Preview text:

lOMoAR cPSD| 58605085

School of Industrial Engineering & Management (IEM) Inventory Management

International University, VNU-HCM

Instructor: Dr. Nguyen Van Hop Homework 5_ Chapter 5

Deadline: Class Day next week I.

Problem Statement: Managing Class A Items 1. Fast – moving items A:

- Assumptions: Items are A categories, fast moving. Demand is probabilistic, normally distributed

- Given: Economic data (holding cost, carrying rate, ordering cost, unit variable cost),

demand distribution and its parameters, lead time, cost of each shortage (B1) (for (Q,s)

model) , fraction of cost per unit short at the end of each period (B3), review time R (for (R,s ,S) model)

- Decision variables: Order quantity Q, reorder point s

- Method: Continuous review: Reorder point – Order quantity (Q,s) model, Reorder point –

Order – up – to level (s,S) model using simultaneous parameter selection (iterative

procedure), Periodic review – Reorder point – Order up to level (R,s ,S) using revised power approximation method 2. Slow – moving items A

- Assumption: Two types: very slow – moving, expensive times (using Q=1¿ and slow –

moving items (Q>1¿. For very slowing moving items, assume demand distribution is

Poisson, D<0.0763∗v, lead time is constant, backorder consideration. For slow moving

items, it is the same as in (Q,s) model.

- Given: For Base stock model: Demand rate, unit variable cost, carrying rate r, fraction

charge per unit charge (B2),

- Decision variables: For base stock model: reorder point s. For (Q,s) model: Order quantity

Q and reorder point s

- Method: Base stock model (For Q=1), Continuous review: Order quantity – Reorder point

(Q,s) ( For Q>1) II. Homework

Problem 1: Fast moving items A (Q,s) system (Problem 8.1-page 349 textbook)

Consider an (Q,s) system of control for a single item and with normally distributed forecast errors.

For the following example develop order quantity Q, safety stock factor k and the associated total

relevant costs per year for two strategies:

1. Q=EOQ and corresponding k

2. Simultaneous best (Q,k) pair Item characteristics:

Ordering cost A=$5, carrying rate r=0.16/ yr, unit cost v=$ 2 per unit, demand rate

D=1000units per year, σL=80units, expected number of stockout occasions per year being

