Preview text:

TABLE OF CONTENTS

LIST OF FIGURES......................................................................................................2

EXECUTIVE................................................................................................................. 3

CHAPTER 1. INTRODUCTION....................................................................................4

CHAPTER 2. THEORETICAL BACKGROUND..........................................................5 2.1.

Outbound logistics............................................................................................5 2.1.1.

Definition....................................................................................................5 2.1.2.

Outbound logistics processes......................................................................5 2.2.

Technologies related.........................................................................................6 2.2.1.

Warehouse Management System (WMS)........................................................6 2.2.2.

Big data and internet of things.......................................................................6 2.2.3.

Cloud computing............................................................................................7 2.2.4.

Fleet management system...............................................................................8 2.2.5.

Artificial intelligence and machine learning...................................................9

CHAPTER 3. CURRENT SITUATION AT AMAZON...............................................11 3.1.

Overview of Amazon.......................................................................................11 3.1.1.

Introduction...............................................................................................11 3.1.2.

Mission......................................................................................................11 3.1.3.

Vision........................................................................................................11 3.1.4.

Values........................................................................................................11 3.1.5.

Amazon products and services..................................................................12 3.2.

Technologies applied in Amazon’s outbound logistics..................................12 3.2.1.

Order processing.......................................................................................12 3.2.2.

Fulfillment................................................................................................. 14 3.2.3.

Shipping....................................................................................................18 3.2.4.

Last-mile delivery......................................................................................20

CHAPTER 4. SUGGESTIONS FOR SOLUTIONS.....................................................25

CHAPTER 5. CONCLUSION......................................................................................28

REFERENCES............................................................................................................ 29 1 LIST OF FIGURES

Figure 1: Outbound Logistics Processes..........................................................................5

Figure 2: Amazon's pods...............................................................................................14

Figure 3: Barcode system in the Fulfillment center.......................................................15

Figure 4: The robotic arm..............................................................................................16

Figure 5: Amazon's conveyor belt.................................................................................17

Figure 6: Products sorted for shipping...........................................................................18

Figure 7: Amazon's fleet management system..............................................................19

Figure 8: Amazon's delivery van...................................................................................20

Figure 9: Amazon Scout................................................................................................ 21

Figure 10: Amazon Prime Air's delivery drone.............................................................22

Figure 11: Amazon Key app for in-car delivery service................................................22

Figure 12: Amazon's in-car delivery service.................................................................23

Figure 13: Amazon Locker............................................................................................ 24

Figure 14: Alibaba's autonomous delivery robots Xiaomanlv.......................................26 2 EXECUTIVE

By applying technologies in the outbound logistics process, Amazon has been

operating effectively by taking advantage of the economies of scale as a big global

corporation. When applying advanced technologies, Amazon sometimes faces serious

problems affecting the company’s outbound logistics.

The paper discusses the background of the company, the advanced technologies

used by Amazon, and giving suggestions for further improvement. The purpose of the

paper is to have a clear view about why Amazon is so successful with their outbound

logistics. Therefore, we will see if we can apply any of their technology into Vietnam’s outbound logistics.

About the methods, we analyze the technologies used in Amazon based on the

course, research papers, and internet sources. Then, we do research about the company

and how they apply these technologies in order processing, fulfillment, shipping, and

last-mile delivery. Advanced technologies used in each stage of Amazon’s outbound

logistics have some advantages and disadvantages. Most importantly, the technologies

help their logistics work more smoothly, efficiently, and faster than humans.

However, through our research, the technologies used also have malfunctions

sometimes, which leads to some accidents and waste of money. Thus, we give some

suggestions for improving the technologies’ performance.

Throughout the research, we find that the technologies used in Amazon are highly

advanced. However, it is still hard to conclude that they can be applied in Vietnam

since we have different delivery systems, cultures and living conditions. 3 CHAPTER 1. INTRODUCTION

Amazon has such a well-performed outbound logistics. When applying a range of

advanced technologies, the company has had outstanding success in maintaining

smooth and efficient logistics.

So, what should be discovered in Amazon’s outbound logistics? Firstly, we will

give a theoretical background about the outbound logistics and some related

technologies such as warehouse management system, big data, internet of things, etc.

Secondly, we will give a coherent analysis on the current situation of Amazon. In this

part, we will analyze different technologies applied to its outbound logistics. Therefore,

through the analysis, we recommend some solutions for improving the company’s situation. 4

CHAPTER 2. THEORETICAL BACKGROUND 2.1.

Outbound logistics 2.1.1. Definition

Outbound logistics is the process of storing, transporting, and delivering goods to

the end customers. In other words, it is about how a business moves finished inventory

out of their supply chain – and fulfills customers’ orders. The steps include order

processing, product picking and packing, shipping, delivery, and customer service

related to delivery (Jenkins, Guide to Inbound and Outbound Logistics: Processes,

Differences and How to Optimize, 2020).

