cola's transportation system will be stopped for 1 - 2 weeks. 26 lOMoARcPSD| 36991220

- Infrastructure: The road transport system in some areas is in poor condition.Besides, there

is no North-South expressway. The highway system is being expanded but not much.

Furthermore, the entire South has only 90 km of expressways with a maximum speed of

120 km (the world average is 220 km).

- Warehouse: Vietnam still lacks centralized logistics zones with strategic locations,

synchronized with the system of ports, airports, national highways, and production

facilities; supply and demand imbalance at southern seaports

2.6 Distribution channel

2.6.1 Distribution channel 2.6.1.1 Concept

A distribution channel is a set of interdependent organizations, individuals, vehicles, and

technologies that play a role in the process of getting products or services from the place

of production to the hands of consumers or targeted customer entities.

Individuals and organizations participating in the channel are considered

members. Those members situated between consumers and producers are referred to as distribution intermediaries.

2.6.1.2 The role of the distribution channel For customers:

Ensuring availability: The distribution channel functions to ensure the supply of

products that customers need in a short period and at convenient locations. Customers can

purchase products at grocery stores, supermarkets, distribution points, etc., instead of

having to go to the production site.

Ease of selection and purchase: Customers can easily and conveniently choose

and purchase products through direct information or product display. Additionally, many

distribution points represent the manufacturer to provide technical support, product advice,

helping to save costs and time for customers. For manufacturers: 27 lOMoAR cPSD| 36991220

Market coverage: Manufacturers, with the help of the distribution channel, can

bring their products to various points of sale for consumers in need, effectively covering

the market without spending too much time.

Market understanding: The distribution channel is a tool that manufacturers utilize

to capture the market, understand the needs and purposes of customers regarding the

product, and learn a bit about competitors.

Bridge between production and consumers: The distribution channel is considered

a bridge between manufacturing businesses and consumers. The distribution network

helps bring products from manufacturers to consumers conveniently and quickly.

The entire channel supports manufacturers in effectively caring for customers in

services such as product usage guidance, warranty, maintenance, ordering, shipping, complaint handling, etc.

2.6.1.3 Types of Distribution Channels -

Direct Distribution Channel: This channel involves only two entities, the

manufacturer and the end consumer. The product is directly distributed to the consumer

without intermediaries. The structure of the direct distribution channel is: P (Producer) - > C (Consumer). -

Indirect Distribution Channel: In the indirect distribution channel, there are two

types: traditional distribution channel and modern distribution channel. -

Traditional Distribution Channel: This channel involves multiple stages, with the

product passing through intermediaries before reaching the end consumer.

+ Level 1: P (Manufacturer) -> R (Retailer) -> C (Consumer)

+ Level 2: P (Manufacturer) -> W (Wholesaler) -> R (Retailer) -> C (Consumer)

+ Level 3: P (Manufacturer) -> A&B (Brokers) -> W (Wholesaler) -> R (Retailer) -> C (Consumer) -

Modern Distribution Channel: In this channel, the manufacturer and distribution

intermediaries work together as a unified entity. Products are distributed directly from this

unified entity to the end consumer. The benefit of this channel is cost and time savings in the transportation process. 28 lOMoARcPSD| 36991220 -

Multilevel Distribution Channel (Hybrid): In this distribution channel, entities

other than the manufacturer act as intermediaries or may also be consumers. Implementing

a multilevel distribution channel can have advantages in saving advertising costs, but a

commission must still be paid to the intermediaries.

2.6.2 Members in the Distribution Channel of Saigon Beer -

Manufacturer: The Saigon Alcohol, Beer, and Beverage Corporation, with 26

manufacturing plants, is responsible for supplying products to the members in the distribution channel. -

Distributor: Level 1 Distributor: The first distributor in the distribution channel directly

transacts with the company regarding policies and distribution conditions. They receive goods

directly from the company, possess capital, warehouses, and transportation means. Distributors

must adhere to principles such as ensuring sales volume, providing information to retailers and

end consumers, and offering feedback to the manufacturer. Distributors receive commissions

based on achieved sales targets, with potential reductions for underperformance. • Advantages:

For the Company: Bulk consumption, shared risks, multiple points of contact with end consumers.

