Preview text:

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/378156097

Chiplet Technology: Revolutionizing Semiconductor Design-A Review

Article in Saudi Journal of Engineering and Technology · February 2024

DOI: 10.36348/sjet.2024.v09i02.006 CITATIONS READS 0 1,632 1 author: Vivek Gujar IndoAI Technologies P Ltd

28 PUBLICATIONS 17 CITATIONS SEE PROFILE

Al content fol owing this page was uploaded by Vivek Gujar on 13 February 2024.

The user has requested enhancement of the downloaded file.

Saudi Journal of Engineering and Technology

Abbreviated Key Title: Saudi J Eng Technol

ISSN 2415-6272 (Print) | ISSN 2415-6264 (Online)

Scholars Middle East Publishers, Dubai, United Arab Emirates

Journal homepage: https://saudijournals.com Review Article

Chiplet Technology: Revolutionizing Semiconductor Design- A Review Vivek Gujar1*

1Director, IndoAI Technologies Pvt. Ltd.

DOI: 10.36348/sjet.2024.v09i02.006

| Received: 02.01.2024 | Accepted: 09.02.2024 | Published: 12.02.2024

*Corresponding author: Vivek Gujar

Director, IndoAI Technologies Pvt. Ltd. Abstract

This article explores the transformative journey of semiconductor design from monolithic structures to the cutting-edge era

of chiplets. Chiplets, modular components offering specific functionalities, have emerged as a catalyst, reshaping the global

semiconductor industry. Their capacity for tight interconnectivity, diverse applications, and cost-effective manufacturing

marks a paradigm shift. The article delves into the historical context of Moore's Law, the rise of chiplets, and their impact

on the semiconductor landscape. It further discusses key considerations in chiplet architecture, optimization algorithms,

and future adoption in industries like data centers, mobile devices, AI, and automotive. Chiplet-based designs promise

enhanced efficiency, collaboration, and innovation, heralding a new era in semiconductor evolution.

Keywords: Chiplets architecture, complex-function, manufacturing costs.

Copyright © 2024 The Author(s): This is an open-access article distributed under the terms of the Creative Commons Attribution 4.0 International

License (CC BY-NC 4.0) which permits unrestricted use, distribution, and reproduction in any medium for non-commercial use provided the original

author and source are credited. 1. INTRODUCTION

complete system-on-a-chip (SoC) or a more complex

The technological evolution in semiconductor

semiconductor device. Chiplet technology creates

design has witnessed a paradigm shift from traditional

smaller, specialized chiplets that can be interconnected

monolithic chip architectures to the innovative era of

to form a larger, more powerful chip. These chiplets can

chiplets. Initially, single-chip designs were predominant,

be manufactured separately and assembled onto a

but the limitations posed by size constraints and substrate or package [2].

manufacturing costs led to the emergence of chiplets. These modular components, featuring specific

Chiplets, or small chips, can be the size of a

functionalities, enable a more flexible and scalable

grain of sand or bigger than a thumbnail and are brought

approach. Chiplets optimize performance, reduce costs,

together in a process called advanced packaging [3]. The

and facilitate customization by combining multiple

idea behind chiplets is to break apart the system on a chip

smaller chips into a cohesive system. This evolution

into its composite functional blocks, or parts. Sub-

represents a transformative trend, shaping the future of

elements of a complex-function chip could be made as

semiconductor design, fostering collaboration, and

chiplets, where these sub-elements might include

unleashing new possibilities in diverse industries, from

separate computational processor or graphics unit, an AI computing to IoT and beyond.

accelerator, an I/O function, or a host of other chip

functions [4]. Chiplets are individual semiconductor

In a rapidly evolving technological landscape

components or microchips that are manufactured and

and its advancements, the advent of chiplets has become

designed for specific tasks and are integrated into a larger a transformative force, reshaping the global

circuit [5]. Chiplets, essentially are small semiconductors

semiconductor industry, Chiplets, with their capacity to

integrated into robust systems, have redefined the

integrate small semiconductors into robust systems, have

conventional norms of semiconductor design and

revolutionized the semiconductor landscape. chiplets

manufacturing. Their capacity for tight interconnectivity

have emerged as a catalyst, reshaping the global

has not only propelled performance to new heights but semiconductor industry [1].

has also introduced a cost-effective paradigm to chip

manufacturing. The ability to tightly interconnect Chiplets are individual semiconductor

chiplets boosts performance and offers a cost-effective

components that can be integrated together to form a

approach to chip manufacturing. Bonding chiplets

Citation: Vivek Gujar (2024). Chiplet Technology: Revolutionizing Semiconductor Design- A Review. Saudi J Eng 69 Technol, 9(2): 69-74.

