Preview text:

Exercises lecture Reader DPE Interarrival time: on average 5 minutes P

( oisson distributed arrivals) Process 1 Process 2 Process 3 1 sin gle 1 sin gle 1 single workstation workstation workstation Time required per Time required per Time required per product: product: product: exactly 3 minutes exactly 3 minutes exactly 3 minutes 1.

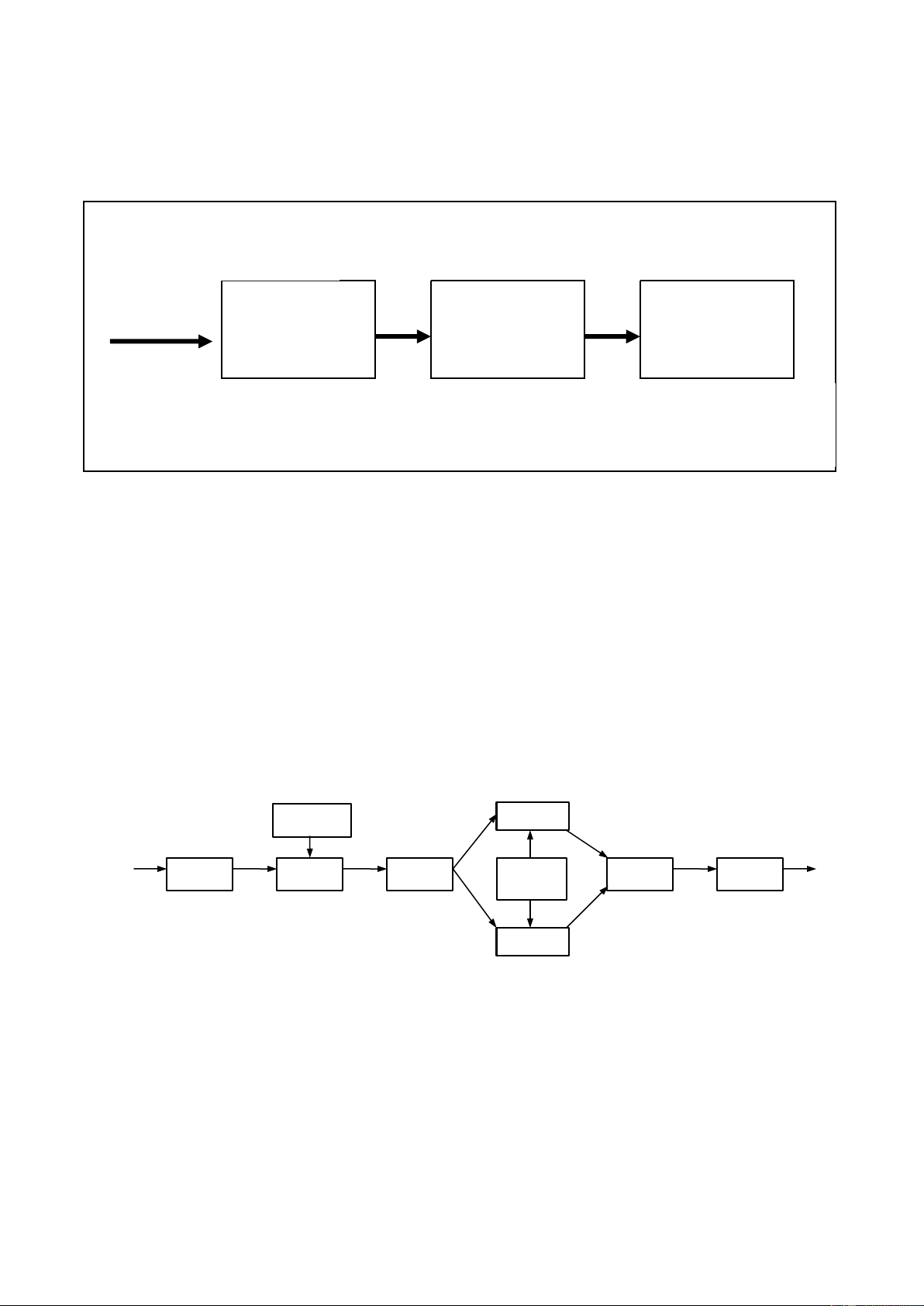

Consider the production system depicted above. The system consists of three identical

processes all having identical processing time. There is space to buffer products before and

after each process. Inter arrival time is on average 5 minutes (Poisson distributed arrivals).

I. How does the Work-In-Progress (WIP) determined with Deterministic Performance

Estimation compare to the WIP resulted from a simulation model of this system? A.

The deterministic WIP is lower than the WIP of a simulation model. B.

The deterministic WIP equals the WIP of a simulation model. C.

The deterministic WIP is higher than the WIP of a simulation model. D.