N=0.5 per year, fixed cost per stockout occasion B1=$50 lOMoAR cPSD| 58605085

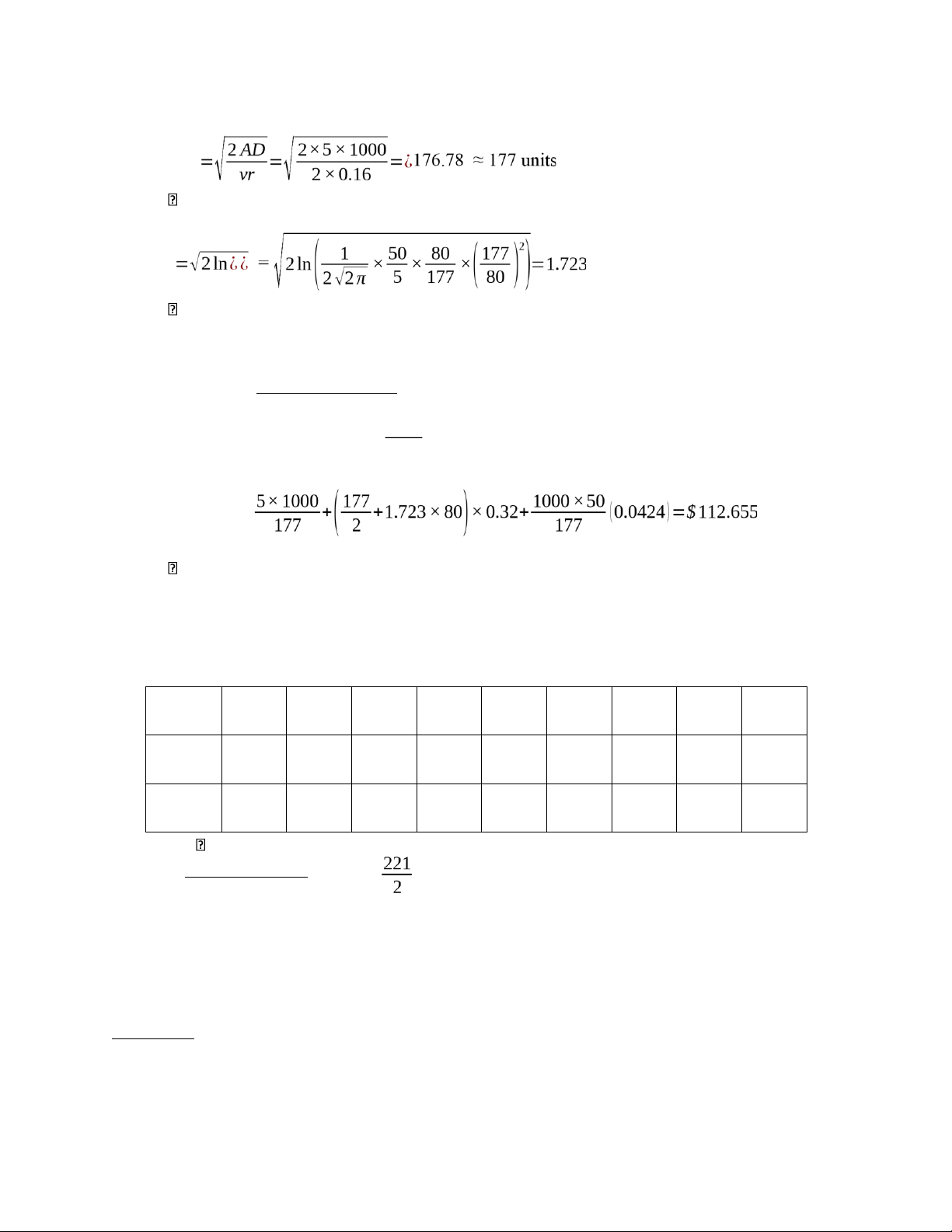

1. Q = EOQ and corresponding k EOQ

Q=EOQ=177units k k = 1.723 Total cost: AD Q DB1 TC (Q,k )= +( +kδL)h+ Pr ( X ≥k ) Q 2 Q ¿ Total cost is $112.655

2. Simultaneous best (Q,k) pair

We have: EOQ = 177 units. With the iteration procedure, we obtain: Iteratio 1 2 3 4 5 6 7 8 n 9

176.7 211.0 218.6 220.3 220.7 220.8 220.8 220.8 220.8 Q 8 1 5 8 8 7 9 9 9

1.722 1.616 1.594 1.589 1.588 1.588 1.587 1.587 1.587 k 6 5 4 4 3 0 9 9 9

Q = 220.89 ≈ 221 units , k = 1.5879

5×10001000×50 The total cost =

+(+1.5879×80)×0.32+ (0.056 ) ¿ $111.304 221221

Problem 2: (Q,s) system (Problem 8.3-page 350 textbook) lOMoAR cPSD| 58605085

Ceiling Drug is concerned about the inventory control of an important item. Currently they are

using an (Q,s) system where Q is the EOQ and the safety stock factor k is selected based on a B2

v shortage costing method. Relevant parameter values are estimated to be:

Demand rate D=2500units per year, unit variable cost v=$ 10 perunit, ordering cost A=$5,

carrying rate r=0.25 $/$/year, fractional charge per unit short B2=$0.6, mean demand during lead

time x^L=500units, lead time demand standard deviation σL=100units.

a. What are the Q and s values currently in use?

b. Determine the simultaneous best value of Q and s.

c. What is the percent penalty (in the total of replenishment, carrying, and shortage costs) of

the simpler sequential approach?

