Preview text:

lOMoAR cPSD| 46560390

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/260155313

Properties of recycled aggregate concrete made with recycled aggregates with different

amounts of old adhered mortars

Article in Materials & Design (1980-2015) · June 2014

DOI: 10.1016/j.matdes.2014.01.044 CITATIONS READS 391 3,296 2 authors: Zhenhua Duan Chi Sun Poon Tongji University

The Hong Kong Polytechnic University

81 PUBLICATIONS 3,592 CITATIONS

612 PUBLICATIONS 46,709 CITATIONS SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Water repellent treatment and multi-functional coating for concrete structures View project

Recycling Waste Timber Formwork into Cement-bonded Particleboards View project

All content following this page was uploaded by Zhenhua Duan on 27 April 2018. lOMoAR cPSD| 46560390 !

The user has requested enhancement of the downloaded file. Original citation:

Duan, Z.H., and Poon, C.S. (2014), "Properties of recycled aggregate concrete made with recycled

aggregates with different amounts of old adhered mortars". Materials and Design, Vol. 58, pp.19-29.

http://www.sciencedirect.com/science/article/pii/S0261306914000703

Properties of recycled aggregate concrete made with recycled aggregates with

different amounts of old adhered mortars

Zhen-Hua Duan, Chi-Sun Poon*

Department of Civil and Environmental Engineering The Hong Kong Polytechnic University, Hung

Hom, Kowloon, Hong Kong Abstract:

This paper presents the experimental results of a study on comparing the difference in properties

of recycled aggregates (RAs) with varying amounts of old adhered mortar obtained from

different sources and evaluating the influence of the different RAs on the mechanical and

durability properties of recycled aggregate concrete (RAC). Four concrete mixes (one with

natural aggregate and three others with recycled aggregates) with 28 day target compressive

strength varying from 30 MPa to 80 MPa are designed by using each RA to fully replace NA.

The properties of RAC are also modeled by using the artificial neural networks (ANN) method.

The experimental results show that the performance of RAs from different sources varied greatly

and RA of good quality can be used to produce high strength concrete with hardened properties

comparable to those of the corresponding natural aggregate concrete (NAC). The comparison of

the predicted results based on the ANN models and the experimental values indicated that the

ANN method could be used to evaluate the properties of RAC made with RAs derived from

different sources. This will facilitate the wider application of RA in concrete.

Keywords: recycled aggregate; mechanical properties; durability; recycled aggregate concrete, artificial neural networks. 1. Introduction

Reuse of recycled aggregates (RAs) to fully or partially substitute natural aggregate (NA) has been

extensively studied. Although the potential of using RA in concrete has been demonstrated

successfully in laboratory studies, the use of RA in practical application is generally limited to non-

structural concrete, and the replacement ratio of NA by RA is recommended not to exceed 30% [1].

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

Old cement mortar attached to RA is generally considered as the main cause of poorer properties of

RA compared with those of NA [2,3,4,5], which are reflected in higher water absorption (Wa), !0!

porosity (p), crushing value (ACV) and Los Angeles abrasion value (LA), and lower specific

gravity (SG) and 10% fines value (TFV). The properties of RA obtained from different sources

vary significantly due to the fluctuationsin compositions and qualities of the parent concrete and attached mortar.

The difference in properties of RAs derived from different sources, together with their influence

on the properties of recycled aggregate concrete (RAC) of various grades, has received increasing

research interest. In a previous study [6], eight kinds of RAs were prepared by crushing old

concretes prepared with four types of NA as coarse aggregates and with designed 28th day

compressive strengths of 45 MPa and 65 MPa. The aggregates used differed in shape, composition

and surface texture. Test results indicated that the type of virgin aggregate played a more important

role than the water-cement ratio (w/c) of the parent concrete in affecting the properties of RA. Tam

et al. [7] conducted a study on RAs obtained from ten demolition sites and the results showed that

the properties of the different RAs varied greatly and the compressive strength of the new concrete

made with such RAs ranged from 50 to 63 MPa. Besides, the quality of parent concrete [8,9,10,11]

and crushing process [12,13] also influenced the properties of RA and RAC significantly and RA

crushed from higher quality old concrete was more suitable to produce RAC with comparable properties [14].

Current specifications generally imposethe maximum allowable quantityof impurities in RA, such

as bricks, tiles, glass, asphalt, plastic, wood, gypsum, clay, etc, to ensure the properties of RAC

can be comparable with that of natural aggregate concretes (NAC). A number of studies [15,16,17]

have been done on assessing the effect of mixed recycled aggregates on the properties of RAC and

the results suggested a higher level of masonrycontent in RAcanbe allowed for concrete

applications but the possible adverse effect of the impurities ontheperformance of RAC, especially

the durability, should not be ignored [17,18,19].

However, the above studies did not quantify the effect of the amount of attached old cement mortar

on RA and RAC. This paper reports the experimental results of a comprehensive study on how the

properties of RAC are affected by RAwith different amounts of adhered mortars which were

derived from three different sources. Four series of concrete mixes with 28 day target strengths

from 30 MPa to 80 MPa are designed by using different types of RA to fully replace NA.

It has been demonstrated by the authors previous studies [20,21] that the artificial neural networks

(ANN) method is able to predictthe mechanical properties of RAC through a gradual

approximation of the nonlinear function. The ANN method is also used in this study to evaluate

the mechanical performance of RAC made with RAs from different sources.

2. Objectives and methodology

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

In the RA, the original virgin aggregate with attached old cement mortar is usually its main

component, and the properties of the RA are determined by both the type and the quality of the

virgin aggregates [1,11], and the quality and amount of attached cement mortar [5,22,23].