2.1.2. Outbound logistics processes

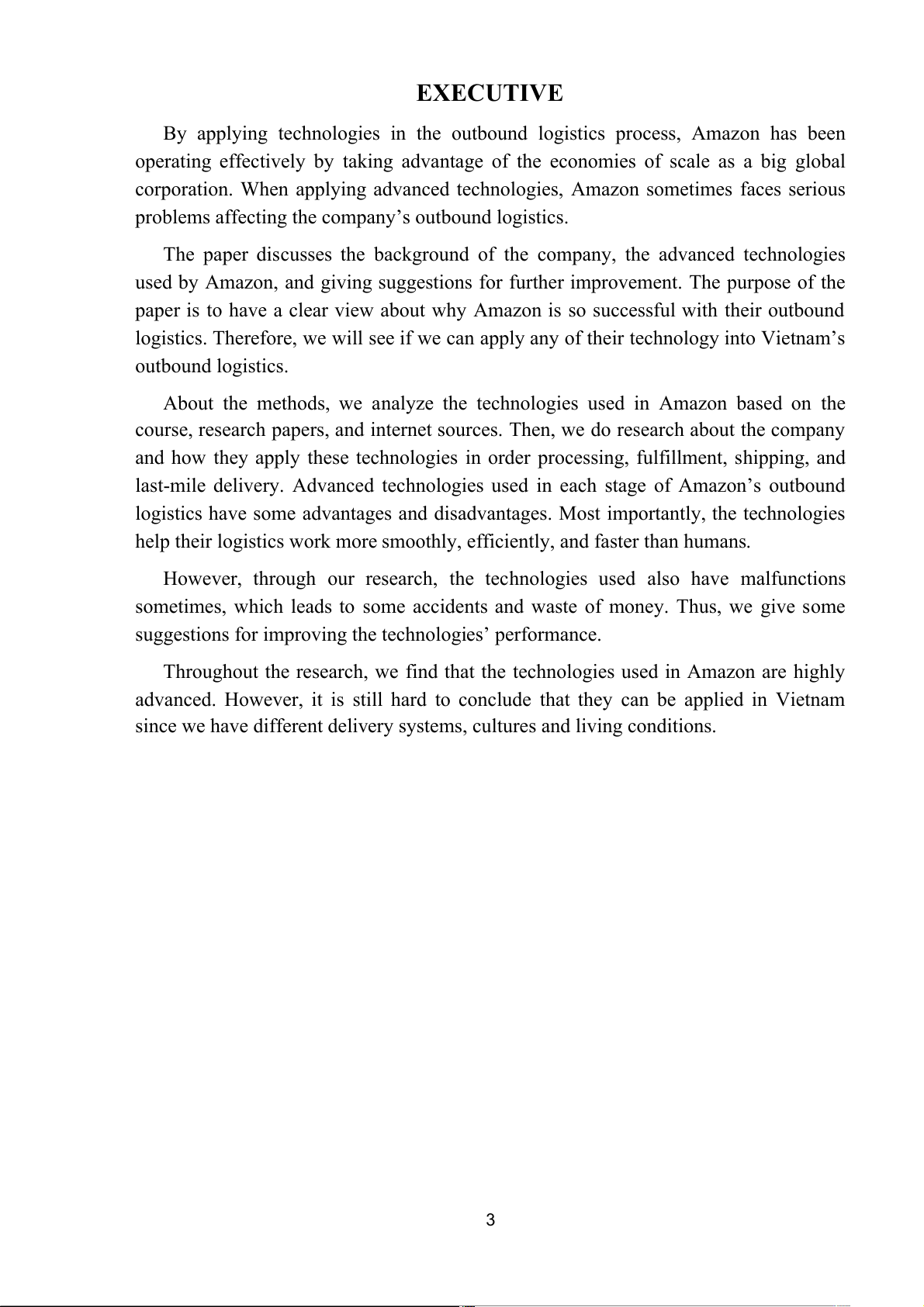

1) Order processing: order processing is

the workflow that ensures customer orders are

properly prepared and delivered to the right

place. Every order is sent through a business’s

order management system. Then, depending

on the scale of a business’s operations, orders

can be passed to a distribution center or

warehouse where pickers, sorters and packers

work in sync toward order fulfillment, or it can

be done by a single person or small group

(Jenkins, What Is Order Processing? 5 Steps & 10 Tips to Improve, 2021).

2) Fulfillment: Fulfillment is the process

of ensuring that all the necessary steps are

taken in order to deliver the goods to the

customer. This includes packing, labeling, and

arranging for a carrier to deliver the goods. It

also involves providing customer service,

tracking orders, and managing returns (Shopify Staff, 2022).

3) Shipping: The order is dispatched to

distribution centers or partner logistic services

from the warehouse. The outbound logistics

personnel ensure that the shipment is properly

labeled and documented for tracking purposes (Locad, n.d.).