Hint: Decision rule for a specified fractional charge (B2) (Section 7.7.6 – page 263 textbook) Qr

a. Select k so as to satisfy pu≥(k )=D B2

b. Reformulate Total cost with B2 derivative function of Q = 0 formular of Q

Total cost TC= ADQ +(Q2 +k σ ) L vr+

B2 v σLQGu (k ) D, where the shortage cost term is D

composed of the ESPRC, σLGu (k), the number of cycles per year Q , and the cost per unit short vB2

Gu(k): a special function of the unit normal (mean 0 and std dev 1) variable used to find

the expected shortages per replenishment cycle (ESPRC) (can be obtained from k, by

using a table lookup shown in appendix II), k is as part (a)

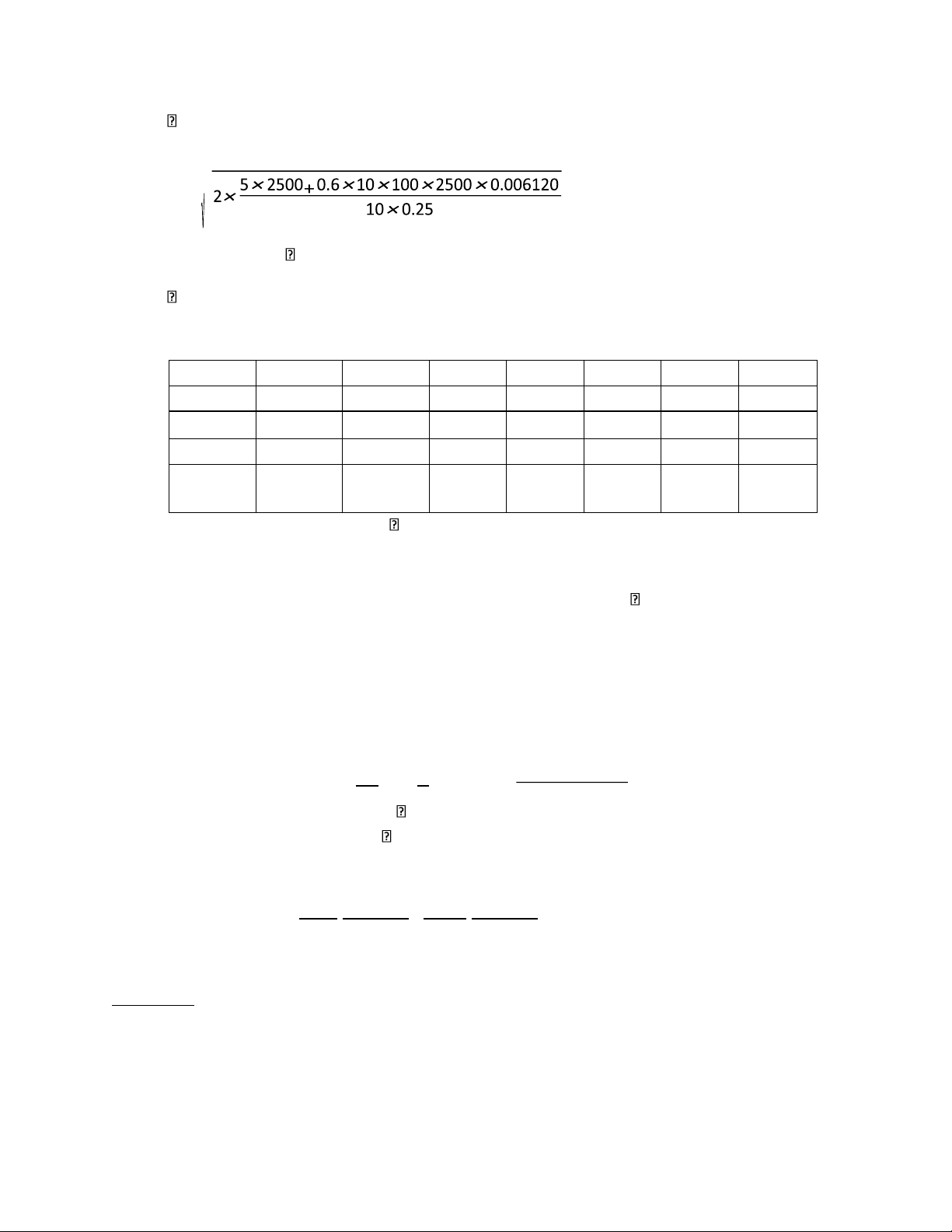

c. Sequencing approach means that the procedure in which Q = EOQ calculation, then k is calculated with respect to Q D = 2500 units/year v = $10 per unit A = $5 r = 0.25$/$/year B2 = $0.6 x^L = 500 units σL = 100 units a. Q=EOQ units Qr 100×0.25 = = 0.0167 lOMoAR cPSD| 58605085 DB2 2500×0.6 Qr

pu≥(k )=D B2 =0.0167 k = 2.12 The reorder point:

s = x^L+σLk=500+100×2.12=712units

The (Q, s) currently in use is (100, 712) b. We have: Total cost :

ETRC(k ,Q)= AD +(Q+k σ ) L

vr+B2 v σLGu (k ) D Q 2 Q

Take derivative of both sides: dETRC (k )

−AD+B v σ D×G (k ) vr dQ Q 2 Qr

Also, we have: pu≥(k )=D B2 Q = EOQ = 100 units o Iteration 1: Q = EOQ = 100 units Qr

Q = 2× AD+B2 v σLD×Gu (k) vr