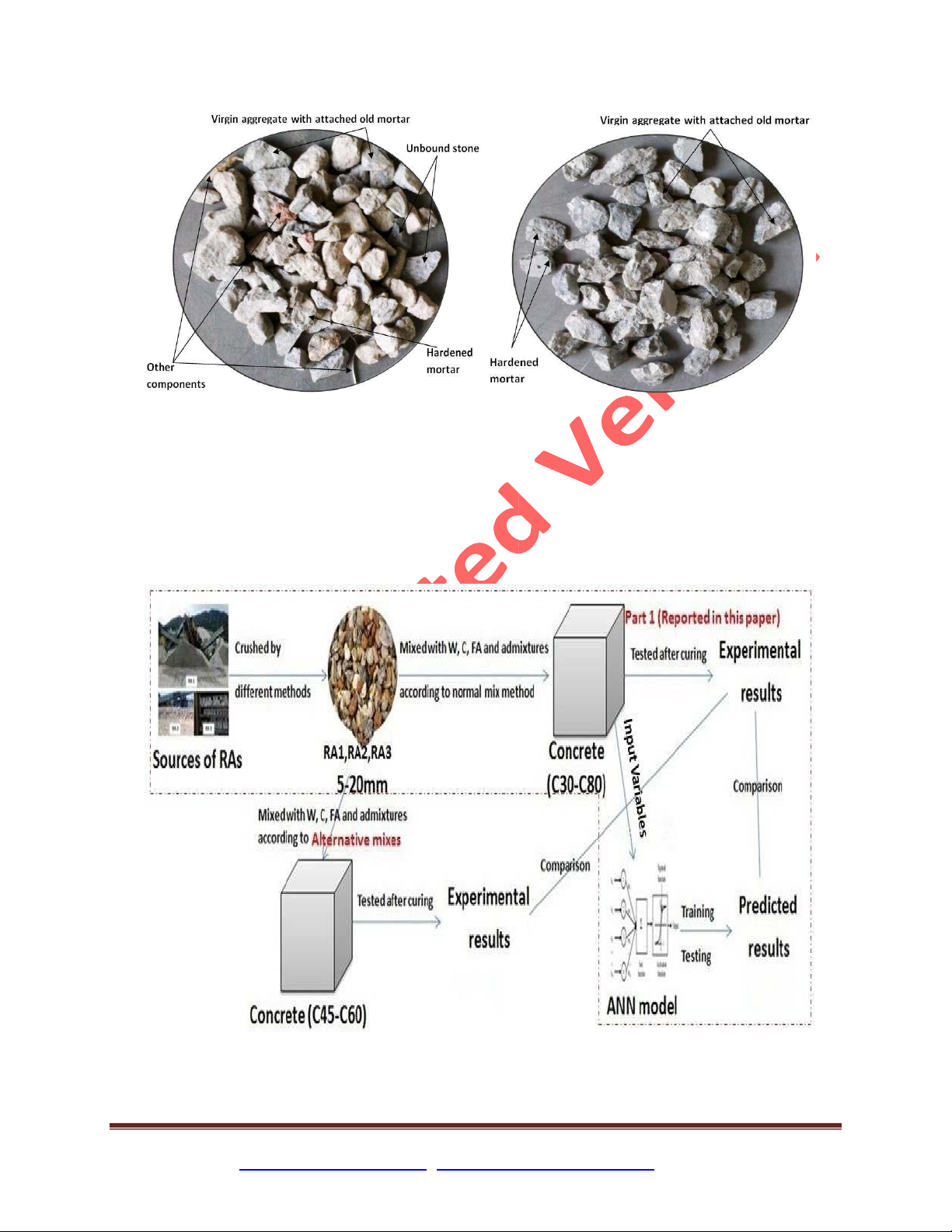

Besides, RAs derived from different sources may consist of unbound stone, original aggregate !5!

with attached old cement mortar, hardened mortar (Fig. 1). Besides, there are also some impurities

present in the RA, such as bricks, tiles, glass, asphalt, plastic, wood, gypsum, clay, etc.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

( a) RA from recycling plant (b) RA from laboratory

Fig.1. RAs from different sources

This experimental study aimed to study the influence of RAs from different sources, in particular

with different amountsof old cement mortar, on the mechanical and durability properties of RAC.

Different target strength of concrete mixtures from 30 MPa to 80 MPa were designed by using

RA to fully replace NA, and the experimental test results were then compared with the predicted

values by ANN method to examine whether the ANN method can be used to model the

mechanical performance of RAC made with RAs from different sources.

Fig.2. Full experimental program !?!

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

3. Experimental program

Fig. 2 shows the full experimental program undertaken and itwas consisted of two parts: (1) an

investigation on the properties of concrete made from RAs obtained from different sources, and

evaluation of the mechanical performance by using ANN method; (2) explore alternative methods

to improve the properties of RAC. The results of the first part of this comprehensive study are presented in this paper.

Fig.3. Sources and crushing procedures of different RA Table 1

Chemical c ompositions of cement Composition w/% Materials LOI SiO 2 Fe 2 O 3 Al 2 O 3 CaO MgO SO 3 Cement 2.9 7 19.6 1 3.32 7.33 63.15 2.5 4 2.1 3 3.1 . Materials 3.1.1 . Cement

An ASTM Type I Portland cement, with a density of 3.15 g/cm3, was used in this study. The

chemical compositions of the cement are shown in Table 1. 3.1.2. Aggregates

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

The fine aggregate (0-5 mm) used was a natural river sand with a fineness modulus (FM) of 2.19.

