Preview text:

Digital Supply Chain

Making the supply chains more

efficient, agile, and customer-focused www.pwc.se Introduction

Behind the great potential of the

In 2018, PwC conducted a worldwide

Digital Supply Chain (DSC) lies the

Global Digital Operations survey with

fourth industrial revolution, Industry

over 1,000 participants from 6 major

4.0, a transformation in both produc-

industrial sectors and 26 countries.

tion and automation. While Industry

It revealed that by digitizing, compa-

nies, over the next five years, expect to

3.0 focused on the automation of

generate 12.3% in cost reductions whilst

individual machines and processes, increase revenues by 14.7%.

Industry 4.0 focuses on the end-to-end

digitization of the supply chain. Pow-

ered by data and connectivity, it will

drive digitization in all aspects of the 1800 1900 1970s 2015+ 2030+

supply chain, leading us on the path Industry 1.0 Industry 2.0 Industry 3.0 Industry 4.0 Digital

towards a digital ecosystem with more ecosystem

flexibility, virtualization, and inte-

grated collaboration both internally The invention Mass produc- Electronics, IT, Digital supply Flexible and in-

and with value chain partners. of mechanical tion, with ma- and industrial chain tegrated value production chines powered robotics for chain networks powered by wa- by electricity advanced Smart manu- ter and steam and combus- automation facturing Virtualized started the tion engines of production process es Digital products, first industrial processes services and busi- Virtualized revolution Introduction of assembly lines Electronics ness models customer inter- and IT (such as face Data analytics computers) and as a core compe- Industry collab- the internet tency oration as a key constitute the value driver beginning of the information age

2 Digital Supply Chain New digital technology

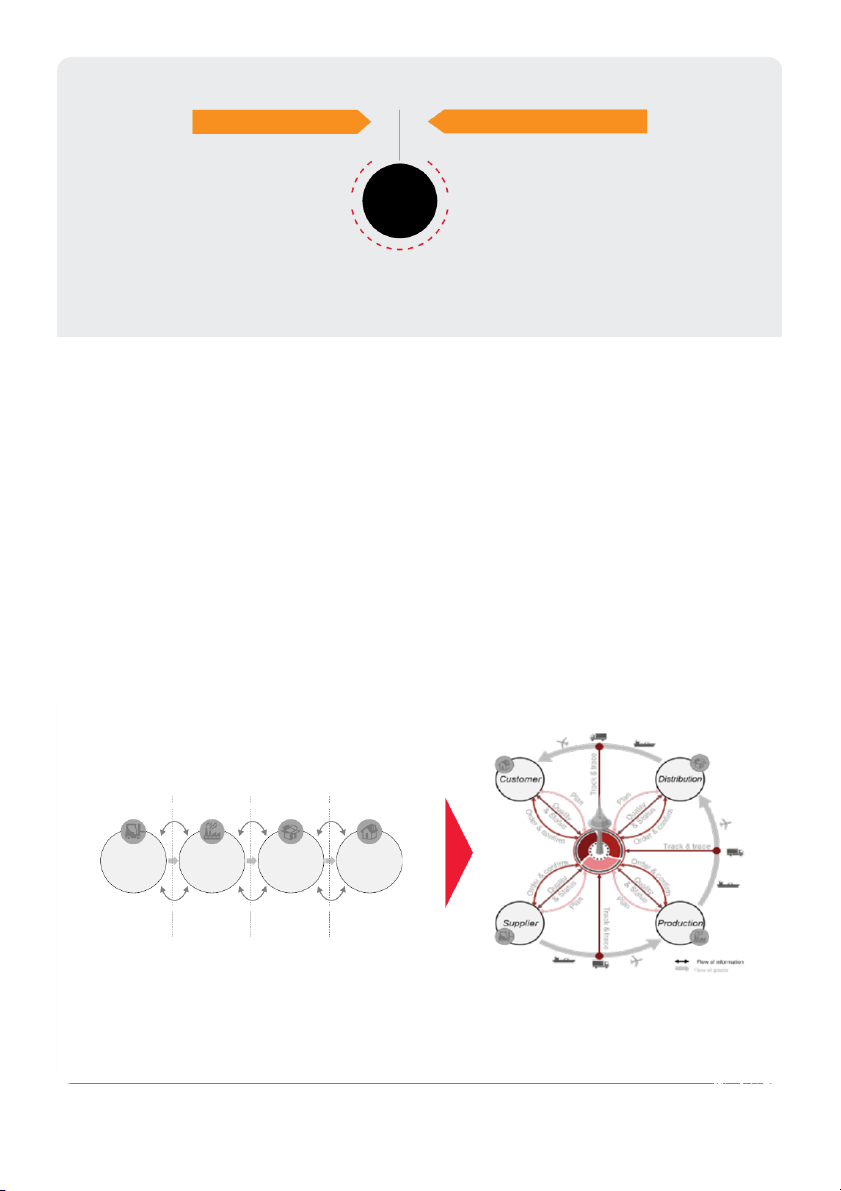

Changing consumer expectations IoT platforms

Digital lifestyle drive proliferation of Cloud solutions

interaction models and willingness to share information Additive Manufacturing/ Customer Centric 3D printing

