Preview text:

lOMoAR cPSD| 58675420 299

Journal of Intelligent and Robotic Systems 40: 299–320, 2004.

© 2004 Kluwer Academic Publishers. Printed in the Netherlands.

Fuzzy PID Control of a Five DOF Robot Arm G. M. KHOURY

Saint-Joseph University, ESIB, Sciences and Technologies Campus, Mar Roukoz, Mkalles, Lebanon M. SAAD

University of Quebec, ETS, 1100 Notre-Dame Street West, Montreal, Quebec, Canada H. Y. KANAAN and C. ASMAR

Saint-Joseph University, ESIB, Sciences and Technologies Campus, Mar Roukoz, Mkalles, Lebanon

(Received: 20 June 2003; in final form: 15 March 2004)

Abstract. This paper studies the application of fuzzy logic control on a five degrees of freedom

(DOF) robot arm, the Maker 100 of U.S. Robots. The elaboration of the fuzzy control laws is based

on two structures of coupled rules fuzzy PID controllers. The fuzzy PID controllers are numerically

simulated and the simulation results confirm the success of the fuzzy PID control in trajectory

tracking problems. Seeking a performance optimization, a systematic study of the choice of tuning

parameters of the controllers is done. The success of the proposed fuzzy control law is again affirmed

by a comparative evaluation with respect to the computed torque control method and the direct

adaptive control method, the last two controls being also numerically implemented using the same

dynamic model of the robot arm.

Key words: five DOF robot arm, fuzzy control, numerical simulation, PID controllers. 1. Introduction

The use of industrial robots became identifiable as a unique device in the 1960s.

Since then, their field of application evolved from rather simple tasks like welding

and painting to those requiring more precision, such as assembly tasks.

Control theory provides tools for designing and evaluating algorithms to realize

desired motions or force application. The methods of linear control and those of

local linearization and moving linearization are not well suited for the control

problem of robotic arms. This is due to the fact that robotic arms constantly move

among widely separated regions of their workspace such that no linearization valid

for all regions can be found. On the other hand, nonlinear control methods are

progressing nowadays and different classes could be identified [13]: Trialand- lOMoAR cPSD| 58675420 300 G. M. KHOURY ET AL.

Error, Feedback Linearization Control, Robust Control, Adaptive Control, and

Gain-Scheduling. Nonlinear control methods used in robot arms’ applications

should however face the major difficulty resulting from the dynamic modeling of

robots, i.e. the indetermination of their parameters [3]. Preferred methods are those

which reduce or eliminate the undesired effects generated by this indetermination

such as the Feedback Linearization control method [13], the Model-Reference

Adaptive control method [12, 13] and the Self-Tuning method [13]. Another

difficulty in robot arm control is the coupling effects of the coriolis and centrifugial

forces that might be canceled in a single axis mode operation where the joints are

activated sequentially. Existing methods of nonlinear control are also used in

robotics in order to eliminate the above mentioned coupling effect like the

Individual Joint PID control method [3] and the PD-plus-gravity control method [3].

Among the recent nonlinear control methods, fuzzy control methods grab

nowadays the attention of many researchers. In fact, these methods do not require

the knowledge of the dynamic model of the controlled system. This feature

becomes of major importance when dealing with complex nonlinear systems.

Moreover, the dynamic modeling of robot arms shows a dependency on their

mechanical parameters, subject to lifetime modifications (friction factors affected

by the abuse of joints), and on their dynamical parameters that vary with the

performed task (centers of gravity of the links affected by tool’s replacements).

These considerations also give advantage to fuzzy control methods on other

nonlinear methods as a result of their robustness towards perturbations affecting the system.

The first fuzzy logic controller was introduced by Mamdani in 1974 [7]. It is

equivalent to two-input fuzzy PI controllers, where error and change of error were

used as the inputs of the inference system. Mamdani’s work also introduced the

most common and robust fuzzy reasoning method, called Zadeh–Mamdani min–

max gravity reasoning. Different comparative studies, like [5], prove that Zadeh–

Mamdani min–max gravity scheme is the best reasoning scheme if the nonlinearity variation is a main concern.

Although control methods, especially nonlinear control methods, had greatly

evolved, the proportional-integral-derivative (PID) control method is still widely

used in all domains [2]. The success of the PID control is attributed to its simplicity

(in terms of design and tuning) and to its good performance in a wide range of

operating conditions. However, the neccesity of retuning the PID controllers

characterizes their major disadvantage when the controlled plant is subject to

disturbances or when it presents complexities (non-linearities).

The majority of applications of fuzzy control methods during the past two

decades belong to the class of fuzzy PID controllers. These fuzzy controllers can

be classified into three types: the direct action (DA) type in which the inference lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 301

system provides the main control action, the gain scheduling (GS) type [18] where

the inference system provides instantaneous adjustments on the gains of a classical

linear PID controller, and a combination of DA and GS types. A comparative study

held in [5] shows that the nonlinear equivalent model of a DA-type fuzzy PID

controller is simpler than that of a GS-type fuzzy PID controller where the

nonlinearity is hard to aquier. As a result, the majority of used fuzzy PID

controllers is of the DA-type.

The main objective of this paper is to study and analyse the adaptation of

existing fuzzy DA PID structures to the trajectory tracking control of a robotic

arm containing high nonlinearities. Performance evaluation of the closed loop

system will focus on the ability of the fuzzy PID structures, in terms of tracking

precision and robustness, to control the arm.

This paper is divided into 7 sections. Section 2 introduces the five degrees of

freedom robot arm Maker 100 and its dynamic model. In Section 3, two structures

of DA fuzzy PID controllers are presented along with their tuning method. Section

4 deals with the integration of the fuzzy structures in the control loop while Section

5 is reserved to the numerical simulation of the control laws and a study of the

results and performances. Section 6 provides a comparative evaluation of the fuzzy

PID control method in respect to other methods of nonlinear control, the computed

torque control method and the direct adaptive control method. Finally, Section 7

discusses the benefits of the studied fuzzy control law and proposes

recommendations for a productive continuity in this line of research. 2. The Maker 100

The Maker 100 of U.S. Robots is a five DOF robot arm. All its joints are revolute