Recycled fine aggregate was not used in this study due to its high water absorption capacity, which

would affect the performance of the concrete seriously [24,25,26]. !@!

Crushed granite with sizes ranged from 5-10 mm and 10-20 mm were used as the natural coarse

aggregate to prepare the control mixes. The sources and preparation methods of the RAs used in

this study are shown in Fig. 3 and described as follows:

RA1: RA1 (10-20 mm) was collected from a construction waste recycling plant which processed

both crushed concrete and excavated rock from construction and demolition activities. The plant

utilized a range of crushing and sieving processes to produce the RA; RA1 (5-10 mm) was obtained

from further crushing the RA1 (10-20 mm) by a laboratory mini crusher;

RA2: RA2 (10-20 mm) was also collected from the same recycling plant, but the source of the

construction waste was different, so the composition and properties of RA1 (10-20 mm) and RA2

(10-20 mm) were not the same; RA2 (5-10 mm) was obtained by crushed concrete lump obtained

from a demolition site, which was originally larger than 200 mm in size, manually (using a

RA3: RA3 (10-20 mm and 5-10 mm) was obtained from crushing (manually and by a laboratory

mini-crusher) old concrete prisms that had been previously prepared in our laboratory with an

hammer) crushed to 50-80 mm and then by a laboratory mini-crusher.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

original 28th day compressive strength of about 45 MPa.

Fig.4. Test procedures of mortar content of coarse aggregates

The test of aggregate properties, such as fineness modulus, water absorption, specific density,

aggregate crushing value and ten percent fine value were performed in accordance with BS 812-

103.2 [27], BS 812: Part 2 [28], BS 812-110 [29] and BS 812-111 [30]. As there is no standard method

in measuring old cement mortar amounts in RAs, the test of the mortar content (Fig. 4) was based

on a hydrochloric acid dissolution method [31] as follow: !3!

Firstly, the aggregate samples with particle size of 5-10 mm or 10-20 mm, after washing by distilled

water and sieving to remove the fine particle, were dried in an oven at a temperature of 105¡C for 24h.

Then, appropriate amount of each sample (m1), about 100g, was taken and immersed in a solution

of 10% hydrochloric acid for 8 h.

Next, the sample was washed again by water to remove the loose particles, and dried in an oven at

a temperature of 105 ¡C for 24 h.

In this way, most of the attached cement mortar on the recycled aggregates could be easily removed,

and the remaining mortar could be removed by a hammer and a steel brush.

The sample was sieved through a 5 mm sieve to obtain the mass of the original aggregate (m2).

The mortar content was calculated using Eq. (1). For each type of aggregate, 6 samples were tested to obtain the average value.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

Mc (%) = (m1- m2) / m1 × 100 (1)