pu≥(k )=D B2 =0.0167 k = 2.12 lOMoAR cPSD| 58605085

Gu (k )=0.006120 o Iteration 2: Q = = 131.697

pu≥(k )=0.02195 k = 2.02

Gu (k )=0.008046

With the iteration procedure, we obtain: Iteration 1 2 3 4 5 6 7 Q 100

131.697 140.197 143.057 144.043 145.043 145.04 pu≥(k ) 0.0167

0.02195 0.02337 0.02384 0.02401 0.02417 0.02417 k 2.12 2.02 1.99 1.98 1.97 1.97 1.97 G 0.008046 u (k) 0.00612 0.00872 0.00896 0.0092 0.0092 0.0092 0

Q = 145 units and k = 1.97 The reorder point:

s = x^L+σLk=500+100×1.97=697units The

(Q, s) currently in use is (145, 697)

c. We have the formula of total cost:

ETRC(Q,k)= ADQ +(Q2 +k σ ) L vr+

B2 v σLQGu (k) D ETRC(100, 2.12) = $871.8

ETRC (145, 1.97) = $855.13 The percent penalty:

ETRC(100,2.12)−ETRC (145,1.97) PCP =

×100=0.0195×100=1.95% ETRC(145,1.97)

Problem 3: Fast moving items (R,s,S) system (Problem 8.7-page 350 textbook)

a. Consider an item for which an (R,s ,S) system is used. The review interval is 1 week.

Other characteristics include lead time L=2weeks, demand rate D=800units/ yr,

ordering cost A=$20, unit cost v=$ 1.50 per unit, carrying rate r=0.26$/$/year, lOMoAR cPSD| 58605085

fractional charge per unit short per time B3=0.3 $/$/short/week, variance during

replenishment interval σR+L=14.2units.

Using the revised power approximation, find the appropriate values of s and S. (Assume that

there are exactly 52 weeks per year)

