Preview text:

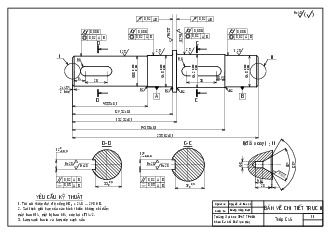

358 14.1 11.2 285.4

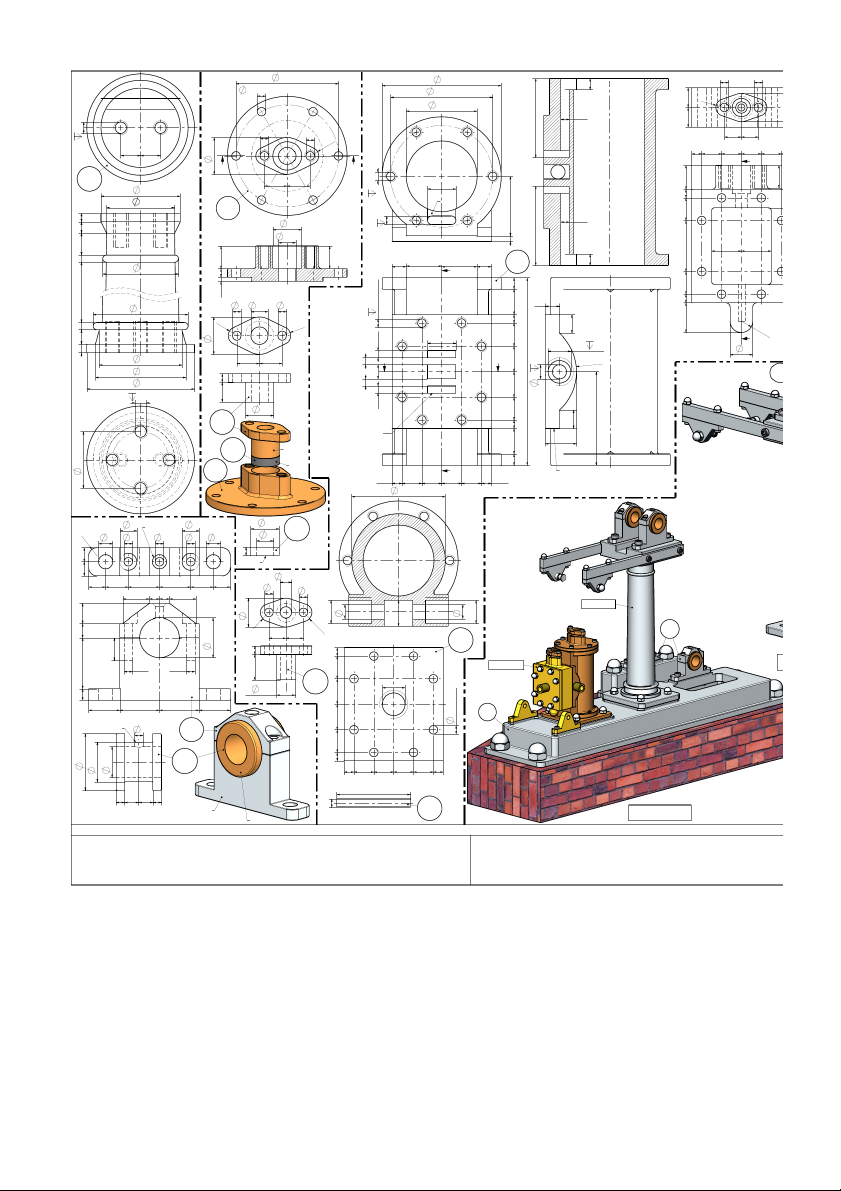

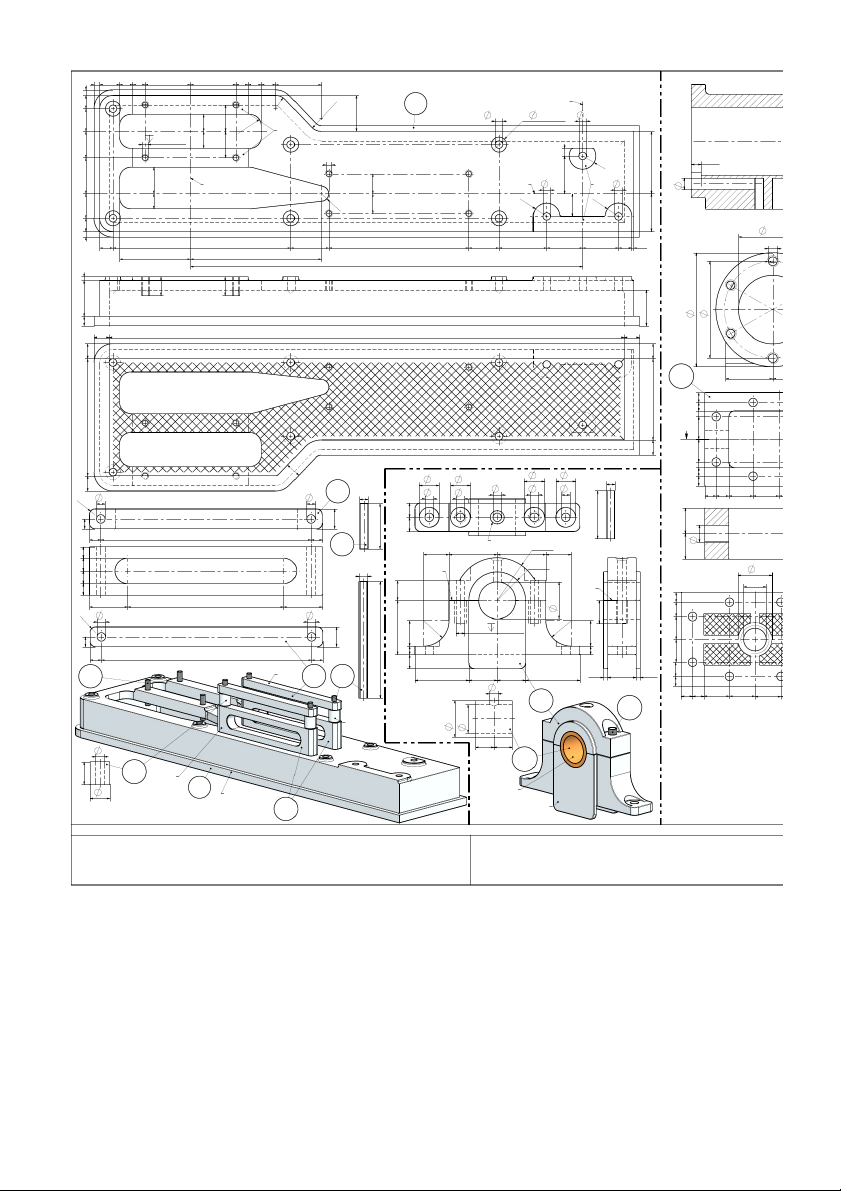

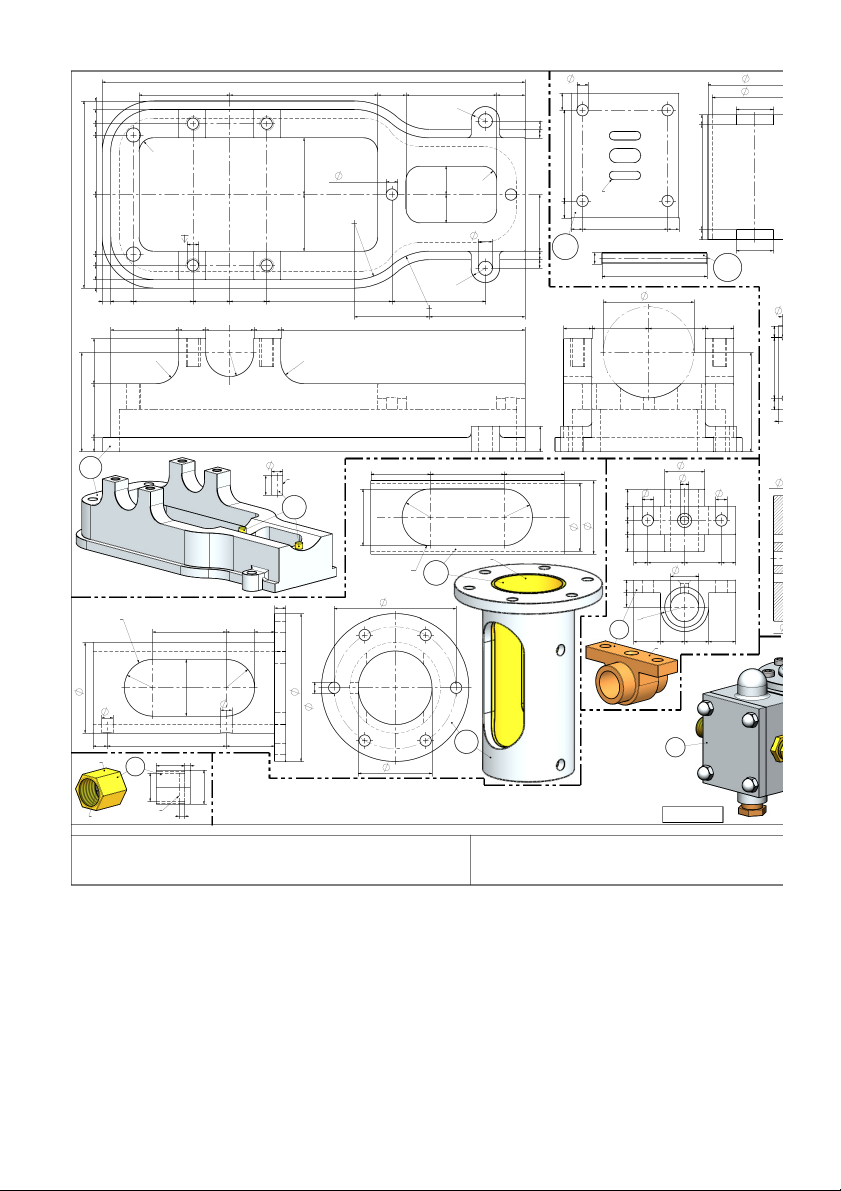

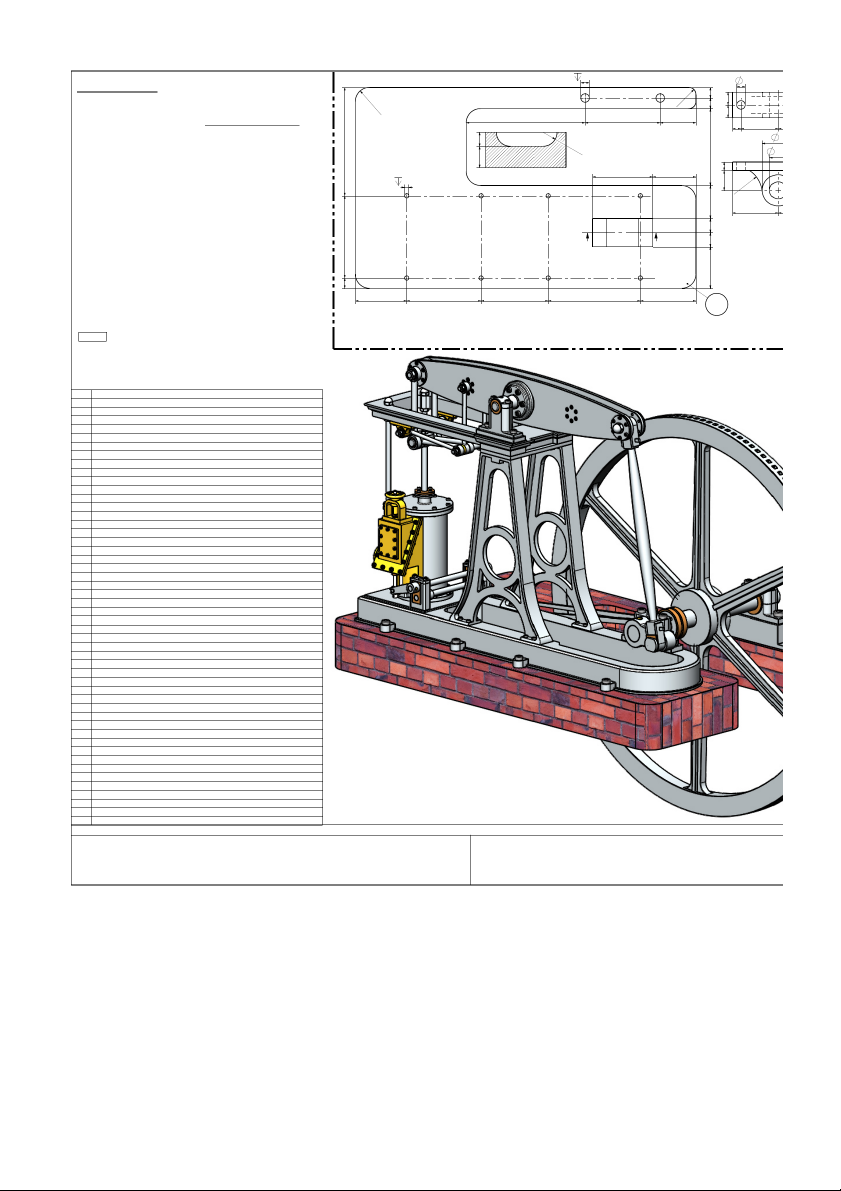

NOTES: THE ORIGNAL DRAWINGS WERE GIVEN TO ME. THE AUTHOR/DRAFTER AND PUBLISHING MAGAZINE ARE UNKNOWN. THE ENGINE SHOWN ON THESE DRAWINGS ARE TO THE OR TITLE DRAWING CONTENTS

1 CYLINDER BALANCED BEAM STEAM ENGINE GENERAL ARRANGEMENT, ISOMETRIC (BORE=25mm STROKE=50mm) VIEW AND BILL OF MATERIALS NOTES: 80

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS ARCHED AREA 8mm DEEP 1-01.2

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO 5 32 3 25 27 33 27 27 BEAM CL 6.5 17.5 17.5 6.5 HOLE AND SHAFT TOLERANCES.