Vivek Gujar; Saudi J Eng Technol, Feb, 2024; 9(2): 69-74

tightly together can help make more powerful systems

For instance, the Intel 4004 chip in 1971, with 2,250

without shrinking the transistor size [3].

transistors and a 10,000nm process, exemplified the

doubling trend. Subsequently, the 1974 Intel 8080 chip,

The technology of ongoing race to reduce

featuring 6,000 transistors and a 6,000nm process on a

transistor sizes, the global chip industry has increasingly

20mm2 chip, continued this trajectory. This remarkable

embraced in recent years as chip manufacturing costs

trend persisted until the early 2020s, with the exponential

soar in the race to make transistors so small they are now

increase in transistor count contributing to the

measured in the number of atoms. The tightly bonded

continuous enhancement of computer performance [6].

assembly of chiplets is a pivotal strategy for achieving

However, challenges emerge as the industry approaches

more powerful systems without further reducing the size

physical limits and encounters economic constraints in

of individual transistors. This has become particularly

maintaining Moore's Law as Moore’s Law shows signs

crucial as the semiconductor landscape experiences a

of slowdown since 2000. The gap between predictions of

seismic shift in response to the escalating demand for

Moore’s Law and the actual performance of chips grew

more potent and energy-efficient electronic devices. In a

by 15 times by 2008. Dennard scaling began to slow

panel discussion at CadenceLIVE Europe, experts from

down significantly in 2007 and nearly lapsed in 2012 [7,

academia and industry converged to address the

8]. Despite these challenges, the enduring legacy of

limitations posed by Moore's Law and traditional 2D

Moore's Law has significantly shaped the trajectory of chip architectures.

technological advancement, marking a pivotal era in the

history of microchip evolution [6].

As the industry grapples with these challenges,

the promises of 3D-IC chiplet integration have gained

3. Modularity of Chiplets & Design

prominence. Chiplets, through decades of industry

The modularity of chiplets, a revolutionary exploration, have evolved into indispensable

concept in semiconductor design, allows for the creation

components that offer a flexible and efficient solution for

of highly customized systems by combining smaller,

various compute subsystems. The potential to

specialized components. This modular approach

revolutionize the semiconductor industry became

enhances flexibility, promotes cost-effectiveness, and

evident as chiplets opened doors to a whole new level of facilitates the seamless integration of diverse

soft IP reuse, steering away from the monolithic design

functionalities, ushering in a new era of adaptable and

philosophy that encapsulates everything onto a single

efficient semiconductor architectures. chip.

The inherent modularity of chiplets not only

This evolution of monolithic design creates

optimizes system performance but also offers scalability

unprecedented opportunities for catering to dedicated

and ease of upgrades. By breaking down traditional

needs in analog, radio frequency (RF), compute, and monolithic designs, chiplets enable targeted

power domains. The modular nature of chiplets allows

enhancements in specific areas like processing power,

for the customization of semiconductor systems,

memory, or specialized functions. This flexibility fosters

optimizing performance for specific functions. Thus, innovation, cost-efficient manufacturing, and

chiplet technology has become a cornerstone in

adaptability to evolving technological demands, marking

overcoming the limitations of traditional semiconductor

a paradigm shift in semiconductor engineering.

designs, ushering in a new era of flexibility, efficiency,

and innovation in the global semiconductor landscape.