This cannot be determined without actually making the simulation model. II. How

would the answer change with interarrival times of exactly 5 minutes? Assemb . Interior work 2 Cover buffer Assemb . buffer buffer plates Assemb. .bly 1 1 2 3 Assemb . 2 2.

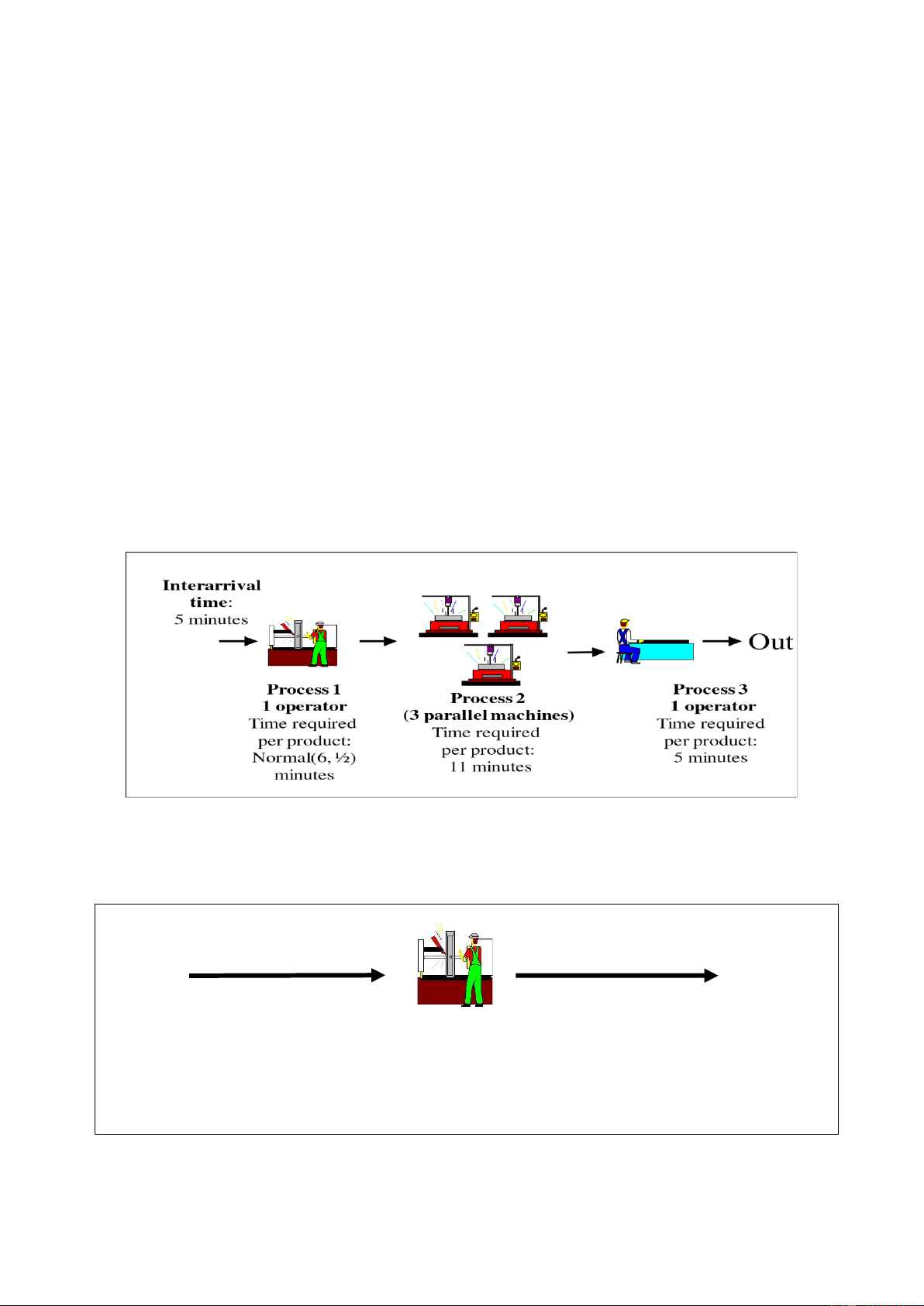

The above figure shows a schematic overview of an assembly line for car radios, as it has

been designed for the producer by an engineering consultant. Assembly will take place in

three steps. In the first step (assembly 1) the supplied empty casing will be provided with a

printed circuit board (PCB) and the mechanics for a CD player (the lining or interior). In the

second step (assembly 2), this printed circuit board is soldered to the casing, after which the

whole is mounted with a cover. Two parallel workstations are available for this operation.

The radio is tested in the third step and a label with the type and serial number will be attached (assembly 3).

The following facts are known about the assembly process: •

An empty casing arrives at the assembly line on every 50 seconds •

The assembly of the interior work takes 35 seconds •

Soldering the PCB and mounting the cover takes 80 seconds •

Testing and labeling on the radio takes 25 seconds •

Printed circuit boards, interiors and covers are always sufficiently available A.