4) Last-mile delivery: In a product’s

journey, it is moved to the customer’s doorstep 5

Figure 1: Outbound Logistics Processes

– the final step of this process, known as the “last mile of delivery”. Last mile delivery

is the most expensive and time-consuming part of the shipping process (Dolan, 2023). 2.2.

Technologies related

2.2.1. Warehouse Management System (WMS)

A warehouse management system (WMS) is a software solution that offers visibility

into a business’ entire inventory and manages supply chain fulfillment operations from

the distribution center to the store shelf. WMS solutions additionally enable companies

to maximize their labor, space utilization and equipment investments by coordinating

and optimizing resource usage and material flows. Specifically, WMSs are designed to

support the needs of an entire global supply chain, including distribution,

manufacturing, asset-intensive, and service businesses.

With the progress in IT capabilities, WMSs started to be developed and early

systems were used to keep track of the receipts versus releases, and the balance

constituted the available on-hand inventory.

With the progress in mobile hardware technology, further enhancements were

introduced into the warehouse such as barcode scanning with handheld devices and the

introduction of material handling automation inside facilities. Barcode readers work by

using a beam of light to read the black and white pattern printed on the adhesive tag. In

today’s environment, the systems deployed inside the facilities have to be seamlessly

customizable and configurable to support the execution of the processes.

On the other hand, RFID (or Radio-Frequency Identification) leverages radio waves

to transmit data from RFID chips to the readers. While barcode scanners require a line

of sight to scan each code individually, RFID scanners can read multiple codes at once.

Items in supply chain and retail stores are tagged with RFID tag, which allows

instantaneous non-line-of-sight (NLOS) bulk readouts as well as real-time inventory

counts. RFID is deployed in logistics and retail field, and it is described as middleware

solutions to complement functionality of common WMS or retail systems.

In addition, since goods still need to be transported in a cost-efficient manner, a

WMS can be complemented with transportation management systems (TMSs), which

optimize the shipment planning, execution, and transportation, considering the required

service levels in order to deliver a shipment from the facility to the consumption point.

2.2.2. Big data and internet of things

The Internet of Things (IoT) describes the network of physical objects – “things” –

that are embedded with RFID tags sensors, software, actuators, mobile phones, and

other technologies for the purpose of connecting and exchanging data with other

devices and systems over the internet. The increasing volume and detail of information

generated by organizations, social media and the IoT has led to an explosion in the

amount of data captured, and the concept of big data emerged. 6

Big data refers to datasets whose size is beyond the ability of typical database

software tools to capture, store, manage and analyze. Big data has four key attributes as

defined by IBM (Zikopoulos, deRoos, Bienko, Buglio, & Andrews, 2015): Volume: scale of data;

Velocity: analysis of streaming data, velocity as the rate at which data arrives at

the enterprise and the time that it takes the enterprise to process and understand that data;

Variety: different forms of data: structured and unstructured;

Veracity: uncertainty of data, refers to the quality or trustworthiness of the data.

Big data analytics describes the process of uncovering trends, patterns, and

correlations in large amounts of raw data to help make data-informed decisions. These

processes use familiar statistical analysis techniques—like clustering and regression—

and apply them to more extensive datasets with the help of newer tools (Tableau, n.d.).

In the case of Amazon, it has been using The Apache Hadoop software library,

which is a framework that allows the distributed processing of large data sets across

clusters of computers to use simple programming models. It is designed to scale up

from single servers to thousands of machines, each offering local computation and

storage. Rather than rely on hardware to deliver high availability, the library itself is

designed to detect and handle failures at the application layer, so delivering a highly

available service on top of a cluster of computers, each of which may be prone to

failures (Apache Hadoop, n.d.). 2.2.3. Cloud computing

Cloud computing refers to a model of computing in which firms and individuals

obtain computing power and software and install it on their own computers It can be

classified into three types: public cloud, private cloud, and hybrid cloud (Armbrust, et

al., 2010, pp. 50-58). Cloud computing is on-demand access, via the internet, to

computing resources – applications, servers (physical servers and virtual servers), data

storage, development tools, networking capabilities, and more – hosted at a remote data

center managed by a cloud services provider (CSP). The CSP makes these resources

available for a monthly subscription fee or bills them according to usage. Cloud

computing helps do the following: lower IT costs, improve agility and time-to-value,

scale more easily and cost-effectively.

Amazon Web Services (AWS) is Amazon’s cloud computing model. AWS has

significantly more services and more features than any other cloud provider – from

infrastructure technologies like compute, storage, and databases – to emerging

technologies, such as machine learning and artificial intelligence, data lakes and

analytics, and Internet of Things. This makes it faster, easier, and more cost effective to

move existing applications to the cloud and build nearly anything that can be imagined. 7

AWS also has the deepest functionality within those services. For example, AWS offers

the widest variety of databases that are purpose-built for different types of applications

so users can choose the right tool for the job to get the best cost and performance

(Amazon, Cloud computing with AWS, n.d.).

