Preview text:

Motor Carriers 175

Network Truck Stops Many motor carriers make contracts with a limited number of truck

stop chains to reduce their fuel procurement costs. The basic approach here is to make a

contract with a specific truck stop chain (for example, Flying J and Pilot), such that a car-

rier commits to a certain (minimum) amount of fuel purchases within a given time period

from the chain, and receives a price discount in exchange. If the carrier fails to purchase the

committed amount within the time period, the contract becomes void. The truck stops with

which a carrier has such purchase contracts are cal ed the carrier’s “network truck stops.”

Typical y, the network truck stops wil issue fueling cards to the carrier drivers, so that when

drivers buy fuel within the network, they automatical y receive the price discount at the

pump. Drivers are encouraged to refuel only at network truck stops (so that the carrier can

meet or exceed the commit ed purchase quantity), unless it is absolutely necessary for them

to buy fuel outside the network (for example, when fuel is low and there are no network truck

stops within 100 miles). Note that drivers have incentives to refuel at network truck stops

too, because if they buy fuel outside the network, they cannot use fueling cards, meaning

that they may need to tentatively pay the fuel cost (which may be in excess of $500 if they top off) out of their pocket.

There are three methods of setting price discounts with truck stop chains. The first is

the “retail minus” method. This method gives discount to carriers by subtracting a prede-

termined amount from the normal retail price (for example, “retail minus five” means that

a carrier’s purchase price is five cents less than the normal retail price at the pump). The

second is the “cost plus” method. Under this method, the discounted price is computed

by first estimating the truck stop’s cost of fuel (cost of goods sold, which includes the cost

of fuel per se at the nearest pipeline, cal ed the rack price, cost of transporting fuel from

pipeline to the truck stop, and other miscel aneous cost items), and then adding the profit

margin of the truck stop. For example, “cost plus three” means that the discounted price is

the truck stop’s cost of fuel plus three cents. The third is the “best of ” method, which is a

hybrid of the above two methods, such that the discount price is determined by the lower

of the prices given by the two methods. For example, “best of retail minus five or cost plus

three” means that the price is determined by first computing the price based on the “retail

minus five” and “cost plus three” methods, and then choosing the lower of the two prices. In

many cases, a carrier approaches multiple truck stop chains by first providing the commit ed

purchase quantity, and then soliciting for price quotes based on the committed purchase

quantity. After obtaining responses from the chains, the carrier can either choose the chain

that provided the best deal, or continue to negotiate price discounts based on the results of

the responses from chains (execute the second round of bidding based on the results of the first round bidding).

Bulk Purchasing Some large motor carriers have a network of terminals across the United

States. These terminals typical y have fuel pumps so that their trucks can refuel at these ter-

minals. Since these terminals refuel many trucks, they buy large amounts of fuel from fuel

suppliers on a daily basis, meaning that they can receive sizable quantity discounts from sup-

pliers. Some carriers claim that if their trucks refuel at these terminals rather than at truck

stop chains, their fuel cost can become considerably lower, because this wil al ow them to

avoid paying “profits” for truck stop chains. As such, these carriers normal y encourage their

drivers to refuel at these terminals whenever possible. They, however, discourage drivers to

use these facilities when it requires trucks to deviate considerably, say more than 20 miles,

off the shortest route between origin and destination.

Equipment Adjustments One of the most widely used approaches to enhance fuel efficiency

of trucks is the adjustment of equipment (tractor or trailer). These adjustments wil improve

Copyright 2019 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s).

Editorial review has deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it. 176 CHAPTER 5

fuel consumption rates of trucks via enhancing air drags and low rolling resistance. Such

adjustments include the use of trailer and cab roof fairings, trailer side skirts, aerodynamic

side mirrors, and SmartWay certified tires. Some articles claim that these adjustments can

give 1 percent to 6 percent savings in fuel cost.24

Large Fuel Tank Typical y, heavy-duty trucks (such as U.S. Class 8 trucks) are equipped with

fairly large fuel tanks that can carry 200 to 240 gal ons. Some motor carriers, however, are

instal ing even larger tanks to their vehicles to save fuel costs. This is because many carriers

believe that having large tanks would help them reduce fuel procurement costs. The basic

logic behind this approach is that, by having large fuel tanks, many trucks can possibly avoid

buying fuel in regions where fuel prices are expensive. If, for example, a truck is making a

round trip from a region where the fuel price is cheap (region A) to a region where the fuel

price is expensive (region B), the truck may need to buy fuel before completing the round trip

(possibly at or near region B) if it has a smal fuel tank, whereas it may be able to finish the

round trip without any refueling (avoid buying fuel at or near region B) if it has a large tank.