Calculate the total number of produced radios for 4 weeks (one week consists of 5

days and one day consists of 8 hours). B.

Give an estimate for the total Work in Progress using the Little's equation. C.

Now suppose that empty casings arrive at the assembly line every 20 seconds. What

will be the changes in total production (for 4 weeks) and Work in Progress? 3.

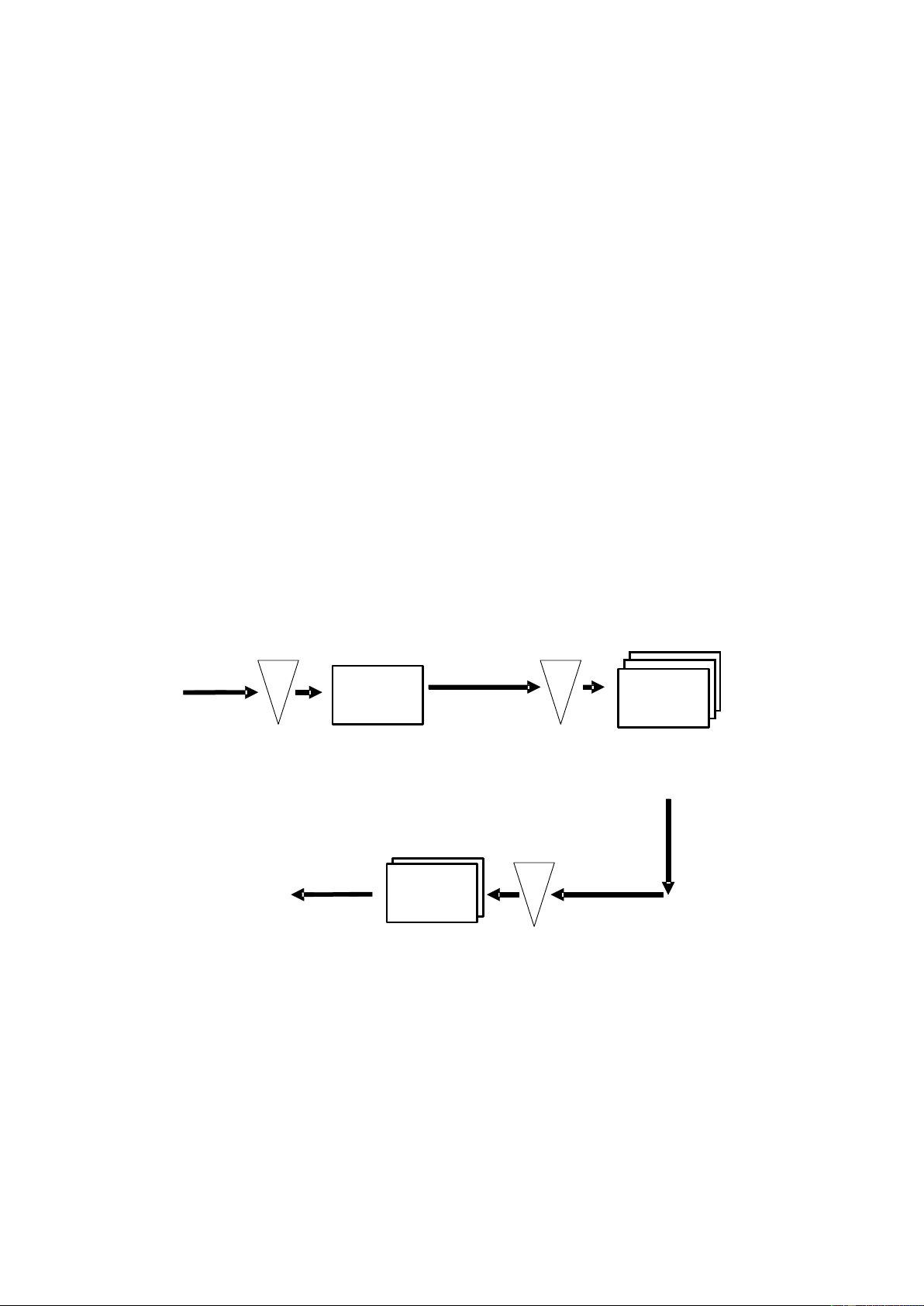

Consider the process depicted below. By means of Deterministic Performance Estimation

(DPE), what is the utilization of process 2? Interarrival time is 5 minutes. 4.

Consider the process depicted below. What is the minimum batch size to prevent process 1 from being a bottleneck? In Out Arrivals : Process 1 10 products

Time required: 4.2 minutes per product per hour

Production batch size is x

Set-up time per batch: 24 minutes 5.