2.2.4. Fleet management system

The fleet management system (FMS) interface provides a read-only standard

interface providing some common metrics, and also acts as a firewall, protecting the

internal CAN from injection of data from unknown ECUs. Its purpose is to maintain an

accurate and up-to-date overview of vehicle diagnostics, geolocation, and identifying

risky or unsafe driver behaviors while simultaneously reducing manager workload.

With data stored on a cloud-based platform and easily accessible in real time from

multiple locations, fleet management has never been more straightforward (lytx, n.d.).

Some examples of specific fleet metrics that can be tracked, monitored, and

managed using fleet management software include: Vehicle speed Brake switch Total fuel used Engine speed Axle weight Tachograph information

Engine coolant temperature (Wikipedia, n.d.).

Going into some of the metrics in more detail:

A tachograph is a recording device fitted to a vehicle, which automatically records

the vehicle speed and distance as well as the ‘mode’ the driver is currently in.

Tachographs offer two types of data, both of which are available from the K-Line and CAN: Live data: - odometer - speed - driver(s) numbers and names - driving mode

- information on compliance with regulations for driving (DDS). Historical data:

- driving history for past two months on driver’s card

- history for several years within tachograph

- speed data for last 24 hours of driving, to one-second accuracy.

Global positioning system (GPS) is to track the location of an entity or object

remotely. The technology can pinpoint longitude, latitude, ground speed, and course 8

direction of the target. The GPS is a "constellation" of 24 well-spaced satellites that

orbit the Earth and make it possible for people with ground receivers to pinpoint their

geographic location. The location accuracy is anywhere from 100 to 10 meters for most equipment.

Latitude and longitude, together with complete CAN and tachograph data then may

provide much more data such as:

Recording arrival and departure from known locations (defined by polygenic geofences)

Monitoring the route taken by the vehicle and altering when deviating from given route

Recording infringement to speed on the current road

Analyzing fuel usage against other metrics

Advising on expected arrival times of vehicle to its destination and alerting when predicted to be late.

When evaluating GPS systems, it is vital to ensure it gives those features required to

make the system an asset for the customer.

2.2.5. Artificial intelligence and machine learning

Machine learning is a branch of artificial intelligence (AI) and computer science

which focuses on the use of data and algorithms to imitate the way that humans learn,

gradually improving its accuracy (IBM, n.d.).

Machine learning is an important component of the growing field of data science.

Through the use of statistical methods, algorithms are trained to make classifications or

predictions, and to uncover key insights in data mining projects. These insights

subsequently drive decision making within applications and businesses, ideally

impacting key growth metrics. As big data continues to expand and grow, the market

demand for data scientists will increase. They will be required to help identify the most

relevant business questions and the data to answer them.

This technology has been applied to several tasks of Amazon, including autonomous

trucking. The term autonomous trucks is applied to trucks that will be controlled from

other sources such as satellites and advanced GPS (Global Positioning Systems),

models currently on the road already provide a semi-autonomous mode of operation, in

which the unmanned system and/or a human operator conduct a mission, have various

levels of human-robot interaction. In the fully autonomous mode of operation, the

unmanned system is expected to accomplish its mission, within a defined scope,

without human intervention. In the teleoperation mode of operation, the human

operator, using video feedback and/or other sensory feedback, either directly controls

the actuators or assigns incremental goals, waypoints in mobility situations, on a

continuous basis, from off the vehicle and via a tethered or radio linked control device. 9

And, finally, in the remote-control mode of operation, the human operator, without

benefit of video or other sensory feedback, directly controls the actuators of the

unmanned system on a continuous basis, from a location off the vehicle and via a

tethered radio linked control device using visual line-of-sight cues (Madhavan, Elena,

& James, 2006, pp. 324, 325). 10

CHAPTER 3. CURRENT SITUATION AT AMAZON 3.1.

Overview of Amazon 3.1.1. Introduction

Amazon (Amazon.com) is the world's largest online retailer and a prominent cloud

service provider. Headquartered in Seattle, Amazon has individual websites, software

development centers, customer service centers, data centers and fulfillment centers around the world.

Originally started as an online bookselling company, Amazon has morphed into an

internet-based business enterprise that is largely focused on providing e-commerce,

cloud computing, digital streaming and artificial intelligence (AI) services.