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE

APPROXIMATELY 5% TO 8% LARGER THAN THE MATCHING TAPPED HOLE. 14 3 7

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR SPF 12 BOLTS TO BE METRIC FINE (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE 26

BUILDER CAN MAKE HIS/HER OWN MATERIAL CHOICE. SPF 18 29 25 SPF 17

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO R5

IT SHALL BE SILVER/HARD SOLDERED. M4-10PL 11

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), 18 25 26

UNCOMPRESSED STATE IS APPROX 40% TO 60% LONGER THEN 29 32 32 M3-4PL COMPRESSED STATE. R 5 R 5

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED 3

AND PARTS CAN BE BONDED TOGETHER BY USING EITHER HIGH STRENGTH 14 GLUE, EPOXY RESIN, OR SOLDER. 10 22 25 12 18 18 51 18 18 72 64

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER 87 90 CR

SHOULD BE CONSTRUCTED USING NON-FERROUS OR NON CORROSIVE CYLINDER CL

MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, 5 87 33 54 39 48 COPPER OR MONEL.

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED 2

AND THE MODEL IS ASSEMBLED IS ENTIRELY LEFT TO THE BUILDER/MODEL MAKER. 20

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER. 5 22 294

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED

IS ENTIRELY LEFT UP TO THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES,

WERE DEEMED NECESSARY TO PREVENT PARTS FROM LOOSENING. 11

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED WHERE DEEMED NECESSARY.

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT

HESITATE TO CONTACT ME SO THAT THE ERRORS/OMISSIONS CAN BE ARCHED SECTION 17mm DEEP RECTIFIED. 56 MATERIAL ABBREVIATIONS: ALU = ALUMINIUM HALU= HARD ALUMINIUM BRS = BRASS

BRZ = BRONZE OR GUNMETAL (BRZ/GM) 11 CI = CAST IRON 30 278 CU = COPPER GRA = GRAPHITE R 3 M10 M8 SCALE 1:2 3 2 3

MS = MILD STEEL/BRIGHT MILD STEEL

SS = SILVER STEEL OR STAINLESS STEEL R 4 3 3 3 4 3 3 F SPS = SPRING STEEL M 3 PEEK= POLYETHER ETHER KETONE 18 P 5 12.5 12.5 5 5 14 11R

SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, TEFLON OR RUBBER 4RM 5

IN GENERAL SYNTHETIC MATERIALS SOULD BE ABLE TO R5 6.5 7.5 10 10 7.5 6.5

WITHSTAND THE HEAT AND PRESSURE(S) APPLIED TO THEM. 33 2 5 5 5 4 3 . 3 5 . 5 4 5

nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED 1-01.6 1-02.2 OTHER ABBREVIATIONS 51 5 AS = AS SHOWN 9 BRZ DP = DEEP 7 DAA= DRILL AFTER ASSEMBLY 4 REQD 4

D&TAA= DRILL AND TAP AFTER ASSEMBLY 8 9.5 9.5 8 1-02.1 1-01.7 SPLIT CF = CLOSE FIT (SIZE FOR SIZE) LINE 8 BRS PF = PRESS FIT 12 M3 14PF M3 PFAA= PRESS FIT AFTER ASSEMBLY 1-01.5 1-01.4 PCD = PITCH CIRCLE DIAMETER 4 RM = REAM 2 REQD BRZ/GM 24 24 MS/ALU HEX = HEXACON, 6SIDED 1-01.6 CP = COMPRESSED ALU/MS KNL = KNURLED MS 1-01.7 1-01.3 CSK = COUNTERSINK A PL = PLACES DWL= DOWEL SPF= SPOTFACE

(T)HESOP=(TAPPED)HOLES EQUALLY SPACED ON PCD

(T)HESOC=(TAPPED)HOLES EQUALLY SPACED ON CIRCUMFERENCE OD = OUTSIDE DIAMETER ID = INSIDE DIAMETER SA-xxx = SUB ASSEMBLY-xxx CRANKPIN THE OFF SET ANGLE OF THE X 1-01.1 OFF SET ANGLE ECCENTRIC IN RELATION TO ECCENTRIC 1-01.2 THE CRANK AXIS TO BE EXPERIMENTALLY BRICKWORK DETERMINED FOR THE SMOOTH RUNNING OF THE ENGINE AND SATISFACTION OF THE BUILDER

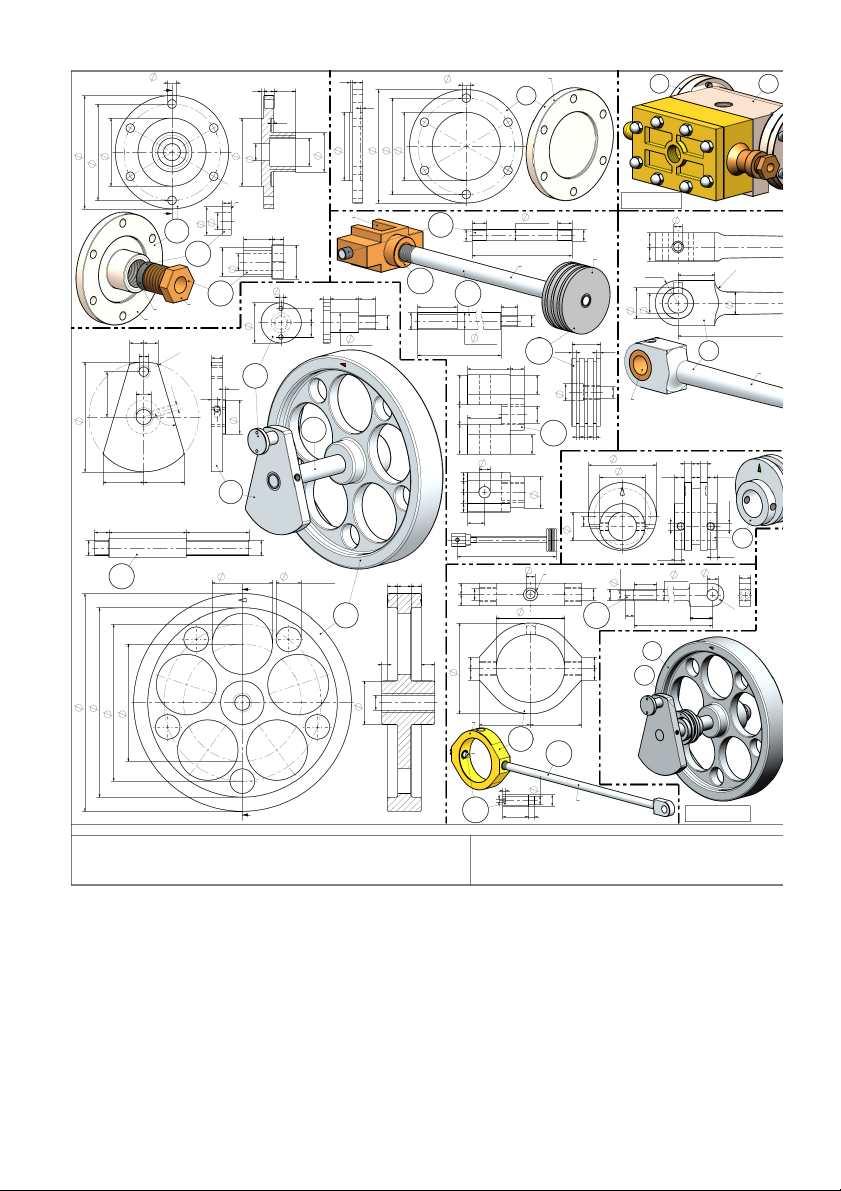

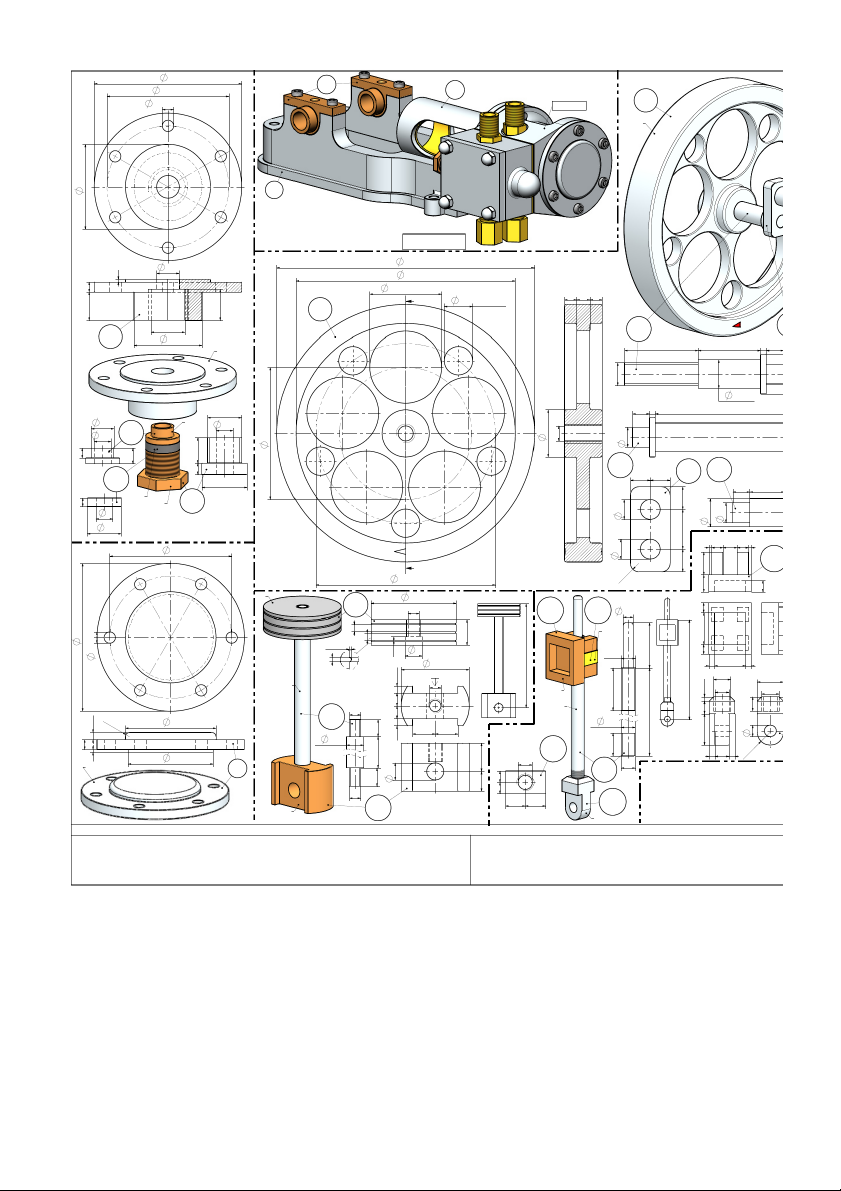

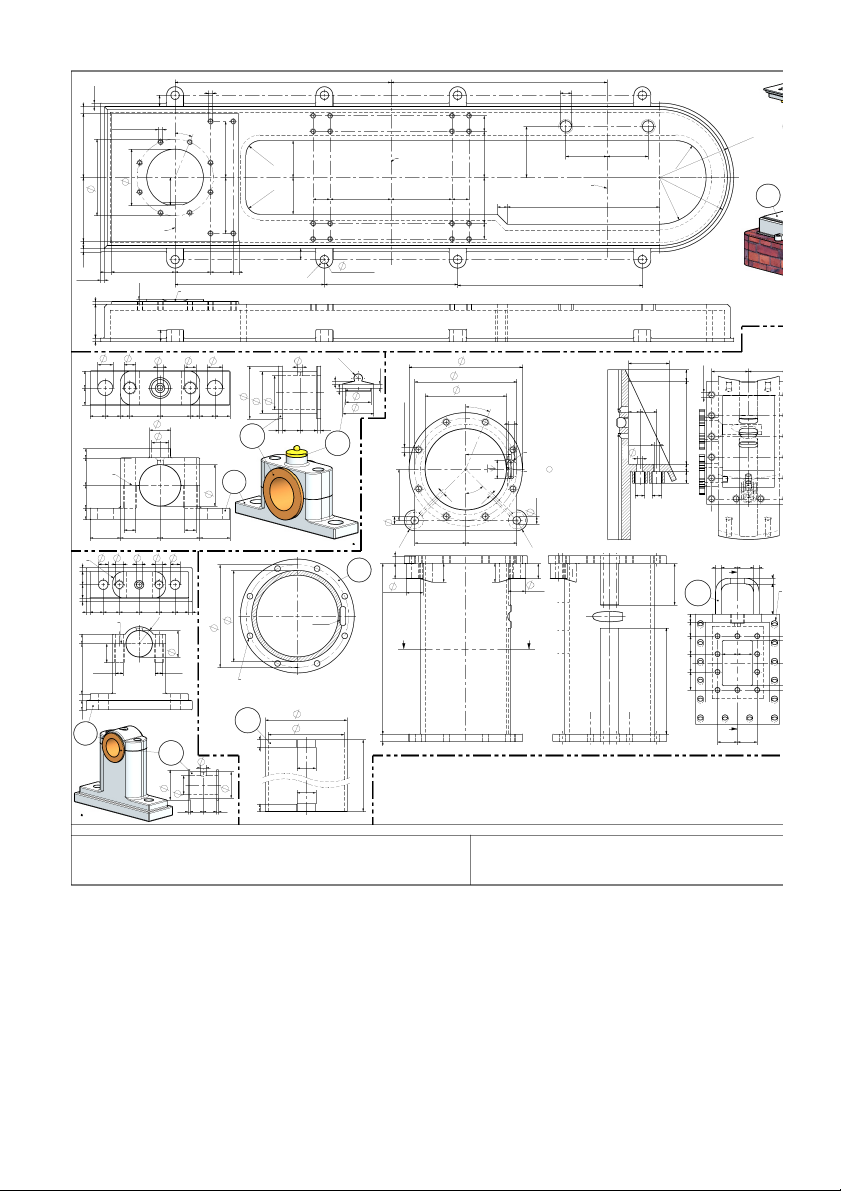

NOTES: THE ORIGNAL DRAWINGS WERE GIVEN TO ME. THE AUTHOR/DRAFTER AND PUBLISHING MAGAZINE ARE UNKNOWN. THE ENGINE SHOWN ON THESE DRAWINGS ARE TO THE OR TITLE DRAWING CONTENTS

