Preview text:

Operational reliability assessment of an aircraft environmental control system K. Jenab , K. Rashidi

Department of Mechanical and Industrial Engineering, Ryerson University, Toronto, Ontario, Canada M5B 2K3 a r t i c l e i n f o a b s t r a c t Article history:

The aircraft environmental control system (ECS) is composed of several non-identical and nondedicated subsystems working Received 29 August 2007

as warm–cold standby subsystems. Also, their state transition times are arbitrary distributed. This paper presents a flow-graph- Received in revised form

based method to calculate time-to-failure data and failure probability of the ECS. The obtained data from the model may be 14 February 2008

used for maintenance optimization that employs the failure limit strategy for ECS. The model incorporates detectable failures Accepted 9 May 2008 Available

such as hardware failures, critical human errors, common-cause failures, maintenance categories, and switch activation online 17 May 2008

methods. A numerical example is also presented to demonstrate the application of the model.

& 2008 Elsevier Ltd. All rights reserved. Keywords:

Hybrid warm–cold standby system Human errors Flow-graph Maintenance optimization 1. Introduction

human error failures were studied. In [11], assuming imperfect repair, an

In [1], authors developed probabilistic reliability models taking into

optimal geometric model for a cold standby repairable system with only two

account common-cause failure, human errors, and partially energized standby

identical units was developed. In [12], a system composed of m operating

subsystems. In [2], Using Markovian method, author developed formula for

units, w warm standby units and R repairmen was studied. In [13], using

the availability of the standby system composed of identical units that are reliability techniques, a

preventively maintained. In [3], authors developed a closed-form equation for

statistical method was proposed for preventive maintenance of a standby

a k-out-of-n warm standby system with dormant failure. In [4], authors

relays in power system. In [14], authors developed imprecise reliability models

presented a human errors analysis model with arbitrarily distributed repair

of a cold standby system because of unavailability of precise probability

times for a system composed of two working units and one standby unit. In

distribution of the unit times to failure. In [15], considering a minimal repair

[5], using exact distribution of the sum of two independent beta variables, the

with negligible repair time, a standby system lifetime was studied. In [16], a

reliability of the standby system composed of units with beta-distributed

warm standby system composed of units with different failure and repair rates

lifetime was calculated. In [6], a two-unit standby system was investigated

was studied. In [17], a cold standby system made up of non-repairable units

wherein the standby unit is put in cold state for a certain amount of time

with Erlang distribution lifetimes was investigated. Table 1 classifies the

before it is allowed to become warm. In [7], using Markovian model, authors

published literature dealt with standby systems subject to human errors,

analyzed a standby system made up of n units in parallel start operating and

common cause (CC), and hardware failures (HFs). This classification shows that

remaining m units are in standby mode. In [8], considering the constant failure

the published papers overlooked a warm–cold standby system defined as

rate, the availability of a standby system with n+1 identical units and one

hybrid standby system with arbitrary failure distributions. Therefore, the aim

standby unit was studied. In [9], several measures of reliability for a two-unit

of this study is to investigate such a standby system, and calculate time-to-

warm standby system with slow switch considering hardware and human error

failure data and the system failure probability by using a flow-graph-based

failures were assessed by Markovian method. In [10], using the regenerative

method. The results are required for maintenance optimization employing the

point technique in Markov renewal processes, the reliability measures for a

failure limit strategy [18]. 2. Problem description

two-unit warm standby system with a slow switch subject to hardware and

Corresponding author. Tel.: +1416 979 5000x6424; fax: +1416 979 5265. E-mail

address: jenab@ryerson.ca (K. Jenab).

0951-8320/$ - see front matter & 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.ress.2008.05.003