Consumers expect seamless experien- Push Supply Chain Pull ce across channels

Big data solutions and analytics & Operations

Demand for personalized products Industry 4.0 and sensors and services UX / eCommerce / omnichannel

Customers expect order and delivery visibility

Increased consumer expectation for “instant”order fulfilment

Driving the transformation are two

Together, these technologies will enable

Traditionally communication has been

tightly intertwined, but opposite acting

new business models, the digitization of

sequential within the supply chain, in (push-pull), trends:

products and services, and the digitiza-

the direction of goods/services, with

tion and integration of every link in a

limited interaction between the dif-

• New technology: pushing new capa-

company’s value chain (i.e. the digital

ferent steps. Industry 4.0 extends the

bilities and solutions to market by the

workplace, product development and

vertical integration of all corporate

use of big data analytics, the cloud,

innovation, engineering and manufac-

functions to the horizontal dimension,

and the Internet of Things, 3D prin-

turing, distribution, and digital sales

knitting together relevant players — the

ting, augmented reality, etc.; and,

channels and customer relationship

suppliers of raw materials and parts, the

• Expectations: More exacting expecta- management).

production process itself, warehousers

tions from consumers, employees, and

and distributors of finished products,

business partners, drive companies

At the heart of all this activity sits the

and finally the customer — through a

(pulling them) to develop more reliab-

Digital Supply Chain ecosystem, and it

network of sensors and social technolo-

le and responsive supply chains.

is key to the operations of every com-

gies, overseen via a central control hub,

pany that manufactures or distributes

and managed through an overarching

The Digital Supply Chain ecosystem will

anything. Indeed, for many companies data analytics engine.

be based on full implementation of a

the supply chain is the business.

wide range of new digital technologies.

