Preview text:

DEMAND MANAGEMENT Definition

Demand management: The creation across the supply

chain and its markets of a coordinated flow of demand.

Link to other function: Procurement & Purchasing,

Production, Transportation, Distribution, Sale, Inventory.

Estimate and manage customer demand => shape operating decisions:

Better than just forecasting

Intergration of demand and supply

Improves communication, coordination, collaboration

Improves basic supply chain flows Why important: Maximize revenue Optimize cash Control cost

The bullwhip effect: The small changes in demand => A whip-like effect upstream.

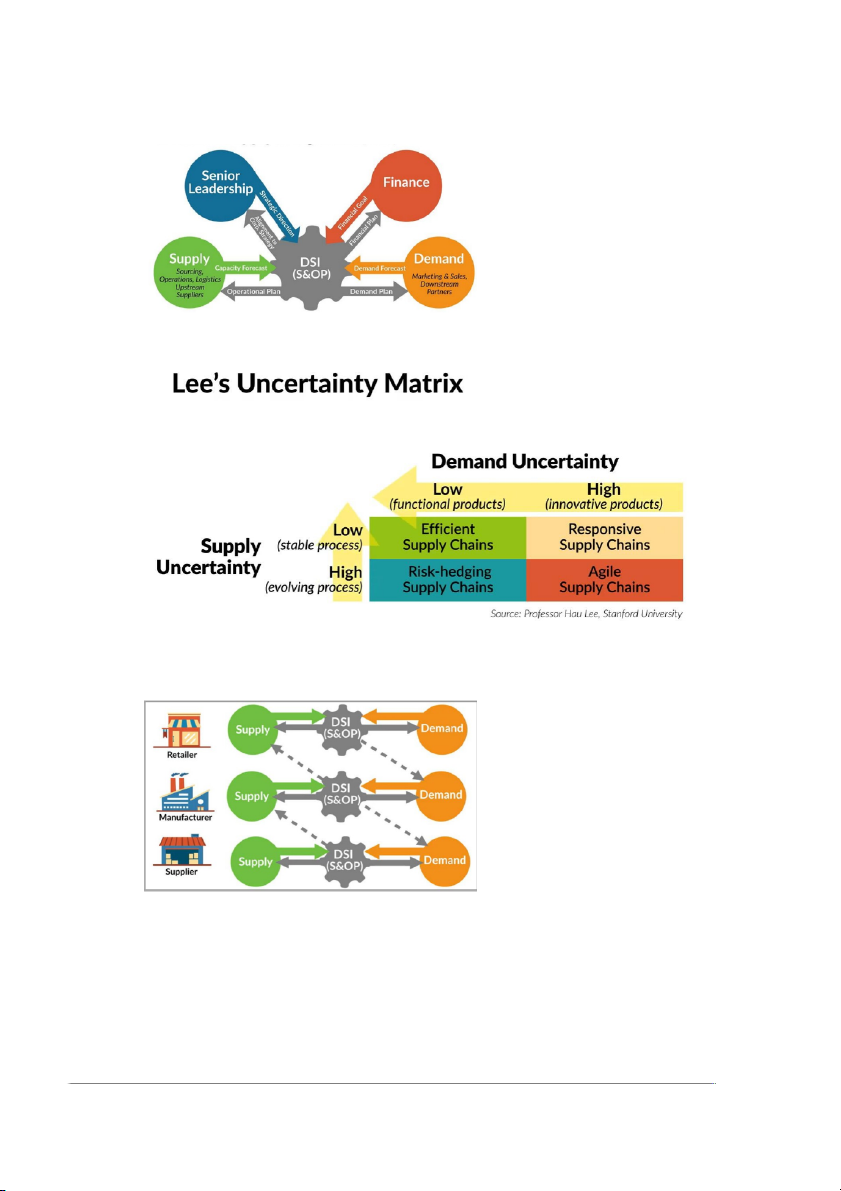

Demand Supply Intergration

DSI (or Sales & Operation Planning):

Lee’s Uncertainly Matrix:

DSI – Across the SC: DSI (or S&OP) control supply and

demand from Retailer to Manufacturer and Supplier: Demand Forecasting Techniques:

Qualitative: Expert opinions, Market research,…

o Methods: Executive Opinion, Delphi Method,

Sales Force Estimates, Consumer Surveys.

