Preview text:

BREAKDOWN OF DHL WAREHOUSE ACTIVITIES: 1. Receiving the cargoes:

Pictures: Information board for receiving goods

Staff will check the empty number of the goods. If yes, staff will receiving the cargoes.

After receiving the goods, the staff will enter the products information on the

system such as: What time does the cargoes receive? Where will the goods be placed? Pictures: DHL Dock Shelter

21 complete loading bays with swing lip dock levellers , sectional overhead

doors & curtain dock shelters. Including sectional overhead doors in 4 level access ramps.

The DHL distribution hub receives around-the-clock deliveries by a wide range of road

transport including vans, trucks, container lorries and double deck trailers. The ‘goods in’

area of the hub features an installation of six loading bays most of which comprise WE

574 collapsible frame dock shelters, XF 3020 dock levellers, Thermadoor sectional

insulated doors and wheel guides plus LED dock and traffic lights. However, two of the

loading bays, which are designated to accommodate double deck vehicles, incorporate

extra height WIS dock shelters featuring revolutionary head curtains. Pictures: DHL Dock Lever

DHL transports 40 million pounds of freight and 2 billion shipments a year, with 76,200

vehicles and more than 250 aircrafts. The company employs over 530,000 people worldwide.

Upon arrival, these vehicles, which carry palletised consignments and roll cages

containing boxed goods, are unloaded and individual items are placed onto conveyers

that transport the boxes into the heart of the distribution hub for sorting and processing. Picture: Packing List Form Picture: Invoice Form Receving the cargoes Receving the cargoes

Base on document, Staff will check the quantity of goods, check Invoice, packing list provided by the customer.

2. Indentification the cargoes:

Pictures: Indentification of the cargoes

A camera and weight scale in the inspection line shoot and weigh the product,

respectively. The photo and weight are then compared with pre-registered product data.

High-speed, high-accuracy image recognition technology, in combination with weight

data, enables instant confirmation of the number of items. Conventional checking by

experienced operators is no longer necessary. 3. Quality and Inspect:

Pictures: Quality and Inspect of the cargoes 4. Storage:

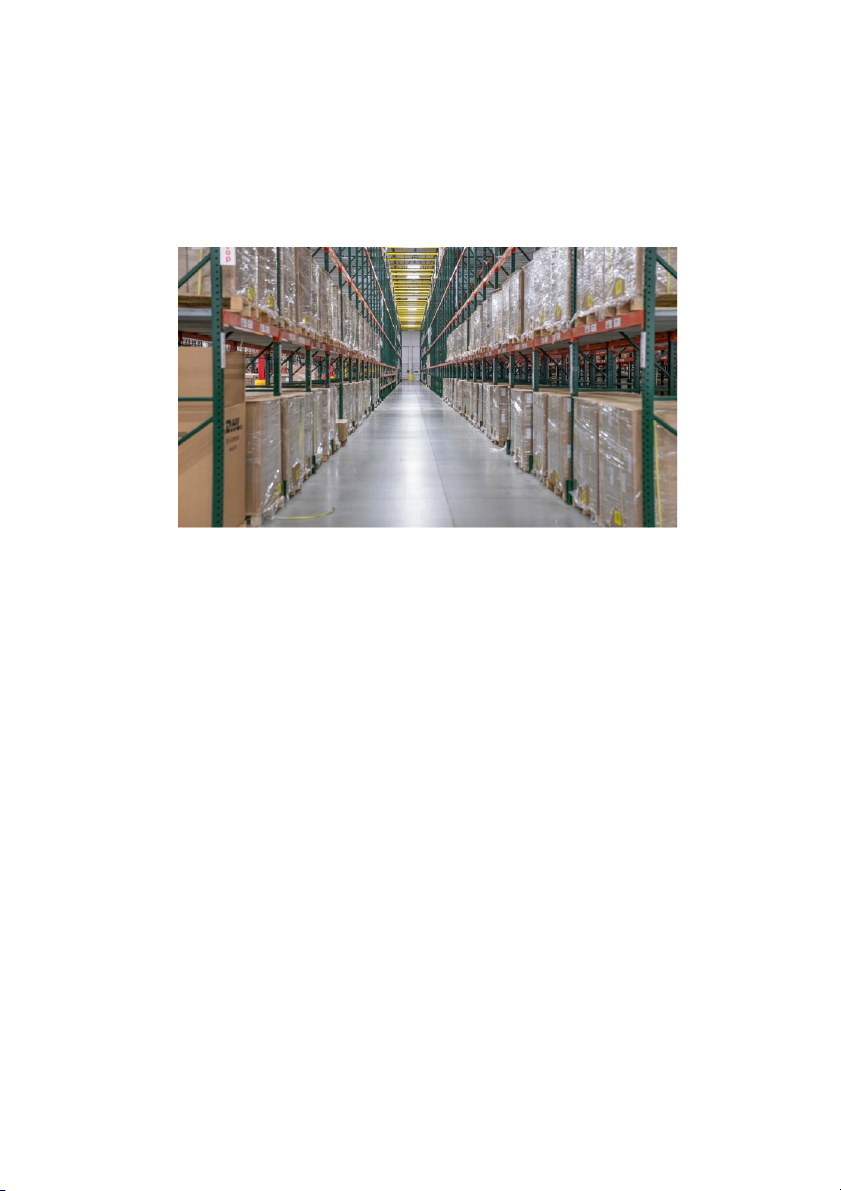

Pictures: DHL Aisles Pallet Racking System

DHL Supply Chain’s relationship with ADS started in 2019 by opening a 100,000-

square-foot retail fulfillment center in Wilkes-Barre, PA, and establishing a truck fleet to

service ADS’ customers in the northeast. Then in 2021, the partnership expanded to

include two DHL Supply Chain-operated facilities in Greer, SC, and Middletown, OH,

totaling over 487,000 square-feet in warehouse space. The investment allowed ADS to

consolidate its eCommerce fulfillment operations, provide additional capacity for

finished goods distribution throughout its network, increase fill rates, and reduce order cycle times.

Each product has a reference, a barcode and a name. DHL employees use barcode

scanners to read barcodes. Automatic Folklift will loading the cargoes and the

Automatic Folklift devices stop and loading the aisles pallet racking system.

Pictures: Screen to monitor the picking of goods in stock

The tracking of products being picked up and dropped off at the proper location. Device

for monitoring employees and alerting with the staff.