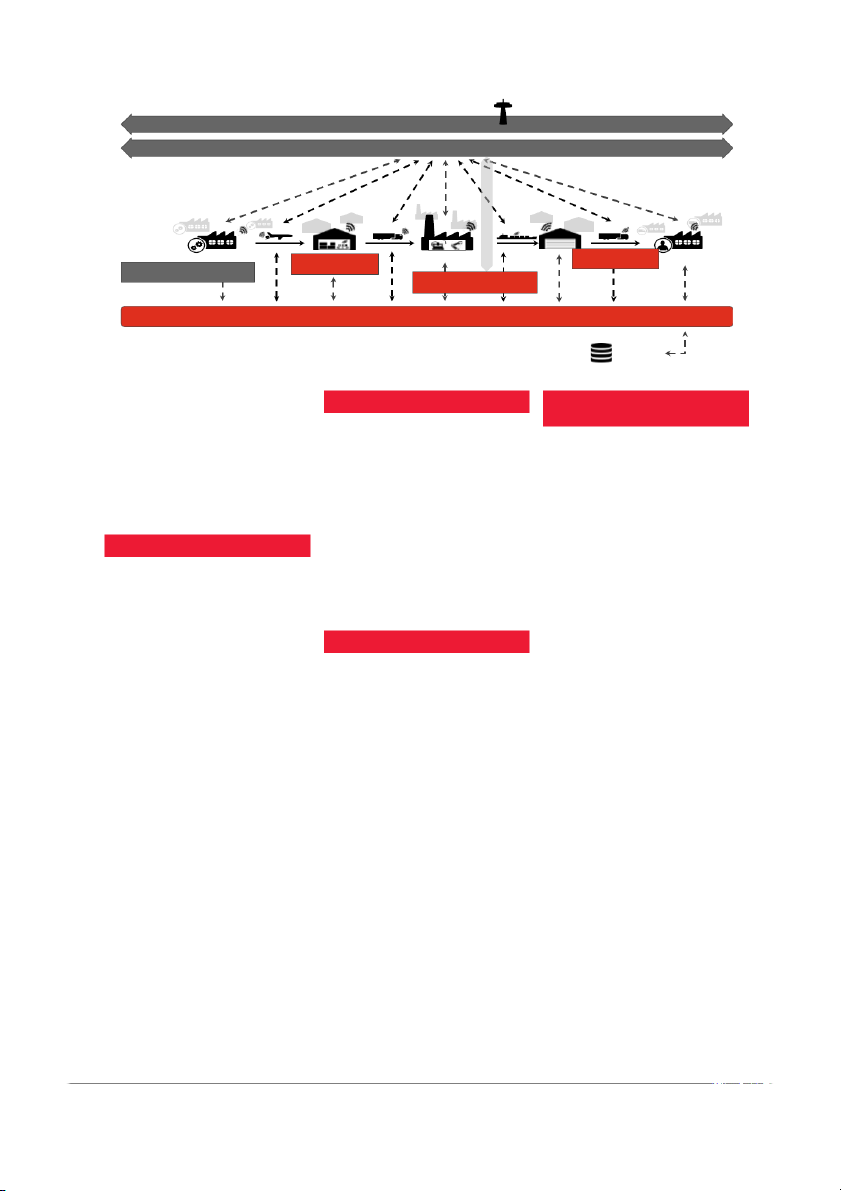

Integrated supply chain ecosystem

Traditional supply chain model Plan Plan Plan Supplier Production Distribution Customer Order & confirm Order & confirm Order & confirm