Due to Moore framework, chiplet-based design

As the industry continues to explore and refine chiplet

technology addresses multiple challenges. Firstly, it

technologies, the future holds promising prospects for

integrates modular chips into a single package,

further advancements in semiconductor design and

efficiently solving scale, development cost, and period manufacturing.

issues. Secondly, advanced packaging technologies like

2.5D and 3D enable high-performance multi-chip

2. Background and Evolution interconnection, enhancing system integration,

In 1965, Gordon Moore, the Co-founder of

performance, and power optimization. Lastly, modular

Intel, made a groundbreaking prediction that has since

integration accelerates development speed, lowers costs,

become widely recognized as Moore's Law. This

and reduces thresholds, shifting the focus of chip

prediction posited that every two years, the number of

research and development towards core technologies and

transistors on a microchip would double at the same

algorithms, significantly boosting overall innovation

manufacturing cost per silicon area. The implication was

capabilities [8]. Chiplets improve the optimization

a consistent acceleration in the power and capabilities of

potentials on performance and power consumption by

computers, accompanied by a steady reduction in costs

recombining multiple small chips. Thus, it supports the

for consumers. Gordon Moore's foresight held true for

domain-specific customization and mitigating the effect

several decades, earning Moore's Law recognition as one

from the slowdown of Moore’s law for developing

of the most influential guiding principles in modern diverse chips.

innovation. Over the years, this prediction materialized

as demonstrated by the evolution of Intel's microchips.

© 2024 | Published by Scholars Middle East Publishers, Dubai, United Arab Emirates 70