Following an Amazon-to-buyer sales approach, the company offers a monumental

product range and inventory, enabling consumers to buy just about anything, including

clothing, beauty supplies, gourmet food, jewelry, books, movies, electronics, pet

supplies, furniture, toys, garden supplies and household goods (Yasar, 2022). 3.1.2. Mission

Amazon is guided by four principles: customer obsession rather than competitor

focus, passion for invention, commitment to operational excellence, and long-term

thinking (Amazon, Who We Are, n.d.). Its mission is “to serve consumers through

online and physical stores and focus on selection, price, and convenience” (Björklund, 2014). 3.1.3. Vision

Amazon states its vision as: “Our vision is to be Earth's most customer-centric

company, where customers can find and discover anything they might want to buy

online, and endeavours to offer its customers the lowest possible prices” (Amazon,

Amazon Mission, Vision & Values, n.d.). 3.1.4. Values

Amazon has ten values as follows: Customer Obsession Ownership Invent and Simplify Learn and Be Curious Hire the Best The Highest Standards Think Big Bias for Action Earn Trust 11

Deliver Results (Amazon, Amazon Mission, Vision & Values, n.d.).

3.1.5. Amazon products and services

Amazon offers an ever-expanding portfolio of services and products. Following is a

list of its noteworthy offerings. 1) Retail

Amazon Marketplace. Amazon's e-commerce platform enables third-party retailers

to showcase and sell their products alongside Amazon items. 2) Amazon Fresh

Amazon's grocery pickup and delivery service is currently available in nearly two

dozen U.S. cities and a few international locations. A grocery order can be placed

through the Amazon Fresh website or the Amazon mobile app. Customers can either

get their groceries delivered or visit the store for pickup. 3) Amazon Vine

Launched in 2007, Amazon Vine helps manufacturers and publishers get reviews

for their products to help shoppers make informed purchases. 4) Woot

Acquired by Amazon in 2010, Woot offers limited time offers and special deals that

rotate daily. This shop features refurbished items, as well as new items that are low in

stock. Prime members get free shipping. 5) Zappos

Amazon bought Zappos in 2009. This online retailer of shoes and clothing carries a

wide range of brands, including Nike, Sperry, Adidas and Uggs. 6) Merch by Amazon

This on-demand T-shirt printing service enables sellers to create and upload their T-

shirt designs for free and earn royalties on each sale. Amazon does the rest -- from

printing the T-shirts to delivering them to customers. 7) Amazon Handmade

This platform enables artisans to sell handcrafted products to customers around the world (Yasar, 2022). 3.2.

Technologies applied in Amazon’s outbound logistics

In this part, the technologies that are used by Amazon are going to be described as

the process of outbound logistics – order processing, fulfillment, shipping, and last-mile delivery. 3.2.1. Order processing 12

As soon as the customers press the “Buy now” button, it comes to Amazon’s

outbound logistics. The information about the orders will come to Amazon’s system

and the robots will inform the workers about which items are ordered and where they

are located (Amazon Tours, 2021).

a) Routing orders into optimal warehouse

When a customer places an order on Amazon's website, the order is processed by

Amazon's software system, which identifies the item, the quantity, and the delivery

address. This information is then transmitted to the Amazon fulfillment center where the item is stored.

Once the order is received by the fulfillment center, it is processed by Amazon's

proprietary Warehouse Management System (WMS) which tracks inventory levels

and manages the movement of products throughout the facility. The company's back-

end systems use a complex algorithm to determine the most appropriate warehouse or

fulfillment center to fulfill the order. The algorithm takes into account a variety of

factors, including product availability, proximity to the customer, delivery speed,

workload, cost, etc. (Data4Amazon, n.d.)

In the context of order processing, big data analytics is used to analyze customer

behavior, inventory levels, and shipping patterns in real-time to optimize the routing of

orders and reduce shipping times. The technology can also be used to track the

performance of different warehouses and fulfillment centers and identify areas where

improvements can be made. For its big data analytics, for example, Amazon uses

Apache Hadoop - an open-source software framework for storing and processing large

datasets across clusters of commodity hardware. Amazon offers Hadoop as a managed

service called Amazon EMR (Elastic MapReduce), which makes it easy to process

large amounts of data using Hadoop without having to manage the underlying

infrastructure (AWS, Apache Hadoop on Amazon EMR, n.d.).

Amazon's backend systems rely heavily on cloud computing to process and store

data, as well as to run applications that support order routing and fulfillment. Amazon

Web Services (AWS), the company's cloud computing platform, provides the scalable

infrastructure needed to handle large volumes of orders and data (AWS, Amazon Web Services, n.d.).

Moreover, Amazon uses collaborative filtering, which is a machine learning

algorithm, and GPS tracking to

route the orders optimally. Collaborative filtering may

be used to analyze the order history of customers who have ordered similar products

and route the order to the appropriate warehouse or fulfillment center based on the

historical patterns of those orders. For example, if a customer has a previous order of

the same product, the system will automatically choose the same warehouse for this

order. In another words, collaborative filtering works by analyzing data on past 13

customer behavior and identifying patterns and trends. The algorithm uses this data to

build a model of the customer's preferences and interests, which can be used to predict

future behavior and make recommendations or routing decisions (Hardesty, 2019).

b) Receiving orders at the warehouse

When the orders are well received in the warehouses, they will be processed by

some robots. Amazon's robots are connected to the internet and use Internet of Things

(IoT) sensors to communicate with the WMS and other systems. This allows them to

receive real-time instructions on which items are placed (Amazon Tours, 2021).