1 CYLINDER BALANCED BEAM STEAM ENGINE NOTES, PARTS AND ASSEMBLIES (BORE=25mm STROKE=50mm) 36PCD 42 M3 M3 3-6HESOP 36PCD 4 R3 7 L 25RM 3 7 20-2P 28 M3 M3 6 6 4 R3 P 3.5 7 7 7 7 7 7 3 M 13 O ES D A A H 1-03.8 8 8 8 8-6T =10= 8.5 28 3 24 2 4 3 4DP 1-06.1 M 7 2 21 8 3 3 10 4 28 6RM 3 2 8 10.5 10.5 OPPOSITE FACE EQUAL 18 8 8 5 12.5 12.5 2.5 5 1-05.1 4 27 B SECTION B-B 3 SECTION A-A L 4 8 1.5 108 5 3 7-8P 33.5 3 6R M 3 9 R3 3 3 S R3 10.5 R 13 M 6.5 4 2.5 5 =10= 8 D M8 8 3 2.5 8 29 8 8 C C 9 13 R18 32 2.5 5 5 1-04 38 3 (66) 2.5 9 M4 16-4PL 7 10 2.5 SLOTS 8 1-06.2 9mm 3 6.5 33 DEEP 11 CD 9 1-06.3 BRZ 20P SYN 4 1-06.1 B OPPOSITE FACE EQUAL 3.5 7 7 7 7 3.5

HIDDEN LINES REMOVED FOR CLARITY 33 6 6 10 CSK 1-06.3 R3 5 3 3 3 5 6 5 3 SEAL 5 4RM 6 8 11 11 8 6 3 9 4 4 9 3 10 5 SA-1-101 8 5 8 7 9 M M F R3 R3 P 5 6 6 1-02 14 SECTION C-C 1-05.5 8 3 3 SA-1-102 S 18 M3 M3 9 8 1-05.4 M8 6.5 L 4 9 P 11 14 14 11 8 - 3 1-01 9 DAA 3 1-04.1 8 F M P 20 14 11R 3 1-04.2 3.5 7 7 7 7 3.5 3mm THICK 26 3 5 5 3 3 MS/ALU M 1-05.7 8 REQD SA-1 SA- - 1 1 - 0 1 5 0 BRZ

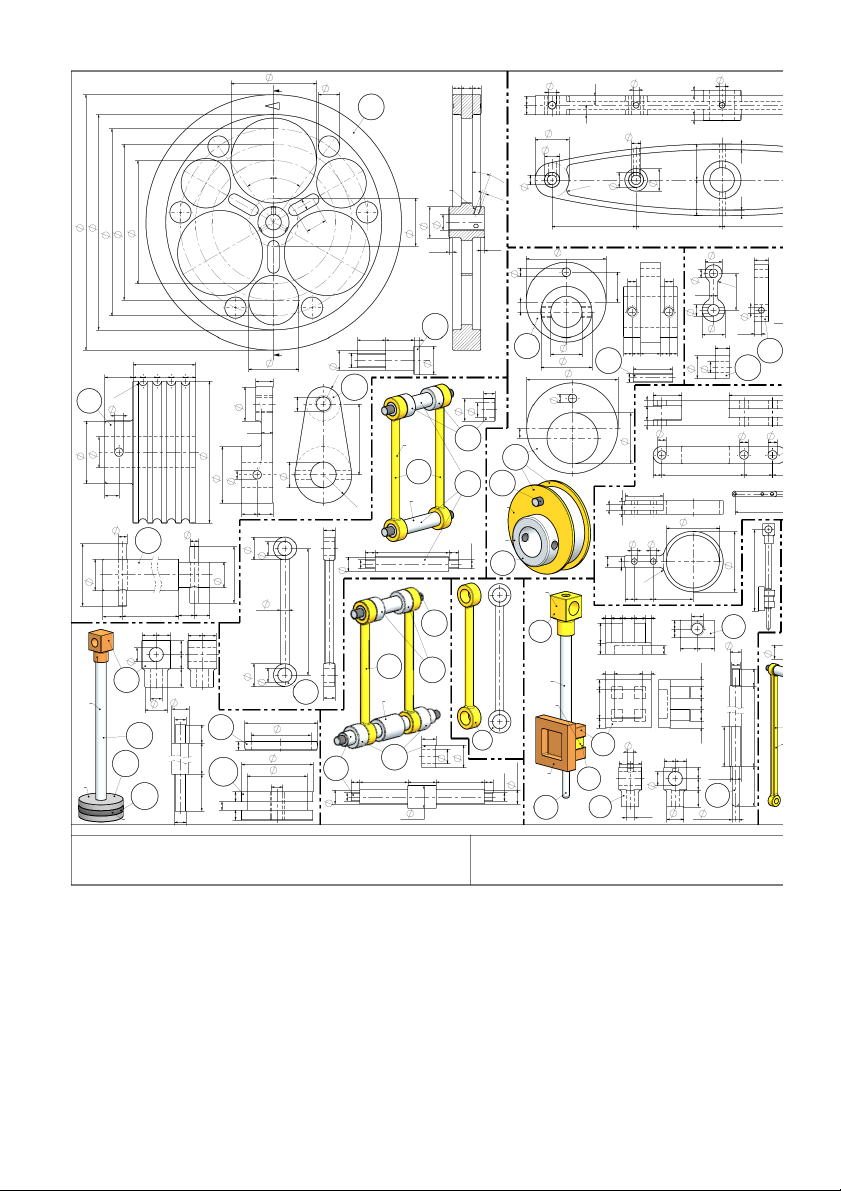

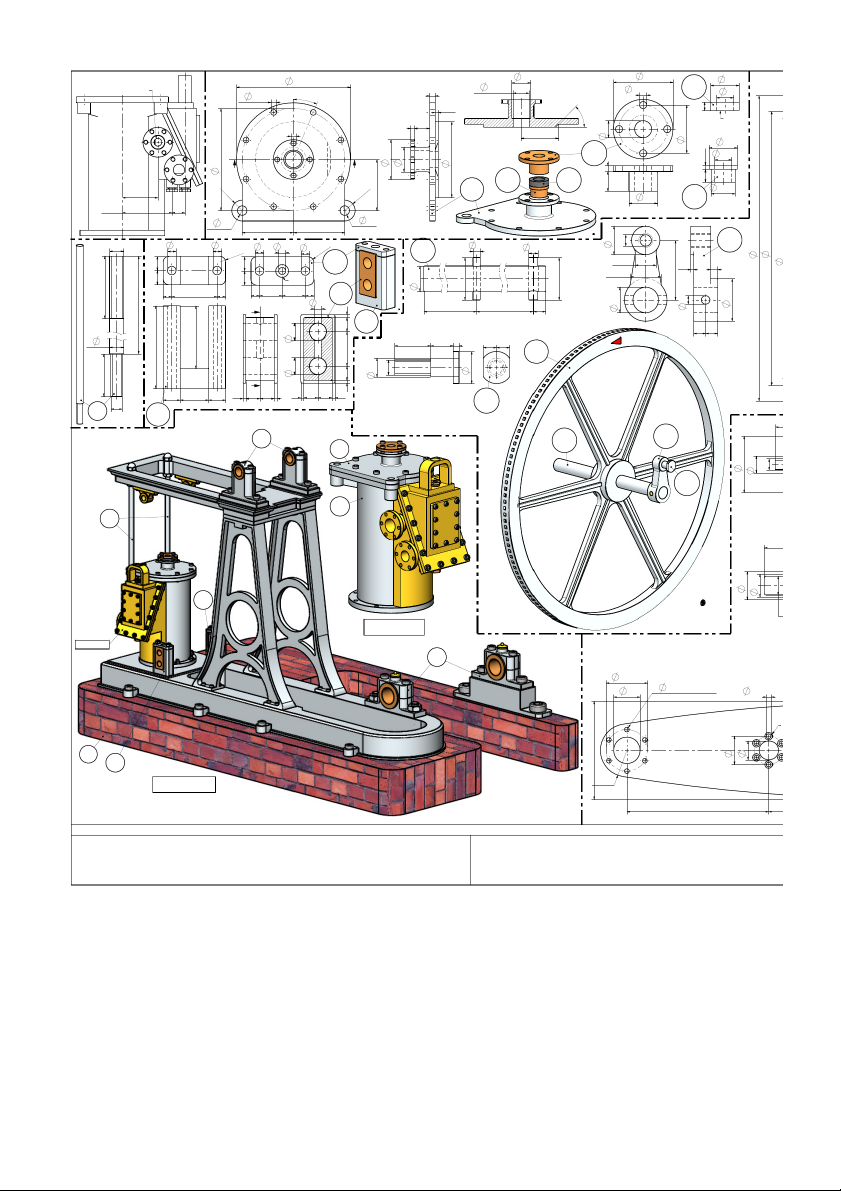

NOTES: THE ORIGNAL DRAWINGS WERE GIVEN TO ME. THE AUTHOR/DRAFTER AND PUBLISHING MAGAZINE ARE UNKNOWN. THE ENGINE SHOWN ON THESE DRAWINGS ARE TO THE OR TITLE DRAWING CONTENTS

1 CYLINDER BALANCED BEAM STEAM ENGINE PARTS AND ASSEMBLIES (BORE=25mm STROKE=50mm) 60 3 6 8 6 4 3 15 E 3 3 2-02.2 5 5 3 3 18 5RM 8PF 3 19 3 2 F 6 M ° 0 36° ° 5R 8P 12 R3 3THESOC M3 8 19 3 CD CD CD CD P 2 11 180 152 2 44.5 45.5 132P 110P 87P 15 34 SCALE 1:1.5 2.5 2.5 28CF 6 5 3 M M3 M3 3R R1 2 3 3 10.5 2 13 F 4 2P 3.5 R3 2-02.5 8 2.5 10 10 2 6 5 2-08.1 11 3 3 7 3 3 F 2-09.1 E C 5 10 22 7 SECTION E-E 18 2-07.3 35 14 8 4 M 2-09.3 SCALE 1 : 2 10 3.5 5 5 5 3.5 6 32 3 6 R 2-02.4 4 M R1.5 3 10 20 2-02.1 12 5 5 8 2 3PF M 5 4 2 18 3 3 3 2-05.3 3.5 22 11 25 BRS 50 2-08.2 F 20 9 2-05.1 3 29 10 5 3P 2-05.2 2-08.3 1mm THICK 5 R10 MS 5.5 5.5 BRS 3 2 20.3 21 4 2 28RM 3PF 3PF 2-02.3 8 M MS 5R 26 3 3.5 3.5 3 3 IN 2 F C 3 /M F 5 3 M 2-08.1 X M 3 6 A 11CF 9P R3 22 20 BRS 5 10 21 SCALE 1:1.5 57.5-M 3 .5 7 115 5.5 5.5 4 M4 2 4 4 4 2 4 2-05.2 5 5 5 5 2-11.1 3 2-11.3 7 3 M 6 6 4CF 5 5 5R 4 3 3 4mm THICK M3 M BRZ 5 8 M 2-05.1 2-05.3 3 10 3 5R 2-04.1 2.5 6.5 SS 6 M4 2-05.1 4 3.5 SS 6CF MS 4 8 BRS 10 4 M4 25.5 4 6 2-044 21 5 3.5 4 2-04.2 6.5 2-07 REFER 2.5 2-11.2 3 5 8 2 2-05.1 14 25 2-06.2 4 4 4 4 2-04.3 81 2-06.1 F M 2-04-3 21 C BRZ M4 3 17 10 17 3 5 3 2-11.3 5R 4 M4 CI F M 4 C 3 2-04.4 5 2-11.4 14 13 3.5 M 6 2-11.4 2-11.1 3 8 M3 6 2.5CF M4 SYN 3.5

NOTES: THE ORIGNAL DRAWINGS WERE GIVEN TO ME. THE AUTHOR/DRAFTER AND PUBLISHING MAGAZINE ARE UNKNOWN. THE ENGINE SHOWN ON THESE DRAWINGS ARE TO THE OR TITLE DRAWING CONTENTS

1 CYLINDER BALANCED BEAM STEAM ENGINE PARTS AND ASSEMBLIES (BORE=25mm STROKE=50mm) 2-06 2-03 2-01 2-07 2-05 2-07 2-14 2-07 2-07 2-11 SA-2-201 2-12 SA-1-105 2-10 2-09 SA-2 SA- - 2 2 - 0 2 5 0