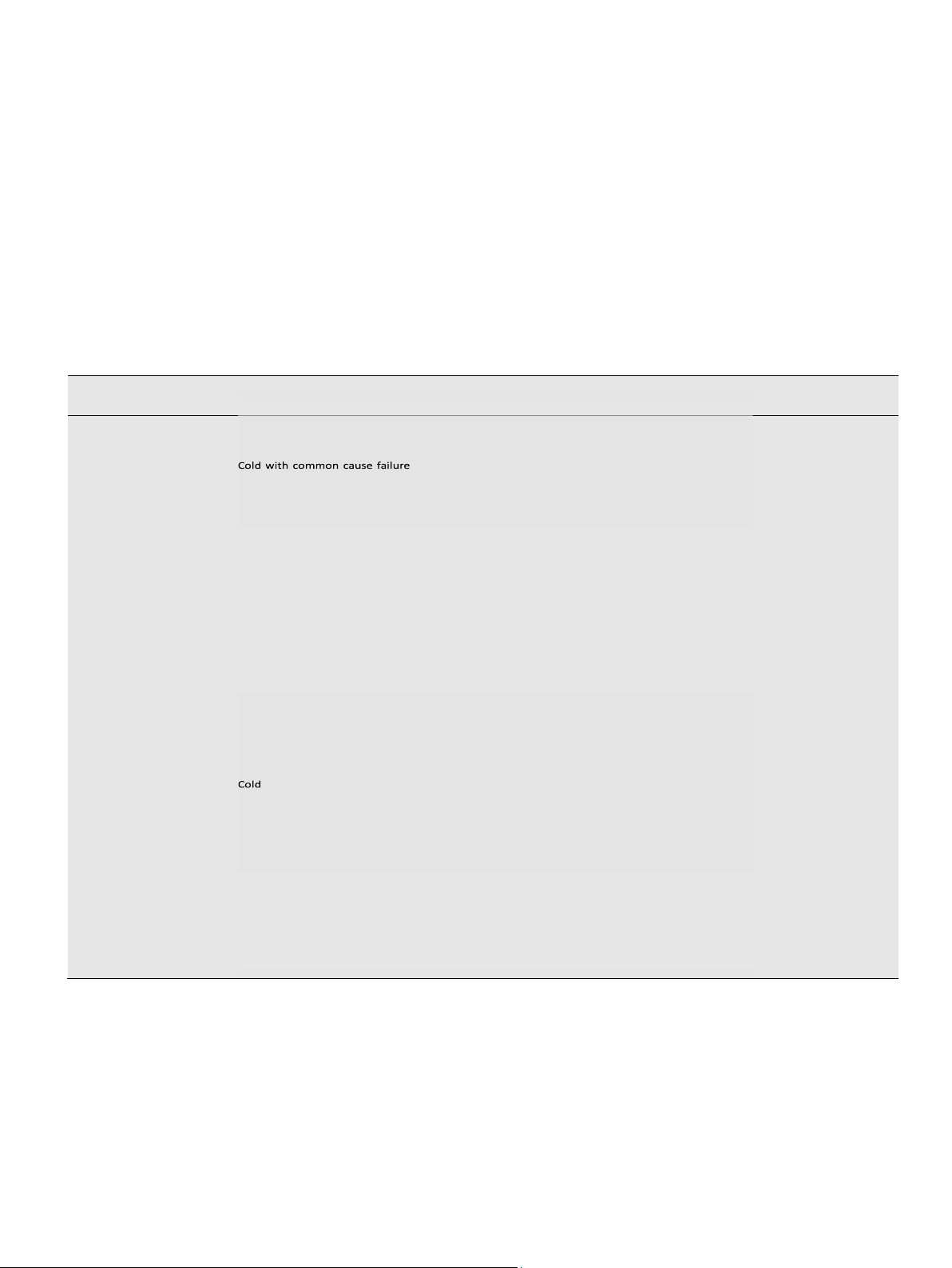

One of the major functions of the aircraft environmental

control system (ECS) is to maintain the temperature of the cabin at passenger

comfort level. This hybrid standby system is made up Table 1

Classification of published literature on standby systems Failure distribution Ref. Model Configuration of standby With human errors Exponential [1] Markov Exponential [4] Cold Markov Exponential [7] Warm Markov Exponential [9] Warm Mathematical expansion Exponential [10] Warm Mathematical expansion Without human errors Exponential [2] Cold Markov/simulation Exponential [3] Warm Mathematical expansion Beta [5] Cold Mathematical expansion Exponential [6] Hot/warm/cold Mathematical expansion Exponential [8] Cold Markov Exponential [11] Mathematical expansion Exponential [12] Warm Mathematical expansion Exponential [13] Cold Mathematical expansion Exponential [14] Cold Mathematical expansion Weibull [15] Cold Simulation Exponential [16] Warm Markov Erlang [17] Cold Mathematical expansion

of two dedicated cooling packs, and a non-dedicated RAM air as shown in

instructed to switch manually to RAM air in accordance with the aircraft flight

Fig. 1. The non-dedicated subsystem can be manually activated only in the

manual. This stage is a cold standby with slow switch subject to hardware

certain flight altitude by the flight crew. In the normal operation, both

and crew error failures. The crew errors may result from poor control panel

cooling packs are automatically operating. In case of one pack failure, the

design, poor work environment, poor task assignment, inadequate training,

remaining pack will automatically take over the load and an appropriate

poorly written flight manual, operating procedures, and deficiency of master

message will be posted on the crew alert system display (CAS) in the aircraft

minimum equipment list. Therefore, the required maintenance activities cockpit.