This is the end of the order processing step. Now, the orders are going to the

fulfillment centers with different technologies used. 3.2.2. Fulfillment

Amazon uses RFID and barcode technology to track the movement of products

throughout its warehouses and fulfillment centers. This technology allows the back-end

systems to locate and retrieve products quickly and accurately, which is essential for

efficient order routing and fulfillment.

The process in the fulfillment center (FC) includes pick, pack, and SLAM (scan,

label, apply, and manifest) respectively as discussed in the following: a) Pick

Amazon has been using robots for the picking process. From the moment product

comes into the warehouse, everything is moved on either floor robots, conveyor belts,

or elevators. In the first stage, the product is loaded into the pods, which are carried on

top of a robot. Since items are stored randomly, the item may be stored in more than

one pod. An algorithm in the Cloud calculates the most efficient combination of picker,

pod, and drive unit to process each customer order. Figure 2: Amazon's pods 14

The way that Amazon keeps track of all the robots is as follows: The FC floor is a

grid system, and each square has a unique QR code. As the drive unit moves, the robot

uses a camera sensor underneath it to constantly scan and update its new location in the

cloud. A sensor is a device that detects and responds to its physical environment. This

combination of real-time sensing and cloud processing allows the drive units to work

together to clear paths for each other and fulfill orders as efficiently as possible (Amazon News, 2022).

Figure 3: Barcode system in the Fulfillment center

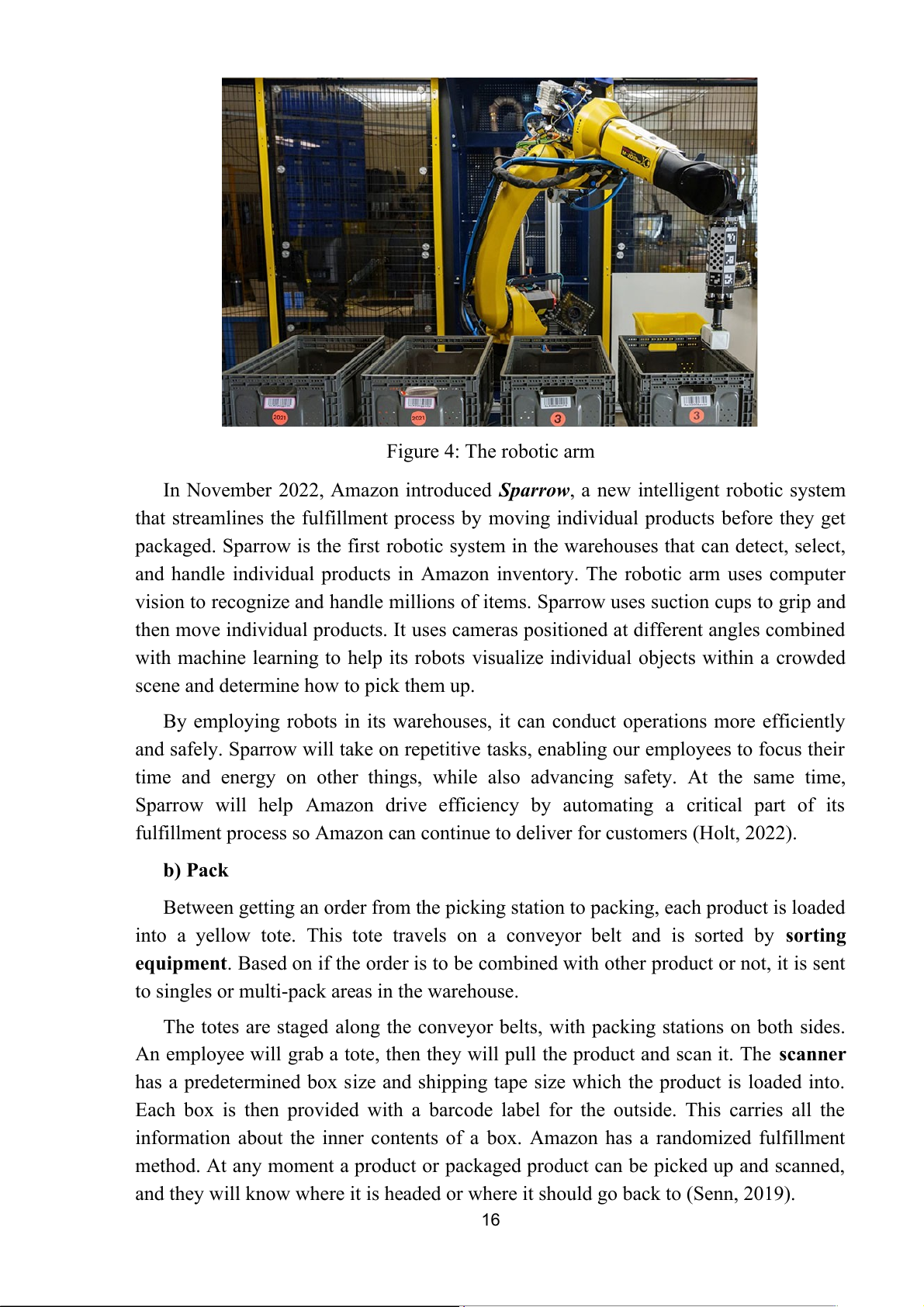

Another technology that is applied in this step is computer vision, which is a

critical component of Amazon's picking system in its outbound logistics operations.