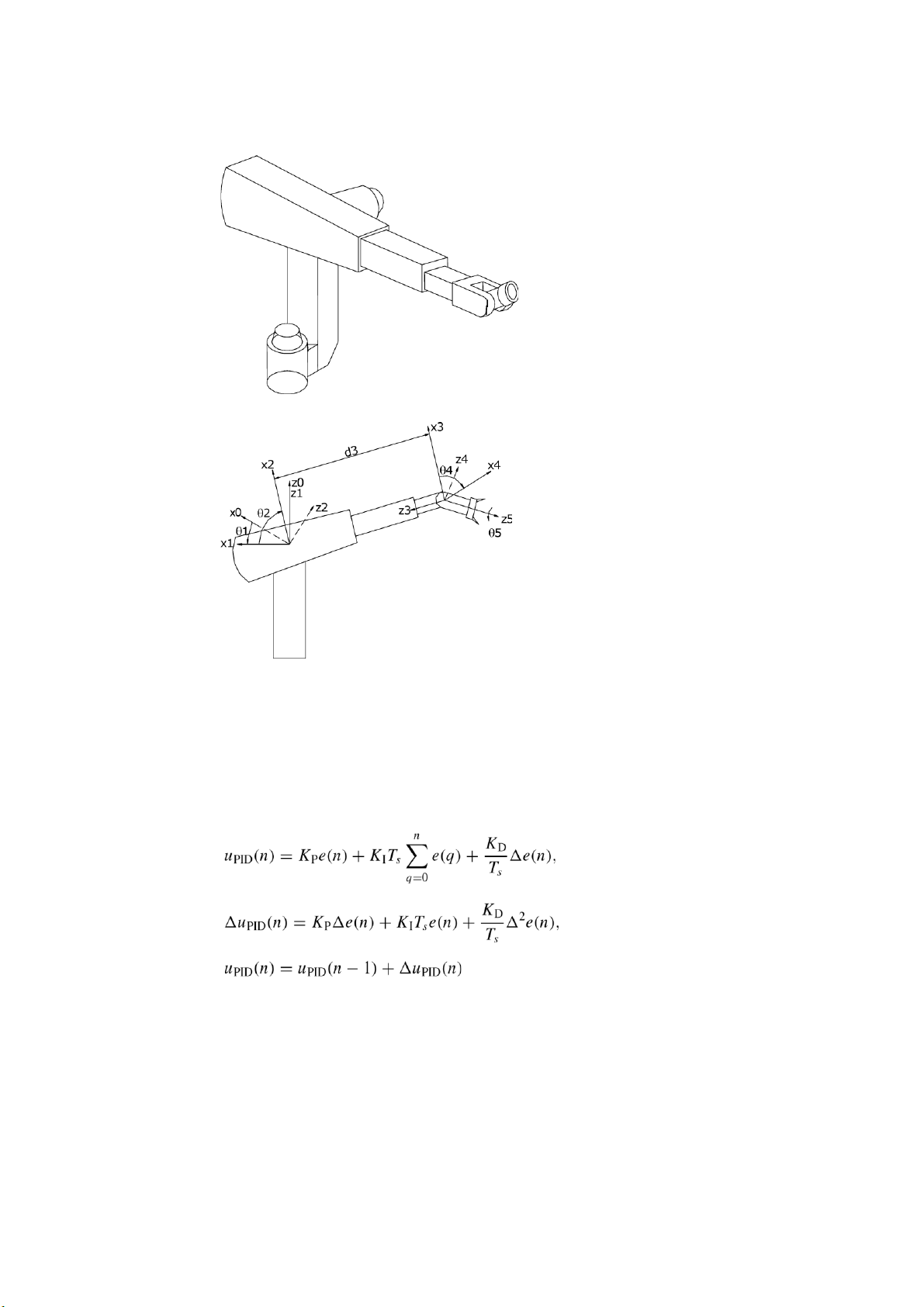

joints except the third, which is prismatic. Figure 1 shows the Maker 100 while

Figure 2 shows its structural state variables.

The dynamic model of the Maker 100 is given by Equation (1).

τ = M(q)q¨ + V(q,q)˙ + G(q) + F, (1)

where: τ = [τ1 τ2 τ3 τ4 τ5]T the joint input torque vector, q = [θ1 θ2 d3 θ4 θ5]T the joint

position vector, q˙ = [θ˙1 θ˙2 d˙3 θ˙4 θ˙5]T the joint velocity vector, q¨ = [θ¨1 θ¨2 d¨3 θ¨4

θ¨5]T the joint acceleration vector.

Note that vectors q, q˙ and q¨ are defined in the joint space.

And: M positive definite inertia and mass matrix, V matrix of coriolis and

centrifugal forces, G state varying vector of gravity terms, F state matrix of friction terms. M(q),V(q,q),G(q)˙

and F are given in Appendix A. lOMoAR cPSD| 58675420 302 G. M. KHOURY ET AL. Figure 1. Maker 100.

Figure 2. State variables representation.

3. Fuzzy PID Structures

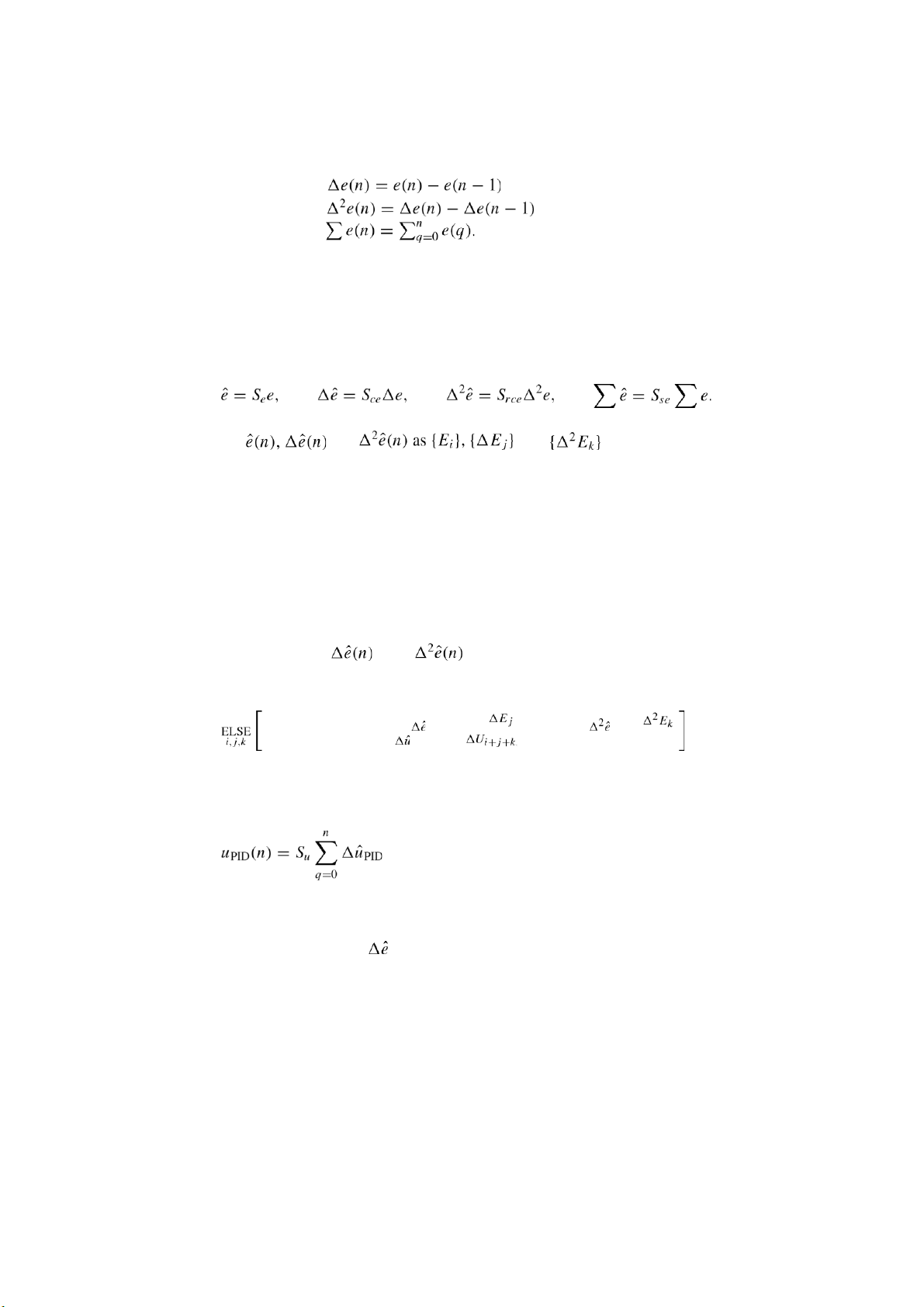

Refering to [8], the control signal of a linear PID at any given time instance n with

a sampling time Ts can be expressed in its absolute form, expression (2), or in its

incremental form, expression (3). (2) (3) where .

The terms KP, KI, and KD stand for proportional, integral, and derivative gains,

respectively. The error state variables are defined as: lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 303 Error e(n) = y(n) − yd(n), Error change , Rate of error change , Sum-of-error

The term y(n) is the feedback response signal, and yd(n) is the desired response or

reference input at the nth sampling instant. In a fuzzy PID controller, the error

terms in (2) or (3) are expressed in a linguistic form and the fuzzy rules are used

to infer a fuzzy control action. Scale factors Sx for each error state variable x are

defined to obtain the normalized error terms, whose values are chosen within the range [−1,1], as:

Finally we define the linguistic variables that correspond to the input scaled variables , and , and respectively, where:

i = 0,1,2,... ,Ne − 1; j = 0,1,2,... ,Nce − 1; k = 0,1,2,... ,Nrce − 1.