Digital Supply Chain 3

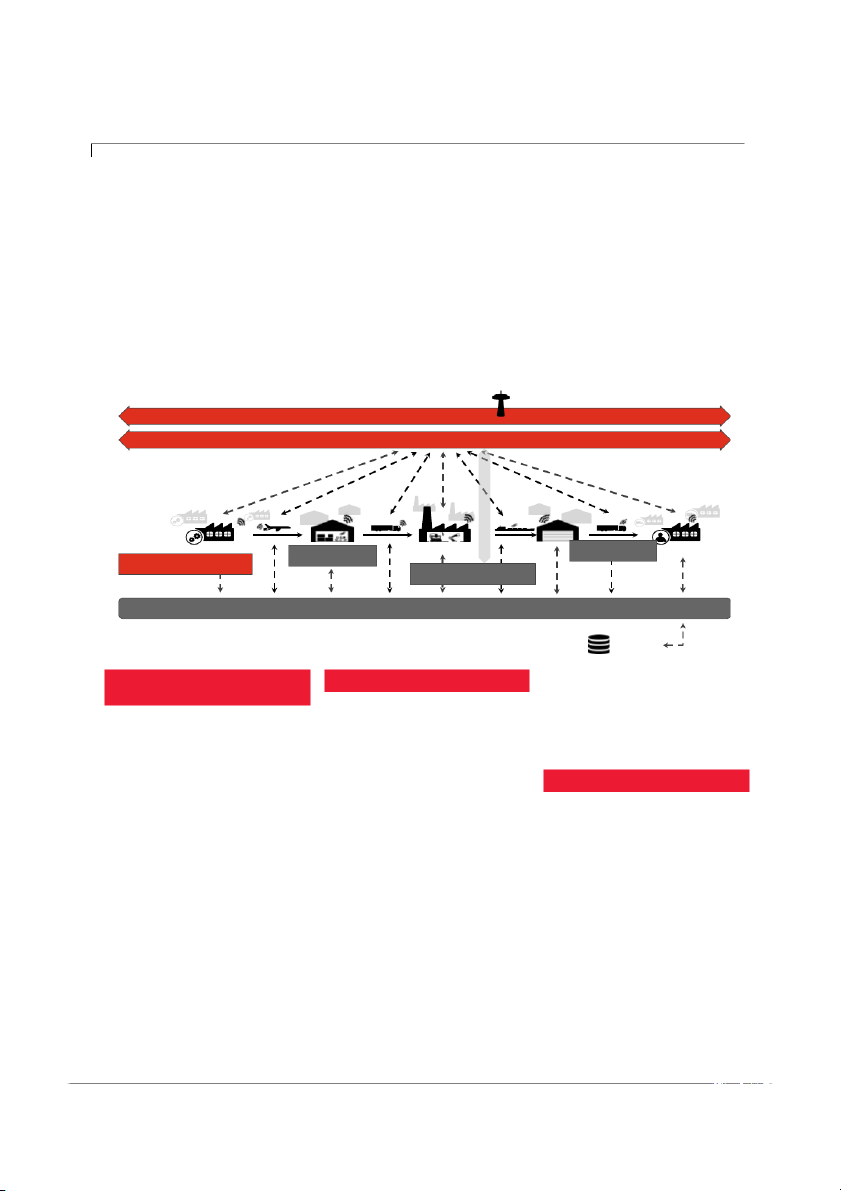

Core elements and new technolo-

gies of the Digital Supply Chain

Today most supply chains operate along traditional

warehousing, efficient spare parts management, auton-

standardized processes such as plan, source, make, deliver,

omous and B2C logistics, and prescriptive supply chain

return, and enable. Every one of these elements is rapidly

analytics (illustrated below). All of these elements are

being revitalized through technological innovation. The

interrelated, and build on each other. Consequently, a

technologies disrupting the traditional processes affect

digital supply chain strategy needs to consider all of them

seven key areas of the supply chain: integrated planning

to leverage the full benefits of digitization. Let’s look more

and execution, logistics visibility, Procurement 4.0, smart

deeply at what these critical elements mean.

Integrated planning and execution Logistics visibility V ertical Integration Supplier Production Autonomous Logistics Smart Warehousing Procurement 4.0 Smart Spare Parts Management

Prescriptive Supply Chain Analytics External data

customers of endangered arrival times

1. Integrated planning and

2. Logistics visibility

and engage in mitigation actions early. execution

Visibility on transport status, expected

The key to success for any supply chain

external impacts on lead time, and the

In a world with more customized

is efficient exchange of information,

ability to change plans accordingly, will

manufacturing and more demanding

making it visible across the entire chain. be instrumental for companies.

customers, delivering the right product

And customers, both in the B2C and

to customers as quickly as possible —

B2B markets, are pushing companies to

responsively, reliably and efficiently

provide this level of visibility across the

3. Procurement 4.0

— is a huge competitive advantage and

supply chain, demanding more infor-

is quickly becoming the new norm. By

mation about shipment arrivals with

Adopting the digital supply chain

integrating data across the entire supply real-time updates.

ecosystem will require a much closer

chain, in real time and often without

relationship between the different par-

human intervention, delivery lead times

Gathering data from across the supply

ties across the supply chain. Digitization

can be significantly reduced and freight

chain and consolidating it, enriched

tools will help companies connect more

and inventory management optimized.

with cross-referenced information such

closely with suppliers and distributers

The rapid exchange of information also

as supply chain events impacting supply

to aid the planning process, improve

boosts the agility of the entire supply

shipments (e.g. weather and traffic), will

sourcing, actively manage risk, and

chain, while enabling much closer inte-

let companies increase their efficien-

boost collaboration. Resulting in lower gration with customers.

cy by optimizing their choices under

costs and faster delivery throughout the

different conditions, using the informa- entire supply chain.

tion to alert factories, warehouses, and

4 Digital Supply Chain

Integrated planning and execution Logistics visibility V ertical Integration Supplier Production Autonomous Logistics Smart Warehousing Procurement 4.0 Smart Spare Parts Management

Prescriptive Supply Chain Analytics External data

Digitizing procurement will also trans-

5. Smart spare parts management

7. Prescriptive supply chain

form the tools and skills that companies analytics

will require. This includes companies

Spare parts have historically been kept

whose supply chain needs have solely

in high volume inventories, often or-

With a more digitized supply chain, the

been limited to physical goods, which

dered as one-time requests from differ-

number and quality of data sources will

will now have to become equally adept

ent suppliers with offshore production,

increase. This will enable companies to

at buying digital supplies and services

and kept for long periods to manage

use prescriptive analytics, to in real time

such as sensors, software, digital plat-

long-living machines. With 3D printing

adjust and optimize the supply chain to form solutions, etc.

the spare parts supply chain can be re-

any number of changing factors across

duced to fewer suppliers, even enabling the entire supply chain, E2E.

4. Smart warehousing

own production. Hence, spare part pro-

duction can be done closer to customers,

As analytics become increasingly ad-

New technology or new usage of exist-

removing the need to follow cheap labor

vanced and sophisticated, it will be able

ing technology (e.g. sensors, connectivi-

rates. Resulting in faster delivery and

to better support supply chain managers

ty, etc.) is significantly improving ware-

significantly reduced inventory levels.

in decision-making. Additionally, with

housing operations, including inbound

the help of self-learning algorithms,

logistics and distribution. Managing the

prescriptive analytics will be able to

6. Autonomous logistics

data by an intelligent warehouse man-

act autonomously on simple decisions,

agement system and updating inventory

improving efficiency in the supply chain

Transportation of goods between

status in real time, will enable an opti- process.