For Consumers: Access to wholesale-priced products, assurance of product availability. • Disadvantages:

For the Company: Conflict resolution among distributors can be time-consuming, and negative

distributor attitudes may impact the company's image.

For Consumers: Limited availability for purchasing small quantities. -

Supermarkets: These represent a mixed or specialized distribution channel with

sophisticated and convenient services for customers. Supermarkets, favored by consumers, directly

receive goods from the company and have capital, display areas, warehouses, and transportation means. • Advantages:

For the Company: Direct interaction with end consumers, diverse and abundant store systems.

For Consumers: Ensured product availability, prices not affected by external factors, confidence

in quality, comfortable shopping experience. • Disadvantages: 29 lOMoARcPSD| 36991220

For the Company: Competing with rival products, sales heavily depend on supermarket display strategies.

For Consumers: Prices may be higher compared to small retailers. -

Key Accounts: These are significant consumers of a business, often focusing on large target

groups such as restaurants, hotels, eateries, and bars. Key Accounts receive goods directly from

the company, are monitored but not managed by the company, and have direct interaction with customers. • Advantages:

For the Company: Direct interaction with end consumers, diverse and abundant store systems.

For Consumers: Assured product availability. • Disadvantages:

For the Company: Selling products of competitors, challenging to control the sales volume, cutting

company promotions for additional profit. -

Retailers: Encompassing businesses, organizations, and individuals selling goods to

individual consumers or households, retailers are in direct contact with the end consumer,

understanding their needs and desires better than anyone else. -

End Consumers: Including individual consumers, industrial users, and professional

organizations, end consumers are the ultimate target of the entire commercial system.