Ne, Nce, and Nrce denote the total numbers of fuzzy membership functions assigned

for each of the fuzzy linguistic variables.

3.1. THREE-INPUT FUZZY LOGIC CONTROLLER (FLC) STRUCTURE WITH COUPLED RULE The inputs are ê(n), , and

, corresponding to an incremental type

fuzzy PID controller as shown in Figure 3.

The rule base structure can be expressed by: IF eˆ IS Ei AND IS AND IS . THENPID ISPID

The final PID control output is produced after taking the cumulative sum of the

FLC output given by expression (4). (q). (4)

3.2. TWO-INPUT FLC STRUCTURE WITH COUPLED RULE Having the inputs eˆ and

as the useful PID elements for fuzzy control, by

combining both PI and PD actions as shown in Figure 4, a two-input fuzzy PID

controller can be formed. The rule base structure is identical to Mamdani-type fuzzy PI controller. lOMoAR cPSD| 58675420 304 G. M. KHOURY ET AL.

The basic rule base of this conventional type is given by: ELSEIF eˆ IS Ei AND IS . i,j THEN PD IS PD

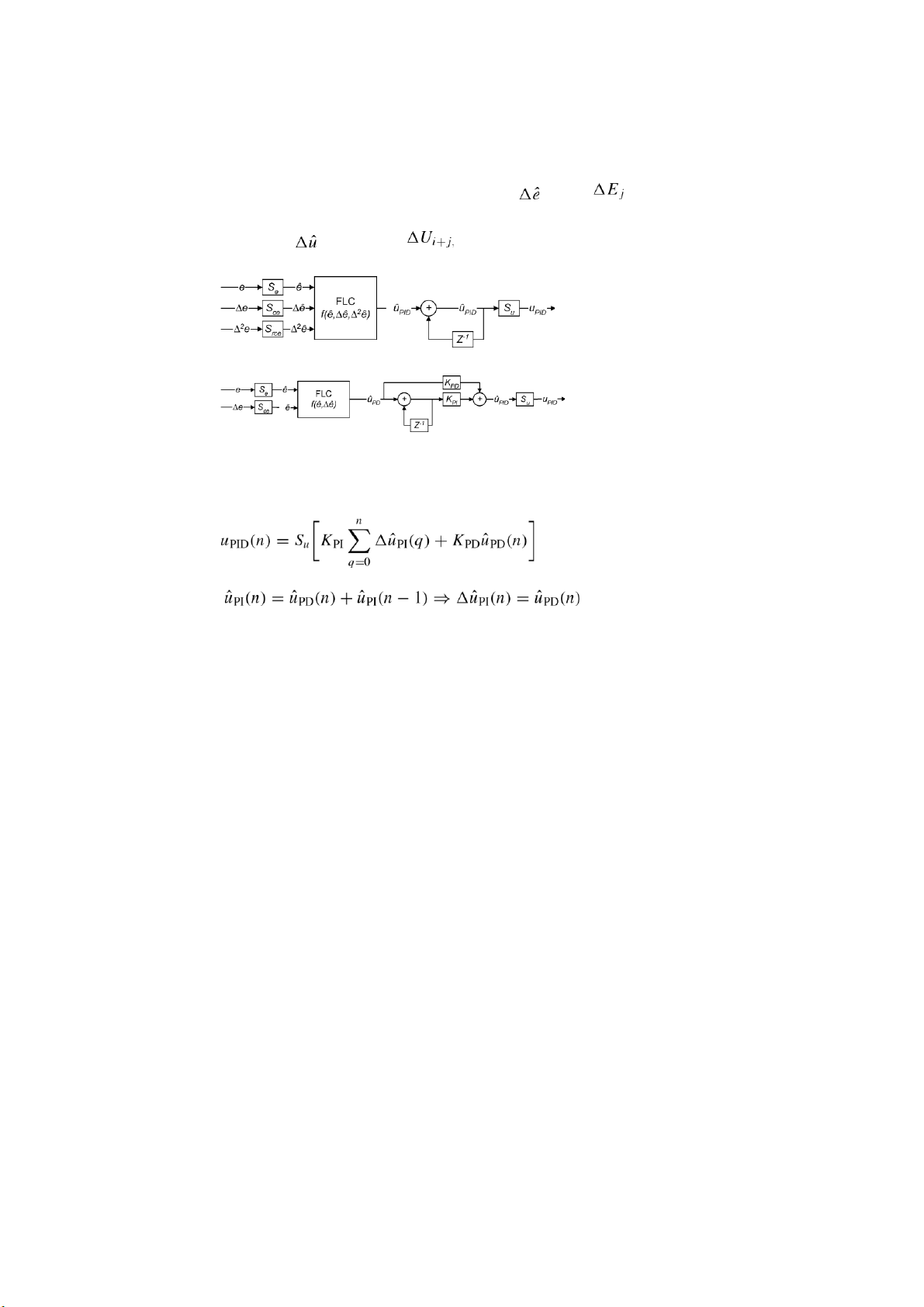

Figure 3. Three-input fuzzy PID controller.

Figure 4. Two-input fuzzy PID controller.

With the additional gains KPD and KPI, the final PID control signal shown in Figure 4 is given by expression (5). , (5) where . 3.3. INFERENCE SYSTEM

The output of each fuzzy inference system is derived using the standard Zadeh–

Mamdani’s min–max gravity reasoning method.