In Amazon's picking system, computer vision is used to enable the robots to locate

and pick the correct items from their storage locations. The robots are equipped with

cameras and sensors that capture images of the items stored in the warehouse.

Computer vision algorithms then analyze these images to identify the location of the

item, its orientation, and any other relevant details quickly and accurately. Amazon’s

robotic arm is an example, it is used for identifying individual products. It can be seen

that Amazon is using computer vision to automate its logistics operation with robotics. 15 Figure 4: The robotic arm

In November 2022, Amazon introduced Sparrow, a new intelligent robotic system

that streamlines the fulfillment process by moving individual products before they get

packaged. Sparrow is the first robotic system in the warehouses that can detect, select,

and handle individual products in Amazon inventory. The robotic arm uses computer

vision to recognize and handle millions of items. Sparrow uses suction cups to grip and

then move individual products. It uses cameras positioned at different angles combined

with machine learning to help its robots visualize individual objects within a crowded

scene and determine how to pick them up.

By employing robots in its warehouses, it can conduct operations more efficiently

and safely. Sparrow will take on repetitive tasks, enabling our employees to focus their

time and energy on other things, while also advancing safety. At the same time,

Sparrow will help Amazon drive efficiency by automating a critical part of its

fulfillment process so Amazon can continue to deliver for customers (Holt, 2022). b) Pack

Between getting an order from the picking station to packing, each product is loaded

into a yellow tote. This tote travels on a conveyor belt and is sorted by sorting

equipment. Based on if the order is to be combined with other product or not, it is sent

to singles or multi-pack areas in the warehouse.

The totes are staged along the conveyor belts, with packing stations on both sides.

An employee will grab a tote, then they will pull the product and scan it. The scanner

has a predetermined box size and shipping tape size which the product is loaded into.

Each box is then provided with a barcode label for the outside. This carries all the

information about the inner contents of a box. Amazon has a randomized fulfillment

method. At any moment a product or packaged product can be picked up and scanned,

and they will know where it is headed or where it should go back to (Senn, 2019). 16 .

Figure 5: Amazon's conveyor belt

To practice efficiency when choosing a box to ship an item, they need to pick the

smallest box possible while also protecting the items. When an item arrives at Amazon

to be sold, the staff record many facts about it: Its height, width, and weight. These

facts are stored in a database. When an item is ordered, the cloud pulls the item’s

dimensions and weight for the database and automatically calculates (using an

algorithm) which box will be the best. Using a database to estimate package size helps

Amazon stay more efficient with shipping.

c) SLAM (scan, label, apply and manifest)

Once the items are packed, they are sent down to SLAM for quality control.

At the SLAM station, the customer address label is applied, and a sensor weighs the

box to make sure everything is correct. The system uses the database to compare the

actual package weight with the expected package weight to see if the two weights

match. If they do not match, the box is pulled off, inspected, and corrected by an

associate. If they match, it heads onto shipping.

The sorter uses an algorithm to assign the packages to the truck that will provide the

fastest delivery route. After being sorted, parcels are scanned and sent to the correct

pallet or ATS cart, and then scanned to send onto the trucks for shipping (Senn, 2019). 17

Figure 6: Products sorted for shipping 3.2.3. Shipping

Amazon has been testing and using autonomous trucking for its shipping.

Amazon ordered 1,000 autonomous truck-driving systems from a startup called

Plus. This system operates similarly to Tesla’s “full self-driving” software, which

requires a licensed driver to keep their eyes on the road in case the system malfunctions

or needs intervention (Kay, 2021). Autonomous technology can make Amazon delivery

trucks safer, more fuel efficient, and more comfortable for drivers. Besides,

autonomous trucking is potential to reduce the carbon emissions and fuel costs (Moorhead, 2021).

To fulfill the autonomous trucking technology, there is a need for cloud computing

capacity for simulation and data processing. And in addition to simulation, Amazon

also needs big data, for extensive real-world data collection, to ensure that it has

enough long-tail scenarios captured in its simulations.

In 2021, Amazon was applying Level 4 technology into trucks with drivers that

supervise the system. Long-tail scenarios and data gathered in these driver-in-trucks is

then fed back into the driving AI to improve it, which is also a machine learning

process. To handle the amount of data harvested from real-world operation, the truck-

driving system provider – Plus relies on Amazon Web Services (AWS) for its cloud

computing (AWS Automotive Editorial Team, 2021).