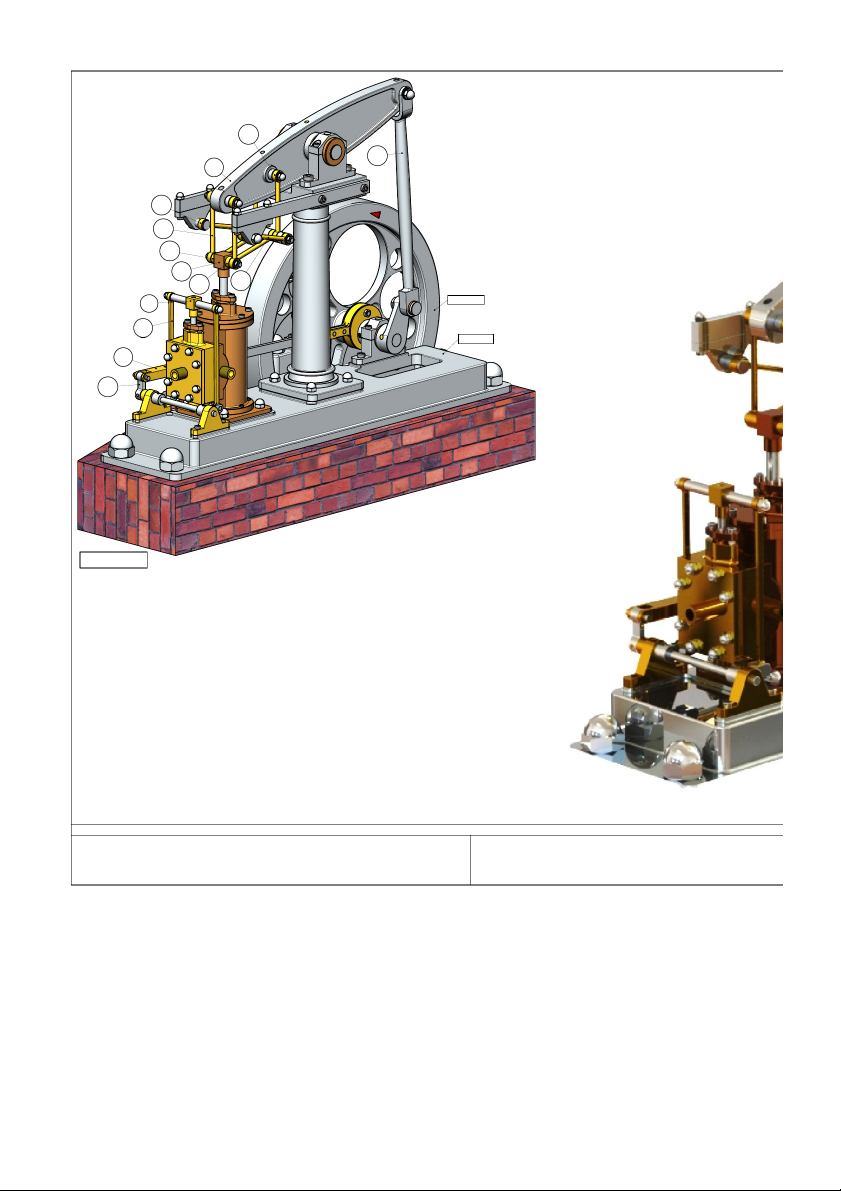

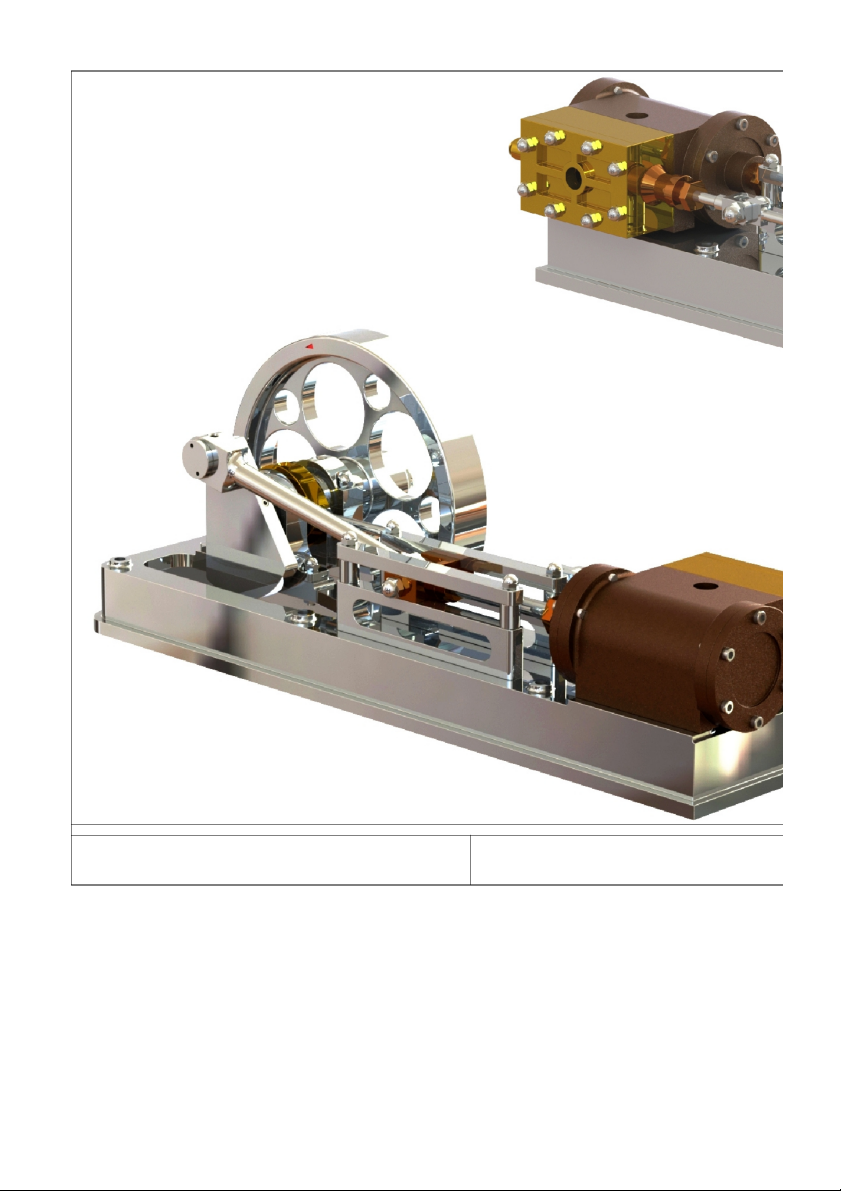

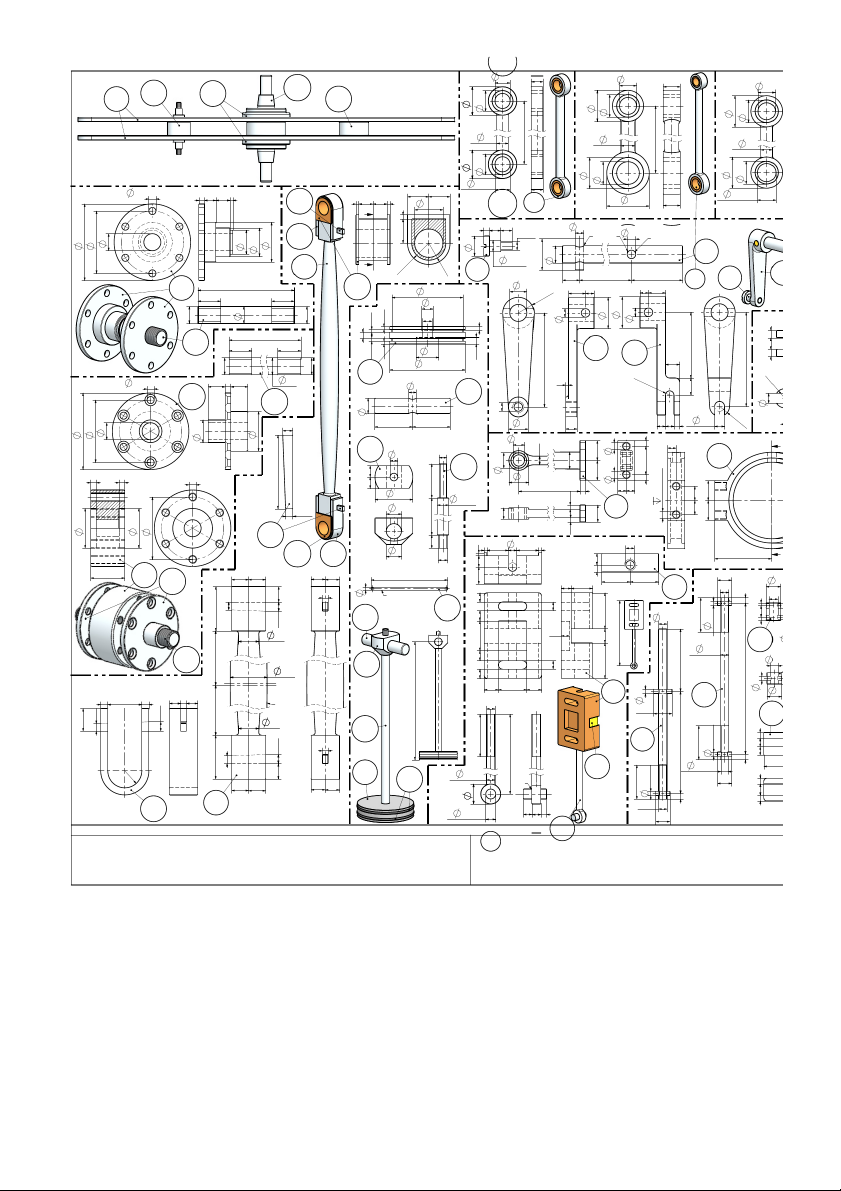

NOTES: THE ORIGNAL DRAWINGS WERE GIVEN TO ME. THE AUTHOR/DRAFTER AND PUBLISHING MAGAZINE ARE UNKNOWN. THE ENGINE SHOWN ON THESE DRAWINGS ARE TO THE OR TITLE DRAWING CONTENTS

1 CYLINDER BALANCED BEAM STEAM ENGINE PARTS AND ASSEMBLIES, (BORE=25mm STROKE=50mm) RENDERED PICTURE 308.5 12.1 MATERIAL ABBREVIATIONS: ALU = ALUMINIUM HALU= HARD ALUMINIUM BRS = BRASS

BRZ = BRONZE OR GUNMETAL (BRZ/GM) CI = CAST IRON CU = COPPER GRA = GRAPHITE

MS = MILD STEEL/BRIGHT MILD STEEL

SS = SILVER STEEL OR STAINLESS STEEL SPS = SPRING STEEL PEEK= POLYETHER ETHER KETONE

SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, TEFLON OR RUBBER .6

IN GENERAL SYNTHETIC MATERIALS SOULD BE 4

ABLE TO WITHSTAND THE HEAT AND PRESSURE(S) APPLIED TO THEM. 116.5

nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED 4 102.5 NOTES:

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO TOLERANCES.

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHA

8% LARGER THAN THE MATCHING TAPPED HOLE.

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. T HIS/HER OWN MATERIAL CHOICE.

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), U

APPROX 40% TO 60% LONGER THEN COMPRESSED STATE.

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMIT

BONDED TOGETHER BY USING EITHER HIGH STRENGTH GLUE, EPOXY R

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER

USING NON-FERROUS OR NON CORROSIVE MATERIAL SUCH AS BRASS,

STAINLESS STEEL, COPPER OR MONEL.

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURE

ASSEMBLED IS ENTIRELY LEFT TO THE BUILDER/MODEL MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO T

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTU THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACE

TO PREVENT PARTS FROM LOOSENING.

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED WHERE DEEM

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO N

SO THAT THE ERRORS/OMISSIONS CAN BE RECTIFIED.