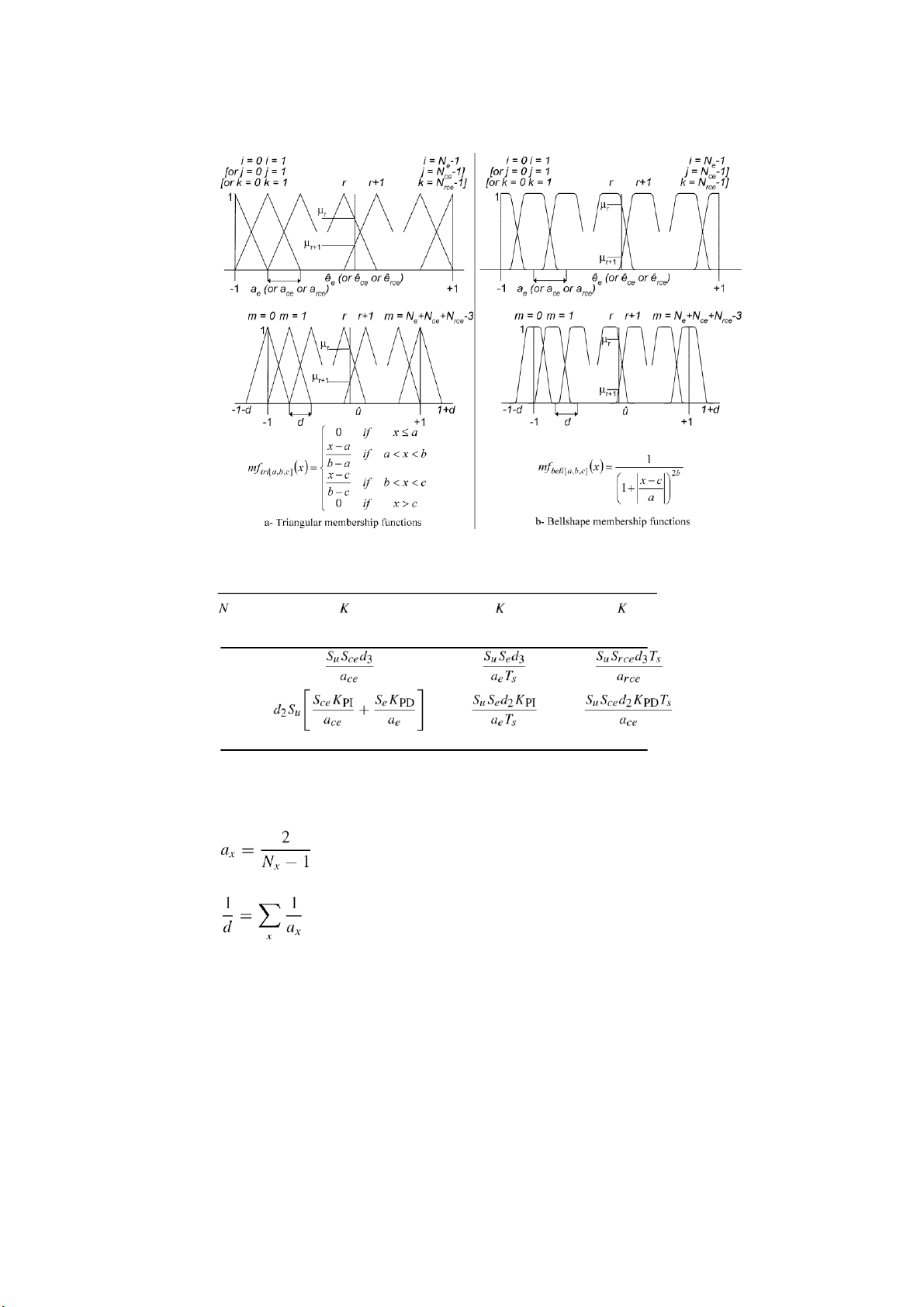

The universe of discourse of each input variable is defined to be within the

range [−1,1]. For simplicity we will use symetrical triangulare or bellshape

membership functions as shown in Figure 5. Any other symetrical shape

membership function can be used. Let ax be the corresponding distances between

two adjacent input memebership functions for the fuzzy input x. The output

linguistic variables are defined within the universe of discourse of [(−1 − d),(1 +

d)] where d is the distance between two adjacent output membership functions. The factor d is derived lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 305

Figure 5. Membership functions’ distribution of fuzzy inputs and output of a three inputs fuzzy PID.

Table I. Apparent linear gains for the three and two-input fuzzy PID controllers Pa Ia Da 3 2

from the choice of the number of membership functions Nx of the input variables x via the formulas: , (6) . (7) lOMoAR cPSD| 58675420 306 G. M. KHOURY ET AL. 3.4. TUNING LEVELS

Any fuzzy PID structure together with its fuzzy knowledge base usually results in nonlinear PID actions.

The first level of tuning relates to the normalized nonlinear characteristics and

is usually obtained by changing the knowledge base parameters of the fuzzy system.

The second level of tuning is related to scale factors and other gain parameters

used in constructing the fuzzy PID system. This second tuning level determines

the overall characteristics of the controller. For this purpose, we define the so

called PID apparent linear gain (ALG) terms: KPa, KIa, and KDa. Note that the

definition of the ALG terms in [8] imposes that (1) the universes of discourse of

all input variables are uniformely partitionned; (2) the membership functions are

placed with 50% overlap supports and; (3) the rules are defined in a linear form.

In practice, the choice of the ALG terms is a trial and error tuning process.

However, the behavior of these gains is expected to be linearly equivalent to

conventional PID gains. A pole placement method [9] could therefore be used to

determine the values of the ALG terms. Once these values are obtained, the scale

factors and structural gains could be deduced. Other tuning methods are also

studied in [10, 16] and [17]. Table I, where N is the number of fuzzy inputs, gives

the ALG terms for the two PID structures used in this paper.

4. Integration of the Fuzzy PID Controller in the Control Loop

The dynamic model of the Maker 100 shows important nonlinearities. For each

joint an individual PID controller will be used. In this respect, it should be

emphasized that the coupling effects between the joints are not thus taken into

consideration by the controller. Clearly, this is a difficulty, which is to be alleviated

by the fuzzy PID controller by means of the nonlinearity of its inference system.

A similar uncoupled structure of fuzzy controllers is used in [4] for the tracking

problem of a two DOF robot arm. The study proved to be a success (maximum

peak to peak relative position error of 0.158%) of the tracking loop thanks to an

online mechanism of adjustment on the aggregation operator of rule premises.

The control will take place on the state variables in the joint space. Each joint

has it’s own PID controller. The control action of the fuzzy PID controllers was

scaled to a torque control action apllied to the Maker’s dynamique model, the

denormalization factor Su was so multiplied by a scaling factor of 10. For

simplicity, the parameters of those controllers are fixed similarly. This choice

eliminates the possibility of refining the control on some DOF more than on others.

Moreover, the choice of the same parameters for an angle measured in degrees and

a distance measured in meters is somehow unreasonable, but the fact that the lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 307

tracking position error should stay relatively small makes all DOF comparable.

However, this assumption will have to be verified later.

On the other hand, the attribution of numerical values for the normalization and

denormalization factors is largely related to the amount of error acceptable in the

feedback system. Enlarging the input interval [−1/Sx,1/Sx] to all the admissible

position error [−Emax-admissible,Emax-admissible], where Emax-admissible corresponds to the

maximal applicable step reference input to the joint state variable x, (i.e. Emax-

admissible = max[Xdesired-reference-position − Xactual-measured-position] over the whole working

space of the corresponding joint), will increase the tracking performance for the

maximal step reference input but will largely decrease its sensitivity and

performance towards small displacements of this joint. In fact, if the normalization

was tuned to increase the control sensitivity towards large displacements of the

corresponding joint, a small displacement of this joint will only involve a limited

number of membership functions, those located around zero, and consequently

only a few rules will be activated throughout the whole trajectory tracking

problem. Moreover, if the user seeks precision rather than speed, he should apply

a position step reference relatively close to the joint’s actual position. For this last

purpose, a fine trajectory generation should be used in order to optimize the overall

performance of the closed loop system.

In this paper, the tracking trajectory in the end-effector space is assumed to be

linear since the majority of robotic applications requier linear trajectories in their

working space. In fact, the robot follows the triangle reference trajectory defined

in the next section. The trajectory generation is based on the Bounded Deviation

Method [11], which was proposed by Taylor in [14], using third order polynomial

sub-trajectories [12] and a boundary of precision of 0.001 m on the Cartesian

endeffector trajectory around the theoretical desired linear trajectory.

5. Numerical Simulation of the Fuzzy Control System

The trajectory has a triangular form. The Cartesian coordinates of its corners are

listed in Table II where p stands for the pitch and r for the roll. The manipulator’s

end-effector will make a full turn of the trajectory in 20 s.

The trajectory generator, the five fuzzy PID controllers and the dynamic model

of the Maker 100 were simulated using Matlab/Simulink [15]. The sampling time

Ts is chosen to be 0.001 s for all simulations.

The performance of the fuzzy PID controllers were tested via two error

variables: (1) the absolute average position tracking error e¯i and (2) the relative

peakto-peak position tracking error eipp. The reader is invited to consult Appendix

B for the definition of these two error variables. lOMoAR cPSD| 58675420 308 G. M. KHOURY ET AL.

5.1. TWO-INPUT FUZZY PID CONTROLLER – KNOWLEDGE BASE DIMENSIONS

After a performance optimization sequence of trials, a preliminary study on the

effect of the number of rules in the inference system for the two input fuzzy PID

was held for multiple cases of rule base dimensions. Table III summarises the

different simulation results in the case of triangular membership functions.