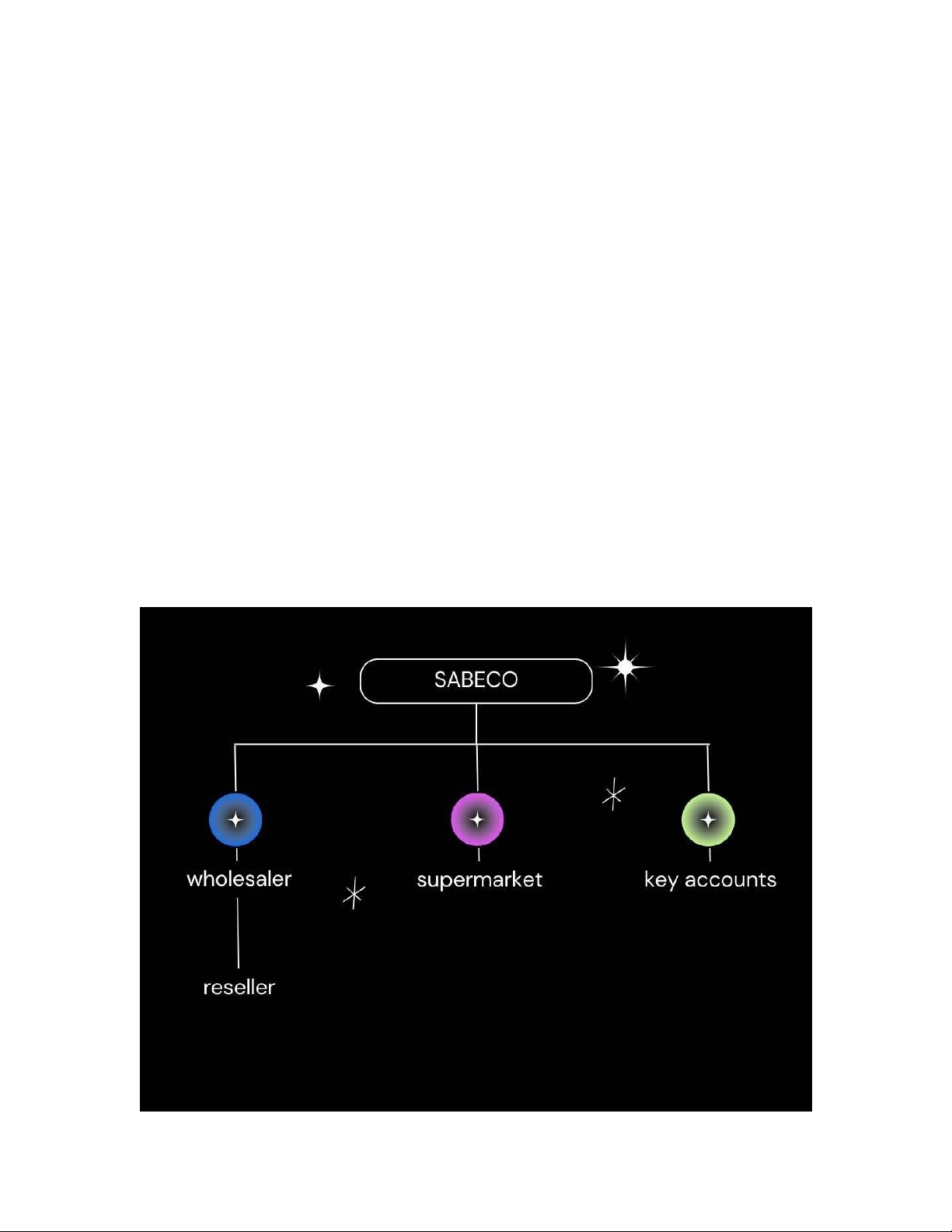

2.6.3. Distribution Channel Structure

Currently, SABECO has a network of 26 factories, 10 member trading companies, and a network

of over 100,000 points of sale across the country. SABECO owns multiple beer brands in the

market, such as Bia Saigon Special, Bia Saigon Export, Bia Saigon Lager, Bia Saigon Gold, and Bia 333.

The establishment of 10 joint-stock trading companies in 10 key provinces and cities in the

North, Central, and South regions aims to foster the bond of distributors in distributing SABECO's

products. This strategy focuses on deepening the market, avoiding overlap and competition among

distributors, ensuring SABECO's products reach consumers quickly and conveniently.

The Saigon Alcohol, Beer, and Beverage Corporation is organizing its distribution channel

according to the parent company - subsidiary model to enhance distribution efficiency and save distribution costs. 30 lOMoARcPSD| 36991220 -

Online Channel: Collaborating with e-commerce platforms such as Lazada, Shopee, Tiki,

etc., to make its products available on these online marketplaces. These platforms act as traditional

agents for SABECO, placing orders from SABECO and distributing them to online customers. -

Offline Channel: SABECO utilizes a parallel distribution system, including both a one-tier and a two-tier channel. -

One-tier Channel: SABECO directly distributes Bia Saigon Lager to major consumers, such

as large supermarkets nationwide (Co-op mart, BigC, Vinmart, Metro, Saigon Tourist, etc.) and

small retail chains (Familymart, Circle K, Ministop, Bach Hoa Xanh, etc.). Additionally, this

channel includes Key Accounts (restaurants, bars, hotels, institutions, etc.) with large sales

volumes. This channel is essential for promoting the company's image, introducing products to

consumers, and significantly influencing customer preferences.

Two-tier Channel: This is a strategic sales channel for SABECO. Level 1 distributors directly

receive goods from Saigon Beer Trading Co., Ltd., and distribute them to level 2 distributors.

Recommendations for Channel Improvement: + For the Company:

Develop a unified distribution strategy for the entire distribution channel system, providing

specific regulations for each member to create a strong and cohesive distribution system.

Offer special assistance in training human resources and sales capabilities for new distributors.

Strengthen cooperation with tourism companies to increase the company's visibility.

Increase advertising activities to promote the brand and the company's image, enhancing

competitiveness against competitors. + For Distributors:

Adhere to contract regulations, avoid territorial encroachment, price manipulation, and refrain

from dealing with low-quality products.

Establish close ties with other channel members with a spirit of mutual development, minimizing conflicts.

2.6.4 Distribution Channel Design Process

Step 1: Implementing General Strategy

• Regularly analyze and evaluate the distribution results of focused distributors, identifying conflicts within the channel: 31 lOMoAR cPSD| 36991220

• Vertical conflicts: between focused distributors and Saigon Beer Manufacturing Company

regarding discount payment issues.

Horizontal conflicts: among focused distributors competing for market share, retail spaces, and against competitors.

Step 2: Analyzing Influencing Variables

• Analyze variables that influence distribution decisions:

• Characteristics of target customers/market. • Market geography. • Product characteristics. • Company characteristics.