Qualitative: Simple Moving Average, Weighted Moving Average.

o Analyse and assess the situation

o Establish forecasting model and statistical forecast o Post-forecast

o Methods: Naive Approach, Moving Averages,

Exponential Smoothing, Trend Projection. Demand (sales) forecasting:

Helpful in make-to-stock situations, make-to-order situations. Process:

Three basic types: Judgmental, Time series, Cause and effect (associative) Issuses:

o An inappropriate technique → reduce forecast accuracy.

o Accuracy leads to important logistical implications.

o Software unable to completely eliminate forecast errors.

Demand (material ) forecasting: Determined demand:

Identifying department materials requirement:

o Purchase requisition (Internal document): Department name, …

o Table of materials demand estimation: N = Q x M

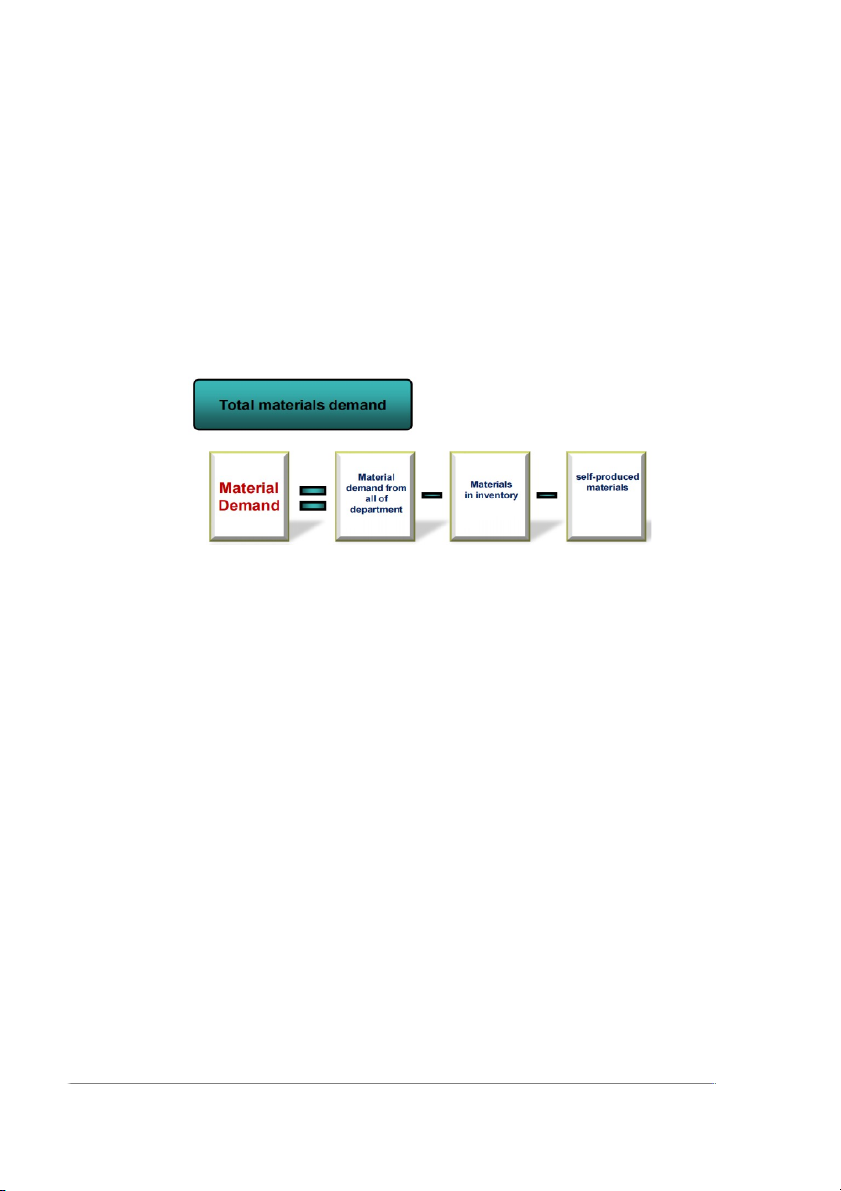

Summing up the company materials requirement:

o Supply department will be received purchase

requisition then check the accuracy and

completeness each type of material data.

o To build up the table of total company material demand Total materials demand: Role:

o No accurate data on production plan and raw material uses for production.

o Prepare a material supply plan

o Calculate the amount of necessary materials reserve