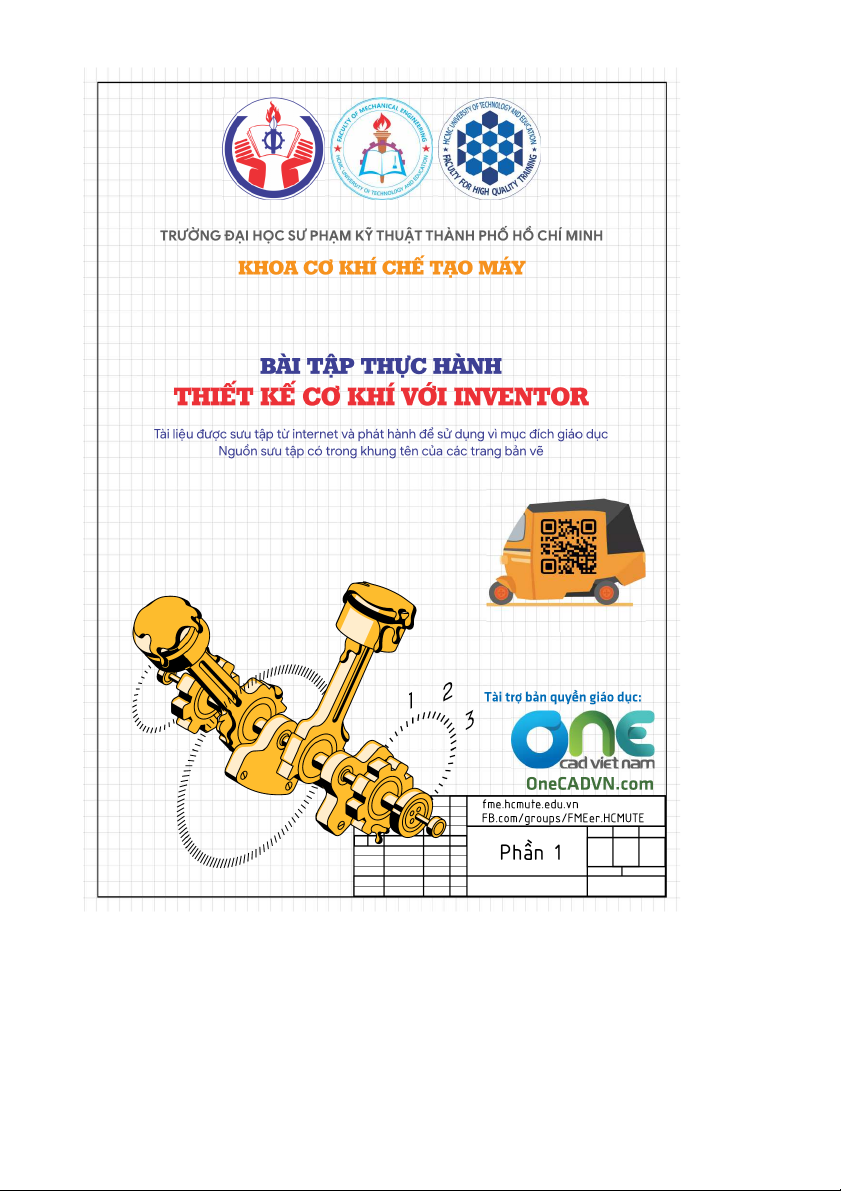

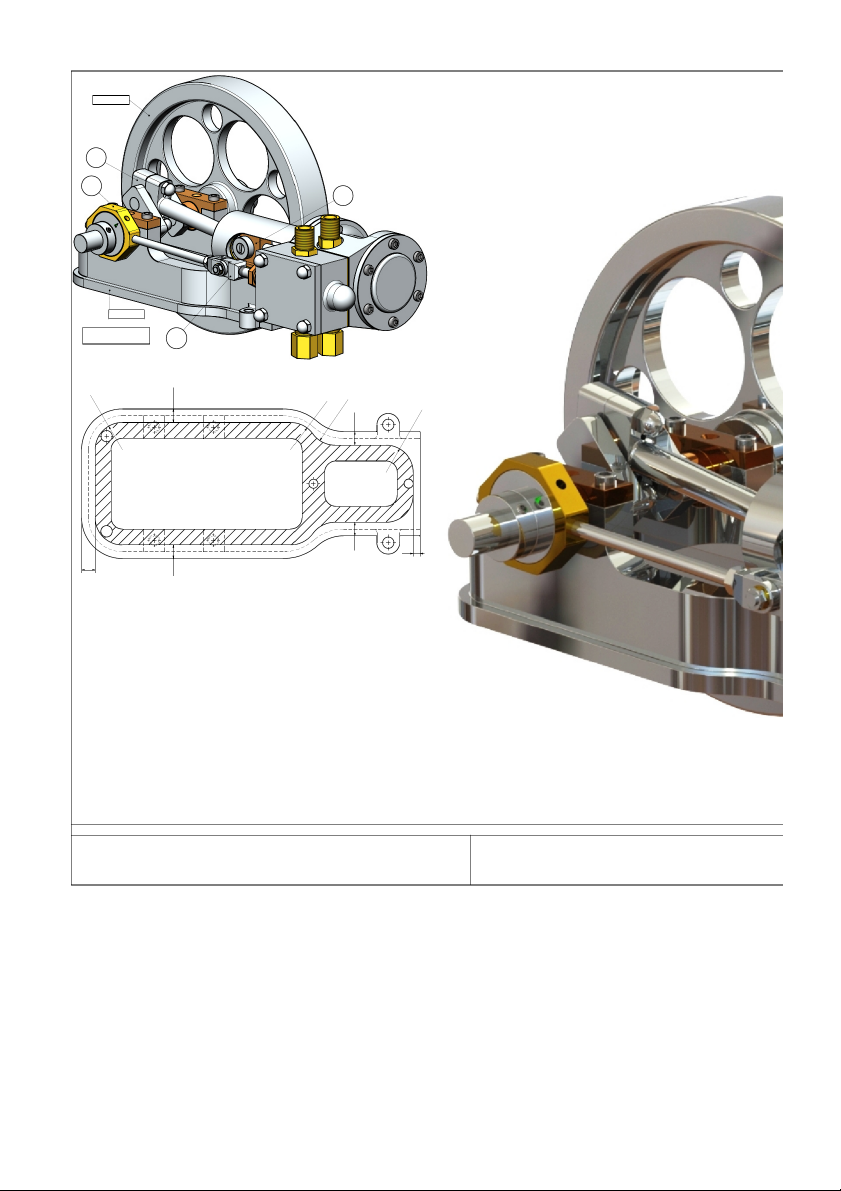

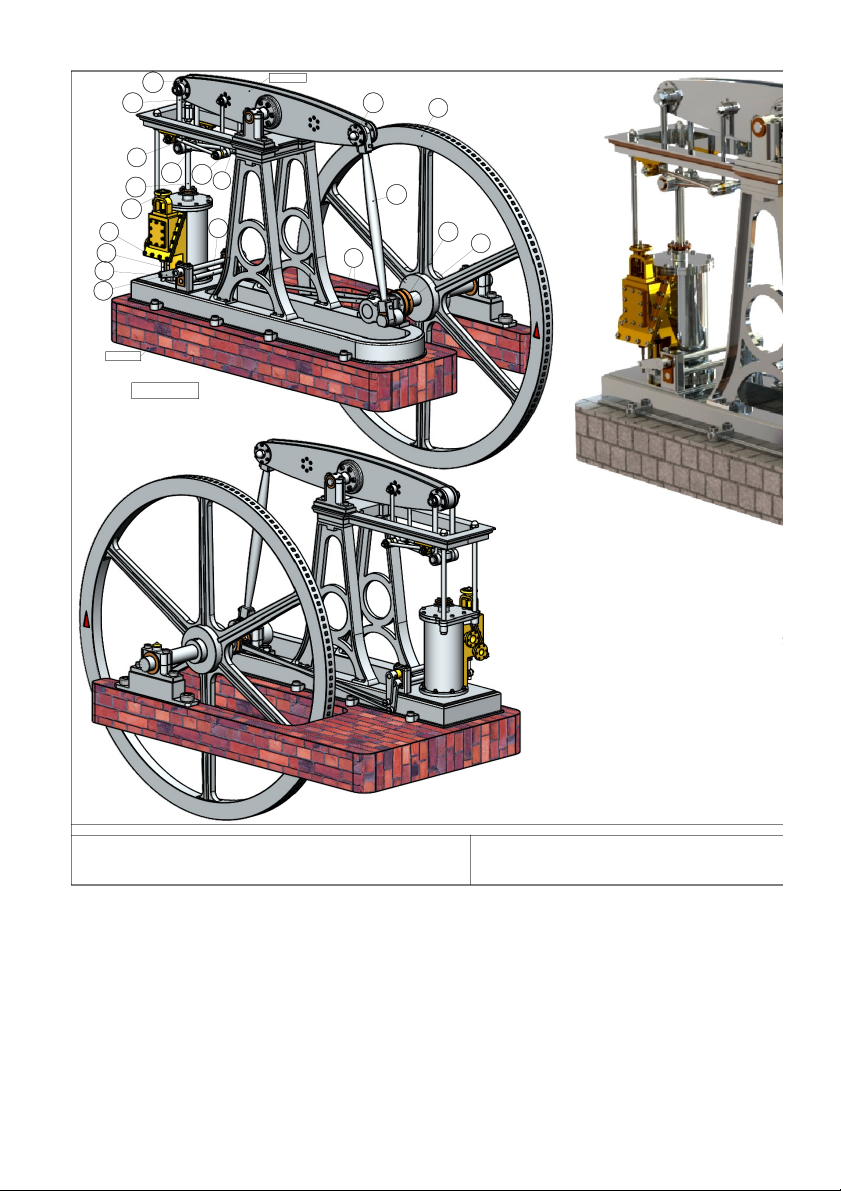

NOTES: THE ORIGINAL DRWINGS WERE GIVEN TO ME. THE ORIGINAL DRAWINGS WERE PUBLISHED IN THE "MODEL ENGINEER" MAGAZINE OF 1992, ARTICLES WRITTEN BY TUBAL CAIN. TITLE DRAWING CONTENTS

1 CYLINDER HORIZONTAL MILL ENGINE NON GENERAL ARRANGEMENT,ISOMETRIC

REVERSING CALLED "SALLY" (B=24 S=48mm) VIEW, NOTES, BILL OF MATERIALS 3 1 0.5 7 6.5 24 24 6.5 7 7.5 24 3 CYLINDER MID LINE 1-01.1 7 R7 R7 4-6PL 8-6PL 4 19 12 9 14 R6 SPF M3 9 10-4PL 14 14 4 R M3-4PL 7 3.5 33 4 19 20 14 CRANKSHAFT CL CYLINDER CL 4 SPF 4 10.5 R R7 R 4 7 8 13 10.5 12 20 SECTION 7 24R 3 7 94 20 74 16 25 19 19 7 1 M3-6THES 37.5 69 207-MAX/MIN 10 2 0 19 10 4 34 19 60° 5 8 272 8 8 8 16.5 1-03.2 3 4 3 3.5 2 62 C 8 8 8 8 ARCHED AREA 19mm DEEP SCALE 1:1.5 2 7 3 7 7 7 M3 8 3.5 1-01.2 M3 3 3 3 3 3 4 4.5 8.5 9 R 3 3 2 5 17 7 F 9 5 3.5 16 6P 4 74 4 CSK 1-01.6 R15 2 REQD 9 17 17 9 9 4 4 REQD .5 R10 12 S M3 SPLIT LINE .5 4 SPLIT ARCHED AREA M8 4 F LINE 2.5mm DEEP 4 7 13.5 55 13.5 13P R 3 3 5 3.5 2 8 R9 M3 8-2PL 19 R9 8 1 9 9 3.5 7 4 4 74 4 3 3 8 5 5mm THICK 1-01.6 MS 1-01.3 1-01.5 19 10 10 19 1.5 10 1.5 3 3.5 5 4 4 9 9 9 1-02.1 F 4 REQD M 1-02.2 5mm THICK MS 13P 10R 6.5 6.5 3 1-02.3 1-01.4 8 MS 1-01.1 BRZ 7 MS/ALU 4 REQD MS/ALU 1-01.2

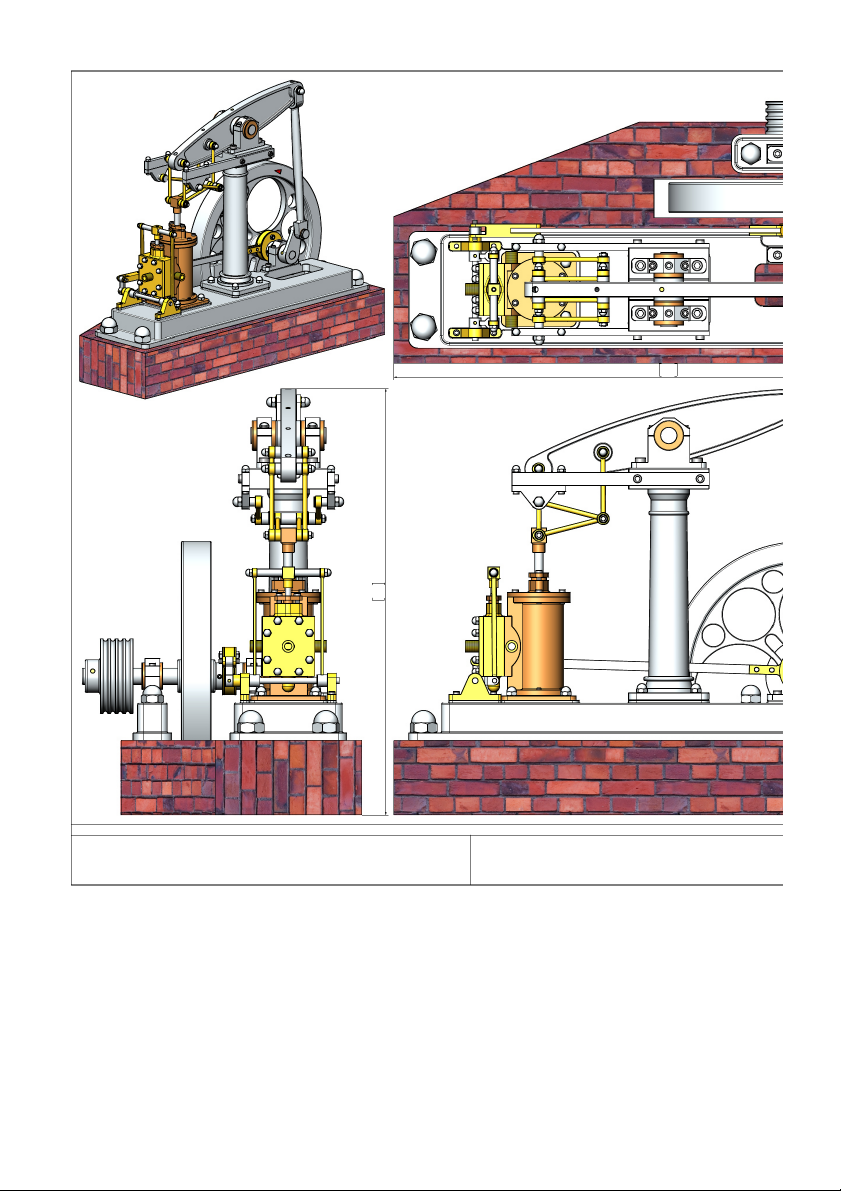

NOTES: THE ORIGINAL DRWINGS WERE GIVEN TO ME. THE ORIGINAL DRAWINGS WERE PUBLISHED IN THE "MODEL ENGINEER" MAGAZINE OF 1992, ARTICLES WRITTEN BY TUBAL CAIN. TITLE DRAWING CONTENTS