Step 3: Determining Distribution Objectives

• Batch size: 1 pallet (48 cases of bottles or 120 cases of cans) per order with a lead time of 1 day.

• Optimal location: Distributors located in the center of the customer circle to minimize the

distance from distributors to customers.

Step 4: Identifying Channel Structure and Selecting Optimal Channels

• Three-tier channel: Distributing Saigon Beer to all supermarkets, wholesalers, then

supplying to locations such as restaurants, eateries, convenience stores, and finally reaching end consumers.

Step 5: Classifying Distribution Functions Beer Saigon:

+ Store goods, ensure order fulfillment for level 1 intermediaries.

+ Execute transportation to level 1 intermediaries.

+ Provide support services for intermediaries.

• Exclusive distribution agent: + Store and preserve goods.

+ Arrange and classify goods according to customer needs (retailers).

+ Place orders and receive orders.

+ Collect market information and transfer it to Saigon Beer.

+ Sales: seek customers, sell products, provide services to customers (exchange near-expiry

products, display products according to company regulations at retail stores, etc.).

• Other level 1 intermediaries:

+ Provide sales points, sales staff. 32 lOMoARcPSD| 36991220

+ Display products and promotional activities at the point of sale.

+ Distribute appropriate quantities of goods according to consumer demand.

+ Sell products to end consumers.

2.6.5 Distribution Channel Management

Managing distribution channels is always a challenge for businesses. An efficient system not only

ensures tight management processes and widespread, timely service but also serves as a way to

quickly reach consumers to gain a competitive advantage in the market. Thanks to the application

of information technology, SABECO has effectively managed its product distribution channels.

To effectively manage the distribution channels in the Saigon Beer market, exploring the use of

modern information technology applications is essential. Examples include the Oracle E Business

Suite 11i integrated information management program, Enterprise Resource Planning (ERP)

systems, and Customer Relationship Management (SAP) solutions. These technologies can

enhance the efficiency of distribution channel management for Saigon Beer, ensuring precise

control and timely service delivery.

2.6.6 Distribution Channel flows 33 lOMoARcPSD| 36991220

Figure 2. 8: Flow in distribution channels

Retailers in the distribution channel will directly place orders with wholesalers, and these

wholesalers will then place orders with Saigon Beer Trading Company based on the region,

depending on the quantity of orders and the current inventory levels.

For one-tier channels such as supermarkets and Key Accounts, they will place orders directly with

the company without going through any intermediaries. - Information Flow:

Information is smoothly and continuously transmitted among channel members. The company

provides information about product categories, weight, size, prices, payment terms, discounts, etc.,

to distribution intermediaries and end consumers. The company also receives feedback from other

channel members to leverage, improve, and address weaknesses in the system.

Furthermore, the information flow helps SABECO effectively monitor the activities of

distributors. Distribution-related information is held by the Sales Support department, then

reported to the Consumption-Market-Brand Board for processing and resolving issues to

contribute to better market development and profitability for the company.

- Material Flow and Packaging Retrieval:

In the material flow and packaging retrieval process, the role of the transportation company is

particularly crucial. It is known that the company specializing in transportation for SABECO is

Saigon Beer Transportation and Delivery Joint Stock Company (Sabetranjsc). For products such

as wine, beer, and soft drinks, the company transports using trucks and containers based on the

payload and terrain of the region.

The packaging retrieval process runs counter to the material flow, moving from end consumers

back to the manufacturer. SABECO endeavors to thoroughly retrieve cans, bottles, and beer crates

for reuse, minimizing costs and contributing to environmental protection.

- Ownership Transfer Flow:

The ownership transfer flow runs parallel to the material flow; as products are transferred to

channel members, ownership is also transferred to them. - Payment Flow:

For wholesalers, supermarkets, and key accounts, payments are typically made through bank

transfers. For small retailers or end consumers, they make direct cash payments. 34 lOMoARcPSD| 36991220 - Negotiation Flow:

Through contracts, SABECO negotiates with distributors to sell products at agreed-upon prices

and implement all promotional programs in line with the company's objectives.

