Preview text:

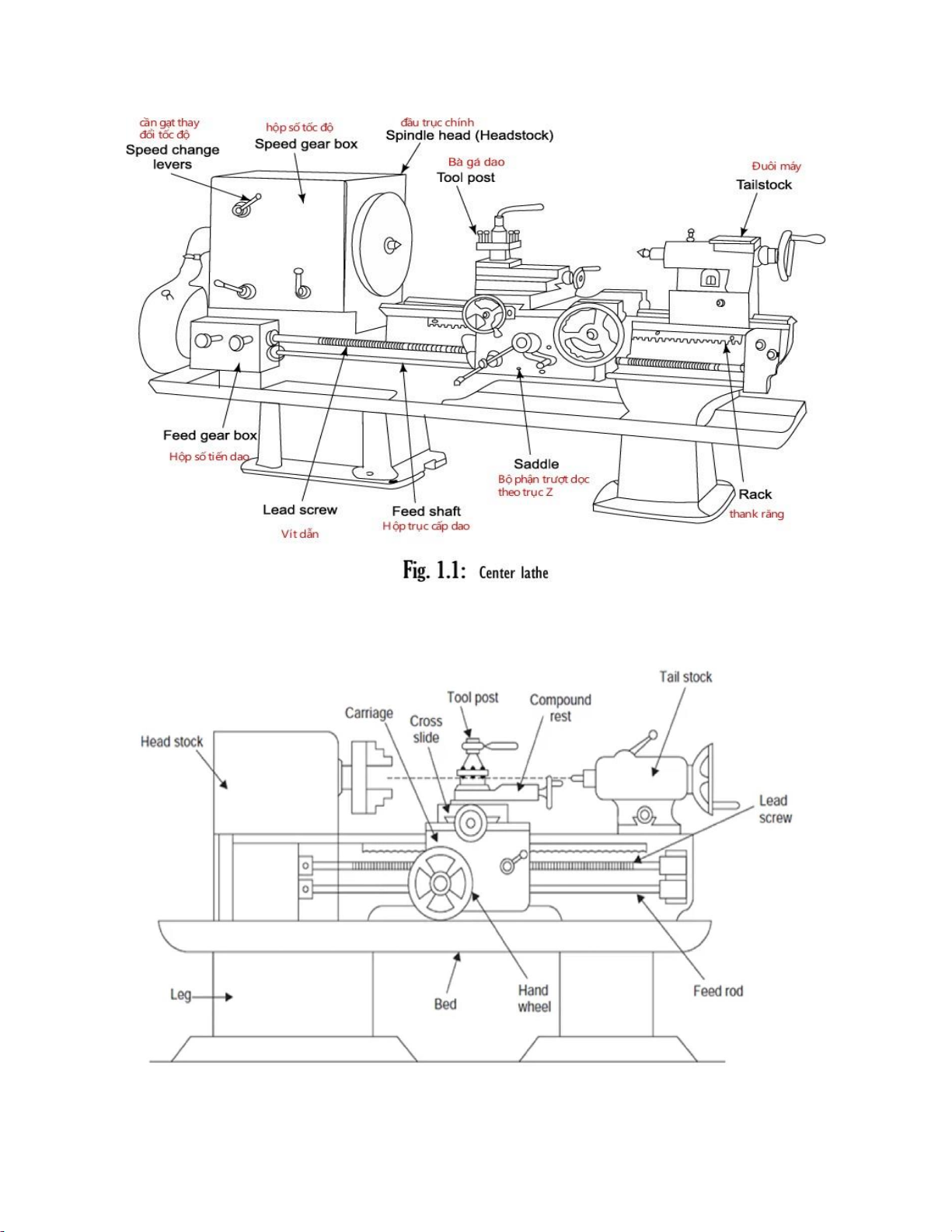

- The center lathe is a general-purpose machine, it comprises a bed with a

guideway. On one end of the bed is mounted with a provides drive to the spindle

mounted with a work holder. The other end is mounted with a tailstock which

supports a longer workpiece on the center.

- The tailstock can be adjusted axially on the guideway, and clamped in a position

suitable for the workpiece length.

- The handwheel, used for fine adjustment of the center, can be clamped in set

position, and the tailstock moved laterally, for taper turning.

- The tailstock shaft has a tapered hole which is used to locate the work-supporting

center, or a drill for cutting holes in the workpiece.

- The handwheel is used, to feed the drill manually into the workpiece.

- Tailstock center is also used to align the threading tap with the spindle center, during manual tapping.

- This ensures perfect concentricity of the thread, with the drilled hole. The

headstock houses the machine spindle in precision bearings. Its speeds should suit

the workpiece/tool materials combination, and the workpiece size [diameter].

- Column drilling machines comprise a base with a tee-slotted table, mounted with

a vertical guide column, for mounting an auxiliary work table with radial tee slots,

for clamping the workpiece. There is a central hole that provides a passage

[overshoot] for the drill. The auxiliary table can be adjusted vertically on the

column, to suit the workpiece height. The column carries the spindle head above

the auxiliary table. The spindle head is also vertically adjustable and clampable on

the column. The spindle can be fed downwards by a levere handwheel.

-On this machine, the cutting stroke is effected by moving the worktable by a

handle, through a screw/nut combin-ation. The workpiece mounted in a jig/fixture

is moved from one spindle to another, for subsequent operations.