Vivek Gujar; Saudi J Eng Technol, Feb, 2024; 9(2): 69-74

3.1 Chiplet Architecture and Design:

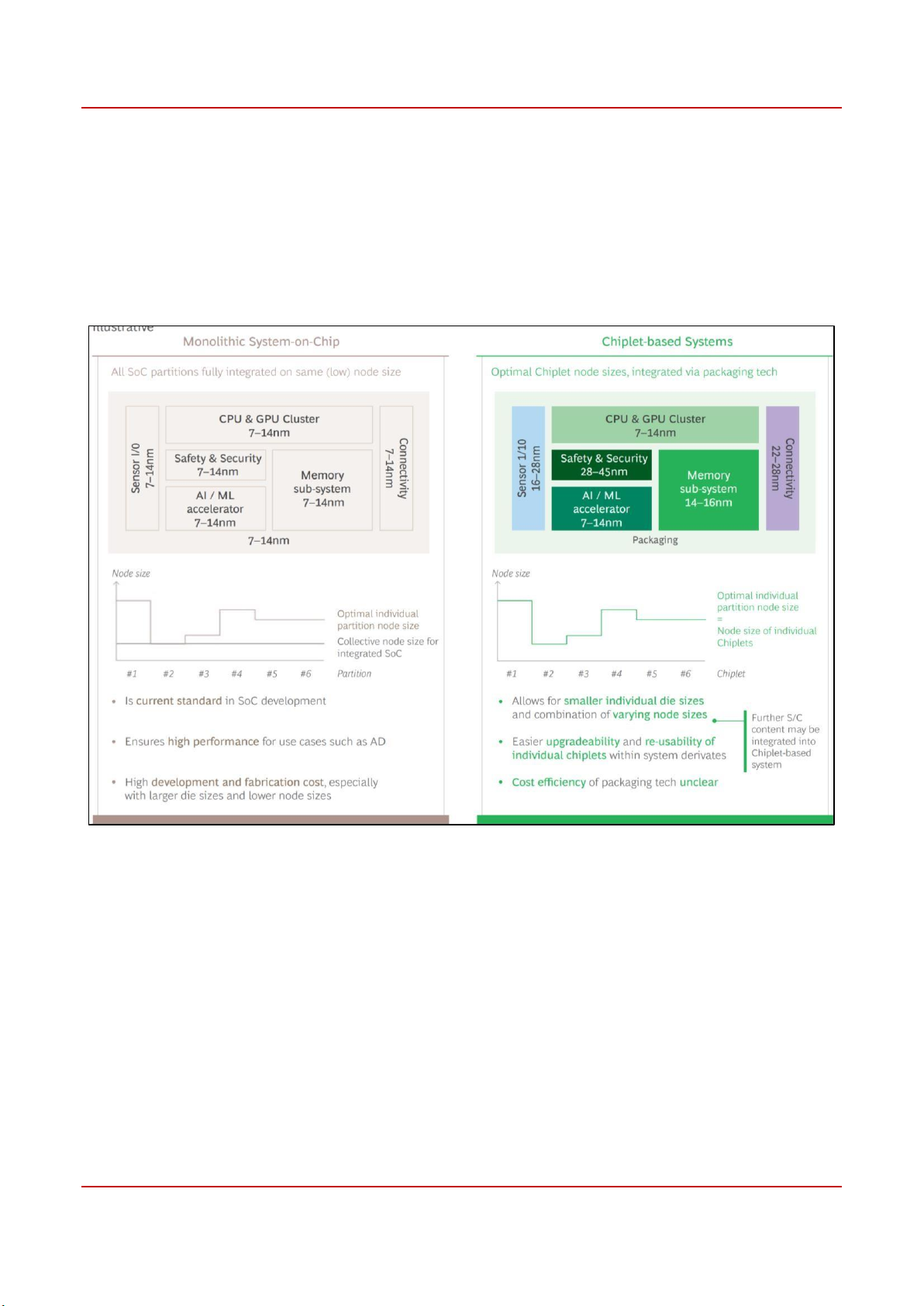

Chiplet Systems revolutionize System-on-Chip

Compute performance has been increasing

(SoC) design by dividing it into smaller units, or

exponentially in the past three decades. For

Chiplets, rather than consolidating all partitions on a

supercomputer, there has been 1.25 years per 2x

single die. Leveraging advanced packaging technologies

performance increase in the past 30 years. For personal

like 2.5D packaging, this modular approach enhances

devices, there has been 2.2~3 years per 2x performance flexibility, performance, and scalability in

increase in the past 15 years. Computing performance

semiconductor design, marking a significant departure

boost synchs with transistor count has been increasing.

from traditional monolithic structures [15]. Exhibit 1.

The available power consumption (power wall) limits

Chiplet Systems as an Alternative Alongside Monolithic

computing performance. Energy efficiency improvement SoC [15].

drives computing performance boost [9].

In chiplet design, critical considerations center

communication consumption and system temperature.

around seamless interconnectivity, efficient power

By introducing communication and temperature-based

distribution, and effective thermal management.

heuristic information, a balance is achieved using the

Interconnectivity is pivotal for the cohesive functioning

weight factor and algorithm, the peak temperature

of modular chips within a system, influencing

reduced by 8.34 K, and communication power

performance and data transfer. Effective power

consumption dropped by 232.13uJ compared to the

distribution ensures that each chiplet receives the

initial layout. This flexibility makes their algorithm

required power, optimizing energy usage. Thermal

adaptable to varying design requirements, offering

management is crucial to prevent overheating, as densely efficient control over the trade-off between

packed chiplets can generate substantial heat. Ensuring a

communication power consumption and temperature

balanced thermal environment enhances reliability and optimization. longevity. The synergy of these key design

considerations is imperative, guaranteeing the successful

Graening et al., 800mm2 design study seems to

implementation of chiplet technology, fostering optimal

indicate that the best size for chiplets is somewhere

performance, energy efficiency, and reliability in

between 50mm2 and 150mm2 for microprocessor logic semiconductor systems [10].

and above 200mm2 for random logic they examined the

case of a large design that could be built as a single

Wang et al., [9] present a multi-objective

monolithic system on chip (SoC) or as a system of

optimization algorithm that simultaneously optimizes

chiplets and show that optimal chiplet size depends on a

© 2024 | Published by Scholars Middle East Publishers, Dubai, United Arab Emirates 71

Vivek Gujar; Saudi J Eng Technol, Feb, 2024; 9(2): 69-74

wide range of parameters. Their analysis indicates that

approach. However, due to restrictions such as the

the smallest chiplet sizes that are viable cost-wise

maximum reticle area, cost, and manufacturing yield, the

depends both on technology node and on type of logic.

chip’s area cannot be continuously increased, and it

The optimal point appears to be 50-150mm2 in 40nm and

encounters what is known as the “area-wall”. In their

40-80mm2 in 7nm for microprocessor type logic [11].

