Preview text:

CONTRACT NO.: DL2301107 DATE: 0 7 .Nov.2023 THE BUYERS:PHU BAO MEDICAL

ADDRESS:Lot C21, D2 Street, Cau Tram IZ., Long Trach W., Can Duoc Dist., Long An Province, Vietnam Hotline : 091 868 1189

Website: http://phubaomedical.com.vn THE SELLERS: Jiangxi Dele Intelligent T echnology Co . , Ltd

ADDRESS: B05- 02 , Xiangtun Eco- Industrial Park, Dexing Hi-tech Industrial Park, Shangrao city, Jiangxi Province CHINA Contact:Xia Chengjun TEL:+86 13879390552

This Contract is made by and between the Buyers and the Sellers, whereby the Buyers agree to buy and

the Sellers agree to sell the under mentioned commodity according to the terms and conditions stipulated below: Name of Quantity Unit Price Total Amount Product F OB Ningbo Price

Full Automatic Dry/Wet towel making machine 2 sets 31,500USD 63,000USD Automatic Bagging machine 28,900USD 2 sets 57,800USD Automatic box-loading machine 35,200USD 2 sets 70,400USD Total 6 sets 191,200USD

1. COMMODITY: Full Automatic Dry/Wet towel making machine/Automatic Bagging machine/Automatic box- loading machine

2. COUNTRY AND MANUFACTURERS:

Jiangxi Dele Intelligent Technology Co.,Ltd CHINA 3. PACKING:

To be packed well. The Sellers shall be liable for any damage of the commodity and expenses

incurred on account of improper packing and for any rust attributable to inadequate or improper

protective measures taken by the sellers in regard to the packing.

4. SHIPPING MARK:

The Sellers shall mark on each package with package number, gross weight, net weight,

measurement and the wordings: " HANDLE WITH CARE" "THIS SIDE UP" etc.

5 . TIME OF SHIPMENT: within 3 2 w o r k s days after receipt of deposit

6. PORT OF SHIPMENT: Ningbo sea port CHINA , 1 7. PAYMENT:

1 .30% deposit to be paid before production by T/T.

2. 65% to be paid after buyer's quality inspection and before shipment by T/T

3. 5% to be paid after buyer’s running the machine and trained the workers within 20days

8. GUARANTEE OF QUALITY:

The Sellers guarantee that the Commodity hereof is made of the best materials with first class

workmanship, brand new and unused, and complies in all respects with the quality and specification

stipulated in this Contract. The guarantee period shall be 24 months counting from the date of signing

the Acceptance Report of this machine at the end-user's site .

9. FORCE MAJEURE:

The Sellers shall not be held responsible for the delay in shipment or non-delivery of the goods due to

Force Majeure, which might occur during the process of manufacturing or in the course of loading or

transit. The Sellers shall advise the Buy ers immediately of the occurrence mentioned above and

within fourteen days thereafter, the Sellers shall send by airmail to the Buyers for their acceptance a

certificate of the accident issued by the Competent Government Authorities where the accident

occurs as evidence thereof. Under suc h circumstances the Sellers, however, are still under the

obligation to take all necessary measures to hasten the delivery of the goods. In case the accident

lasts for more than 10 weeks, the Buyers shall have the right to cancel the Contract. 10. ARBITRATION:

Any dispute arising from or in connection with this Contract shall be submitted to China International

Economic and Trade Arbitration Commission for arbitration which shall be conducted in accordance

with the Commission's arbitration rules in effect at the time of applying for arbitration. The arb it

ral award is final and binding upon both partied. Arbitration fee shall be borne by the losing party.

11. OTHER: This contract signed in three copies, the seller holds one copy and the buyer hold two copies. 12.ACCOUNT

ACCOUNT NO: 36050 18302 50000 01756

PAYEE: Jiangxi Dele Intelligent Technology Co.,Ltd BANK: CHINA CONSTRUCTION BANK

BRANCH: CHINA CONSTRUCTION BANK,JIANGXI BR

BANK ADDRESS: NO.366 BAYI STREET , NANCHANG, JIANGXI P.R . CHINA SWIFT CODE: PCBC CNBJ JXX THE BUYERS THE SELLERS PHU BAO MEDICAL Ji angxi De le I ntelligent Technol og y Co .,Ltd Re resentative p b : y Representative by : ( Mr ) Zheng Zhigang 2

DL-Z600 Full Automatic Dry/Wet towel Line

The performance and characteristics of the equipment:

Processing raw materials: Spunlace non -woven dry wet wipes.