Table II. Desired trajectory Point x (m) y (m) z (m) p (radian) r (radian) A 0.4 0.4 0.4 0 0 B 0.6 0 0 −π/2 π/20 C 0 0.6 0 −π/4 π

Table III. Position tracking errors for multiple cases of rule base dimensions Inference system

Relative peak-to-peak position tracking errors in parameters the joint space N1 N2 NRules e1pp (%) e2pp (%) e3pp (%) e4pp (%) e5pp (%) 3 3 9 0.0034 0.0030 0.0180 0.0039 0.0001 3 7 21 0.0024 0.0029 0.0108 0.0023 0.0078 5 5 25 0.0030 0.0025 0.0157 0.0034 0.0001 5 9 45 0.0022 0.0025 0.0110 0.0023 0.0156 7 3 21 0.0055 0.0046 0.0312 0.0069 0.0001 7 7 49 0.0026 0.0023 0.0142 0.0030 0.0005 9 5 45 0.0038 0.0027 0.0209 0.0046 0.0001 9 9 81 0.0026 0.0022 0.0148 0.0030 0.0005

It is clear from the tracking errors in Table III that, excluding the fifth degree

of freedom, the tracking precision is improved by increasing the number of

membership functions per fuzzy input. This is a direct result to the increase of

precision in the repartition of membership functions along the universe of

discourse of fuzzy inputs. On the other hand, enlarging the rule base dimension

will not only increase the nonlinearities of the fuzzy inference system but will also

slow down the response of the numerical controllers. In fact, for the inference

system to be easily acquired by the designer, it is more suitable to limit its

dimension since the tracking precision improvement is around 25% for an

enlargement of the rule base dimension of 800% (9 rules versus 81 rules fuzzy knowledge base). lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 309

By comparing cases of equal and non-equal numbers of membership functions

per fuzzy input, it is obvious that an increase in precision on the “change of error”

fuzzy input, {N1 = 3 and N2 = 7}, provides improvement on the tracking errors better

than that of enlarging precisions on both fuzzy inputs, {N1 = 7 and N2 = 7} and even

{N1 = 9 and N2 = 9}. This case is true for the first, third and fourth joint variables

where the improvement of the precision reaches 40% (on the fourth joint variable)

for an enlargement of the rule base dimension of 130% ({N1 = 3 and N2 = 7} versus

{N1 = 3 and N2 = 3}). However, this is not true for the second joint variable which

precision slightly improves and for the fifth joint variable which precision considerably decraeses.

As for the behavior of the fifth joint variable, unlike all othe joint variables, it

shows a non-dependancy towards the precision on the “error” fuzzy input and an

inversed dependancy towards its “change of error” membership functions ditribution precision.

The end-user is therefore invited to take advantage of the offered diversity on

the performances of the trajectory tracking problem on the five degrees of freedom

by tuning the fuzzy inference system parameters according to his application’s needs.

Finally, as a compromise and in order to emphasize the effect of the parameters

discussed below, unless otherwise mentionned, the case of {N1 = 3 and N2 = 3} will be used.

5.2. TWO-INPUT FUZZY PID CONTROLLER – MEMBERSHIP FUNCTIONS SHAPE

With the two inputs PID controller, a set of trial and error simulations led to the

optimization of the tracking problem. The values of the PID parameters are listed

in Table IV while the corresponding tracking error values for the five DOF are

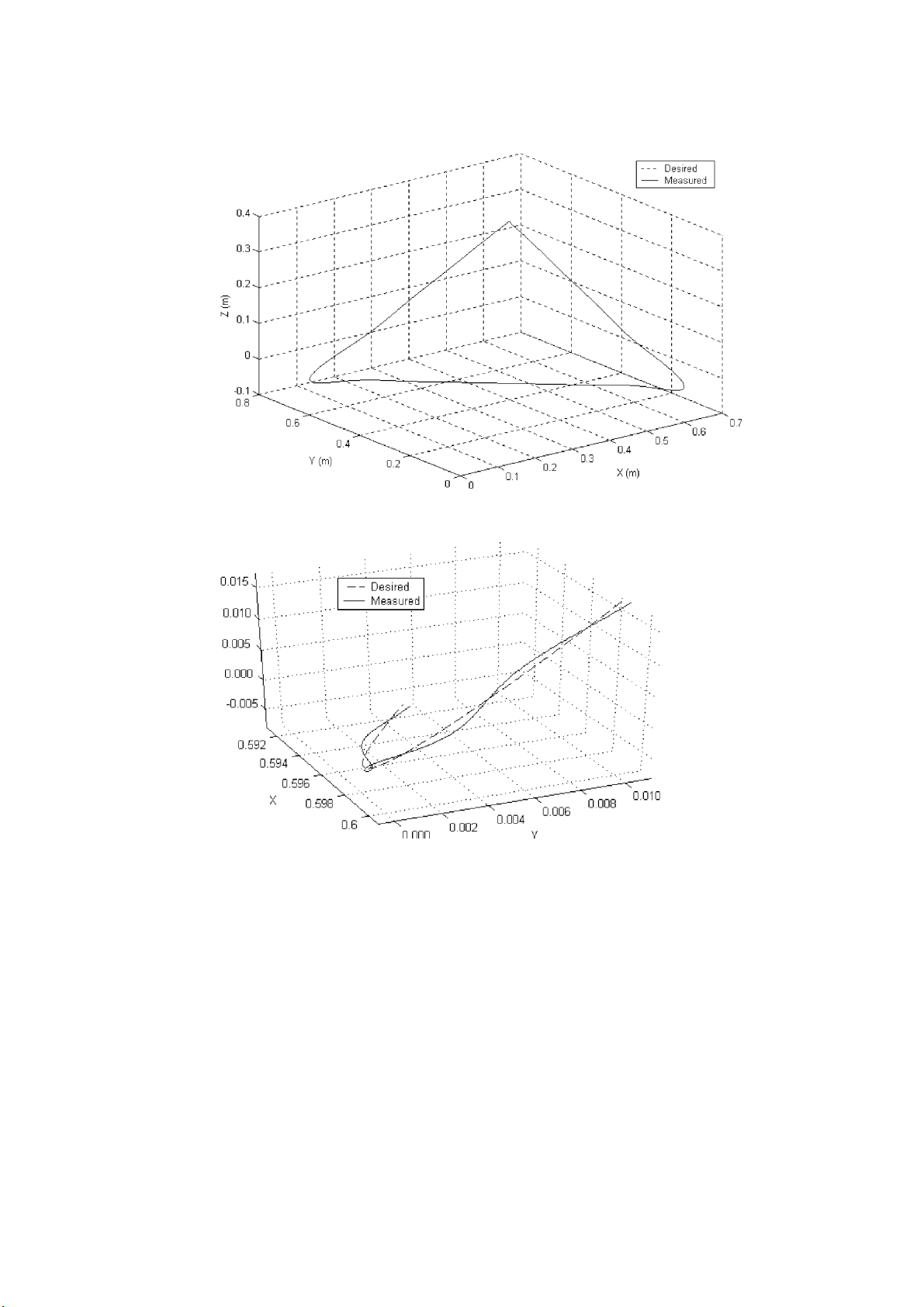

shown in Table V for multiple cases of membership function parameters. Figure 6

shows the desired and measured Cartesian trajectories of the manipulator’s

endeffector for the case of triangular membership functions with {N1 = 3; N2 = 3}

while Figure 7 gives a closer look to change in direction at point B (Table II) in

the case of bell shape membership functions with {N1 = 5; N2 = 5; b = 5}. The two

trajectories are superimposed in Figure 6 while the trajectory-tracking problem is

better illustrated in the case of Figure 7 where the performance is poorer. Figure 8

Table IV. Fuzzy PID controller tuning parameters Proportional integral gain KPI 7.97 Proportional derivate gain KPD 6.83 Denormalization factor Su 260 Normalization factor Se 5 lOMoAR cPSD| 58675420 310 G. M. KHOURY ET AL. Normalization factor Sce 2500