2.6.7 Saigon Beer distribution channel system 2.6.7.1 Domestic

According to statistics, by the end of 2020, Saigon Alcohol - Beer - Beverage

Corporation had 10 regional trading companies, 26 subsidiaries, present throughout

Vietnam with 600,000 people + point of sale.

SABECO's market share in 2018 and 2019 accounted for the largest proportion,

but look tend to decrease due to increasingly fierce competition from competitors. Faced with this

difficult situation and the negative effects of the Covid-19 pandemic on the beer industry,

SABECO is required to have timely strategies to ensure sustainable

development and increase the competitiveness of the beer industry enterprise. 2.6.7.2 Foreign

Saigon Beer is popular with customers around the world and has been exported to 38 countries:

- Europe: France, Netherlands, England, Sweden, Switzerland, Russia, Denmark, Spain,

Czech Republic, Austria, Italy, Germany, Romania

- Asia: Laos, China, Taiwan, Japan, Hong Kong, Korea, Thailand, Singapore, Bahrain, Israel

- Americas: United States, Canada, Panama

- Oceania: Australia, New Zealand, Kiribati

- Africa: Equatorial Guinea, Gabon, Cameroon, Ghana, Republic of Congo, Benin, Liberia and Sierra Leone

2.6.7.3 Functions of the distribution channel system 35 lOMoAR cPSD| 36991220

Distribution channel members perform many important functions including:

- Information function: collect and distribute information about actors and forces in the

distribution system, supporting the company in making strategic decisions.

- Promotion function: deploy and distribute programs to bring the company's image to

customers, enhance the company's brand

- Contact function: plays an important role in learning about and introducing the company's products to the market

- Negotiation function: to agree on a reasonable price so that the sale goes well-

Transportation and storage functions: ensure stability in providing products to customers

- Funding assurance function: finding and using capital sources to offset distribution costs-

Risk function: accept risks in your business.

2.6.7.4 The role of the distribution channel system PRODUCTION ➡ DISTRIBUTION ➡ CONSUMERS

- Distribution of goods and products is a part of production relations, a link between

themproduction and consumption. The distribution system plays an important role in the

process of providing customers with the right products, at the right time, in the right

location, so distribution channels directly affect the success or failure of businesses in

general and for SABECO in particular.

- The distribution system helps adjust the supply and demand of goods and services,

helping businesses focus on specializing in their production activities. Thanks to the

distribution network, businesses can overcome time constraints and increase the ability

to choose goods for customers. Philip Kotler (2008) proposed three basic roles of

distribution channels as follows: increasing transaction efficiency; increase product

supply efficiency; satisfy customers' needs and types of goods. 36 lOMoARcPSD| 36991220

CHAPTER 3: PROBLEM AND SOLUTION

3.1. Problems in Distribution Network

3.1.1. Imbalanced Distribution Market

Saigon Beer Corporation encounters challenges in accessing and effectively operating within

the rural market, particularly in deep rural regions, remote areas, and island districts. This situation

indicates an imbalanced distribution market, where there is a disparity or unevenness in the

availability and accessibility of products and services. Solution:

- Establish Regional Distribution Centers: Set up regional distribution centers strategically

located in or near rural areas. These centers can act as hubs for storing and distributing products to

the surrounding regions. By having distribution centers closer to the target market, transportation

costs and delivery times can be reduced.

- Develop Last-Mile Delivery Solutions: Invest in last-mile delivery solutions tailored for rural

areas. This may involve utilizing smaller vehicles, motorbikes, or bicycles to navigate through

narrow roads and reach remote locations. Additionally, consider partnering with local logistics

providers who have expertise in navigating the specific terrain and infrastructure challenges of rural regions.

- Collaborate with Local Retailers: Build partnerships with local retailers, including small

grocery stores, convenience shops, and village cooperatives, to expand the reach of Saigon Beer

Company's products. These retailers have a better understanding of the local market and can serve

as distribution points in rural areas. Provide incentives and support to encourage their participation

in promoting and selling the company's products.

- Utilize Mobile Sales and Sampling: Deploy mobile sales and sampling teams to visit rural

areas, setting up temporary stalls or vehicles to showcase and sell Saigon Beer Company's

products. This approach can help generate awareness, trial, and ultimately drive sales in remote

regions where traditional retail infrastructure may be limited.