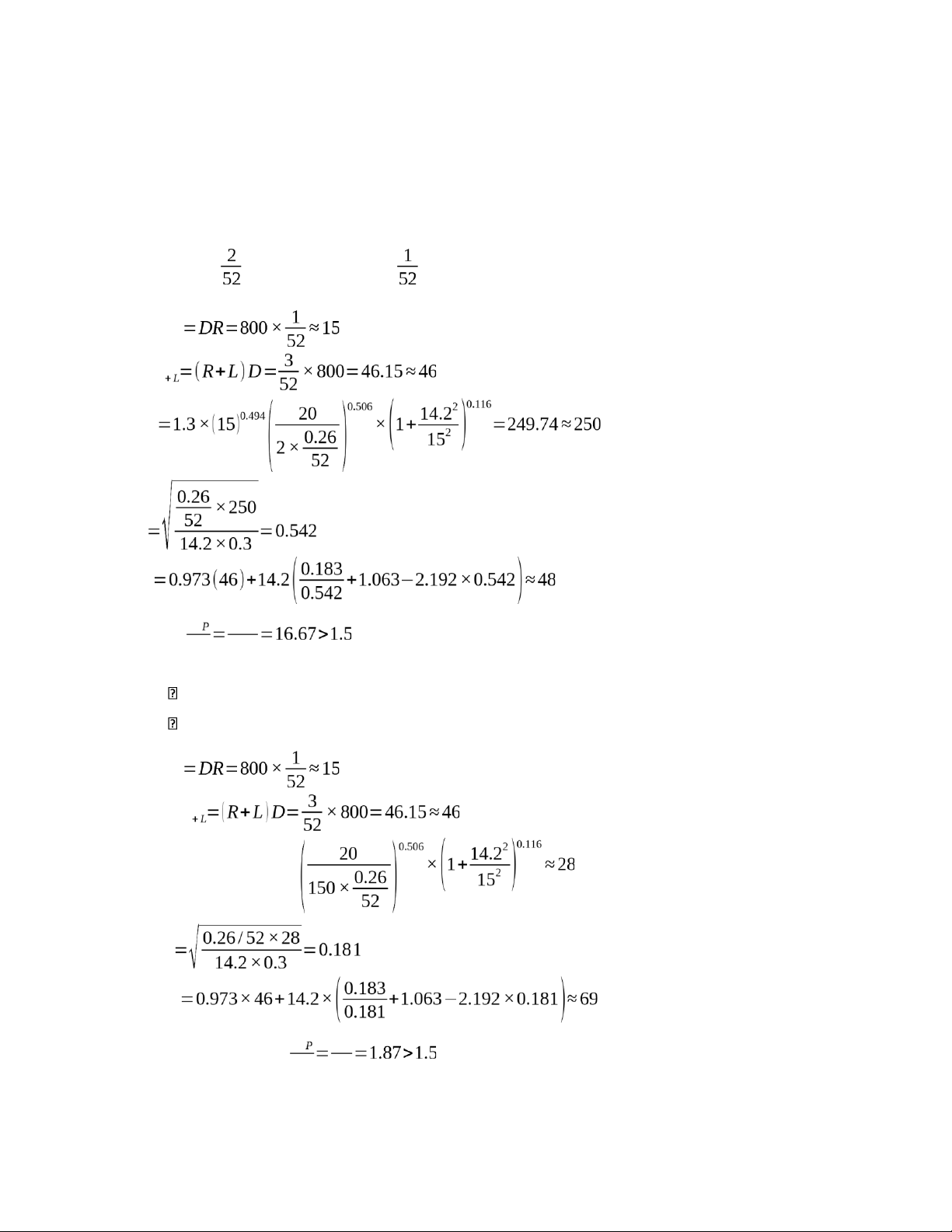

b. Repeat for another item with the same characteristics except v=$ 150 per unit. L = 2 weeks = year, R = 1 week = year a. x^R units x^R units QP units z sp units Q 250 Also: . x^R 15 s¿ sp=48units

S = sp+QP=298units b. x^R units x^R units

QP=1.3×(15)0.494 × unit s z sp units Q 28 Also, we have: . x^R 15 lOMoAR cPSD| 58605085