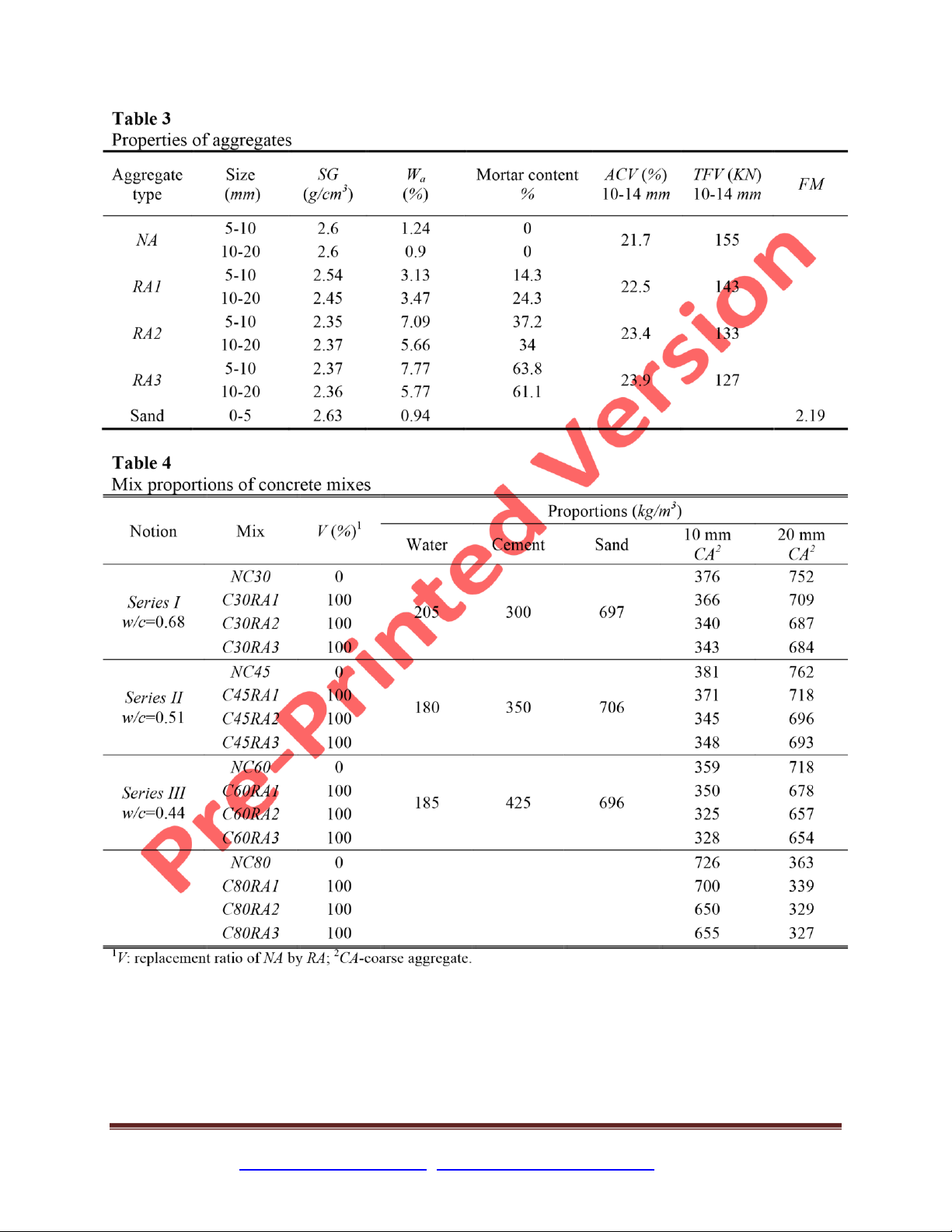

The constituents and properties of the aggregates used are shown in Tables 2 and 3, respectively. Table 2

Constituents of recycled aggregates Aggregate

Constituents (% by mass) type Rock/Concrete Brick Tile Clay Metal Other impurities RA1(20mm) 98.2 0.8 0.6 0.2 0.15 0.05 RA2(20mm) 96.05 2.1 0.75 0.35 0.15 0.65 RA3(20mm) 99 0.8 0.2 0 0 0

3.1.3. Superplasticizer

The superplasticizer (Grace, ADVA-109) used was obtained from Hong Kong Grace Construction Products Limited. 3.2. Concrete mixes

Four series of concrete mixes were prepared using NA and three types of RA. In each series, four

concrete mixes with different 28 day target cube strength between 30 MPa and 80 MPa were

prepared, and the corresponding water to cement ratios were ranged from 0.68 to 0.34. For each

concrete mix, a control concrete (NC) was prepared with 100% NA, while RC1, RC2 and RC3

were made with 100% RA1, RA2 and RA3, respectively. For concrete made with different types

of aggregates, appropriate amounts of superplasticizer were used to achieve a similar slump value

of 70-90 mm for Series I to Series III and 120-150 mm for Series IV. The details of the mix

proportions are shown in Table 4.

All the 16 concrete mixes were designed using the absolute volume method with the aggregates at

the saturated surface-dried (SSD) condition, and the actual proportions of the mixes at mixing were

adjusted according to the moisture contents of the aggregates. For Series I to Series III (C30-C60)

mixes, the coarse aggregates of 5-10 mm and 10-20 mm fractions were added in a !6!

ratio of 1:2, while for Series IV (C80) mixes, the coarse aggregates of 5-10 mm and 10-20 mm

fractions were added in a ratio of 2:1.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 ! Series IV 165 485 685 w/c=0.34

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 ! !A!

3.3. Specimens casting and curing

For each concrete mix, 100 mm cubes, fl100 × 200 mm cylinders and 70 × 70 × 285 mm prisms

were cast. The 100 mm cubes were used to determine the compressive strength. Some of the

cylinders were used to evaluate the splitting tensile strength and static modulus of elasticity; the

rest of the cylinders were cut to fl50×100 mm slices to test the chloride-ion penetration. The

70×70×285 mm prisms were used to determine the drying shrinkage. All the specimens were cast

in steel moulds and compacted using a vibrating table. The specimens were demolded after curing

for 24 hours at a controlled laboratory environment, and then the cubes and cylinders were cured

in a water-curing tank at 27 – 2 …C, while the concrete prisms were stored at a constant

temperature (23 – 2 ¡C) and relative humidity (50 – 5%) chamber until the age of testing. 3.4. Test methods

At the ages of 28th and 90th day, the hardened density, compressive strength and elastic modulus

of the concrete were measured according to BS EN 12390-7 [32], BS EN 12390-3 [33] and BS

1881-121 [34], respectively, while the chloride penetrability of concrete was tested in accordance with ASTM: C1202.

The tensile splitting strength of concrete was determined based on BS EN 12390-6 [35] after 28

days of curing. As regards to the dry shrinkage, ASTM: C157 was followed. The initial lengths of

the specimens were measured and the initial dry shrinkage values were recorded after the

specimens were demolded. Then the specimens were conveyed to a drying-chamber with a

constant temperature of 23 ¡C and a relative humidity of 55% until further measurement at 1, 28,

56, 90 and 112 days, respectively.

4. Results and discussion 4.1. Aggregate properties

Table 3 shows the experimental results of the physical and mechanical properties of the aggregates

investigated, including the mortar content, water absorption, specific gravity (SSD), aggregate

crushing and 10% fines values.

Compared with NA, it can be noticed from Table 3 that the density and 10% fines value of RAs

were lower, but the corresponding water absorption and aggregate crushing value were higher.

As mentioned above, RAs used in this study can be regarded as a composite material containing

unbound stone, virgin aggregate with attached old mortar, hardened mortar and some impurities.

The amount of old mortar in RA1 was the lowest as it contained more crushed rock and was

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

processed at a recycling plant. For RA2, especially the (5-10 mm) fraction, the mortar content was

higher due to its major source was from old concrete, RA3 had the highest mortar content as it

only underwent one crushing process in the laboratory. !2!