1 CYLINDER HORIZONTAL MILL ENGINE NON PARTS AND ASSEMBLIES

REVERSING CALLED "SALLY" (B=24 S=48mm) 3-6HESOP 1 3.5 3-6HESOP BRZ/GM 1-05 1-03 A 1 3.5 7.5 1-05 1 1 0 0 CD M 24 4 34 24 4 P 24 24 14 10 34 6R M 3 SEAL SA-1 SA- - 1 1 - 0 1 1 0 A 6 10 SECTION A-A BRZ 5 4CF 5 3 2-02.1 1-04.1 4 4 10 4 M M 5 M 35 1-04.3 10 EX 6R CI 5 M SS 12H R8 2-02.2 R4 13 1.5 1-04.2 2.5 10 6 2-02.3 F M 8 BRZ 14 6 11P 7R SYN BRZ/GM 14 5 5 6 4 M M M 5 7. 5 7 .5 7CF 6CF 10 M5 1.5 1.5 6 92 2-02.4 2-03 R2 15 5 2-01.2 MS/AL 1.5 M8 M 6 3 7 3 4 10.5 M 24 BRZ 8 5 18 9 12 6 0° 7 M 2-01.4 2-02.2 1 1 1 10.5 7 24CF 2.5 2.5 4 16 3.5 3 3.5 21.5 21.5 3 11 SCALE 1:1.5 2-01.1 4 3 4 2.5 6 10 7.5 41 33 3.5 2.5 M M 2-05 8 8 M M 104-MAX/MIN 2.3 2.3 3 2-01.4 32-5HESOP 13-5HESOP 4RM CSK 3 4 4 5.5 7 5 .5 8 B 4 4 4 4 M M M R4 4 3 24RM 8 8 2-01.3 2-06.2 125.7 2-01 3 7 2 3 4 4 2-05 4 4 CD CD 3 115 100 2 8 83P 62P M BRS 18 18 2-06.1 MS 2-06.2 1 3 4 1 MS 2-06.3 M B 9 2 SECTION B-B SCALE 1 : 1.5 SA-2 SA- - 2 2 - 0 2 1 0

NOTES: THE ORIGINAL DRWINGS WERE GIVEN TO ME. THE ORIGINAL DRAWINGS WERE PUBLISHED IN THE "MODEL ENGINEER" MAGAZINE OF 1992, ARTICLES WRITTEN BY TUBAL CAIN. TITLE DRAWING CONTENTS

1 CYLINDER HORIZONTAL MILL ENGINE NON PARTS AND ASSEMBLIES

REVERSING CALLED "SALLY" (B=24 S=48mm)

NOTES: THE ORIGINAL DRWINGS WERE GIVEN TO ME. THE ORIGINAL DRAWINGS WERE PUBLISHED IN THE "MODEL ENGINEER" MAGAZINE OF 1992, ARTICLES WRITTEN BY TUBAL CAIN. TITLE DRAWING CONTENTS

1 CYLINDER HORIZONTAL MILL ENGINE NON RENDERED PICTURES

REVERSING CALLED "SALLY" (B=24 S=48mm) 5.1 130 248.5 9.8 NOTES:

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER THAN TAPPED HOLE.

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN MATERIAL

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO 60% COMPRESSED STATE.

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER BY

STRENGTH GLUE, EPOXY RESIN, OR SOLDER.

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD BE CONSTRUCTED USING NON-FERROUS

MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL.

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE MODEL IS ASSEMBLED IS ENTIRELY BUILDER/MODEL MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER.

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS ENTIRELY LEFT UP TO THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE DEEMED NECESSARY TO PREVENT PAR

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED WHERE DEEMED NECESSARY.

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT THE ER BE RECTIFIED.

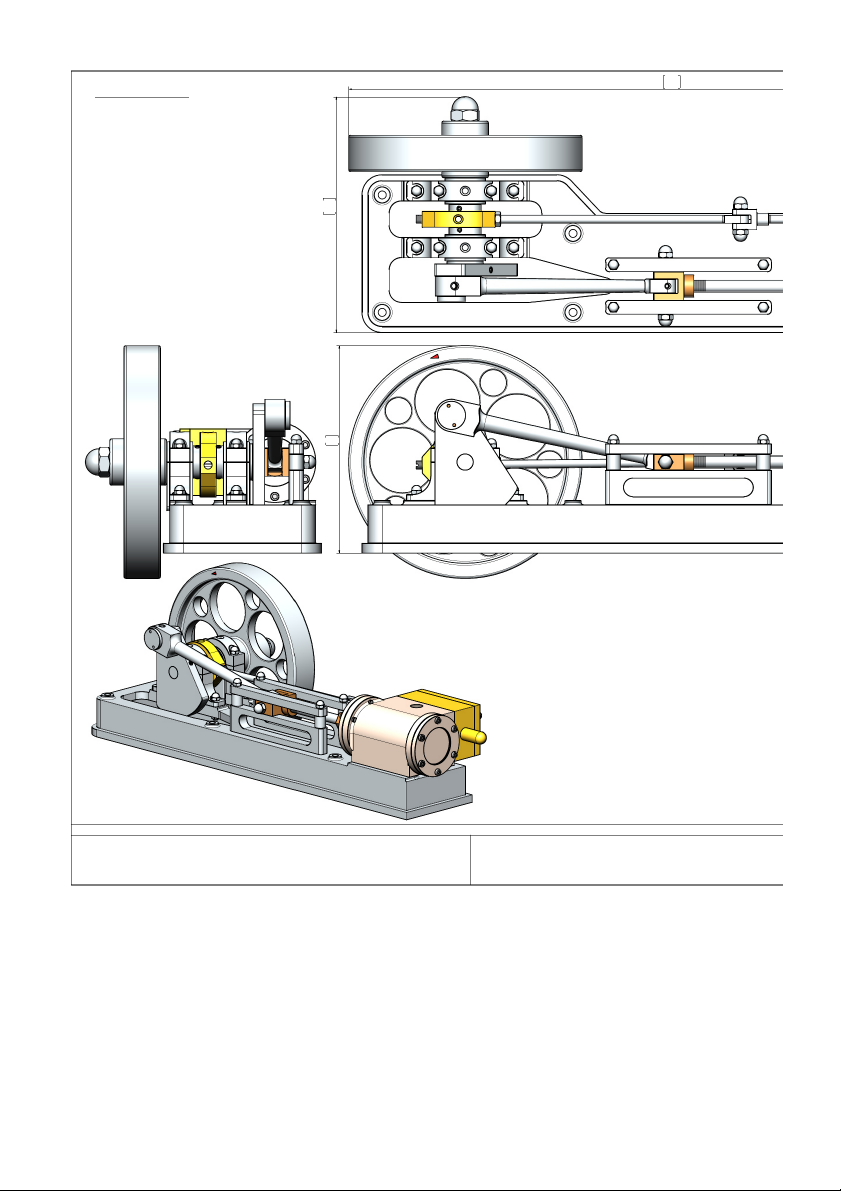

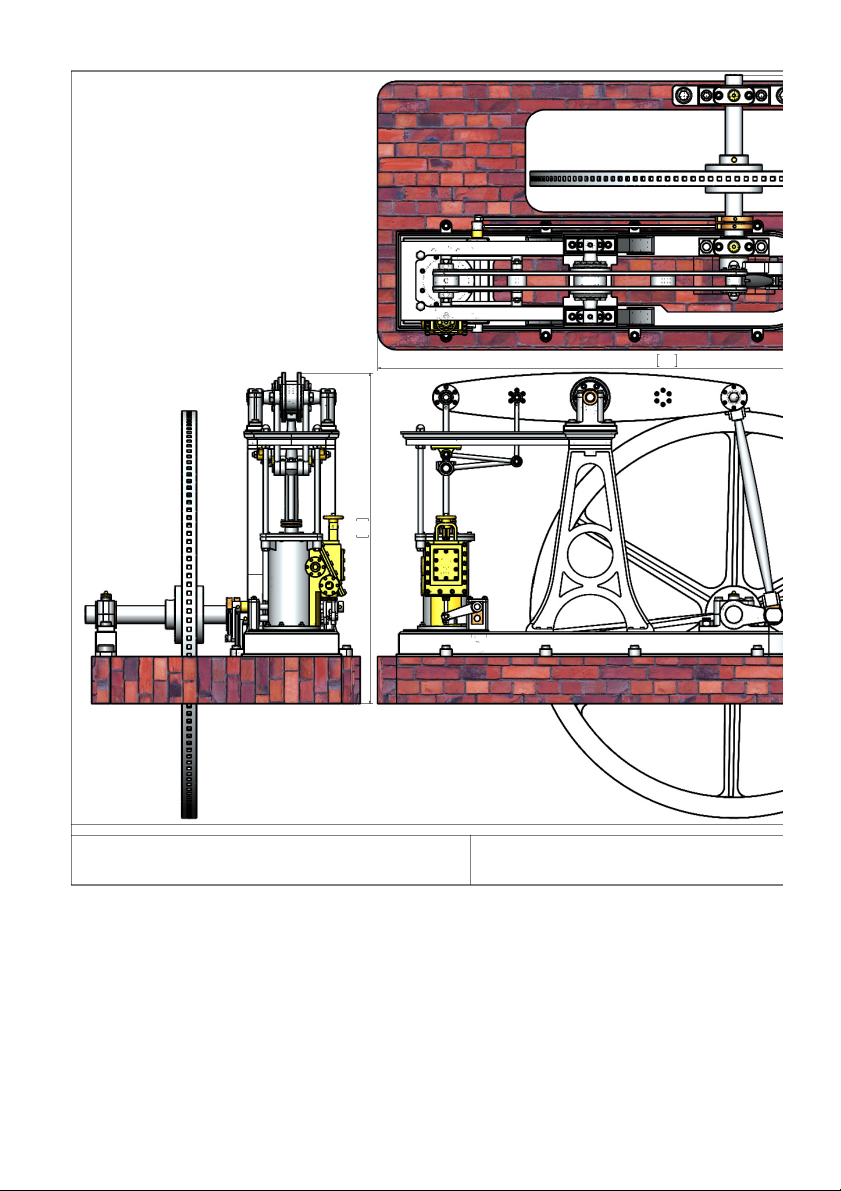

NOTES: THIS DESIGN IS LOOSELY BASED ON DRAWINGS WHICH WERE GIVEN TO ME. THE ORIGINAL DRAWINGS REFERENCE IS STUART 10H. NO REFERENCE DRAWINGNUMBER. THIS ENG TITLE DRAWING CONTENTS

1 CYLINDER HORIZONAL STEAM ENGINE NON GENERAL ARRANGEMENT, ISOMETRIC

REVERSING (BORE=30mm x STROKE=28mm) VIEW, NOTES, BILL OF MATERIALS (149) 4-4PL 33PF 32 52 10 32 10 30RM R5 6 13 3 1mm THICK 5 3.5 4 3 3 R5 32 21 20 4PF-2PL R5 37 10 TAKE OVER ALL SLOTS (66) FROM 1-02.1 10 6 4 30 4 21 20 20 M4 10-4PL R 5-4PL 3.5 20 1-04.4 13 4 3 4 M 3 1-04.12 R 37 5 20 R5 3 3 8 21 13 13 44 33 32 26.5 34 4 24 9.5 17 9.5 86 10 20 20 10 6 R 8 R . 8 5 16 R8 32 35 35 6 19 4 9 5 4PF 14 1-01.1 21 26 21 3 DOWEL 7 4 4 R 6 1-01.2 1 M F 0 R10 R 26P 5 20 24 5 6 5 13 13 5 CUT AFTER BRS ASSEMBLY 10RM REFER TO SHEET 04 1-02.2 .5 FOR BOTTOM VIEW 4 43PCD 5 4 CUT AFTER R8.5 ASSEMBLY 26 17 7 1-03 9.5 8.5 8.5 9.5 BRZ/GM P O R1 2 0 2 3 R10 5 ES 20 -6H 4 4 4 5 42 17 1-02.1 1-04 BRS 10 2 1-07 26PF 10 EX M 12H SEAL 2 SYN SA-1 SA- - 1 1 - 0 1 1 0

NOTES: THIS DESIGN IS LOOSELY BASED ON DRAWINGS WHICH WERE GIVEN TO ME. THE ORIGINAL DRAWINGS REFERENCE IS STUART 10H. NO REFERENCE DRAWINGNUMBER. THIS ENG TITLE DRAWING CONTENTS