Note, however, that there is one disadvantage associated with this approach; that is, recent

studies have shown that a truck with more fuel in its tank (thus with more fuel weight) wil

require more fuel burns.25 As such, the net benefit of this approach may be relatively smal .

Prevent Out-of-Fuel Occasions Sometimes, trucks run out of fuel on the road for multiple

reasons. Occasionally, this may be due to mechanical problems such as a fuel indicator

malfunction. In most cases, however, this happens because of drivers’ negligence of proper

fuel indicator monitoring, or drivers’ reluctance to stop for refueling (many drivers dislike

making frequent fuel stops, as this tends to delay the ETA—estimated time of arrival at

destination). When this happens, carriers usual y have to dispatch a rescue vehicle, which

supplies enough fuel to the “out-of-fuel” truck for it to move to the next available truck

stop. Some carriers estimate the cost of this rescue vehicle to be around $200 per dispatch.

Since this is costly, many motor carriers are creating company policies and guidelines for

truck drivers that specify when they have to stop to purchase fuel. Typical y these guidelines

suggest that when the fuel level reaches at or below 20 percent of tank capacity (for example,

40 gal ons for a truck with a 200-gal on tank) drivers must stop for refueling. Some carriers

have instal ed “engine monitors” to their vehicles, which al ow managers to monitor trucks’

engine conditions, including fuel level, from the headquarters at all times.

Prevent Fuel Leakage and Theft Motor carriers lose fuel because of fuel leakage and drivers’

fuel theft. It may be a surprise to some readers that some (but not the majority of) drivers

steal fuel from their trucks, but this actual y happens (this resembles the situation for retail

stores where products are lost due to employee theft). Since the loss of fuel because of these

reasons increases the cost of carriers without providing any benefit, carriers are trying to

avoid such losses. They are attempting to minimize fuel leakage from tanks by performing

frequent preventive maintenance of their vehicles, and minimize driver theft by perform-

ing driver education and fuel monitoring (ensuring that the fuel spent for a given trip is in

agreement with the miles driven).

Fuel Optimizer Fuel optimizers are software products widely used by TL carriers to reduce

the fuel procurement cost of their fleet at the point of purchase. It is wel known that fuel

prices vary (often substantially) from one truck stop to another, even within the same

region. The basic concept of the fuel-optimizer products is to take advantage of such price

variances across locations (truck stops) to reduce the cost of buying fuel. These products

first download the latest price data of nearly all the truck stops in the United States and

Canada (which are updated daily), and then compute the optimal fueling policy for a given

Copyright 2019 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s).

Editorial review has deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it. Motor Carriers 197 CASE 5-2 Cyclone Transportation