s=sp=69units

S = sp+QP=97units

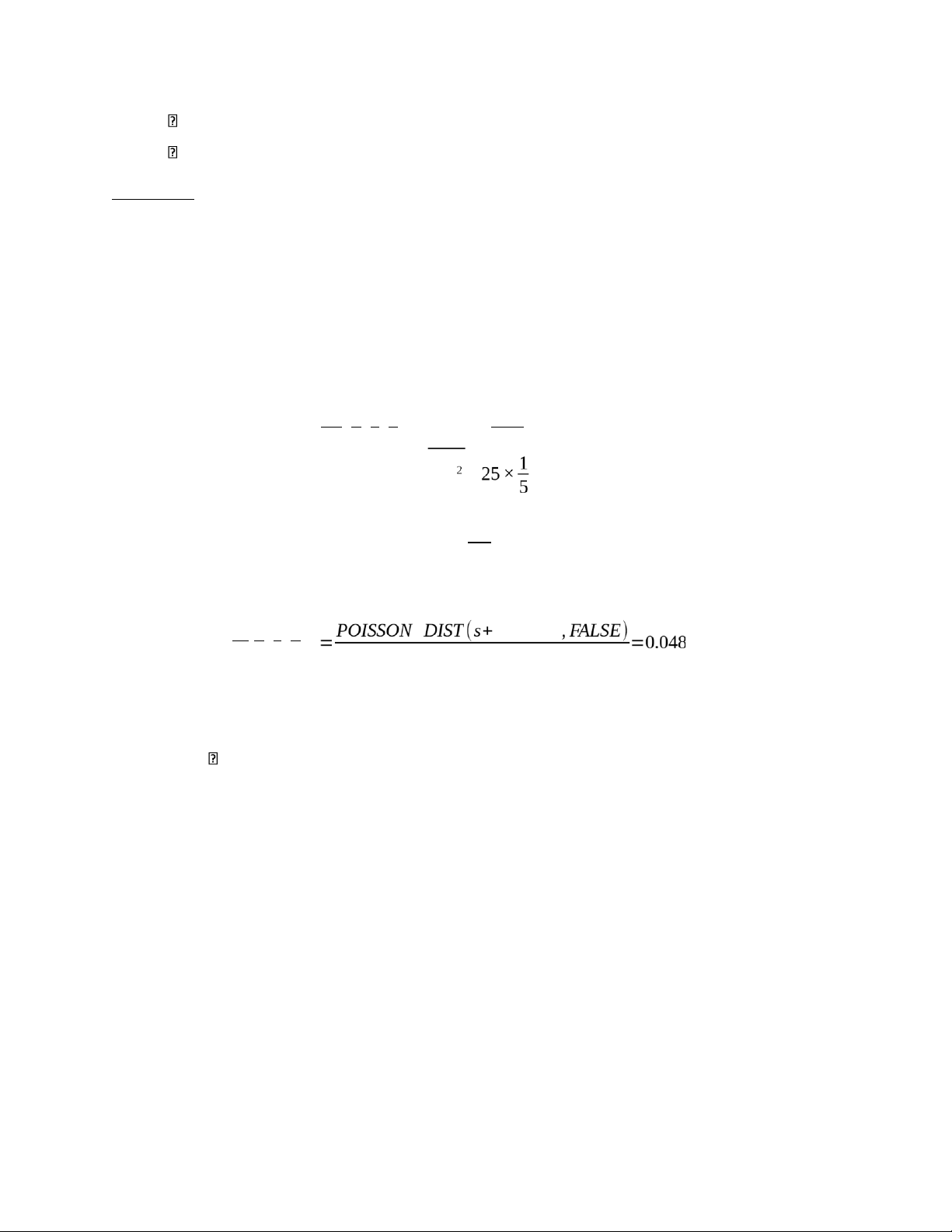

Problem 4: Slow moving item – Base stock policy

Consider the case of a high-value item with unit cost v=$ 350 perunit, demand rate D=25units

per year, carrying rate r=0.24 $/$/year, lead time L=3.5 weeks=3.5/52 year, ordering cost

A=$3.20. and fraction charge per unit short B2 is estimated to be 1/5 i.e., 350/5 or $70 per unit

backordered). Assume the system employs the policy of ordering one-for-one each time a

demand drops to a specific inventory position (order quantity Q=1¿ Develop the policy (find the inventory position) We have: Q = 1

Pr ( X=S+1) r 0.24 = = =0.048/units Pr ( X≤ s+1) D B Mean demand: 3.5

x^L=DL=25( 52 )=1.68units Pr(X=S+1) . 1,0.0048 /units Pr(X ≤s+1)

POISSON . DIST(s+1,0.0048,TRUE)

Using Excel s = 4 or S = 5. Therefore, the order point is 4 units