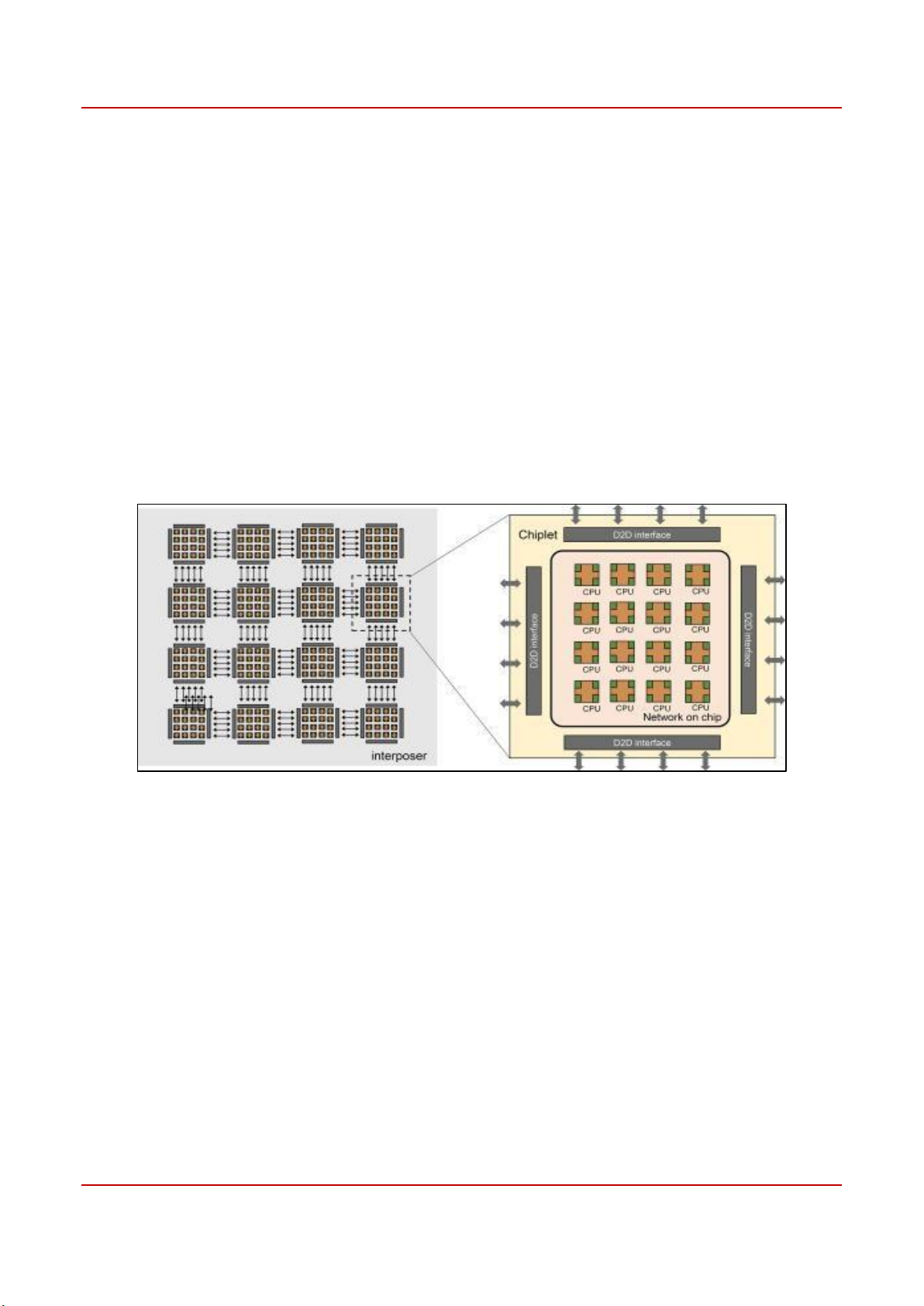

paper Yinhe Han et al., [13] provided a detailed analysis

of the area-wall and propose a practical solution, the Big

For Zhen et al., [12] multi-package architecture

Chip, as a novel chip form to continuously improve

was a popular alternative to optimize the reliability and

performance. The Zhejiang Big Chip adopts a scalable

cost for advanced packages to overcome the primary

tile-based architecture, as illustrated in fig below. This

challenge of the multi-package co-design problem,

processor consists of 16 chiplets, and it has the potential

which is the tradeoff between interconnection cost and

to scale up to 100 chiplets. In each chiplet, there are 16

reliability. Therefore, a co-design methodology was

CPU processors that are connected via a network-on-

adopted to optimize multiple packages simultaneously to

chip (NOC), and each tile is fully symmetrically

improve the quality of the whole system. To tackle this

interconnected to enable communication among multiple

challenge, they adopted mathematical programming

chiplets. The CPU processors are designed based on the

methods in the multi-package co-design problem

RISC-V instruction set. Moreover, this processor adopts

regarding the nature of the synergistic optimization of

a unified memory system, which means any core on any multiple packages.

tile can directly access the memory across the entire processor.

To improve performance, increasing the chip

area to integrate more transistors has become an essential

Zhuoping Yang et al., [14] first discussed the

encapsulated Intel's evolution, emphasizing that it was

diversity and evolving demands of different AI

no longer a one-size-fits-all company.

workloads and how chiplet brings better cost efficiency

and shorter time to market. The authors also discussed

4. Future Chiplet Adoption in Industry & Advantages

about heterogeneous chiplet architecture which is

Chiplet development is still emerging, but it

favored to keep scaling up and scaling out the system as

promises to transform the semiconductor industry and

well as to reduce the design complexity and the cost

electronics. Here's a peek into the potential future:

stemming from the traditional monolithic chip design.

Diverse Specialized Chiplets: Expect more chiplets tailored for specific functions, seamlessly

In the proceedings of ISSCC 2009 [20], Intel

combining different capabilities. This will lead to