Principles of Equipment: Loading the large roll of non -woven raw material rolls → automatic

slitting → automatic folding → automatic liquid adding (can be added or not) → automatic

fixed -length cutting → automatic counting → automatic output → automatic output Products,

the entire line is fully automatic completed.

Production speed: 600--1000 pieces/minute, depending on the different tension of various material roll.

The device is equipped with 6 sets of duck neck multi -angle spraying device. The amount of

spraying liquid can be freely controlled by the computer touch screen as required. It can also be

freely controlled by manual switching. It’s spraying head adopts flat head to avoid the spraying

water intermingle the folded towel; there is a disinfectant automatic circulation system for the

device to prevent the waste of disinfectant.

The device is equipped with a liquid automatic drying device,it will be controlled By PLC,

which can freely adjust the amount of liquid to the wet towel according to actual needs.

The equipment is equipped with a whole set of roller cutting devices. The blade material is

imported white steel. The upper and lower blades are fixed by the stainless steel hexagonal

screw, which is convenient for disassembly.

9. The device is equipped with a set of wide belt synchronous traction devices before and after

the rolling knife. The disinfection solution is acidic, and its wide belt is an imported anti

corrosive wear -resistant material to prevent the belt from being worn off for a long time.

10. The device is equipped with a complete set of automatic stacking devices. The program is

controlled by the servo motor combined with the micro computer. It can set the number of

stacking arbitrarily on the touch screen according to the actual production needs. The operation

is simple, convenient and fast.

11. The device is equipped with an automatic output device for finished products, which can

directly deliver the stack of finished products to packing machine, for easy packaging.

12. Electrical appliance control system: All use the imported PLC program control system,

color computer touch display, frequency conversion, servo motor, imported electrical

appliances, and joint control production; the wiring of electrical parts is reasonable, clean, safe, and easy to operate.

13. All parts of the equipment outer covers and the parts involved in the products are made of

stainless steel materials. The bearing seat materials are made of domestic 45#steel and bearing.

14.The machine will be covered by the safety shield expect the feed frame.

The main technical parameters:

Power: Three -phase 380V/ 50Hz Power: 9.5KW

Product specifications: After expansion size: length 120mm-300mm × width 120mm-300mm.

Folded size: length120mm-300mm × width 95mm-180mm.

Folding method: "Z" type (6 work positions are discontinued)

Counting method: automatic electronic counting, LCD screen setting, variable number stacking system

Model: Variable production of automatic humidification circulation system

Raw material specifications:

Applicable raw materials: non -woven fabric, spunlace non -woven fabric

Raw material grams: 50-100 g/m2

Raw material roll: (150-300) mm × φ1000mm (width × diameter) 2

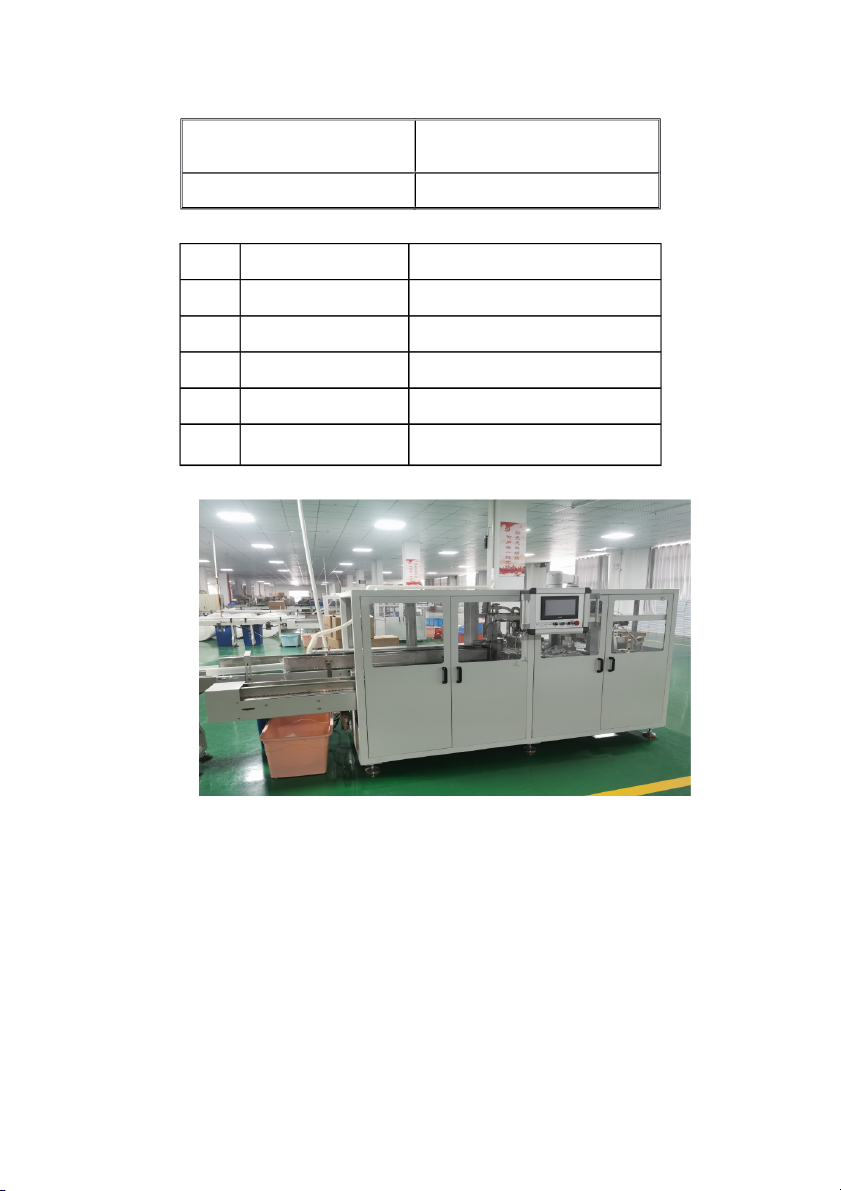

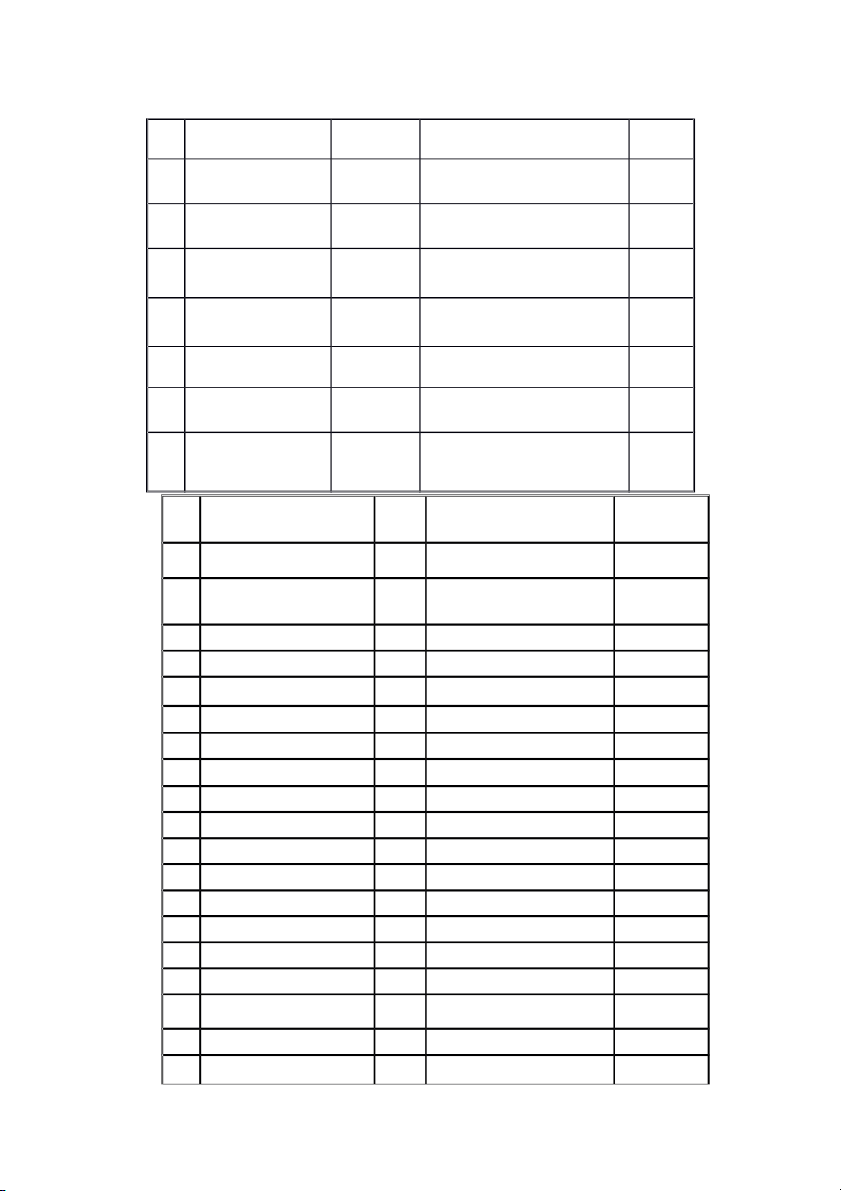

Inner diameter of material roll paper core: 3 inches, 76.2mm Spare parts: Items Qty Cutting knife 1 pcs Folding plate 1 pcs Punching head 1 pcs photoelectric detector 1 pcs encoder 1 pcs Conveyor belt 3pcs Solenoid valve 1 pcs Equipment pictures: 2 2 Automatic Bagging machine:

一.Performance and structural characteristics of the equipment:

1.The working principle of the equipment: automatic bagging--- conveying ---automatic sealing ---- completion automatic

2.The device uses PLC programmable controller to program the whole machine operation。

3. The equipment uses high sensitivity photoelectric detection sensor to feed to prevent blocking and the accuracy of feeding。

4. Device suture temperature independent PID control, better suitable for a variety of packaging

materials, improve the sealing quality。

5. The whole machine has a compact structure, fast packaging speed, stable and reliable

performance, high degree of automation, simple operation, and is the best choice of production and packaging products.。

Technical parameters of the equipment: 20---25bag/min(Due to product, Speed

packaging materials and other factors, the speed is ± 5% deviation) Frequency 50HZ Voltage 220V Power 2.0KW Machine weight 700KG Dimension (mm) 2800×900×1400mm L*W*H 2 L:120mm---200mm Product packaging size range W:100mm---145mm H:20mm---100mm L:150mm---330mm Bag size range W:100mm---180mm