1 CYLINDER HORIZONAL STEAM ENGINE NON PARTS AND ASSEMBLIES

REVERSING (BORE=30mm x STROKE=28mm) 52 1-03 43PCD 1-02 2-01.1 4-6HESOP SA-1-101 MS 30 1-01

PARTS 1-01 AND 1-02 TO BE EITHER BRAZED, GLUED OR SOLDERED TOGHETER DEPENDING ON THE MATERIALS USED SA-1 SA- - 1 1 - 0 1 5 0 136 8PF 116 1 38-5HESOP 3.5 6.5 7 6.5 A 15-5HESOP 10 11 2-01.1 M12 2- 2-01.2 1-05.1 24 26 22 2 6 ALU/MS 8 M 10CF 6 2 48 M12 8PF BRZ 6RM CD 5 F 2 8 6RM 1-05.2 70P 7P M 9 3.5 5.5 2-01.4 4 2-01.5 2-01.3 7 7 1-05.4 16HEX 6 12 SYN F 1-05.3 8 F 3 BRZ F 7P 6 7P 10V 12 F 14 1 4 5 4 1 7P 43 2-04.2 8 A 8 SECTION A-A 95PCD R3 SCALE 1 : 1.5 6 4 CI 30CF 2-02.1 M4 P 2-04.2 2-04.3 3.5CF 3.5 O ES 52 9 BRS IN 11 -6H 0.3 2.5 2.5 /M IN 4 6 3 X 16 A M5 /M 3.5 24CF X 2 11 2 0.5 A DETAIL B 6 9 73-M SS 2.5 M4 6.5 SCALE 3 : 1 M5 6 BRZ 15 1.5 .5 70.5-M 4 SS .5 5 M4 .5 4 2-02.2 R 4 1 61.5 .5 5CF 32 4 2.5 6 8 8 11 6CF 2.5 3.5 2-04.3 8 2 5 2 R4.5 1 30 57 M 10 M5 M5 ALU/MS 1-06 6R 2-04.1 6.5 7 4 M4 4 7 7 2-04.4 2-02.3 BRZ/GM 5mm THICK MS

NOTES: THIS DESIGN IS LOOSELY BASED ON DRAWINGS WHICH WERE GIVEN TO ME. THE ORIGINAL DRAWINGS REFERENCE IS STUART 10H. NO REFERENCE DRAWINGNUMBER. THIS ENG TITLE DRAWING CONTENTS

1 CYLINDER HORIZONAL STEAM ENGINE NON PARTS AND ASSEMBLIES

REVERSING (BORE=30mm x STROKE=28mm) SA-2-201 2-03 2-06 2-02 SA-1-105 SA-2 SA- - 2 2 - 0 2 5 0 2-04 R1 6 2 R12 R12 12 6 R 6 3 6 BOTTOM VIEW 6

IF DESIRED MILL ARCHED AREA 15mm DEEP

NOTES: THIS DESIGN IS LOOSELY BASED ON DRAWINGS WHICH WERE GIVEN TO ME. THE ORIGINAL DRAWINGS REFERENCE IS STUART 10H. NO REFERENCE DRAWINGNUMBER. THIS ENG TITLE DRAWING CONTENTS

1 CYLINDER HORIZONAL STEAM ENGINE NON PARTS AND ASSEMBLIES,

REVERSING (BORE=30mm x STROKE=28mm) RENDERED PICTURE NOTES:

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE

APPROXIMATELY 5% TO 8% LARGER THAN THE MATCHING TAPPED HOLE.

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER

CAN MAKE HIS/HER OWN MATERIAL CHOICE.

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP),

UNCOMPRESSED STATE IS APPROX 40% TO 60% LONGER THEN COMPRESSED STATE.

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND

PARTS CAN BE BONDED TOGETHER BY USING EITHER HIGH STRENGTH GLUE, EPOXY RESIN, OR SOLDER.

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD

BE CONSTRUCTED USING NON-FERROUS OR NON CORROSIVE MATERIAL SUCH AS

BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL.

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE

MODEL IS ASSEMBLED IS ENTIRELY LEFT TO THE BUILDER/MODEL MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER.

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS

ENTIRELY LEFT UP TO THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE

DEEMED NECESSARY TO PREVENT PARTS FROM LOOSENING.

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED WHERE DEEMED NECESSARY.

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT

HESITATE TO CONTACT ME SO THAT THE ERRORS/OMISSIONS CAN BE RECTIFIED. 591.5 23.3 13.8 9.5 34

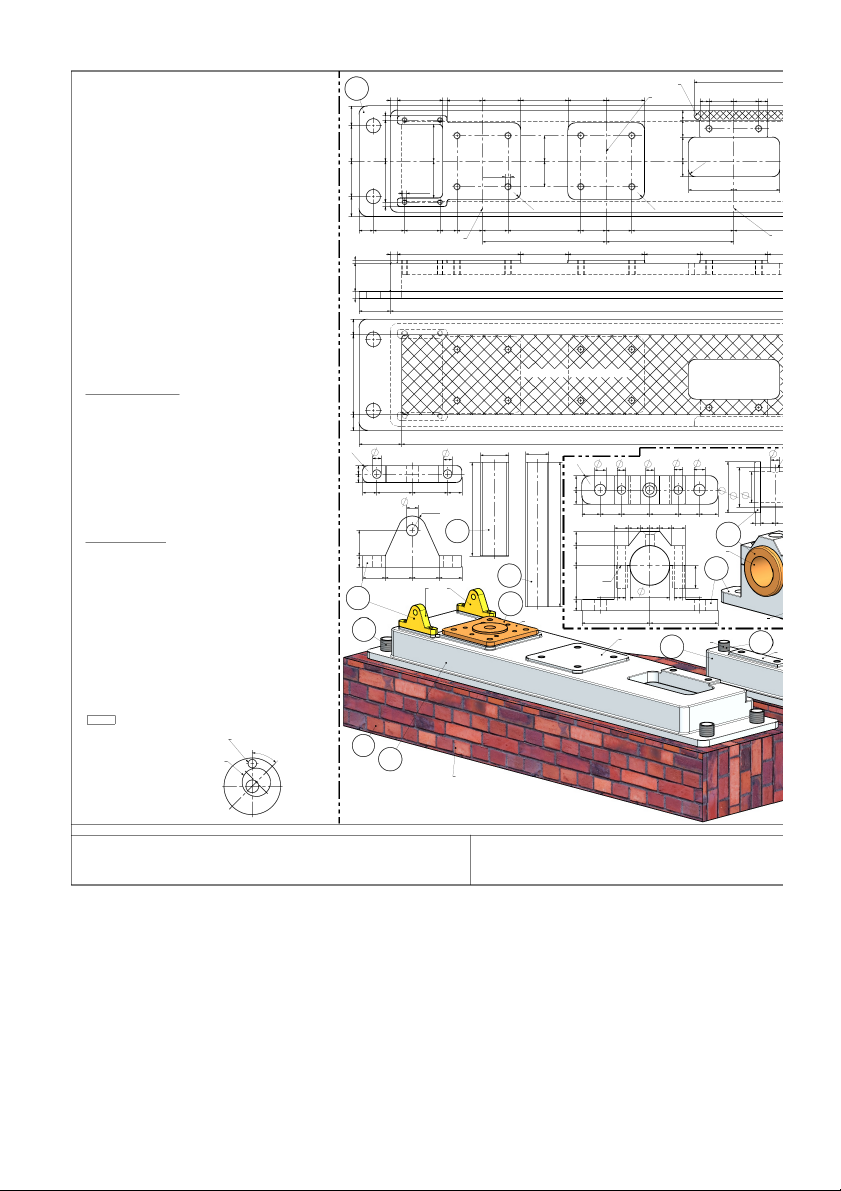

NOTES: FOUND ORIGINAL DRAWING/PRINT ON THE INTERNET. DRAFTER/DESINGER CHAY W. TIAY DATED 1948 TITLE: "BEAM PUMPING ENGINE, BY EASTONS & ANDERSONS CICA 1870, TITLE DRAWING CONTENTS

1 CYLINDER NON REVERSING BALANCED BEAM GENERAL ARRANGEMENT AND

ENGINE WITH MEYER'S VARIABLE EXPANSION

SLIDE VALVES (BORE=40mm STROKE=84mm) NOTES M12 25-2PL 3 OTHER ABBREVIATIONS AS = AS SHOWN R2 15 .5 DP = DEEP 0 R10 15 4 DAA= DRILL AFTER ASSEMBLY .5 167 106 50.5 D&TAA= DRILL AND TAP MATERIAL ABBREVIATIONS: 4 3 13 AFTER ASSEMBLY ALU = ALUMINIUM CF = CLOSE FIT (SIZE FOR HALU= HARD ALUMINIUM R 1 2 SIZE) BRS = BRASS 153 20 0 6R PF = PRESS FIT BRZ = BRONZE OR GUNMETAL 108.5 PFAA= PRESS FIT AFTER (BRZ/GM) 30 ASSEMBLY CI = CAST IRON 85 61 SECTION A-A SCALE 1 : 4 3 PCD = PITCH CIRCLE DIAMETER CU = COPPER M6 15-8PL 7 RM = REAM GRA = GRAPHITE R10 HEX = HEXACON, 6SIDED MS = MILD STEEL/BRIGHT MILD 6.5 CP = COMPRESSED STEEL 4 16 KNL = KNURLED SS = SILVER STEEL OR CSK = COUNTERSINK STAINLESS STEEL PL = PLACES SPS = SPRING STEEL 20 DWL= DOWEL PEEK= POLYETHER ETHER 116 A A 20 SPF= SPOTFACE KETONE (T)HESOP=(TAPPED)HOLES SYN = SYNTHETIC MATERIAL EQUALLY SPACED ON PCD SUCH AS VETON, NYLON, TEFLON (T)HESOC=(TAPPED)HOLES OR RUBBER .5 58.5 EQUALLY SPACED ON IN GENERAL SYNTHETIC CIRCUMFERENCE MATERIALS SOULD BE 14 72.5 105 94 130 78.5 OD = OUTSIDE DIAMETER ABLE TO WITHSTAND 1-01.1 ID = INSIDE DIAMETER THE HEAT AND 50mm THICK SCALE 1:4 MAX/MIN = CRITICAL PRESSURE(S) APPLIED DIMENSION TO THEM. SA-xxx = SUB ASSEMBLY-xxx nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED QTY. PART NUMBER 1 09E-53-00-1-01-BASE PLATE 2