presented a series of papers focusing on the Nehalem

highly efficient systems for tasks like edge

processor. The plenary session, led by Mark Bohr,

computing and scientific research.

underscored Intel's significant investment in advancing

Edge Computing and IoT: Chiplets are ideal for

system-on-chip (SoC) technology. This commitment

making IoT devices more power-efficient and

was evident in the design of the Core i7 Nehalem, which

responsive. In edge computing, chiplets enable real-

featured the integration of memory controllers and

time data processing, fueling smart cities,

DDR3 I/Os onto a shared substrate with the CPU cores.

autonomous vehicles, and intelligent infrastructure.

Notably, Intel signaled a strategic shift during this

Quantum Computing: Chiplets could revolutionize

period, expressing a vision that extended beyond the

quantum computing by offering accessible and

traditional PC market, particularly emphasizing interest

scalable solutions. Quantum chiplets, assembling

in dynamic sectors such as mobile technology. Bohr

quantum processors, may enhance performance and

reliability, pushing the boundaries of computation.

© 2024 | Published by Scholars Middle East Publishers, Dubai, United Arab Emirates 72

Vivek Gujar; Saudi J Eng Technol, Feb, 2024; 9(2): 69-74

As chiplet technology evolves [19], it is 3. Increased Yield:

expected to see chiplets being further utilized in some of

Smaller chiplet sizes enhance wafer utilization.

the following industries prominently.

Minimizes manufacturing defects, ensuring a

Data Centers: Chiplets are revolutionizing higher yield.

data center architectures by enabling efficient

and modular designs. They offer enhanced 4. Cost Efficiency:

performance and energy efficiency while

Enables cost savings by combining dies from

simplifying upgrades and maintenance. different nodes.

Mobile Devices: In smartphones and tablets,

Reduces over-specification and improves

chiplets can be customized to optimize power purpose-specific fits.

consumption, graphics, and AI processing,

resulting in improved performance and longer 5. Performance Optimization: battery life.

Task-specific chiplets deliver performance

AI and Machine Learning: Chiplet-based AI enhancements.

accelerators can be tailored for specific AI

Integrated photonics in multi-die packages offer

workloads, delivering faster inferencing and superior bandwidth density. training capabilities.