performed by the flight crews during the flight (Category I) or by

The system state would be reversible if the cooling pack fails due to

maintenance crews in the bases (Category II) may be associated with human

overheat. Up to this stage, we have the two-unit warm standby system with errors.

automatic switch subject to HFs. In case of both packs failure, crews are

To calculate time-to-failure data and the failure probability of such a

Category I maintenance task can be performed by the flight crews.

system, we define a warm–cold standby system (hybrid) with related terms

Category II maintenance task requires maintenance crews in site.

and conditions in the remaining part of this section. The warm–cold standby

Common-cause and HF rates are arbitrarily distributed and statistically

system comprises of several nonidentical and non-dedicated subsystems, independent.

which are independently functioning; however, they can be manually or

Human errors, common-cause, and HFs occur independently.

automatically activated subject to The repair time of the failed subsystems are arbitrarily distributed. (1) manual override option,

The failed system repair times are arbitrarily distributed.

(2) subsystem availability if it is non-dedicated, and

A common-cause failure or a human error can occur and trigger the system

(3) meeting certain flight operational requirements such as flight altitude.

failure from any of its operable states.

Repair is unrestricted for subsystems and system.

The repaired subsystem or system is as good as new.

The dedicated subsystems work in a warm standby configuration with

Switchover mechanism is automatic in warm standby and is manual in cold

automatic switch activation. On the other hand, the nondedicated standby configuration.

subsystems work in cold standby configuration with manual activation in

Self-loops in flow-graph that represent the corresponding subsystem are

accordance with the flight manual. As a maintenance point of view, the

properly working are s-independent [19].

subsystems may be repaired during the flight by the flight crews or at the

base by the maintenance crews based on maintenance procedures. The

maintenance task may be subjected to critical human errors (CHEs) resulting 2.1. Notation

from poor design, poor work environment, poor t

transition time due to failures (i.e., hardware, human error, common cause) ECS environmental control system CAS crew alert system CC common cause CHE

critical human errors in operation or maintenance HW

hardware failure including subsystem and switch ‘ link index i.e., CC, CHE, HW Pij‘

probability of transition from node i to node j in link ‘ Pstd

failure probability of the hybrid standby system Avij‘

availability of non-dedicated subsystem for switchover in transition ij and link ‘ MTTF

mean time to failure of the hybrid standby system ECS Control Cooling Cooling STTF

standard deviation of time to failure of the hybrid standby system System pack 2 pack 1 fij‘(t)

time distribution function for transition from state i to state j with index ‘ rij‘(t)

time distribution function for switch activation in transition from Dedicated connection RAM

state i to state j with index ‘ Non-dedicated Connection Air Wij

equivalent transition from state i to state j Wstd equivalent transition of the hybrid standby system model

Fig. 1. Environmental control system block diagram.

task assignment, inadequate training, poorly written manuals, operating S i S j

procedures, and maintenance procedures. Also, there exist CC failures that may Transition Description

be caused by a common design or material deficiency, a common installation

error, a common maintenance error, or a common harsh environment. This type Lm

the mth first-order loop in the model t total

of failure leads to total system failure. Third type of failure is HF (i.e., subsystem

number of disjoint loops in the model

failure and switch failure) that can be classified to detectable and non-

detectable HFs. Occurrence of the detectable failure will be announced by

warning, caution, or advisory message to the CAS display in the aircraft cockpit 3. Model description