Consider the process depicted on the below. Products arrive at this process at a rate of 7 product per

hour (Poisson distributed). First, give a deterministic estimate of the throughput time. Then determine

the average time products spend in the buffer before process 1. In Process 1 Process 2 1 mac hine 3 pa rallel operators Time required per product Time required per product On average 7.5 min. Normal (23,4) minutes

Neg. exponentially distributed Out Process 3 2 parallel operators Time required per product on average 14 min. 6.

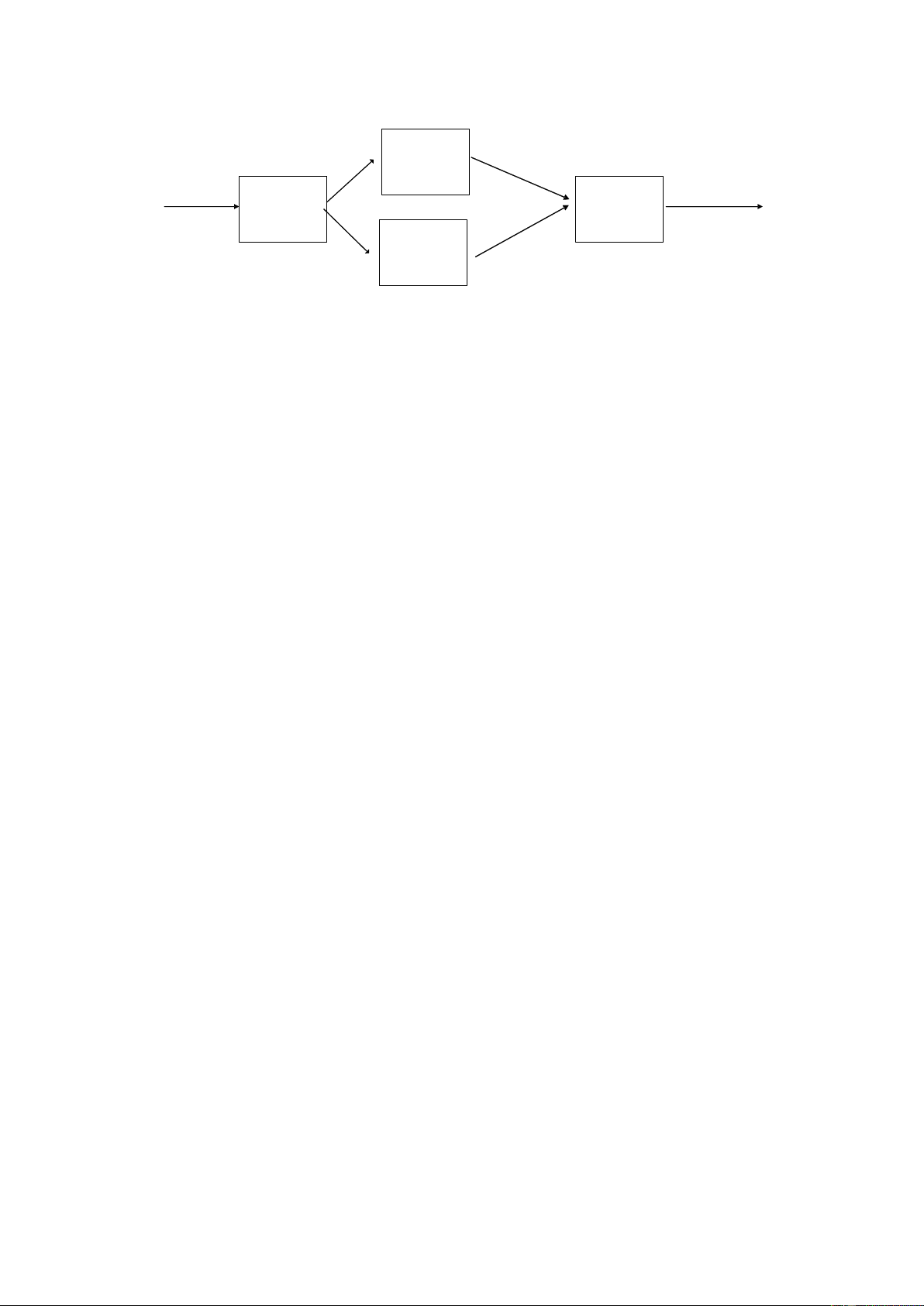

Consider the process depicted below. What is the Work-in-Progress if calculated with the summation formula? Interarrival time of indivi ( dual products): 4 mi Process 2 nutes Out Process 1 Process 3 Required time: Process 2 Required time: Exactly 2 minutes 3 mi nutes per product Batch size = 9 2 parallel machines setup time = 6 minute Required time: 7 mi nutes per product 7.

Can we change to a batch size of 1 for process 3 in the picture above? If yes, why? If no, how many of

these machines would you need to be able to do so?