Automotive: Chiplets can enhance 6. Expanded Chip Area:

autonomous vehicles' processing power and

Overcomes size limitations imposed by reticle safety. size.

Allows for larger chip areas compared to

Chiplet architectures are fundamental to the monolithic designs.

continued economic viable growth of power efficiency

of AI, 5G and edge computing [21]. Due to the platform 7. Lower Power Consumption:

idea, the chiplet approach also allows scaling of Reduces interconnection distance and

computing power. If more power is needed to process AI minimizes power loss.

algorithms, then several of these circuits can be installed

Contributes to lower power requirements in on the chiplet system [22]. chiplet configurations.

Chiplet-based designs promise robust growth, driven by

following several key advantages [16, 17]:

8. Flexibility in Development:

1. Enhance Chip Production Efficiency:

Chiplet modularity facilitates swift adjustments

Independent manufacturing of chip modules. to product portfolios.

Utilizes diverse processes and latest

Enables design reuse and de-risks system-on- manufacturing technologies. chip development.

Elevates production efficiency and cost-

Shortens design time, promoting flexibility and effectiveness. adaptability.

Mitigates entire chip scrappage, enhancing reliability

Chiplets can provide many benefits in the

context of processor design in a post Moore’s Law world,

2. Facilitate Industrial Collaboration and Innovation:

but effective utilization of chiplets still requires careful

Fosters collaboration across diverse industries.

engineering and optimization along many different and

Enables different manufacturers to develop chip

sometimes conflicting dimensions [18]. modules.

In nutshell, the accelerated growth in the

Strengthens cooperative ties, accelerating

advanced packaging market, driven by chiplet innovation.

technology, presents a substantial opportunity for

Introduces a diverse array of product choices to

companies agile enough to embrace and leverage these the market. advancements. Annexure/s

Different Types of Chiplets for Computation Types of Chiplets Description Compute Chiplets

Primary processing units with CPU and GPU cores for executing computational tasks. Memory Chiplets

Dedicated memory modules like DRAM or HBM enhancing data access speeds and storage capacities. I/O Chiplets

Interfaces enable communication between chiplets, the external world, and peripherals. Fabric Chiplets

Facilitating high-speed data transfer and communication between chiplets within a package. Ref: Cadence

© 2024 | Published by Scholars Middle East Publishers, Dubai, United Arab Emirates 73

Vivek Gujar; Saudi J Eng Technol, Feb, 2024; 9(2): 69-74 CONCLUSION

5. https://chipedge.com/power-of-chiplets-in-the-

Over the past several years, chiplets have semiconductor-industry/

moved from a buzzword to a proven technology,

6. https://www.kandou.com/glasswing/2023-09-18-

enabling chip shipments in the millions of units per year.

history-of-the-chiplet-and-why-it-is-the-future/

7. https://fastercapital.com/content/The-Future-of-

Lacking a mature ecosystem, however, chiplet-based

Computing--Moore-s-Law-s-Lasting-Impact-and-

design has been available to only large vendors. Now, the Beyond.html

industry is poised for broader adoption once D2D

8. Li, T., Hou, J., Yan, J., Liu, R., Yang, H., & Sun, Z.

interfaces are standardized and a wave of vendors adopt (2020). Chiplet heterogeneous integration

new chiplet-based business models. Customer demand is

technology—Status and challenges. Electronics, 9(4),

creating momentum behind this approach, with the

670. https://doi.org/10.3390/electronics9040670

ultimate goal of rapid chip design using mix-and-match

9. https://pradeepstechpoints.wordpress.com/category/ch

third-party chiplets. The chiplet approach reduces the iplets/

cost and time required to develop custom processors. By

10. Wang, X., Su, J., Chen, D., Li, D., Li, G., & Yang, Y.

using an off-the-shelf compute die, customers can focus

(2023). Efficient Thermal-Stress Coupling Design of

on developing the IP that differentiates their processor

Chiplet-Based System with Coaxial TSV

for a target application rather than duplicating a common

Array. Micromachines, 14(8), 1493.