for taking appropriate action in accordance with the flight and maintenance

manuals. In fact, the occurrence of the non-detectable failure will remain

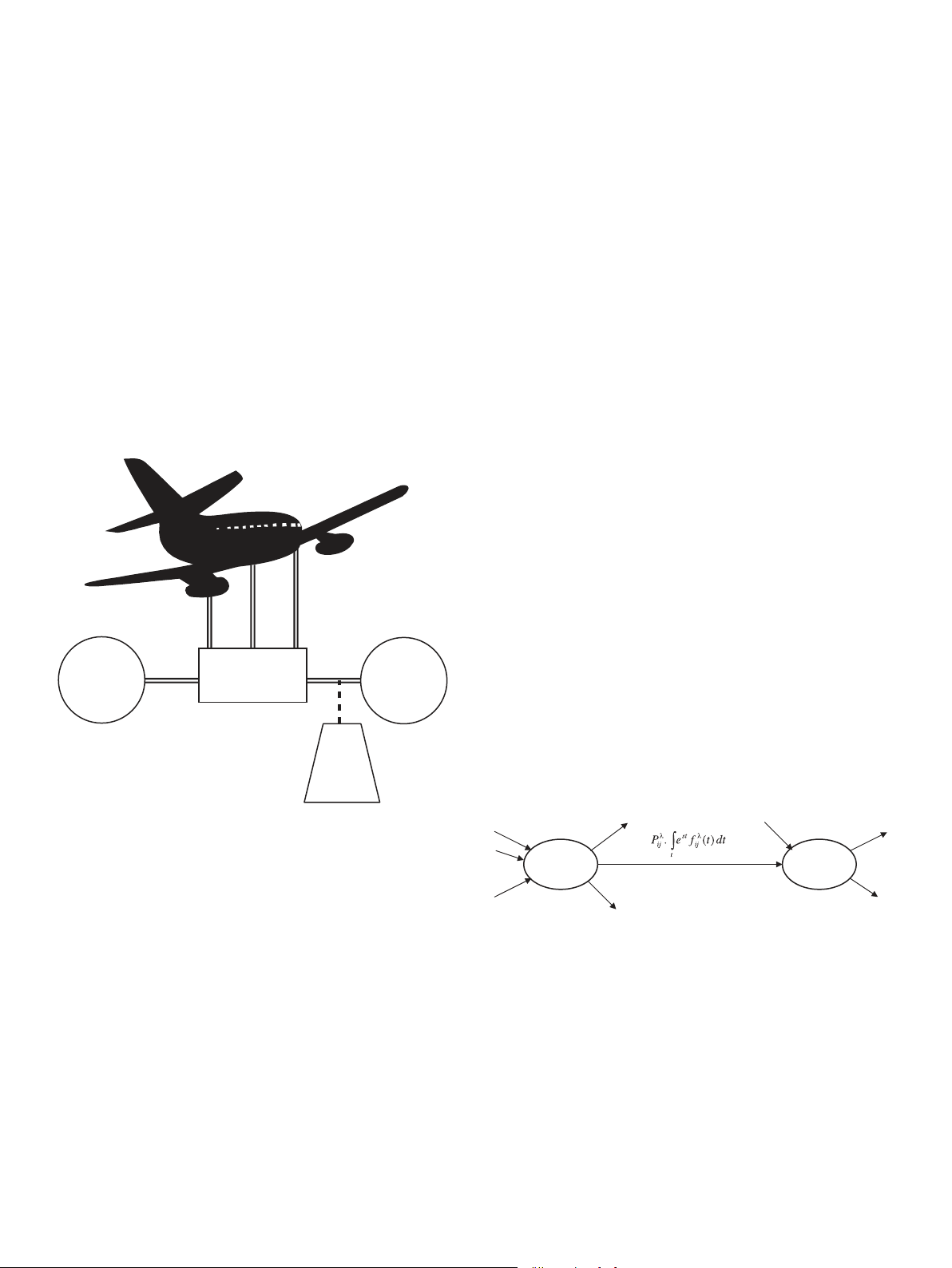

The analytical model is based on the flow-graph concept presented in

dormant until next maintenance inspection.

Appendix A. The flow graph is made up of several nodes corresponding to

To develop an analytical model for computing time-to-failure data and

the states of the warm–cold standby ECS system and of links corresponding

failure probability of such a system, the following assumptions are taken into

to transitions among states. The link represented by an arrow is associated account:

with transition probability, transition time distribution, switch type

(automatic, manual), switch activation requirements (availability,

Dedicated subsystems only serve the warm–cold standby system.

operational procedure), and transition description. Fig. 2 presents a state

Non-dedicated subsystems may serve the warm–cold standby system subject

transition without a switch type and the switch activation requirements used

to availability and meeting the operational requirements.

for the CC failure and maintenance links. In case of more than one link

between two states, we use the index ‘ to differentiate them where the sum

of the probabilities for outgoing links is equal to one. The link description

The first-order loop (i.e., Lm) is composed of only one loop and the

indicates either the type of failures (‘CC’, critical human errors in flight or

second-order loop (i.e., Lm Ln) is composed of the product of two disjointed

maintenance ‘CHE’, ‘HW’) or categories of maintenance activities (Category

loops m and n. These disjointed loops m and n have no intersection in their

I, Category II). Category I is a simple maintenance procedure that may be

nodes and links. Similarly, the tth-order loop can be defined as a product of

performed by the flight crews. However, if a maintenance activity requires

t disjoint loops. The probability of failure of the system is

special tools and skills, this activity falls into Category II, which can be

performed by the maintenance crews in the base.