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

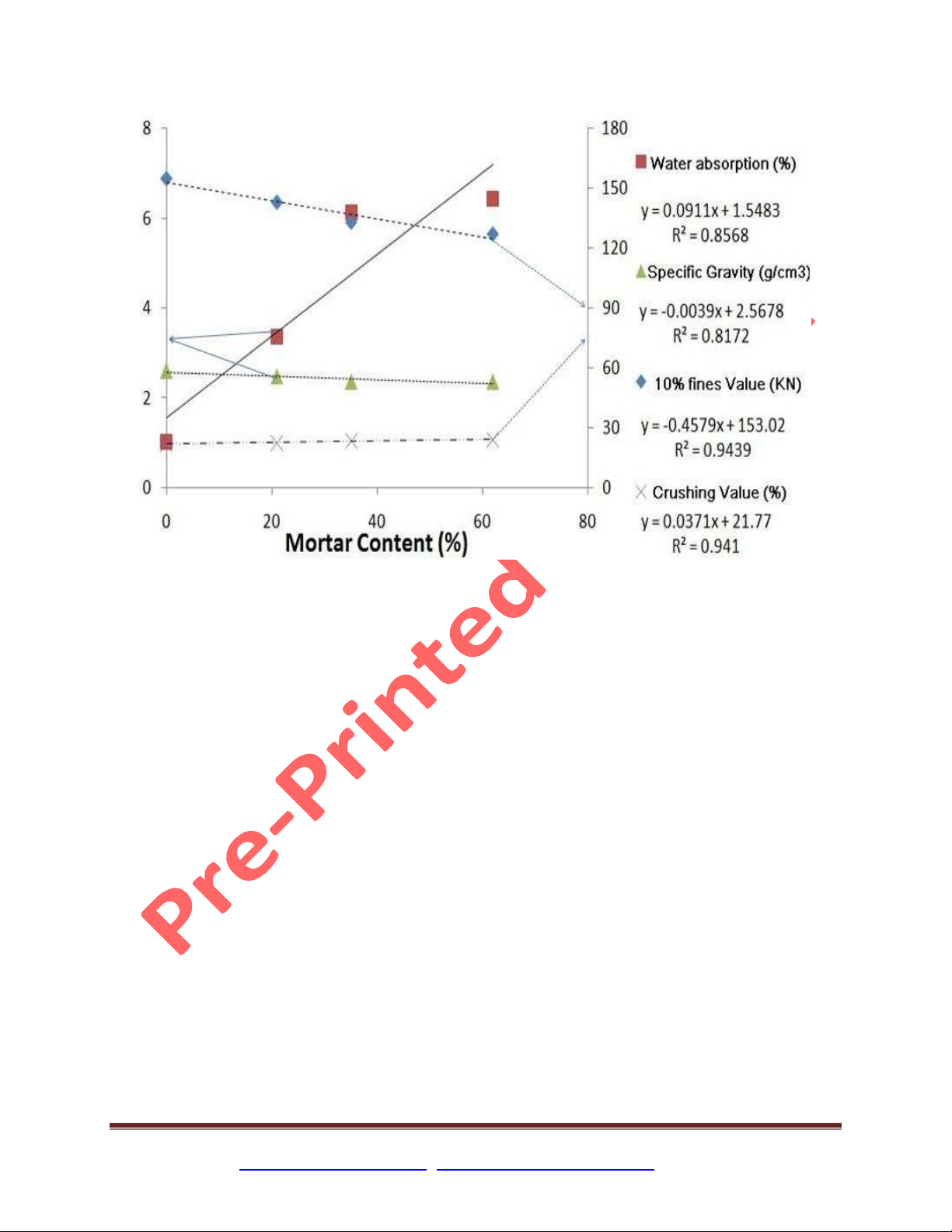

Fig.5. Relationships between mortar content and other properties of aggregates

The influence of the quantity of attached mortar on aggregate properties can be seen clearly from

Fig. 5 . The most noticeable influences of the attached mortar are on the water absorption and the

ten percent fines values (TFV). The water absorption values of RA increased drastically while

the TFV decreased gradually with the increase in mortar content. For evaluating the strength of

the recycled aggregates, it seems that the TFV value is more sensitive than the aggregate

crushing value, because the weaker materials in the RA were crushed before the specified load

(400 KN) was reached. Based on the test results, it seems that RA1 was of the best quality

among all the RAs used; while the properties of RA2 and RA3 were nearly the same. It is noted

that RA2 had more impurities and clay bricks while RA3 contained more attached mortar,