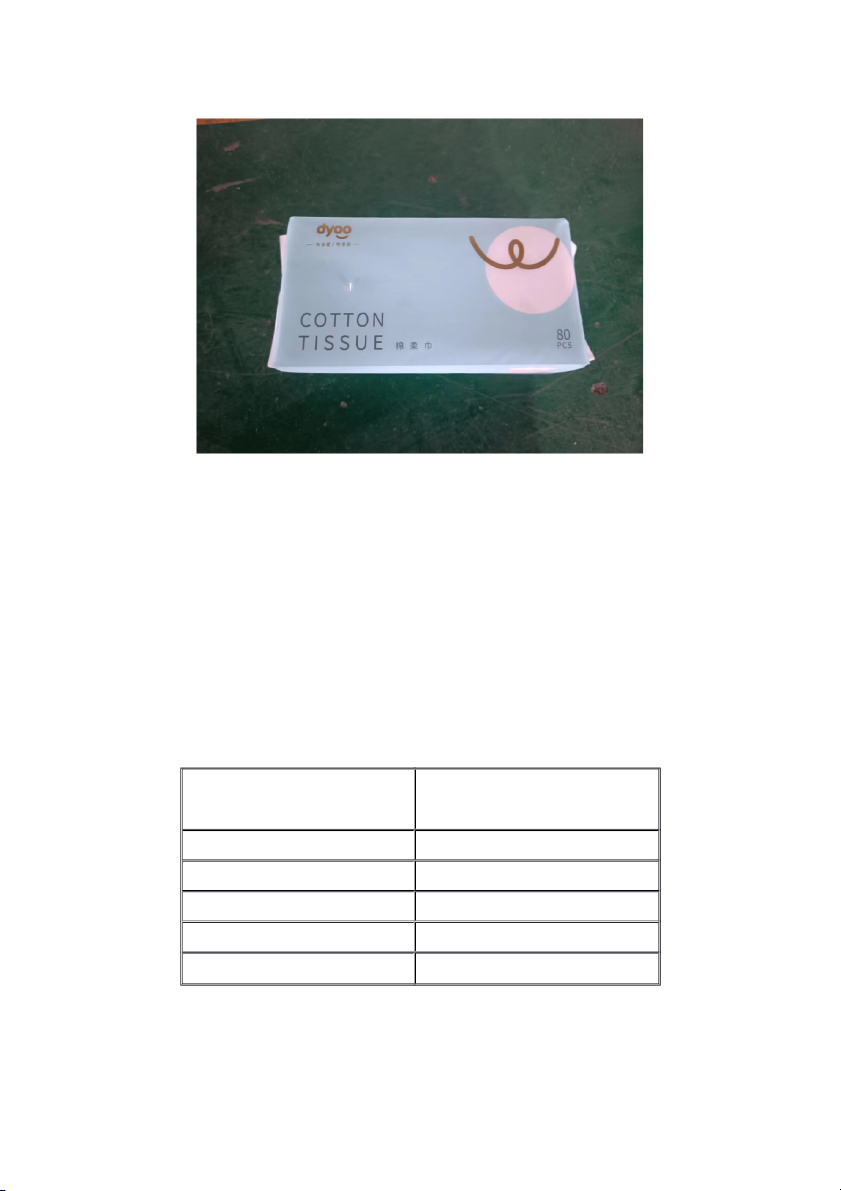

Main electrical accessories brand of each equipment: NO. ITEMS BRAND 1 PLC controller Inovance/Xinjie 2 Touch screen Xinjie/Fanyi 3 Servo motor Inovance/Xinjie 4 Frequency Inovance/Xinjie Photoelectric detection 5 Inovance/Xinjie sensor PICTURES:

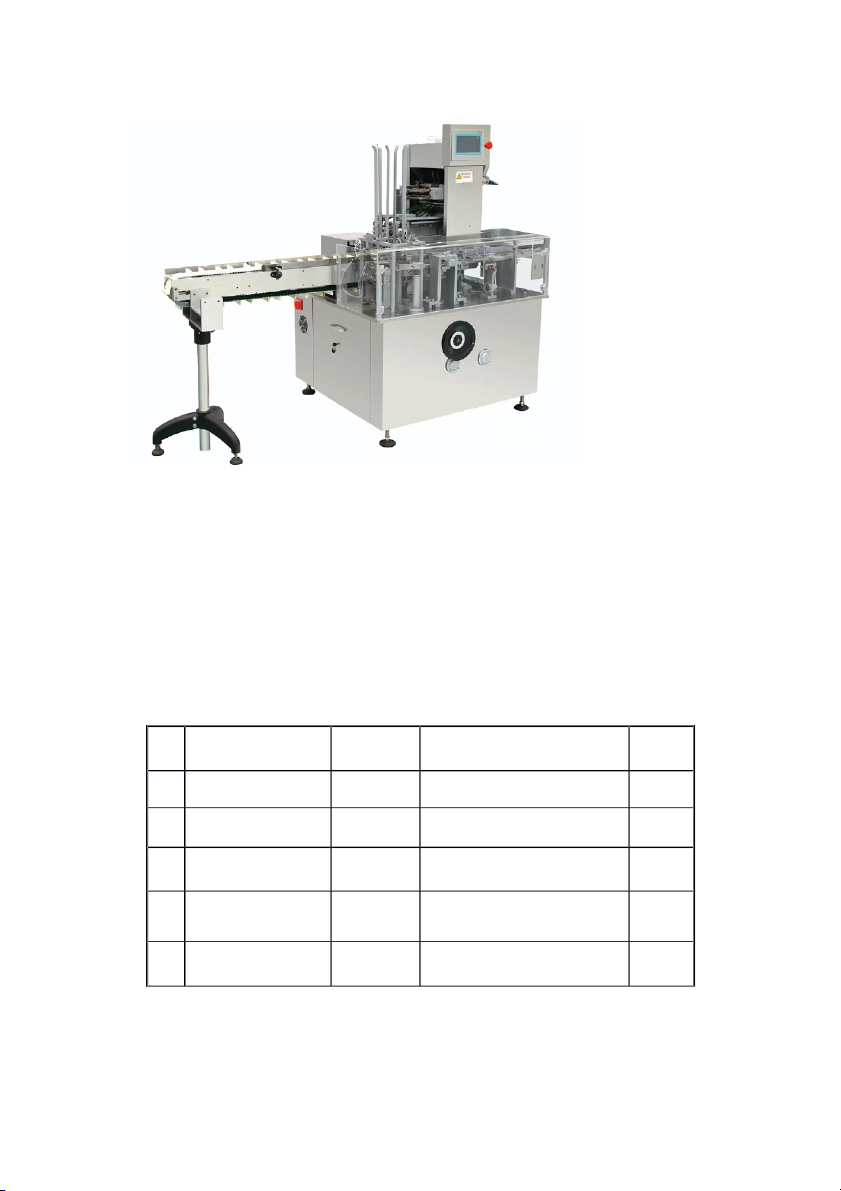

Automatic box-loading machine Machine pictures: 2

Specific technical performance and characteristics of the box-loading machine:

1 The box-loading machine adopts man-machine interface operating system, and the control part

adopts imported programmable controller. Automatic display of packing speed and count; manual

and automatic conversion; automatic detection system, etc。

2 Automatically display the device running speed, and can quickly adjust the packaging speed on the display screen。

3 Automatic counting function, you can understand the output of the machine。

4 Using variable frequency speed regulation system, the speed setting is stable and reliable。

5 Simple and convenient operation, the whole machine compact design, reasonable structure, convenient maintenance.。

6 Few operators, only one person to operate, you can complete the packing machine feed and monitoring。 No. Items Unit Numerical or illustrative Remark 1 Power KW 1.5 2 Voltage V 380 30-50boxes 3 Speed Boxes/min 4 Box dimension L*W*H (150-300)*(120-160)*(50-70) mm 5 Box materials g 350g sqm 2 6 Starting current A 10 7 Numerical or illustrative A 3.5 8 Air pressure capacity L/min 5-20 9 Compressed air MPA 0.5-0.8 L/min 10 Vacuum gas extraction 20 -0.08 11 Vacuity Mpa 6 12 Weight kg 1000 13 Noise ≤dB 75 NO.1 Items Qty Performance instructions Brand 1 Touch Screen 1set Color display Mitsubishi, 24 points (14 points input 10 2 PLC 1set Mitsubishi point output) 3 Rotary encoder 1set Mitsubishi 4 Communication cable 1pcs Mitsubishi 5 Frequency 1set Mitsubishi 6 Main motor 1set ChengBang 7 AC Relay 4pcs Jalle 8 Proximity switch 1pcs Test paper box Jalle 9 Fiber optic switch 1pcs Jalle 10 Photoelectric switch 1 pcs Testing materials Jalle 11 Fan 1pcs Shanghai 12 Combination switch 1pcs Shanghai 13 Small circuit breaker 4pcs Schneider 14 Small circuit breaker 1pcs Schneider 15 Conditioning combination 1pcs Taiwan 16 Cylinder 1pcs Yadke 17 Solenoid valve 1pcs 2 Korea 18 Clutch 1pcs Shanghai 19 Vacuum pump (oil-free type) 1pcs Taiwan 2