Pstd ¼ Wstdjs¼0

(2) and mean time to failure of the system can be

To calculate the time-to-failure data and the probability of the warm–cold

obtained from the below expression:

standby ECS system failure, the equivalent transition (W) of the system can

be derived from the topology equation [1]: 1 qWstd t t t t t t MTTF ¼ (3)

1 X Lm þ X Xman Lm Ln X mXanap X Lm Ln Lp þ ¼ 0 (1) m¼1 m¼1 n¼1 m¼1 n¼1 p¼1 P q std s s¼0

Also, standard deviation time to failure is defined by

where t is total number of disjoint loops in the ECS flow-graph model.

Fig. 2. Flow-graph model for a state transition without switch type and activation requirements. 1 W STTF ¼

uuvtffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffif

fiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffistd q2q std 2 ½MTTF2ffi (4) P s s¼0

A developed model for the warm–cold standby ECS system may be

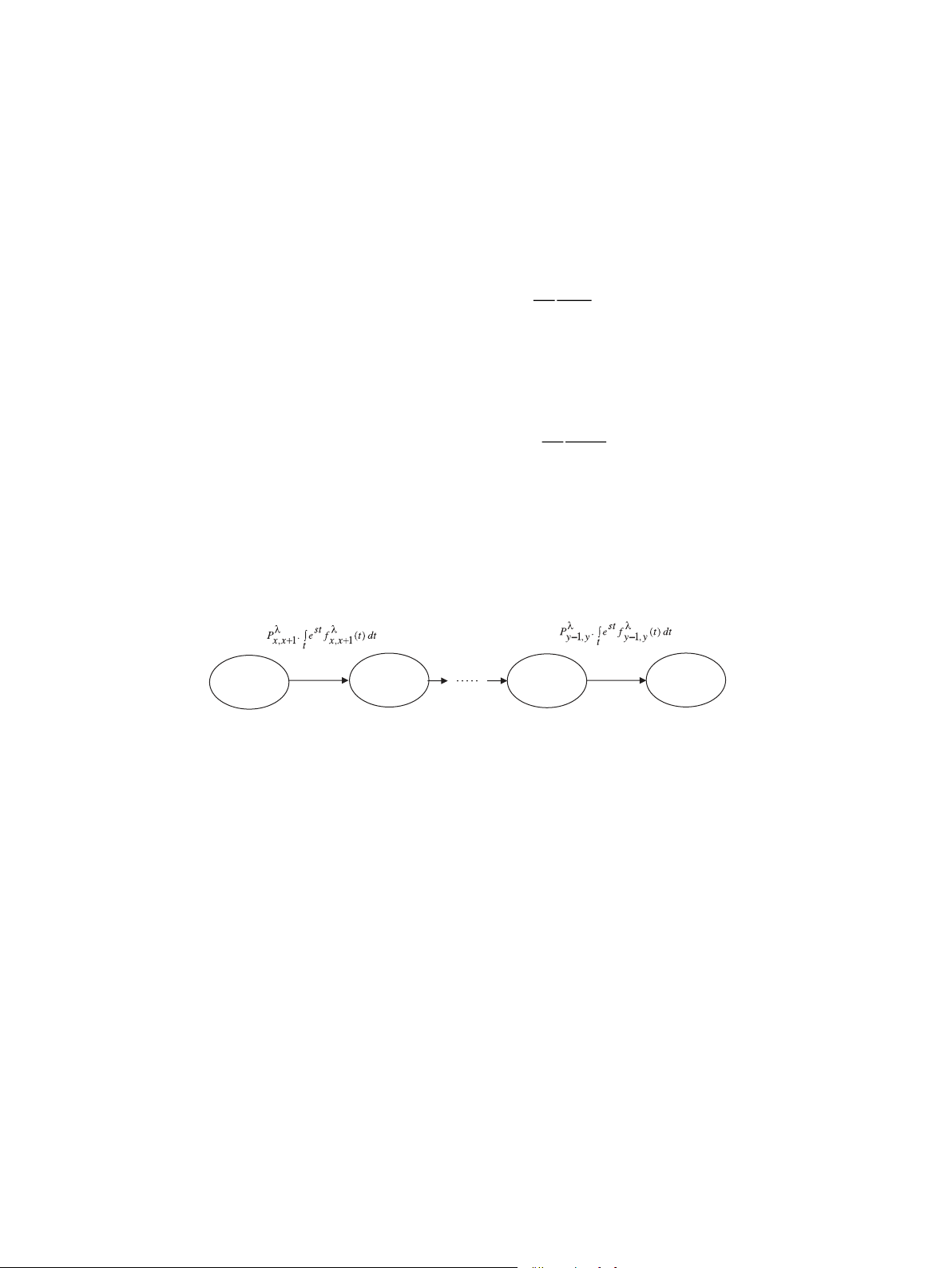

simplified by using series, parallel reduction techniques. S S x x+1 S S y-1 y Transition Description Transition Description

Fig. 3. Flow-graph model for series of state transitions. 3.1.