rendering both of them weaker and more porous. 4.2 . Concrete properties

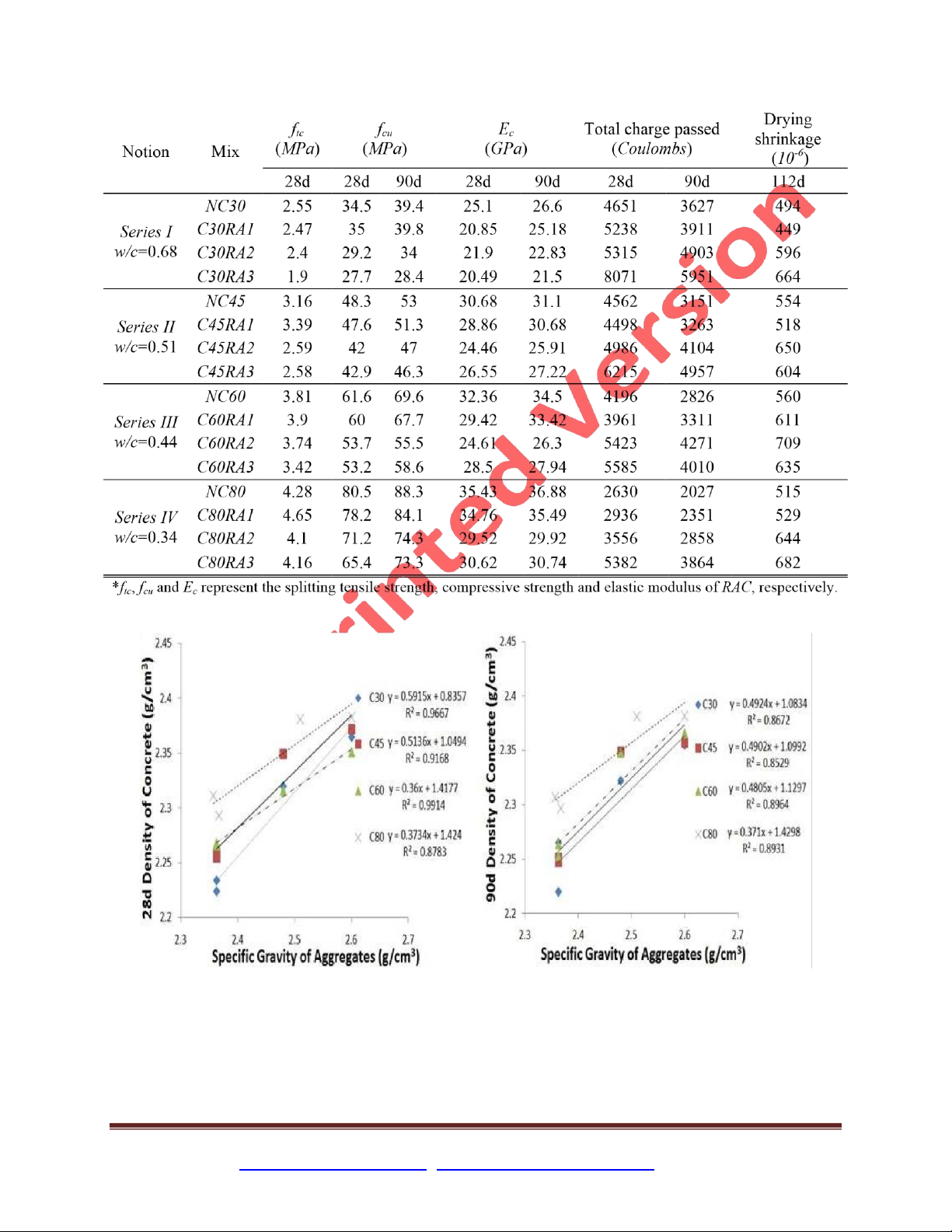

Table 5 lists the test results of different grades of concrete mixtures.

4.2.1 . Density

As shown in Fig. 6, the densities of the hardened concrete made with RA were lower than those

prepared with NA. Good relationships can be established between the density of the concrete and

the specific gravity of the corresponding aggregates used, with the correlation coefficients R2 all exceed 0.85.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

4.2.2. Compressive strength

The compressive strength of concrete made with NA and RAs are shown in Fig. 7. As expected,

the compressive strength of the concrete made with RA were mostly lower than that made with !1!

NA, regardless of the w/c ratio used; besides, the strength of the concrete made with NA and RA all increased with age. Table 5

Properties of concrete mixes

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

Fig.6. Relationship between specific gravity of aggregates and density of concrete !0B!

It can be noticed from Fig. 7 that there were large reductions in compressive strength when RA2

and RA3 (over 10% at both 28th and 90th day) were used to fully replace NA to produce the

concrete, which might be due to the large amounts of old mortar attached to them. With the

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

decrease in w/c ratio, it was increasingly difficult for RA2 and RA3 to produce concrete that can

satisfy the target strength. For Series IV, the strength values were about 11% and 18% lower than

the target strength of 80 MPa when RA2 and RA3 were used, respectively. This might be due to

the porous nature of RA2 and RA3 with a larger amount of cracks and attached mortar.

Fig.7. Effect of different aggregates on compressive strength of concrete mixes

For the concrete made with RA1, the compressive strength was comparable to that of the control

mix (and even exceeded the control in the case of C30 concrete). With the increase in target

strength, the difference between the strength of concrete made with NA and RA1 increased

gradually to about 2.9% and 4.8% for C80 at 28 days and 90 days, respectively. However, it can

be noticed from Table 5 that the concrete made with RA1 was still able to reach the target strength

of 60 MPa. So RAs of high quality may beused for producing concrete with comparable strength

to that of natural aggregates.

4.2.3. Tensile splitting strength

The results in Table 5 indicate that the concrete made with RA1 had higher tensile splitting strength

(except C30) than the corresponding natural aggregate concrete. The improved strength may be

due to the presence of the attached cement mortar, which would enhance the bonding between the

RA and the new cement paste [36]. Furthermore, the rough surface of the RAs might also further

improve the microstructure of the interfacial transition zone (ITZ) [37], and enhanced the splitting tensile strength.

Although RA2 and RA3 also had higher amounts of attached mortar than NA, the excessive

amounts of porous mortar led to a decrease in tensile strength. !00!