- Leverage Digital Platforms: Utilize digital platforms, such as e-commerce websites and

mobile apps, to enable online ordering and delivery of products in rural areas. Partner with existing

e-commerce platforms that have a presence in rural markets or establish a dedicated online

platform to facilitate direct sales to consumers. 37 lOMoARcPSD| 36991220

- Conduct Rural Marketing Campaigns: Develop targeted marketing campaigns specifically

tailored to the rural market. This can include localized advertising, sponsorships of local events,

and engagement with rural communities through social media platforms. Focus on highlighting

the unique value propositions of Saigon Beer Company's products that resonate with rural consumers.

- Provide Training and Support: Offer training programs and support to distributors, retailers,

and sales teams operating in rural areas. This can include product knowledge training, sales and

marketing techniques, and guidance on effective merchandising and display practices. By

empowering local stakeholders, the distribution and promotion of Saigon Beer Company's products can be improved.

- Monitor and Evaluate Performance: Implement a system to monitor and evaluate the

performance of the distribution process in rural areas. Regularly assess key performance indicators

such as sales volume, market share, and customer satisfaction to identify areas for improvement

and make necessary adjustments to the distribution strategy.

3.1.2. Inaccurate Order Fulfillment

Saigon Beer Company faces challenges in accurately processing and fulfilling customer orders.

This can result in incorrect or incomplete products being delivered to customers, leading to

customer dissatisfaction and potential financial losses for the company. Solution:

- Implement an automated order processing system: Invest in an automated order processing

system that minimizes manual intervention. This system should have features such as automated

order entry, real-time inventory tracking, and automated picking and packing processes. By

reducing manual errors, the system can improve order accuracy.

- Enhance inventory management: Implement an efficient inventory management system that

provides real-time visibility into stock levels. This system should integrate with the order

processing system to ensure accurate fulfillment based on available inventory. Regular stock audits

and cycle counts can help identify and rectify any discrepancies.

- Improve communication channels: Establish clear and effective communication channels

between different departments involved in the order fulfillment process, such as sales, warehouse,

and logistics teams. Regularly communicate order requirements and any updates or changes to ensure accurate fulfillment. 38 lOMoARcPSD| 36991220

- Standardize packaging and labeling processes: Develop standardized packaging and

labeling procedures to ensure consistency and accuracy. Clearly define packaging requirements

and labeling instructions to avoid confusion during the fulfillment process. Conduct regular quality

checks to ensure packaging and labeling accuracy.

- Implement quality control measures: Introduce quality control measures throughout the

order fulfillment process, including random checks of packed orders before shipping. This can help

identify and rectify errors before products are dispatched to customers.

- Provide training and support: Train employees involved in the order fulfillment process on

proper procedures, accuracy requirements, and the importance of attention to detail. Offer regular

refresher training sessions and provide ongoing support to address any challenges or questions that may arise.

- Customer feedback and resolution: Establish a mechanism to collect customer feedback on

order accuracy. Actively address any issues or complaints related to inaccurate order fulfillment

promptly and provide appropriate resolutions to ensure customer satisfaction.

3.1.3. Exchange and Return

Saigon Beer Company lacks appropriate regulations and has not satisfactorily addressed cases

where customers purchase faulty products. It will also lead to customer dissatisfaction and

potential financial losses for the company. Solution:

- Clear and customer-friendly policies: Develop clear and easily understandable exchange and

return policies that are prominently communicated to customers. Ensure that the policies include

information on acceptable reasons for exchanges or returns, timelines, and any specific

requirements or conditions. Make these policies accessible through the company's website,

customer service channels, and product packaging.

- Streamlined exchange and return processes: Establish well-defined and efficient procedures

for processing exchanges and returns. This includes providing clear instructions to customers on

how to initiate the process, specifying required documentation (such as proof of purchase), and

designating dedicated staff or departments responsible for handling exchanges and returns.

Streamlining the process will help minimize delays and errors.

- Training and empowerment of customer service staff: Provide comprehensive training to

customer service representatives to handle exchanges and returns effectively. Equip them with the 39 lOMoARcPSD| 36991220

necessary knowledge and tools to address customer concerns promptly and professionally.

Empower customer service staff to make decisions within the established policies to resolve customer issues efficiently.