09E-53-00-1-02-CRANKSHAFT BEARING 2

09E-53-00-1-03-BALANCED BEAM BEARING 1

09E-53-00-1-04-CYLINDER+VALVE CHEST 1

09E-53-00-1-05-CYLINDER TOP COVER 2

09E-53-00-1-06-TOP FRAME SUPPORT COLUMN 2

09E-53-00-1-07-VALVE ROCKER SHAFT BEARING BLOCK 1

09E-53-00-2-01-CRANKSHAFT+FLYWHEEL 1 09E-53-00-2-02-BALANCED BEAM 1

09E-53-00-2-03-BEAM CON-ROD END BEARING 1

09E-53-00-2-04-BEAM CROSSHEAD END BEARING 1 09E-53-00-2-05-CON-ROD 1

09E-53-00-2-06-PISTON+CROSSHEAD 2

09E-53-00-2-07-CROSSHEAD LINK-A 2

09E-53-00-2-08-CROSSHEAD LINK-B. 2 09E-53-00-2-09-BEAM LINK 2 09E-53-00-2-10-CROSS LINK 1 09E-53-00-2-11-LINK SHAFT 1

09E-53-00-2-12-VALVE LOWER ROCKER SHAFT 1

09E-53-00-2-13-VALVE UPPER ROCKER SHAFT 1

09E-53-00-2-14-MAIN SLIDE VALVE ECCENTRIC SHEAVE 2

09E-53-00-2-15-MAIN VALVE ECCENTRIC STRAP 1

09E-53-00-2-16-MAIN SLIDE VALVE 1

09E-53-00-2-17-SECOND SLIDE VALVE ECCENTRIC SHEAVE 1

09E-53-00-2-18-SECOND VALVE ADJUSTING NUT 1

09E-53-00-2-19-SECOND SLIDE VALVE 1 09E-53-00-2-20-HAND WHEEL 2

09E-53-00-M12x30 A-K CYL HEAD SCREW

12 09E-53-00-M2.5x10 A-K C-SINK SCREW

26 09E-53-00-M2.5x6 A-K CYL HEAD SCREW

24 09E-53-00-M2.5x8 A-K C-SINK SCREW 10 09E-53-00-M3 NUT 8

09E-53-00-M3x14 A-K CYL HEAD SCREW 4

09E-53-00-M3x42 A-K CYL HEAD SCREW

14 09E-53-00-M3x6 A-K CYL HEAD SCREW

28 09E-53-00-M3x8 A-K CYL HEAD SCREW 9 09E-53-00-M4 NUT 6 09E-53-00-M4 WASHER

16 09E-53-00-M4x14 A-K CYL HEAD SCREW 2 09E-53-00-M5 DOME NUT 3 09E-53-00-M5 NUT 4

09E-53-00-M5x22 A-K CYL HEAD SCREW 2 09E-53-00-M6 DOME NUT 2 09E-53-00-M6 NUT 2 09E-53-00-M6 WASHER 2

09E-53-00-M6x18 A-K CYL HEAD SCREW

12 09E-53-00-M6x24 A-K CYL HEAD SCREW 2 09E-53-00-M8 NUT 4

09E-53-00-M8x18 A-K CYL HEAD SCREW

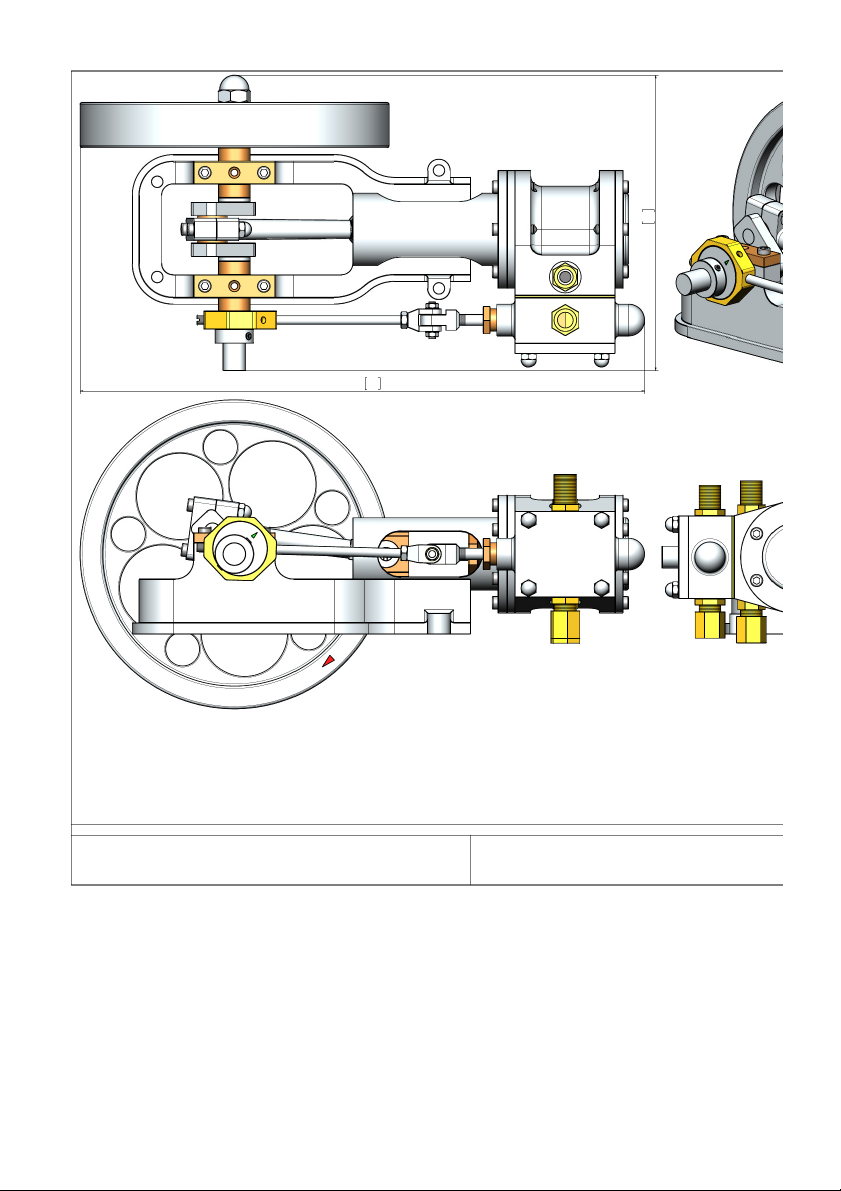

NOTES: FOUND ORIGINAL DRAWING/PRINT ON THE INTERNET. DRAFTER/DESINGER CHAY W. TIAY DATED 1948 TITLE: "BEAM PUMPING ENGINE, BY EASTONS & ANDERSONS CICA 1870, TITLE DRAWING CONTENTS

1 CYLINDER NON REVERSING BALANCED BEAM

ENGINE WITH MEYER'S VARIABLE EXPANSION

ISOMETRIC VIEW, BILL OF MATERIALS

SLIDE VALVES (BORE=40mm STROKE=84mm) NOTES, PARTS AND ASSEMBLIES 152 152 M3-20PL M8-2PL 2.5 8 5 M3-8THESOP 22.5° 11 1 5 R52.5 4 R 29 29 1 39.5 0 BEAM CL 36 CD 26 32.5 R20 P 0 4 54 CRANKSHAFT CL R R 50 12 43 12 3 R10 43 3 19.5 1-01.7 26 7 107 5 32.5 4 39.5 CYLINDER CL 11 5 8 2.5 5 45 25 16 4 6-8PL 2.5 R6 105 94 130 1.5x45deg 1.5 2 23.5 2.5 8 SCALE 1:2 8 6 S 21.5 3 6 8 3 R 60 1.5 19.5 19.5 L 54PCD P F M 9 P 1.5 6 1 28 2 43PF 2 18R 1 3-14 9 9 22.5° M 11 6 9 8 8 5 16 16 5 8 8 P O 3 4 11 2 9 9 2 ES H 4 9 1-02.2 SCALE 1:1.5 M3RM 1-02.3 3-8T 24 MILL OR DRILL 3RM 5 M 4 AFTER ASSEMBLY SPLIT .5 F SAME IN 4 LINE 14 1-02.1 10 BOTTOM 6 22P 2 45° FLANGE M5 M5 12 27 2 4 4 6 M6 M6 R 5 16 21 21 16 5.5 . 27 5 SECTION B-B 27 SCALE 1:1.5 R SCALE 1 : 1.5 VIEW-A R6 5 4 3 4 5 4 3 8 .5 8.5 3 1-04.1 8 C 10 10 8 7 2 9 9 3 22 7 1-04.4 T 2 2 7 8.5 10.5 10.5 8.5 7 2 CD F 16 P 8 MILL OR DRILL 4 AFTER 54 SPLIT LINE R9 ASSEMBLY 25 F P A 2 A 7.3 4 5 14 8 8 12 10 90 M4 9.5 9.5 26.5 M4 12 HOLES AS PER TOP VIEW 56 SECTION A-A SCALE 1 : 1.5 9.5 3.5 25 2 5 SCALE 1:1.5 43PF 1-04.2 40RM 1-03.1 C 10.5 10.5 4 4 SCALE 1:1.5 1-03.2 3 10 M 16 14 98 10R 10 1 7 7 1 4 SCALE 1:1.5 SCALE 1:1.5

NOTES: FOUND ORIGINAL DRAWING/PRINT ON THE INTERNET. DRAFTER/DESINGER CHAY W. TIAY DATED 1948 TITLE: "BEAM PUMPING ENGINE, BY EASTONS & ANDERSONS CICA 1870, TITLE DRAWING CONTENTS

1 CYLINDER NON REVERSING BALANCED BEAM PARTS AND ASSEMBLIES

ENGINE WITH MEYER'S VARIABLE EXPANSION

SLIDE VALVES (BORE=40mm STROKE=84mm) 10 21 DRILL THIS HOLE 60 10 AFTER ASSEMBLY 3 8.5PF 2.5-4PL 1-05.3 6 3-8HESOP 22.5° 1.5 4 5 3 ° M CD SEAL 2 8 M2.5-4PL 6R 19.5 17P SCALE 1:1.5 SECTION A-A SCALE 1 : 1.5 10 CD P 21 13 0 1-05.4 4 54 1.5 6RM A A 2 .5 1-05.2 1-05.3 7 R 4 5 27 8.5PF 25 . 1-05.1 5 10 R5.5 1-05.2 35 9 SCALE 1:1.5 5 5 27 27 SCALE 1:1.5 0 D C 8 2 2-01.3 6 30 P 8 M5 3 3 3 2.5 5F 6 3 6PF M 4 3 R2 2-01.2 6 3 15 1-07.2 2 5 5 R2 5 F 2 C 21.5 4 18 5 5 CSK 30 30 F 3 8 8 3 F 22 3 16 3 0 1-073 3 3mm THICK 18P 6P 2.5 90 111.5 8.5 115 B 1 M SCALE 1:2 1-07.1 SCALE 1:2 6R 5 8. 5 8 .5 5 19 12 3 22 7 7 29 M 12 F 2-01.1 C 6R 10 8 17 M 15 5 SCALE 1:1.5 B 1 5 5 1 1 5 1 5 1 6 10 6 2-01.4 M4 SECTION B-B 1-06 1-07.1 5 1-03 2-01.2 2-01.3 1-05 F C 20 6 4 M 2-01.4 1-04 1-06 17 15 12.5 1-07 SA-1 SA- - 1 1 - 0 1 1 0 SA-1-101 1-02 22PCD 14 2.5-6HESOP 2.5-6HES C 15 10 1-01 52 1-07 R14 SA-1 SA- - 1 1 - 0 1 5 0 75

NOTES: FOUND ORIGINAL DRAWING/PRINT ON THE INTERNET. DRAFTER/DESINGER CHAY W. TIAY DATED 1948 TITLE: "BEAM PUMPING ENGINE, BY EASTONS & ANDERSONS CICA 1870, TITLE DRAWING CONTENTS

1 CYLINDER NON REVERSING BALANCED BEAM PARTS AND ASSEMBLIES

ENGINE WITH MEYER'S VARIABLE EXPANSION

SLIDE VALVES (BORE=40mm STROKE=84mm) 8RM 6 6RM 6 2-02.4 6RM 2-02.2 F 2-02.3 15 F 2-02.1 2-02.5 11P 11 F 8P 11 8P 6 75 5 75 4 68 F 15 15 11P M F 11 11 8R 8P 8R M 6 2.5-6HESOP 2 4 5 1 7.5 7.5 6.4RM 1 5 5 1 2-05.3 10RM 15 6 SCALE 1:1.5 2-07 A F 2 4 4 3PF 6 C M3 3PF 27 22 8.5 14 2-05.2 PFAA 10 8.5 1.5 7 11mm LONG F C 6 2-12.2 R 11 A 6 4CF 2-05.1 R7.5 2-12.1 2 REQD SECTION A-A 6 76 18 2-12 2-08 2-12.1 34 2-03.1 2-05.4 6 6 3 3 6 8 8 37.5 6 R5.5 F F 6 6 6 11 11 3P M5 3P M M 46 2 3 1.5 1.5 2-03.2 8 8 2.5 2-12.3 23 4 1.5 1.5 3.5 12 2-12.4 6 6 5 2.5 40CF 33 33 M M 2-06.1 R R 6 2 6 6 SCALE 1:1.5 1. 3 2.5-6HESOP 1 5 . 4 5 2-06.2 6 F 3.5 2-04.2 2-04.3 C 8 3 R M 3. 2 F 20 20 7 3 3 2 3.5 5 27 2 6 C 14 3.5 4 8 SCALE 1:1.5 4RM F 2.5 2 3 B 2-06.3 M4 4 3 7 2-15.2 5.5P 2 REQD 6 2-06.4 10 2.5 2 2 6 M2.5-6THESOP 26 7 7 L 2 6 18 252 2 3 3 20 5-2P 7 5 6CF 1.5 2-15.1 8 = 2.5 5 6 2.5 7 14 14 22 111 M 1.5 =4 2-05.3 7 1 3 1 M3 2-05.4 2-05.2 8 20 M5 1 7.5 7.5 B SCALE 1:1.5 4 4 12 SCALE 1:1.5 2-04.1 6 6 5 5 2.5 10 10 5 2-04.2 6 3.5 7.5 5 1.5 40.5 5mm THICK 2-16.2 M3 2 SEAL M3 SCALE 1:1.5 F 2-06.5 IN 1 15.5 5.5 2.7 2-06.2 12.5 3CF 12 2 1.5P 3.2 2.7 /M 1 4 3.2 5 3 X 1 7 7 A 7 5 10.5 3.5 3 3.25 2-19.3 3CF 2-04.3 93 68.5-M 2.5 93 2-06.3 22 F 13 1 3 12.5 IN F 3.25 3 3.5 1.5P 5 10 5 53 /M 2-16.1 1.5P 2-19.2 5 2.5 12 2.5 4 2 4 X R1443 A M3 6.5 93 2-19.5 93 8 2.6 3.3 7 7 2-06.4 125-M F 15 2-19.1 2 36 12 1.5P 3.2 3 3 2 2 9 15.5 2.7 61.5 2.7 2-16.2 R 2.5CF 6 2-06.1 F 5.5 3CF 2-06.5 5 6 6 5 5 7 PF 7 12 1.5P 2 4 2-05.1 M 3 2 2 2-05.2 3 3.5CF 3 2 1xR-H 5 1xL-H

NOTES: FOUND ORIGINAL DRAWING/PRINT ON THE INTERNET. DRAFTER/DESINGER CHAY W. TIAY DATED 1948 TITLE: "BEAM 2 P - U 1 M 6. P

3 ING ENGINE, BY EASTONS & ANDERSONS CICA 1870, I TITLE DRAWING CONTENTS

1 CYLINDER NON REVERSING BALANCED BEAM PARTS AND ASSEMBLIES

ENGINE WITH MEYER'S VARIABLE EXPANSION

SLIDE VALVES (BORE=40mm STROKE=84mm) SA-2-201 2-04 2-07 2-03 2-01 2-10 2-08 2-09 2-11 2-06 2-05 2-20 2-16 2-12 2-14 2-17 2-19 2-15 2-18 2-13 SA-1-105 SA-2 SA- - 2 2 - 0 2 5 0 Meyer expansion valve

An expansion valve is a device in steam engine valve gear th

efficiency. It operates by closing off the supply of steam early

travel ed through its full stroke. This cut-off allows the steam

cylinder. This expanding steam is still sufficient to drive the p

pressure decreases as it expands. As less steam is supplied

the valve is open, use of the expansion valve reduces the ste

fuel required. The engine may deliver two-thirds of the work, steam.

An expansion valve is a secondary valve within a steam eng

intermediate step between steam engines with non-expansiv

gears that could provide for expansion by control ing the mot

Expansion valves were used for stationary engines and mar

used for locomotives, although expansive working was achie

variable expansion valve gears.

THIS ARTICLE WAS TAKEN FROM THE INT

NOTES: FOUND ORIGINAL DRAWING/PRINT ON THE INTERNET. DRAFTER/DESINGER CHAY W. TIAY DATED 1948 TITLE: "BEAM PUMPING ENGINE, BY EASTONS & ANDERSONS CICA 1870, TITLE DRAWING CONTENTS

1 CYLINDER NON REVERSING BALANCED BEAM PARTS AND ASSEMBLIES,

ENGINE WITH MEYER'S VARIABLE EXPANSION

SLIDE VALVES (BORE=40mm STROKE=84mm) RENDERED PICTURE