Table V. Position tracking errors for multiple cases of membership functions

Inference syst em pa ramete rs Absolute average

tion trackin g errors in th e joint posi space Membership N1 N2 b

e¯1 (deg) e¯2 (deg) e¯3 (mm) e¯4 (deg) e¯5 functions (deg) Triangular 3 3 – 0.0003 0.0002 0.0019 0.0001 0.0000 Triangular 5 5 – 0.0003 0.0002 0.0017 0.0001 0.0000 Bell shape 3 3 1 0.0008 0.0005 0.0045 0.0002 0.0000 Bell shape 3 3 5 0.0610 0.0613 0.1199 0.0229 0.0009 Bell shape 5 5 1 0.0007 0.0004 0.0038 0.0002 0.0000 Bell shape 5 5 5 0.0264 0.0265 0.0701 0.0098 0.0005 Inference system parameters

Relative peak-to-peak position tracking errors in the Cartesian space Membership N1 N2 b ex pp (%) ey pp (%) ezpp (%) eppp (%) er pp (%) functions Triangular 3 3 – 0.0035 0.0063 0.0085 0.0001 0.0026 Bell shape 3 3 1 0.0086 0.0149 0.0208 0.0002 0.0064

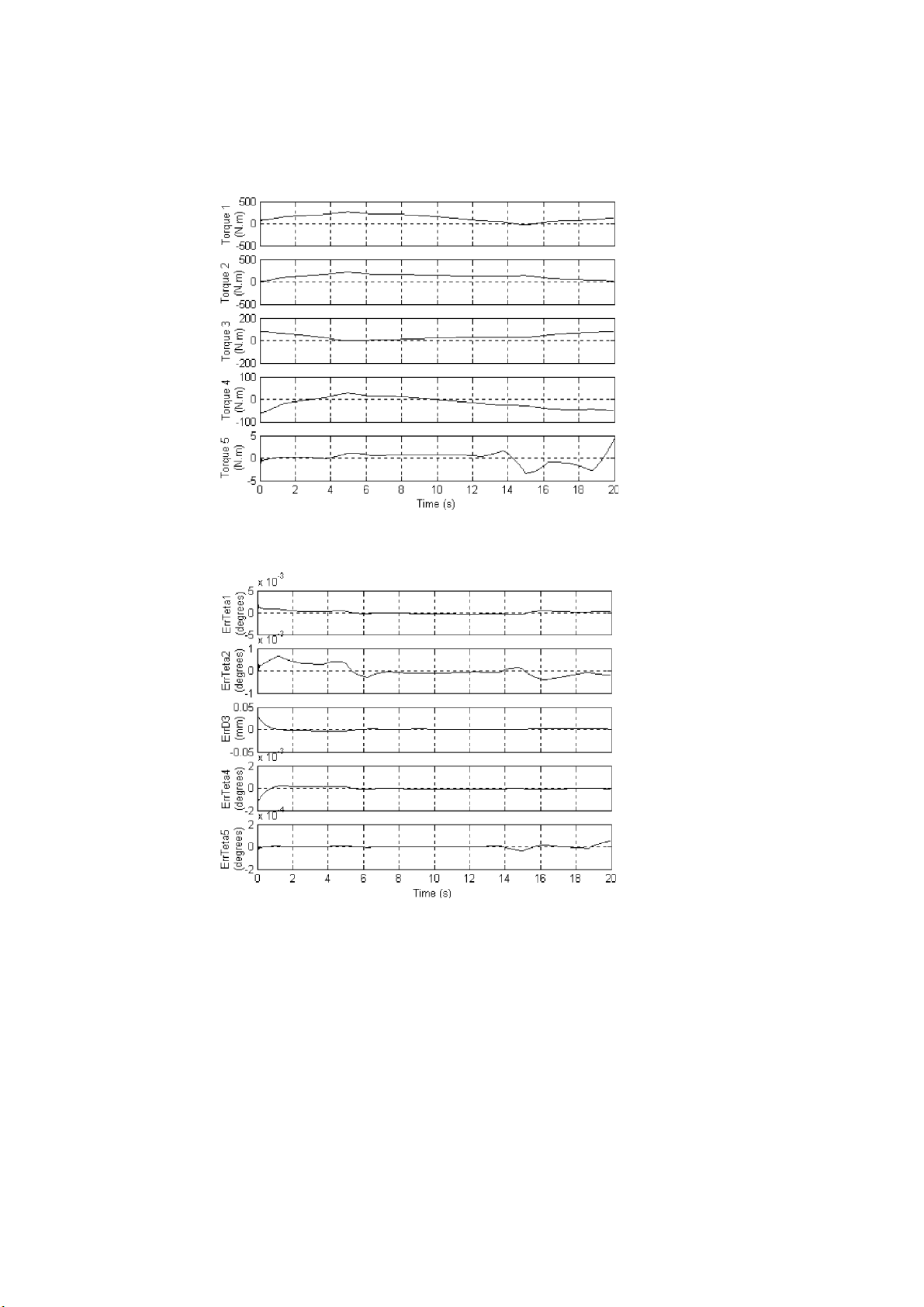

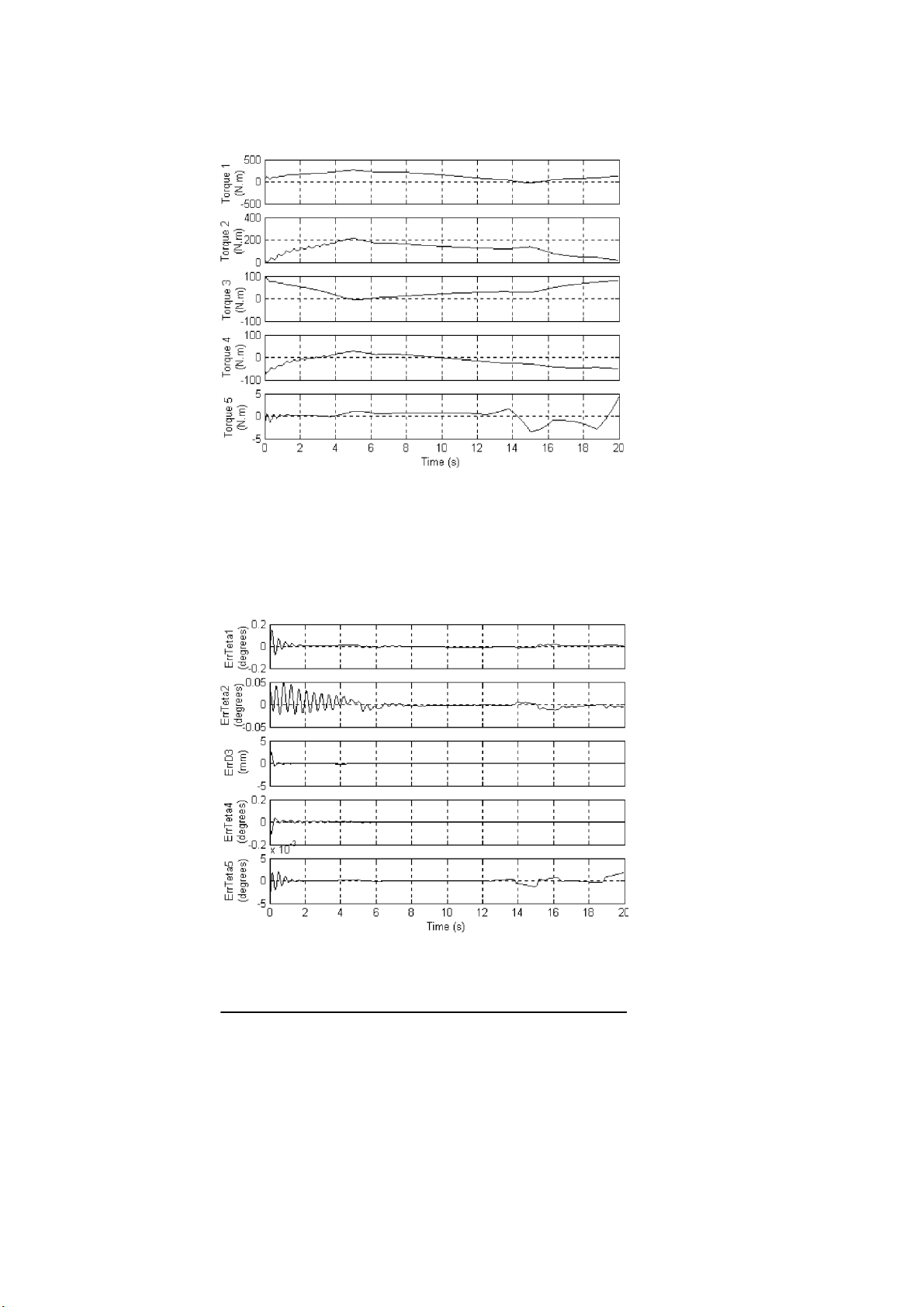

shows the instantaneous joint input torques and Figure 9 the resulting

instantaneous absolute position errors in the joint space for the case of triangular

membership functions with {N1 = 3; N2 = 3}.

Position tracking error values in Table V prove the success of the

implementation of the PID fuzzy control to the trajectory tracking problem of the

robotic arm. The use of triangular membership functions insures better

performences than that of bellshaped membership functions, the difference staying

negligeable and the range of position tracking errors being acceptable in both

cases. A closer look at the results obtained with the bell shape membership

functions shows that: (1) the more membership functions shapes are trapezoidal

{b = 5} the less performant the trajectory tracking problem will be; and vice versa,

(2) the more they are triangular {b = 1}, the closer the results are to those obtained with triangular membership lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 311

Figure 6. Desired and measured Cartesian trajectories of the end-effector. Case of triangular

membership functions with {N1 = 3; N2 = 3}.

Figure 7. Desired and measured Cartesian trajectories of the end-effector. Case of bell shape

membership functions with {N1 = 5; N2 = 5; b = 5}.

functions. This leads to conclude that the behavior of fuzzy PID controllers using

bellshape membership functions tends to that of fuzzy PID’s using triangular

membership functions. This last behavior makes the triangular membership lOMoAR cPSD| 58675420 312 G. M. KHOURY ET AL.

function seems like the best-matching solution for the trajectory tracking problem of the Maker 100.

Figure 8. Instantaneous joint input torques. Case of triangular membership functions with {N1 = 3; N2 = 3}.

Figure 9. Instantaneous absolute position errors in the joint space. Case of triangular

membership functions with {N1 = 3; N2 = 3}. lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 313

Although the tracking problem seems close to perfection, the rate of acceptable

error on the manipulator’s end-effector position is a function of the precision

required by the task at hand and is limited by the mechanical and electrical

performances of the joints’ actuators.

5.3. TWO-INPUT FUZZY PID CONTROLLER – ROBUSTNESS STUDY

5.3.1. Towards Change of Trajectory

Keeping the same tuning for the fuzzy PID controllers as adjusted for the triangular

trajectory tracking with triangular membership functions and three membership

functions per fuzzy input, the robot arm was tested for a different form of linear trajectory (Table VI).

Measured tracking errors listed in Table VII illustrate the ability of the tuned

fuzzy PID controllers to ensure the success of the trajectory tracking problem of

the Maker 100 within its working space. Other trajectory trackings could also be

verified using the same tuning of the fuzzy PID controllers.

5.3.2. Towards Change of Robot Parameters