Series of sate transitions t ‘¼1

Using Eq. (1), the equivalent transition for a series of state transitions

where ‘ is the index for link between state i and state j.

depicted in Fig. 3 can be defined as follows:

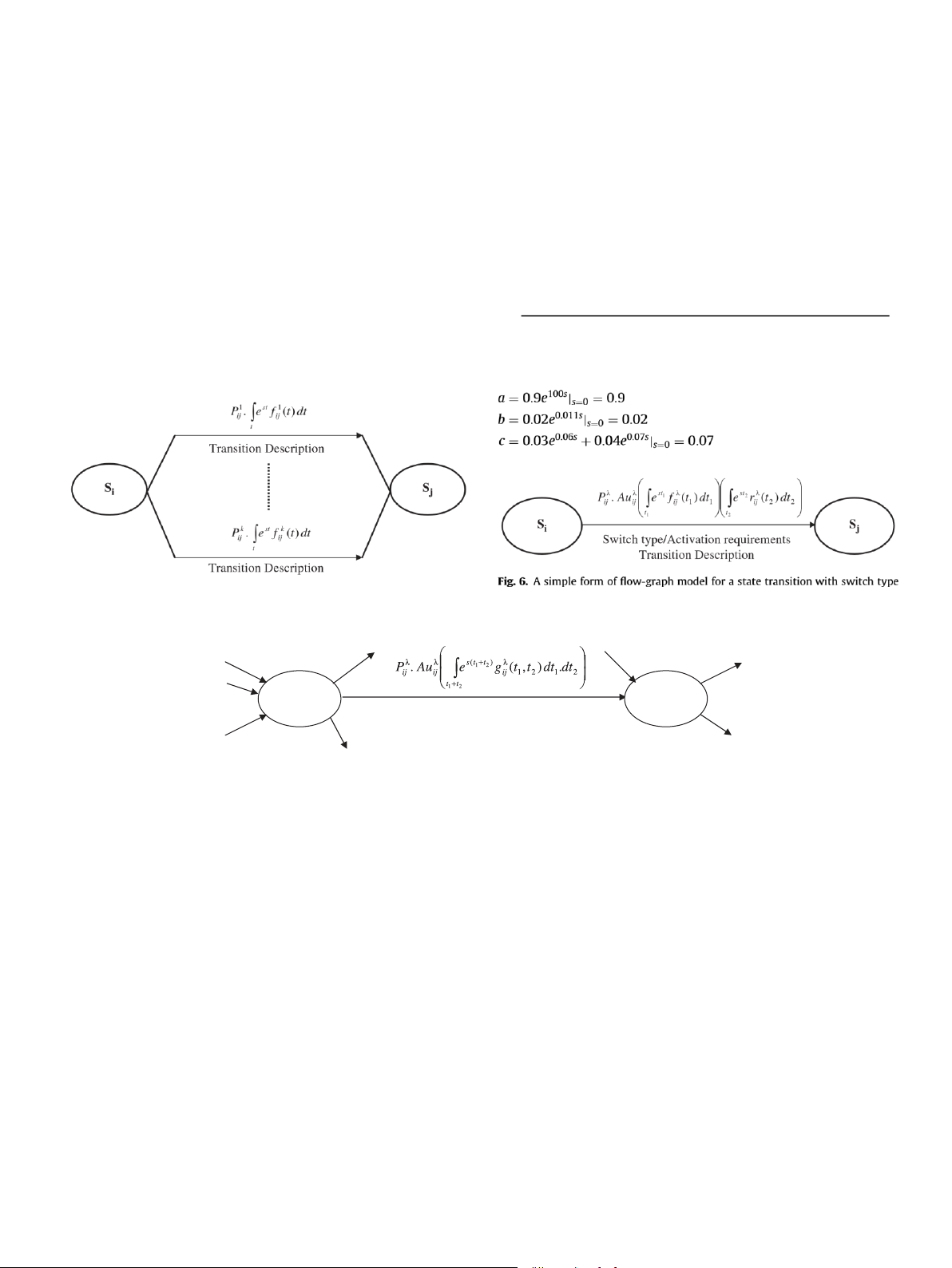

Similarly, we can extend the method for a link associated with switch type

and switch activation requirements shown in Fig. 5. The transition time is a y

random variable made up of two independent random variables (i.e., switch

time (t1) and activation time (t2)).