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

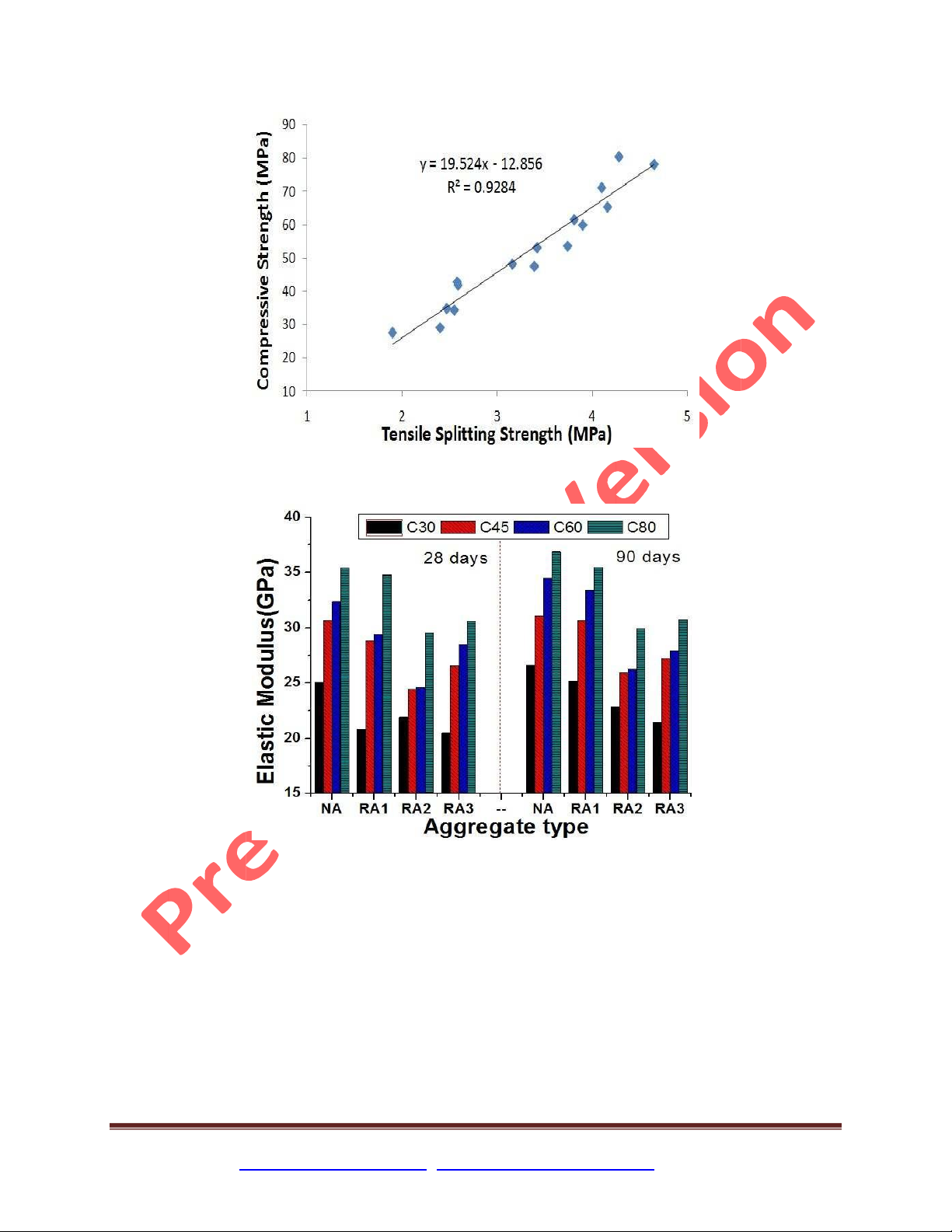

Fig.8. Relationship between 28d compressive strength and tensile splitting strength

Fig.9. Effect of different aggregates on elastic modulus of concrete mixes

As shown in Fig. 8 , the tensile splitting strength of concrete had a good correlation with the

corresponding compressive strength, and the correlation coefficient R2 reached as high as 0.93.

4.2.4. Static modulus of elasticity

The results of the static modulus of elasticity tests are shown in Fig. 9. A decline of elastic modulus

values is noted for the concrete made with RAs and the decrease is more obvious in concrete made with RA2 and RA3.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

The elastic modulus values of the concrete made with RA1 were almost as good as those made

with NA in all the mix series at both 28 and 90 days of curing. As the elastic modulus of !05!

concrete is related to the quality of coarse aggregate, a comparison between mechanical strength

(TFV and ACV) of NA and RA1 in Table 3 further proves that good quality RA is able to fully

replace NA to produce even high strength concrete.

Fig.10. Relationship between compressive strength and elastic modulus

Fig.11. Effect of different aggregates on chloride ion penetration and shrinkage of concrete mixes

Fig. 10 shows the relationship between elastic modulus and compressive strength of all mixes at

both 28 and 90 days. The relationship stipulated by ACI 318-95 [38] and BS EN 1992-1-1 [39],

together with some empirical relationships (Eqs.2-4) that have been proposed by other researchers

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 !

[36,40,41] based on their laboratory studies on testing concrete produced with RA, are also plotted

to compare the present findings with that of the relationships. !0?! Ravindrarajah and Tam [36]: Ec= 7.77fcu0.33 (2) Dhir et al [40]: Ec= 0.37 fcu+ 13.1 (3) Dillmann [41]: Ec= 0.63443fcu+ 3.0576 (4)

The regression equation based on the 28 and 90 days experimental results in this study can be expressed as follow: Ec= 4.7863fcu0.4485 R2=0.828 (5)

where fcu and Ec are expressed in MPa and GPa, respectively.

It can be noticed from Fig. 10 that most of the codes and established empirical relationships

overestimate the elastic modulus of the RAC. This may be due to that only one parameter,

compressive strength, was used to evaluate the corresponding elastic modulus value in such

relationships. More parameters, such as aggregate characteristics and cement type, should be

considered to be included for better estimation of the properties of recycled aggregate concrete.