In these simulations, the control loop was tested in presence of uncertanities in the

robot arm’s model. In each simulation, using triangular trajectory of Table II and

the previously tuned PID controllers, one or more of the Maker’s nineteen

parameters was made subject to variations throughout the trajectory tracking

problem. Results of the different cases are listed in Table VIII where uncertainities

were added to frictions F1, F4 and F5, mass m5 and centre of mass z5.

The simulation results show the robustness of the proposed fuzzy PID control

towards uncertanities affecting the Robot mechanical parameters.

It should be mentionned that all the previous developments can be extended

easily to the three inputs fuzzy PID controllers case.

Table VI. Desired trajectory Point x (m) y (m) z (m) p (radian) r (radian) A 0.3 0.6 0.4 0 π B 0.5 0.5 0.1 −π π/2 C 0 0.6 0 −π/4 π D 0.3 0.4 0.2 π/4 0 E 0.3 0.1 0.8 −π/3 π/4

Table VII. Position tracking errors for multiple trajectories lOMoAR cPSD| 58675420 314 G. M. KHOURY ET AL. Trajectory

Relative peak-to-peak position tracking errors in the Cartesian space ex pp (%) ey pp (%) ezpp (%) eppp (%) er pp (%) Table II 0.0035 0.0063 0.0085 0.0001 0.0026 Table VI 0.0047 0.0103 0.0045 0.0001 0.0031

Table VIII. Position tracking errors for multiple cases of uncertainities within the robot dynamic model Perturbation

Relative average position tracking errors in the joint space

e1pp (%) e2pp (%) e3pp (%) e4pp (%) e5pp (%) None

0.0034 0.0030 0.0180 0.0039 0.0001

F1 starts increasing at t = 4 s with a slope

of 10 and stops at t = 13.37 s

0.0036 0.0030 0.0180 0.0039 0.0001

F4 starts increasing at t = 5 s with a slope of 8 and stops at t = 13.25 s

F5 starts increasing at t = 6 s with a slope

of 10 and stops at t = 15.78 s

0.0034 0.0030 0.0180 0.0039 0.0009

m5 steps at t = 6 s to 5 times m5 z5

steps at t = 6 s to 5 times z5

0.0038 0.0567 0.0180 0.0311 0.0001

5.4. THREE-INPUT FUZZY PID CONTROLLER – TUNING METHOD

In the case of the three inputs fuzzy PID structure, the choice of the PID parameters

was made possible by a pole placement method [9]. First, we consider the dynamic

behavior of the position tracking error to be similar to its behavor in a Computed

Torque Control, and which is given by: . (8)

By substituting Equation (8) by its Laplace equivalent, we obtain: (s3 + K (9) Ds2 + KP s + KI)E(s)ˆ = 0.

Equation (9) could be rewritten [6] as Equation (10): lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 315 , (10)

where: α is a positive real number for the dynamic behavior of the position error

to be stable, ξ is the damping ratio, wn is the natural pulsation, ts is the settling time

defined as the time by witch the second order system response enters for the last

time from the top or the buttom the band [95%;105%] of the step refernce input.

The dynamic behavior of the position error is thus governed by the choice of

its three poles which will lead us to the desired proportional, integral and derivate

gains. By identifying these gains to the ALG terms of the three inputs fuzzy PID

Table IX. Fuzzy PID controller tuning procedure

Pole placement for the dynamic behavior of the position error Alpha (real pole) α 5ξwn Response time (s) tr 0.3 Damping ratio ξ 0.5

Computation of the equivalent linear PID gains Apparent proportional gain KPa 1533.3 Apparent integral gain KIa 22923 Apparent derivate gain KDa 73.2567

Choice of the first normalization factor Normalization factor Se 1/0.2

Deduction of the other scale factors Denormalization factor Su 13.7540 Normalization factor Sce 334.4404 Normalization factor Srce 15979 lOMoAR cPSD| 58675420 316 G. M. KHOURY ET AL.

Figure 10. Instantaneous joint input torques.

structure, the values of the normalization and denormalization factors will be

obtained obtained. Table IX summarizes this tuning procedure.