block. Most of the I/O-hub functions are readily

https://doi.org/10.3390/mi14081493

available as IP blocks, so the customer task is primarily

11. Graening, A., Pal, S., & Gupta, P. (2023, July).

integration. Using a compute chiplet also allows

Chiplets: How Small is too Small?. In 2023 60th

customers to use leading-edge process technology for ACM/IEEE Design Automation Conference

that function, whereas many SoCs lack the volume to (DAC) (pp. 1-6). IEEE.

justify a monolithic design in that same node.

https://nanocad.ee.ucla.edu/wp-content/papercite- data/pdf/c124.pdf

In summary, the shift from monolithic to

12. Zhuang, Z., Yu, B., Chao, K. Y., & Ho, T. Y. (2022,

chiplet-based semiconductor design represents a

October). Multi-Package Co-Design for Chiplet revolutionary change. Chiplets offer flexibility,

Integration. In Proceedings of the 41st IEEE/ACM

scalability, and cost efficiency, addressing challenges International Conference on Computer-Aided Design (pp. 1-9).

posed by traditional architectures. Ongoing research and

https://www.cse.cuhk.edu.hk/~byu/papers/C147-

studies highlight benefits and challenges, contributing to ICCAD2022-MPCD.pdf

the continuous refinement of chiplet technology.

13. Han, Y., Xu, H., Lu, M., Wang, H., Huang, J., Wang,

Y., & Sun, N. (2023). The Big Chip: Challenge,

The advantages of chiplet architectures,

Model and Architecture. Fundamental Research.

including enhanced production efficiency and increased

https://doi.org/10.1016/j.fmre.2023.10.020

yield, position them as key players in various industries.

14. Yang, Z., Ji, S., Chen, X., Zhuang, J., Zhang, W., Jani,

Future adoption in data centers, mobile devices, AI, and

D., & Zhou, P. (2023). Challenges and Opportunities

automotive sectors promises transformative outcomes.

to Enable Large-Scale Computing via Heterogeneous As chiplets move towards broader adoption, Chiplets. arXiv preprint arXiv:2311.16417.

standardization of interfaces will be crucial, driven by

https://arxiv.org/pdf/2311.16417.pdf

customer demand for rapid and cost-effective chip

15. BCG, The Future of Automotive Compute Are Chiplet design.

Systems a promising technology step on the path

toward a centralized stack? White paper, jun 2023,

Thus, chiplet technology heralds a new era in

https://media-publications.bcg.com/The-Future-of- semiconductor evolution, fostering innovation, Automotive-Compute.pdf

adaptability, and efficiency in a rapidly advancing

16. https://www.pcbaaa.com/chiplet-technology/ technological landscape.

17. https://medium.com/bcgontech/chiplets-opportunities-

and-challenges-for-the-semiconductor-industry- REFERENCES

18. Loh, G. H., Naffziger, S., & Lepak, K. (2021,

1. Shahid, H. (2024). How chiplets are revolutionizing February).

“Understanding Chiplets Today to

China's semiconductor industry, Thu, February 1,

Anticipate Future Integration Opportunities and 2024.

Limits”, Advanced Micro Devices Inc. Fort Collins,

https://www.koreatimes.co.kr/www/opinion/2024/01/ CO, USA, https://past.date- 137_355297.html conference.com/proceedings-

2. https://resources.pcb.cadence.com/blog/2023-the-rise- archive/2021/pdf/2001.pdf of-chiplets

19. https://resources.pcb.cadence.com/blog/2023-the-rise-

3. https://economictimes.indiatimes.com/tech/technolog of-chiplets

y/chip-wars-how-chiplets-are-emerging-as-a-core-

20. https://www.eetimes.com/chiplets-a-short-history/

part-of-chinas-tech strategy/articleshow/101723403

21. https://www.semicontaiwan.org/en/node/7601#:

4. IBM, What are chiplets, https://research.ibm.com/blog/

22. https://semiengineering.com/edge-ai-and-chiplets/ what-are-computer-chiplets

© 2024 | Published by Scholars Middle East Publishers, Dubai, United Arab Emirates 74 View publication stats