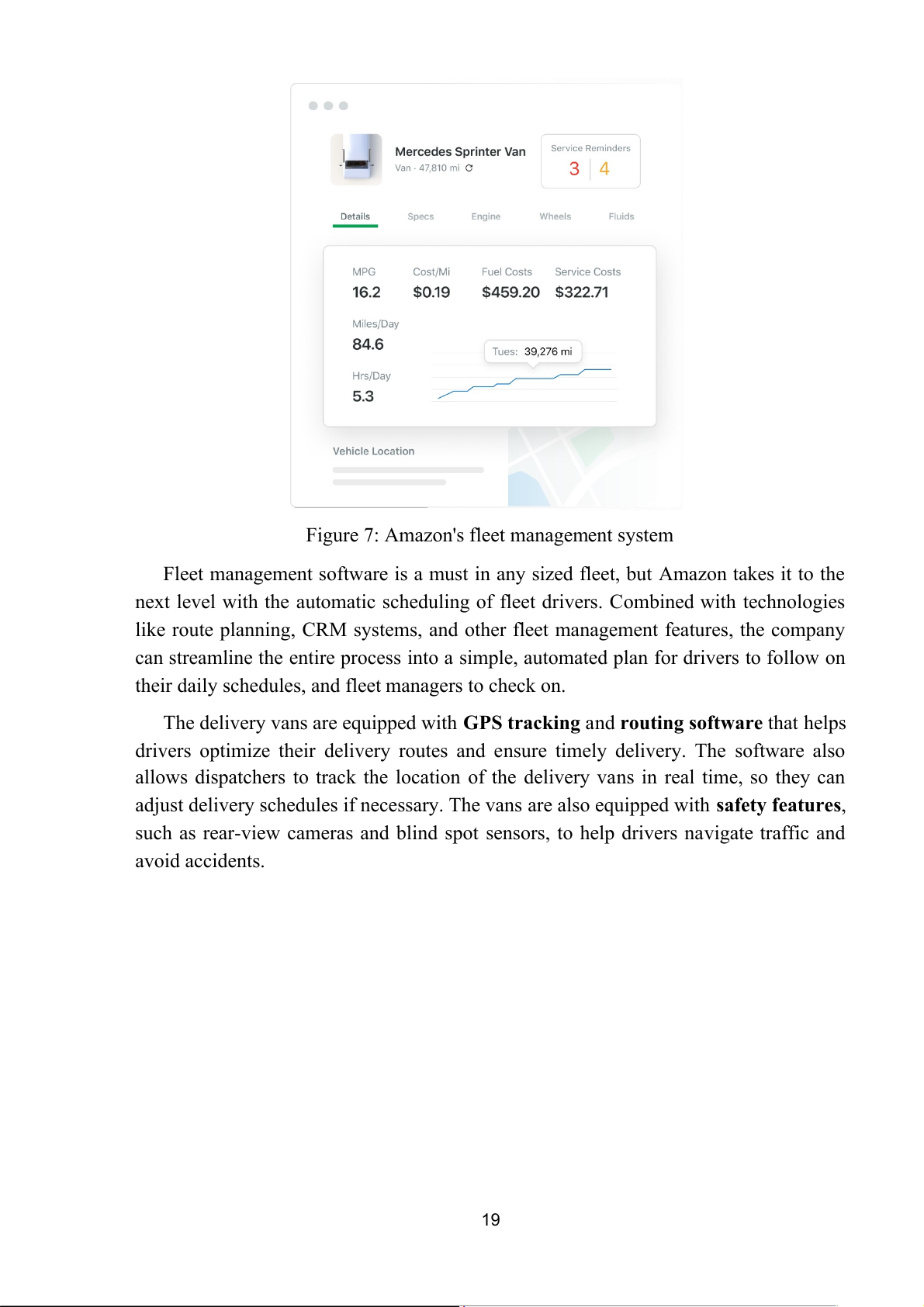

Besides, Amazon applies fleet management system from the process of shipping to

last-mile delivery. With the installation of Internet of Things (IoT) and automation,

Amazon can manage its fleets productively. 18

Figure 7: Amazon's fleet management system

Fleet management software is a must in any sized fleet, but Amazon takes it to the

next level with the automatic scheduling of fleet drivers. Combined with technologies

like route planning, CRM systems, and other fleet management features, the company

can streamline the entire process into a simple, automated plan for drivers to follow on

their daily schedules, and fleet managers to check on.

The delivery vans are equipped with GPS tracking and that routing software helps

drivers optimize their delivery routes and ensure timely delivery. The software also

allows dispatchers to track the location of the delivery vans in real time, so they can

adjust delivery schedules if necessary. The vans are also equipped with safety features,

such as rear-view cameras and blind spot sensors, to help drivers navigate traffic and avoid accidents. 19