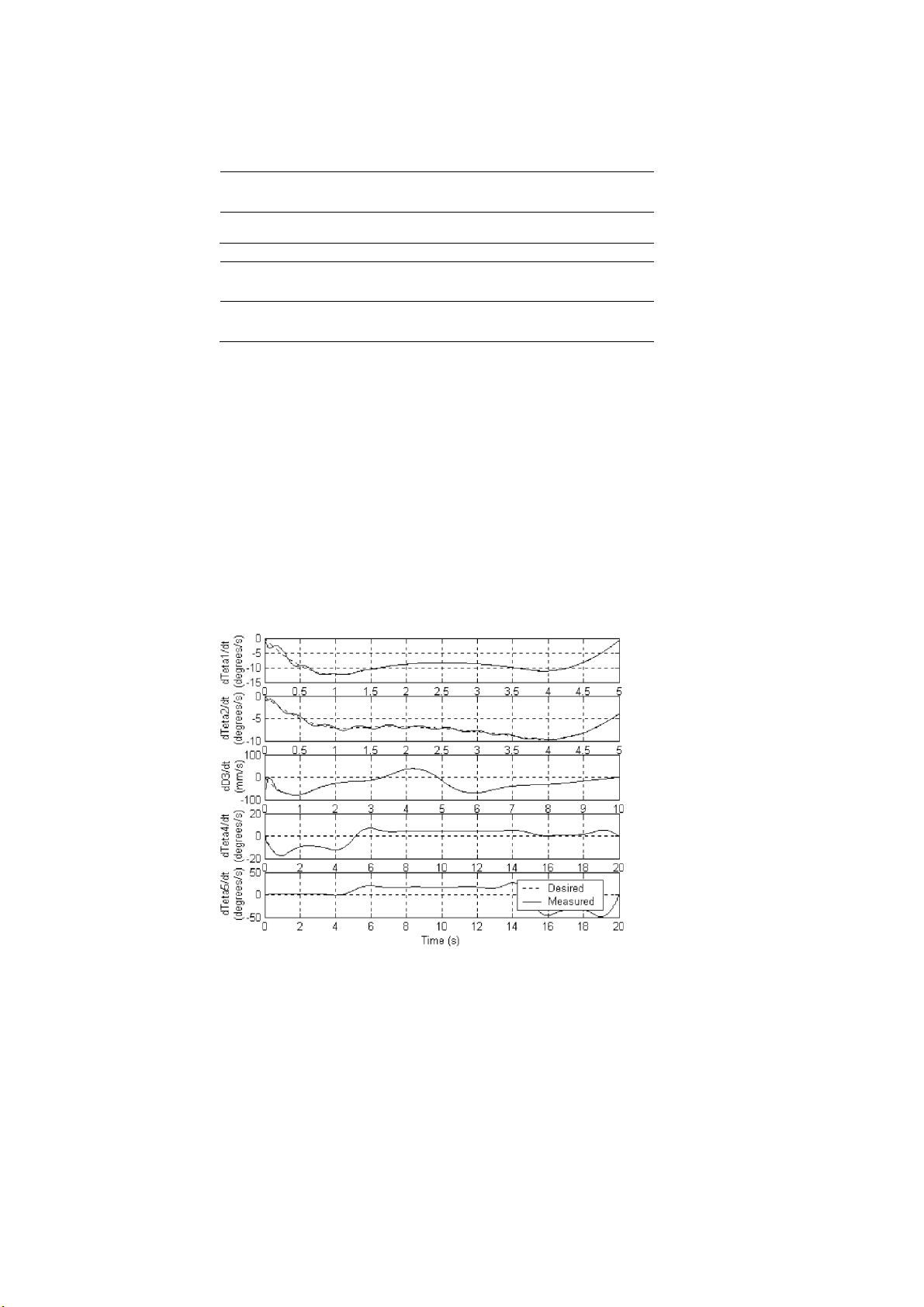

Figure 10 shows the instantaneous joint input torques and Figure 11 the

resulting instantaneous position absolute errors in the joint space for the case of

Figure 11. Instantaneous absolute position errors in the joint space.

Table X. Position tracking errors lOMoAR cPSD| 58675420

FUZZY PID CONTROL OF A FIVE DOF ROBOT ARM 317

Absolute average position tracking errors in the joint space e¯1 (deg) e¯2 (deg) e¯3 (mm) e¯4 (deg) e¯5 (deg) 0.0089 0.0063 0.0539 0.0031 0.0003

Relative peak-to-peak position tracking errors in the joint space e1pp (%) e2pp (%) e3pp (%) e4pp (%) e5pp (%) 0.2452 0.1919 1.1833 0.2550 0.0026

triangular membership functions with {N1 = 3; N2 = 3; N3 = 3} Table X gives the

resulting tracking error variables. Figure 12 shows the desired and measured

variations of the velocities in the joint space. The velocity variations illustrate the

tracking dynamics of the control loop. They show a transient oscillatory behavior

around the desired velocity reference. This transient phase is then followed by the

convergence of the velocity to its desired instantaneous value.

6. Comparison to Other Nonlinear Controls

Using the same simulated dynamic model of the Maker 100, the computed torque

and the direct adaptive control methods [12, 13] were simulated. For a more

realistic simulation, the Maker’s parameters used in the computed torque control

were taken equal to 1.1 times those of the simulated dynamic model of the Maker 100.

Figure 12. Instantaneous joint velocities in the joint space.

Table XI. Position tracking errors lOMoAR cPSD| 58675420 318 G. M. KHOURY ET AL. Control method

Absolute average position tracking errors in the joint space e¯1 (deg) e¯2 (deg) e¯3 (mm) e¯4 (deg) e¯5 (deg) Computed torque 1.3e−5 1.5e−5 1.5e−3 6e−5 2.5e−5 Direct adaptive 0.1e−3 0.1e−3 6.7e−3 0.2e−3 0.1e−3 Fuzzy 2-input PID 0.3e−3 0.2e−3 1.9e−3 0.1e−3 0.0e−3 Fuzzy 3-input PID 8.9e−3 6.3e−3 53.9e−3 3.1e−3 0.3e−3

Similarly, the initial values for the parameters’ estimation algorithm in the adaptive

control were taken 1.5 times those of the simulated dynamic model. The sampling

time Ts was chosen to be 0.001 s for all simulations. The performances of the fuzzy

PID controls are evaluated by examining the error variables listed in Table XI.

The errors obtained with the two fuzzy PID controllers are acceptable. Even

though the two-input structure provides better performance in term of tracking

errors, the three-input structure offers the advantage of a simpler and clearer tuning

procedure and so seems more interesting to use.

The performances provided by the computed torque and the direct adaptive

controls overpass those of the fuzzy PID controllers. However these performances

are limited to the simulation case where the adoption of a simulated dynamic

model similar for both the controller design and the controlled model offers

optimized working conditions for the tracking problem. And on the other hand, in

the real case, the manipulator’s dynamic parameters are partially unknown and

could not be known with high precision.

The tracking simulated errors are therefore the most realistic in the case of the

fuzzy PID controllers. This criteria represents the main advantage of the fuzzy

control approach, i.e. its non-dependency on the dynamic model of the plant. 7. Conclusion

This paper studied the design and performances of the DA fuzzy PID control

method on a five DOF robot arm. The study confirmed the success of the proposed

fuzzy control laws. The major difference between the two used fuzzy PID

structures was revealed in their tuning procedures. With the three-input structure,

the pole placement method along with the use of the structure’s apparent linear

gains allowed numerical calculation of it’s tuning parameters, avoiding so the trial

and error procedures usually used in fuzzy control design methods. A comparative

study of the designed fuzzy control to other nonlinear controls confirmed again

the success of the fuzzy tracking control system.