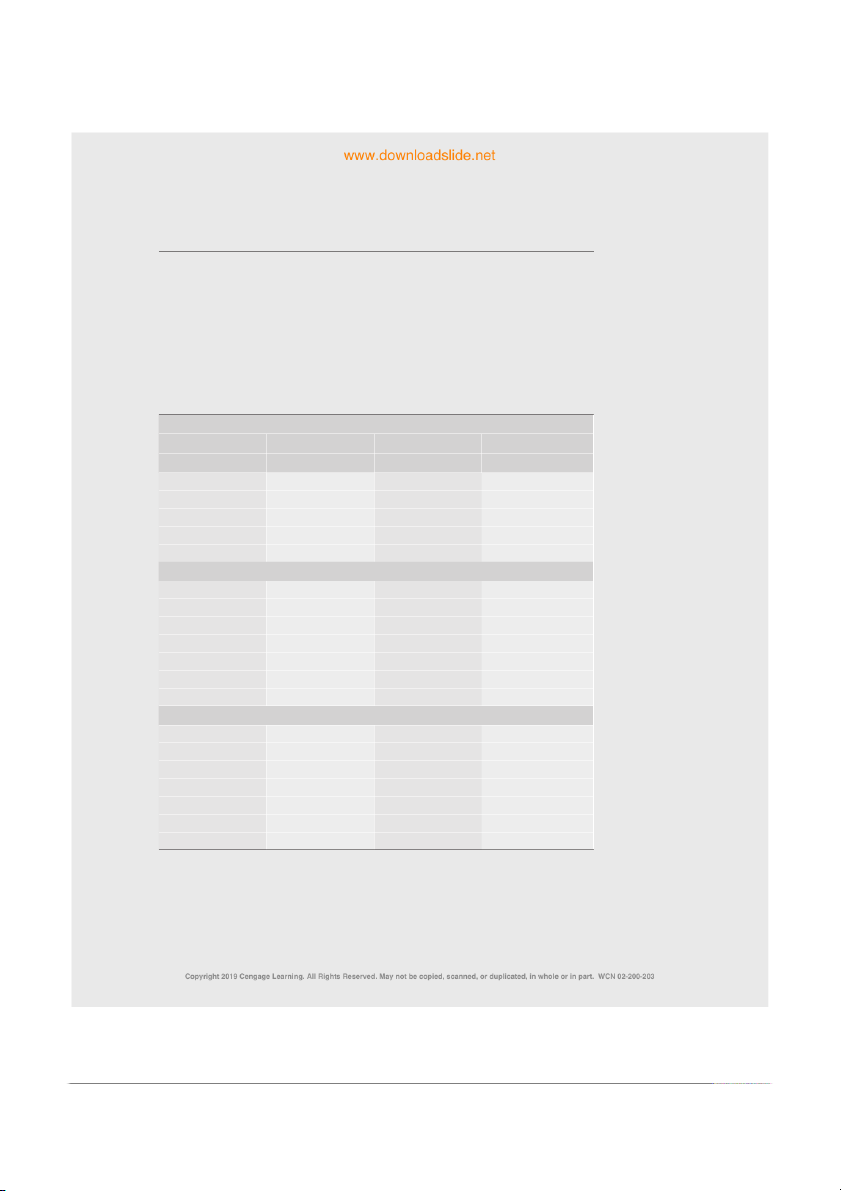

Cyclone Transportation is a medium-sized truckload carrier based in Ohio, United States.

You are a procurement manager of this company, whose main responsibility is the procure-

ment of diesel fuel for the company’s fleet of Class 8 trucks.

You have been assigned to negotiate the fuel contract for the Perrysburg, Ohio market.

Your assistant has collected the fol owing per gal on information concerning the major truck

stop chains (A, B, and C) around that area. You wil use this information to analyze each fuel vendor’s proposed contract. CHAIN A RETAIL PRICE RETAIL PRICE TRUCK STOP COST DATE INCL. STATE TAX NO STATE TAX NO STATE TAX 10/20/17 2.822 2.568 2.514 10/21/17 2.810 2.557 2.421 10/22/17 2.938 2.674 2.460 10/23/17 2.958 2.692 2.738 10/24/17 2.927 2.664 2.570 CHAIN B Retail price Retail price Truck stop cost Date (incl. state tax) (no state tax) (no state tax) 10/20/17 2.972 2.705 2.475 10/21/17 2.946 2.681 2.557 10/22/17 2.922 2.659 2.606 10/23/17 2.831 2.576 2.439 10/24/17 2.846 2.590 2.550 CHAIN C Retail price Retail price Truck stop cost Date (incl. state tax) (no state tax) (no state tax) 10/20/17 2.956 2.690 2.618 10/21/17 2.844 2.588 2.362 10/22/17 2.794 2.543 2.466 10/23/17 2.982 2.714 2.516 10/24/17 2.802 2.550 2.353

Copyright 2019 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s).