B2B, within production facilities, and

mized flow through the warehouse.

between B2C (the last mile) constitutes

Embracing the technological advance

PwC has seen examples where pro-

an integral part of the supply chain. will allow:

gress in analytics is being made within

Logistic fleets will include numerous

individual steps of the supply chain.

• Trucks on the way to a warehouse to

driverless vehicles and other robotic

The challenge companies are facing,

communicate their position, load, and

innovations (e.g. drones), which will

is to connect and integrate these steps

arrival time prior to arrival, allowing

play an increasingly important role in

horizontally so that they can reach the it to be optimally planned;

moving goods around the world.

supply chain eco-system that PwC pre-

• RFID-GPS tags to update the entire dict is the future.

supply chain on goods location and

The virtues of such innovations include once they have been delivered;

faster and more reliable delivery times,

lower labor costs, the elimination of

• Guiding tools to significantly enhance

human error, and reduced emissions

the workforce efficiency and accura-

thanks to more efficient operations, such cy; and,

as routing and convoying of trucks.

• Control the warehouse environment,

Additional benefits can include im-

(e.g. temperature, light and humidi-

proved on-site employee safety and

ty), reducing energy consumption.

freeing up resources to conduct more value-adding tasks.

Digital Supply Chain 5 Blueprint for Success

Understand your starting point and map out your strategy

Many businesses have already begun digitizing, but often in silos rather than via a holistic

approach. Hence, it is important to understand the digital maturity and how to leverage the

existing strengths. When developing the company vision, consider the supply chain design 1

that best supports it, the road map and necessary implementation steps, and the champions

who need to be engaged to achieve the vision. Deploy pilot projects

Many applications that make up the digital supply chain represent a radical change for most

organizations. Companies should first carry out smaller pilots that showcase benefits and

help develop the right capabilities. These “lighthouse” projects should aim at testing the 2

end-to-end flow for a specific supply chain (rather than implementing a limited set of tech-

nologies on a broader scale) and gain buy-in from the organization as well as funding for a larger roll-out. Define the capabilities needed

Building on the lessons learned from the pilot projects, it is important to define what capa-

bilities across the four dimensions: organization structure (e.g. incubator, idea labs, etc.),

people (e.g. attract the right skills), process (e.g. processes to foster new collaboration), and 3

technology (e.g. develop an agile IT function); that are required to make the roll-out of the pilot projects successful. Becoming a data virtuoso

Key to successfully adopting Industry 4.0 will be to identify, gather, and use data correctly,

as well as analyzing it efficiently. Developing an effective data analytics strategy, and how it

will be implemented is essential. Considerations will include data platforms, development 4

of a master data management procedure, and organizational structure (e.g. starting with a

cross-functional expert team before fully embedding the capabilities in a standalone function).

Transform into a digital enterprise

Even for companies whose supply chain needs have solely been limited to physical goods, it

will be essential to transform the company culture. A digital culture and mindset is highly

collaborative and crosses company boundaries to include partners and customers. To suc- 5

cessfully implement such a mindset change, it is important that there is a strong leadership

commitment from top management.

Actively plan an ecosystem approach

Industry 4.0 needs to extend far wider than horizontal and vertical integration within an organi-

zation. Breakthrough performance is achieved when companies understand consumer behavior

and offer a comprehensive digital ecosystem and orchestrate its role within an ecosystem of 6

partners, suppliers and customers. The biggest challenge will be to set the right incentives and

find suitable sharing models that compensates everyone fairly for their contribution.

6 Digital Supply Chain

Digital Supply Chain 7

Want to learn more?

PwC Sweden is the market leader within

Please do not hesitate to contact us

auditing, tax and advisory services, with 2,800

people at 34 offices throughout the country.

Using our experience and unique business know-

ledge, we enhance value for our 45,000 clients,

who are comprised of global companies, major

Swedish companies and organisations, smaller Peter Malmgren

and medium-sized companies, primarily local, 0723 – 53 00 20 and the public sector. peter.malmgren@pwc.com

PwC Sweden is a separate and independent legal

entity. We are the Swedish member firm of the

PwC global network. More than 236,000 people Tobias Kihlén

in 158 countries across our network share their 0725 – 84 98 43

thinking, experience and solutions to develop

tobias.kihlen@pwc.com

fresh perspectives and practical advice. www.pwc.se James Persson 0725 – 84 92 79

james.persson@pwc.com

© 2018 PricewaterhouseCoopers i Sverige AB. Whole or partial duplication of the contents of this document is forbidden in

accordance with the Swedish Act on Copyright in Literary and Artistic Works (1960:729). This prohibition applies to every form

of duplication by printing, copying, etc.