- Simplified return logistics: Design a straightforward and convenient return process for

customers. This can involve providing prepaid return labels or arranging for product pickups from

customers' locations. Simplifying the logistics will make it easier for customers to return products,

thereby improving their overall experience.

- Continuous feedback analysis: Regularly analyze customer feedback related to exchanges

and returns to identify recurring issues, patterns, or areas for improvement. Actively listen to

customer concerns and use their feedback to refine policies and processes to better address their needs.

- Quality control and product improvement: Implement stringent quality control measures to

minimize the occurrence of product issues that lead to exchanges and returns. Continuously

monitor and evaluate product quality, and address any recurring issues promptly. This proactive

approach will help reduce the need for exchanges and returns in the first place.

3.2. Problems in Inventory Management

3.2.1. Inefficient product storage managing

Managing the storage of products by distributors presents many challenges. It leading to

several negative consequences and impacts on various aspects of the distribution network. Solution:

- Optimize Warehouse Layout: Evaluate and optimize the layout of the warehouse to maximize

space utilization and streamline product flow. This includes organizing products in logical

categories, creating clear aisles, and utilizing efficient shelving systems.

- Implement Inventory Tracking Systems: Adopt inventory management systems or software

that provide real-time visibility and accurate tracking of inventory. This enables distributors to

monitor stock levels, track product movement, and identify potential issues promptly.

- Enhance Product Labeling and Categorization: Implement clear labeling and

categorization systems to facilitate easy identification and retrieval of products. Utilize barcode or

RFID technology to streamline inventory tracking and reduce errors. 40 lOMoARcPSD| 36991220

- Establish Stock Rotation Procedures: Develop and enforce stock rotation procedures, such

as the First-In, First-Out (FIFO) method, to ensure older products are used or sold before newer

ones. Regularly review inventory to identify slow-moving or obsolete items and take appropriate actions.

- Improve Storage Conditions: Assess and improve storage conditions to protect products from

damage or deterioration. This may involve implementing proper temperature and humidity

controls, investing in appropriate packaging materials, or implementing security measures to prevent theft.

- Regular Audits and Continuous Improvement: Conduct regular audits of the storage area to

identify inefficiencies and areas for improvement. Seek feedback from warehouse staff and

stakeholders to implement continuous improvement measures and optimize storage practices.

3.2.2. Excessive or Insufficient Inventory

Maintaining excessive inventory ties up valuable capital and storage space, increases carrying

costs, and can lead to obsolescence or spoilage. On the other hand, insufficient inventory can result

in stockouts, missed sales opportunities, and dissatisfied customers. Solution:

- Optimize Demand Forecasting: Improve demand forecasting accuracy through the use of

data analysis, historical sales data, market trends, and customer insights. This helps to align

inventory levels with expected demand, reducing the risk of both excess and insufficient inventory.

- Implement Just-in-Time (JIT) Inventory Management: Adopt JIT principles to minimize

inventory levels while ensuring that products are available when needed. JIT allows for

streamlined inventory replenishment based on actual demand, reducing the risk of excess inventory and associated costs.

- Set Reorder Points and Safety Stock Levels: Determine optimal reorder points and safety

stock levels for each product based on lead times, demand variability, and desired service levels.

This helps to prevent stockouts while avoiding excessive inventory accumulation.

- Establish Effective Supplier Relationships: Collaborate closely with suppliers to improve

visibility and communication. Implement vendor-managed inventory (VMI) or consignment

programs where appropriate, allowing suppliers to monitor and manage inventory levels on behalf of the distributor. 41 lOMoAR cPSD| 36991220

- Utilize Inventory Management Systems: Implement inventory management software or

systems that provide real-time visibility into inventory levels, sales data, and demand patterns.

This enables better decision-making and inventory control, reducing the risk of excessive or insufficient inventory. 42 lOMoARcPSD| 36991220 -

Implement ABC Analysis and SKU Rationalization: Conduct an ABC analysis to categorize

products based on their value and contribution to sales. Focus on optimizing inventory

management for high-value products while considering SKU rationalization for slow-moving or low-demand items.

- Enhance Communication and Collaboration: Improve communication and collaboration

between different departments involved in inventory management, such as sales, marketing,

operations, and finance. This ensures better alignment between inventory levels and anticipated demand.