Editorial review has deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it. 198 CHAPTER 5

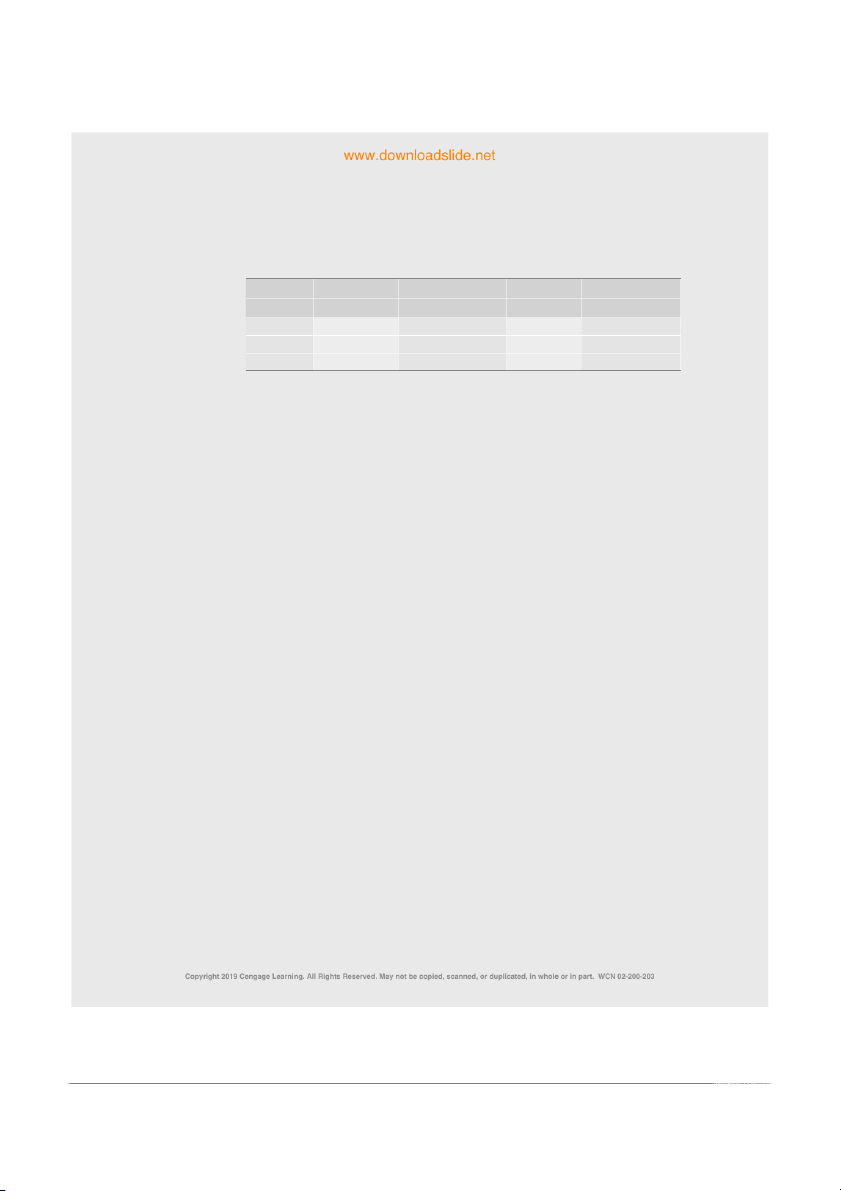

Your company purchases approximately 100,000 gal ons of diesel fuel each month in the

Perrysburg market. Chains A, B, and C have each sent you a contract in hopes of winning

your company’s business. The contract proposals are listed below. BIDS SUPPLIER METHOD RETAIL DISCOUNT PUMP FEE TRANSACTION FEE A Cost plus 0.02 0.25 B Retail minus 0.03 0.00 C Best of 0.02 0.03 0.50

As discussed in this chapter, the price of the cost-plus method is given by the truck

stop cost plus pump fee, while that of the retail-minus method is given by the retail price

(without state tax) minus retail discount. There is also a transaction fee associated with

purchasing fuel from each of the vendors. This is a one-time cost per transaction, meaning

that your trucks must pay this cost every time they buy fuel, regardless of the amount of

fuel purchased. The average fuel purchase quantity of your drivers (per transaction or per

refueling stop) is roughly 100 gal ons. CASE QUESTIONS

1. Given the proposed contracts, what is your company’s average cost of fuel per gal on with each of the fuel vendors?

2. Which truck stop chain should you choose if your goal is to minimize fuel cost?

3. Chain B real y wants your business and says they wil do anything to obtain it. What

should their retail discount be in order to obtain your business?

Copyright 2019 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s).

Editorial review has deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.