4.2.5. Chloride ion penetrability

Fig. 11 shows the effect of different types of aggregates and w/c ratios on the resistance of chloride

ion penetration of the concrete. The results show that concrete made with RAs generally had poorer

resistance to chloride ion penetrability, and it decreased with the trend: RA1 > RA2 > RA3.

However, it should be noted from the Figure that the resistance to chloride ion penetration of the

concrete made with RA1 was the best in all mix series, and it can be comparable with those

prepared with NA, especially in Series II and III mixes at 28 days. 4.2.6. Drying shrinkage

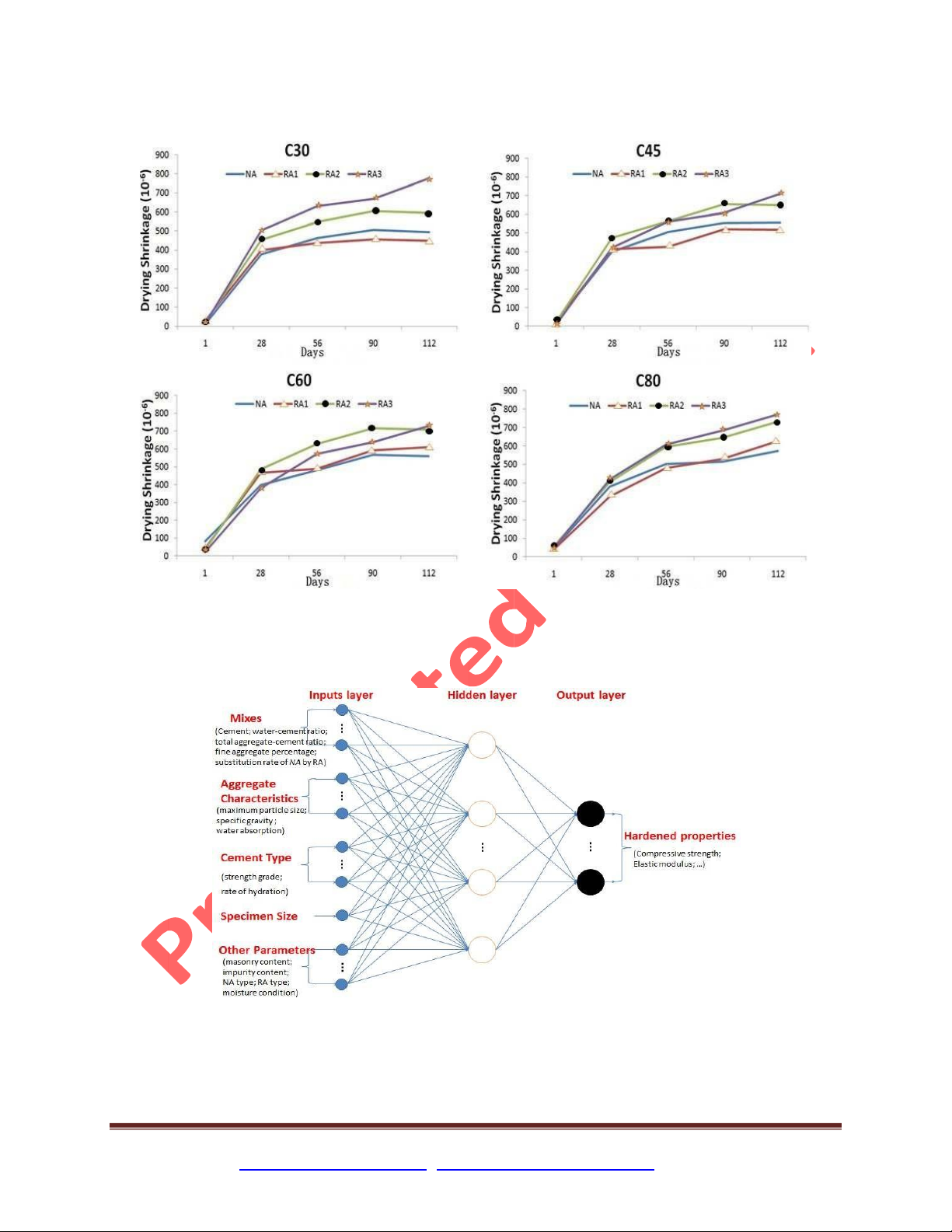

Fig. 11 also illustrates the effect of RA on the drying shrinkage of the concrete at 112 days and the

trends are similar to that of the chloride ion resistance test results. For concrete made with the

better quality of RA, lower shrinkage values were recorded generally.

The drying shrinkage development of concrete made with different coarse aggregates in all series

is presented in Fig. 12. As expected, the drying shrinkage of concrete increased with the curing

days in all series. Similar to the chloride penetration test, the drying shrinkage of concrete made

with RA1 was the best in all series, and can be comparable with those with NA.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! ! lOMoAR cPSD| 46560390 ! !0@!

Fig.12. Drying shrinkage of concrete made with different types of aggregates 4.3 . Modeling by ANN

Fig.13. Constructed ANN model

ANN model with a 16-40-1 structure (Fig. 13), proved previously to be capable of predicting the

properties of concrete made with RAs derived from different sources after training and testing [20],

was also used in this study to model the compressive strength and elastic modulus values.

"#$%&!’(&)*$+!,(’-.)/-)(’0123405678*9:!.)/-)7,(’-48*--/8&7;*<=(7)>!! !