Wxy ¼ Y P‘ij Z

estf ‘ijðtÞdt (5)

Because transition time and activation time are independent, the total

transition time distribution function can be defined as follows:

ji¼¼iþx1 t

g‘ijðt1; t2Þ ¼ f ‘ijðt1Þr‘ijðt2Þ (7)

where ‘ ¼ 1, x is the starting state and y is the last state in the series.

Therefore, the simple form of the link is given in Fig. 6.

Similarly, using the approach for transition without switch type and 3.2.

Parallel state transitions

activation requirements, the system failure probability, MTTF and STTF can be

calculated for the warm–cold standby system with switch type and activation requirements.

Fig. 4 shows parallel transition states between state i and state j that

4. Numerical illustration

represents transitions because of HFs, CHEs in operation, maintenance, etc.

The equivalent of this parallel transition can be derived from the topology

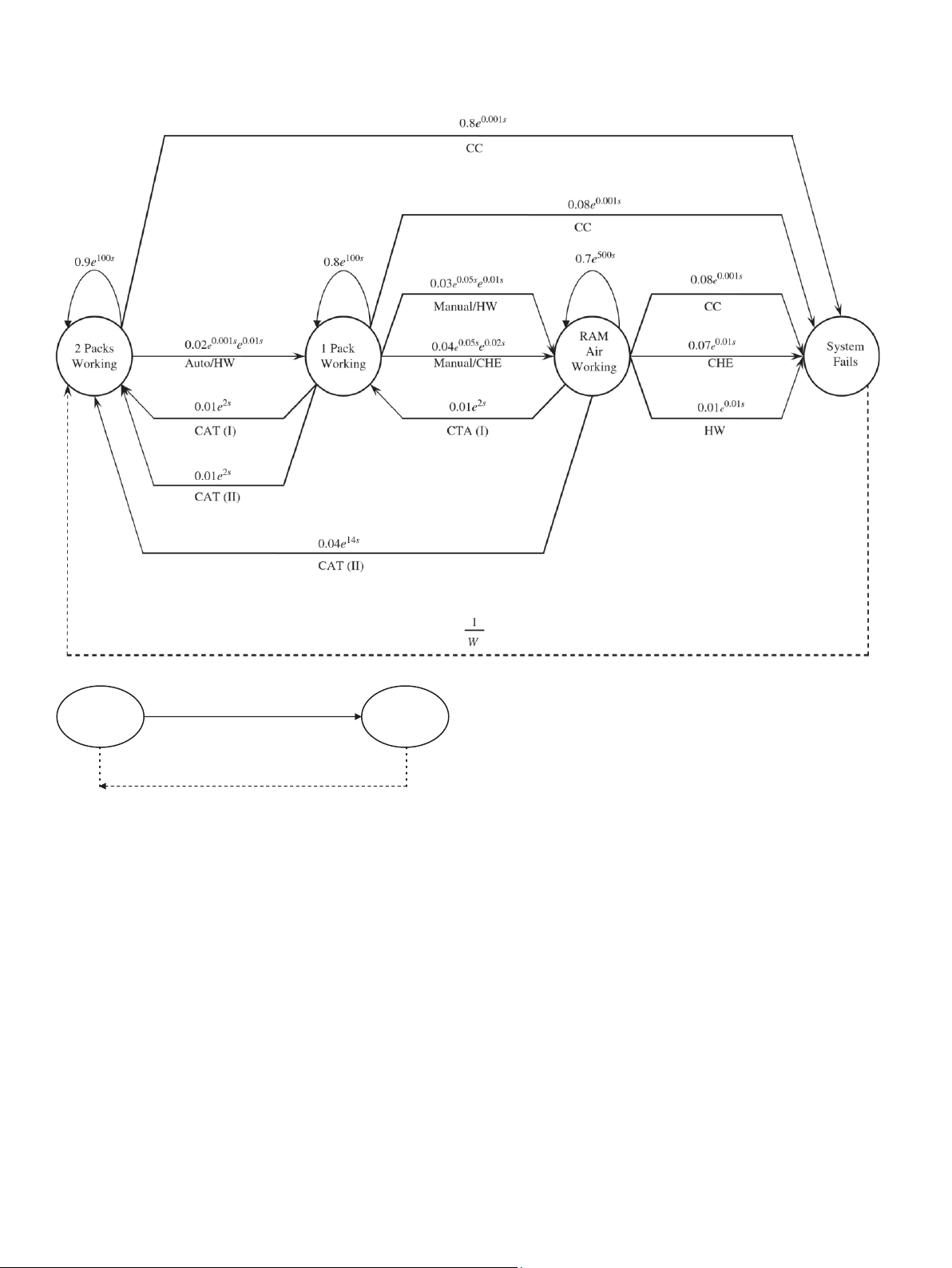

Consider an aircraft ECS presented in Fig. 1 that maintains the temperature equation as follows:

of the cabin at the passenger comfort level. This warm–cold standby ECS k

system is made up of two dedicated cooling packs and a non-dedicated RAM

air functioning as warm–cold standby subsystems. In the normal operation,

Wij ¼ X P‘ij Z

estf ‘ijðtÞdt (6)

the cooling packs are automatically operating. However, flight crews always

have manual override option. In case of one pack failure, the warm standby

In state 1, the cooling packs work with reliability 0.92, mean time to failure

cooling pack can be instantaneously activated. Subsequently, if the remaining

100 h shown with a self-loop. State 2 shows that the ECS is vulnerably working

pack fails, RAM air can be automatically activated if the flight altitude is at or

with just one cooling pack. State 3 indicates that the RAM air standby

below 10,000 feet. Otherwise, flight crews may switch manually to the cold

subsystem with reliability 0.7 and the mean normal lifetime 500 h is activated.

standby RAM air subsystem. The manual switch activation requires certain

Finally, the RAM air failure due to CC, CHEs, or HF leads to the ECS system

procedure, which is time consuming. The required switch time is normally failure in State 4 (Fig. 8).

distributed with mean time 0.01 h. Also, in both switching cases, the required

Using step-wise reduction techniques and Eq. (1), we have the equivalent

time to change the flight altitude is normally distributed with mean 0.05 h. If

transition (W) from State 1 to State 4 as follows: e þ bcd þ bf eðcj þ g þ hÞ bfh

a pack fails due to overheat, the flight crews may repair the pack during flight.

The mean time to repair the overheat pack is normally distributed with mean þ egh

time 2 h. Also, it is assumed that all normal distributions have zero standard

deviation. The flight crew errors or maintenance crew errors in repairing the W ¼

pack may result in changing the state of the system. Fig. 7 presents the flow-

1 bi cj bck a g h þ bih þ cja þ aðg þ hÞ þ ghð1 aÞ

graph model for the warm–cold standby ECS including four states and all (8)

transitions with their associated parameters. where

Fig. 4. Flow-graph model for series of state transitions. and activation requirements. S i S j

Switch type/Activation requirements Transition Description

Fig. 5. Flow-graph model for a state transition with switch type and activation requirements.

Fig. 7. Flow-graph model for a simple version of ECS. 5. Conclusion W S 1 S 4

This study focuses on the warm–cold ECS standby system composed of

Equivalent transition for state 1 to state 4

non-identical and (non)-dedicated standby subsystems that may be activated

through automatic and manual switches under certain activation 1 / W

requirements. Contrary to dedicated subsystems, non-dedicated subsystems

are not general part of the ECS system. They can only be activated if they are

Fig. 8. Reduced flow-graph model for Fig. 7.

not serving other systems. Therefore, their activation method is manual

switch subject to meeting certain flight operational requirements.

Furthermore, because human plays a vital role in preparing the situation for

d ¼ 0:08ðe

switchover and maintenance activities, human errors may cause the system

0:001s þ e0:01sÞjs¼0 ¼ 0:16

degradation or failure. Therefore, we consider three types of failure including

e ¼ 0:08e0:001sjs¼0 ¼ 0:08 f ¼ 0:08e0:001sjs¼0 ¼ 0:08

CCs, human errors, and HFs in the developed model. Also, maintenance

activities are classified into two categories. Category I refers to the repair of

g ¼ 0:8e100sjs¼0 ¼ 0:8 h ¼

the subsystem by the flight crew during the operation time. Category II refers

0:7e500sjs¼0 ¼ 0:7 i ¼

to the repair activity performed by maintenance crews in the next

maintenance inspection in site.

0:02e2sjs¼0 ¼ 0:02 j ¼

The developed model for calculating the time-to-failure data and the 0:01e2sj

probability of the ECS system failure is based on the flowgraph concept. The s¼0 ¼ 0:01

model is made up of nodes and links representing states and transitions

k ¼ 0:04e14sjs¼0 ¼ 0:04

among states with arbitrary time distribution function. Using reduction

techniques and topology equation, the equivalent transition (W) from the

Using Eqs. (2)–(4), the mean time to failure of the system is

starting state to the end state can be obtained. Using Eqs. (2)–(4), we can

1078 flight hours. Also, standard deviation of time to failure is 1182 flight hours.

calculate the system failure probability, MTTF, and STTF. These data can be

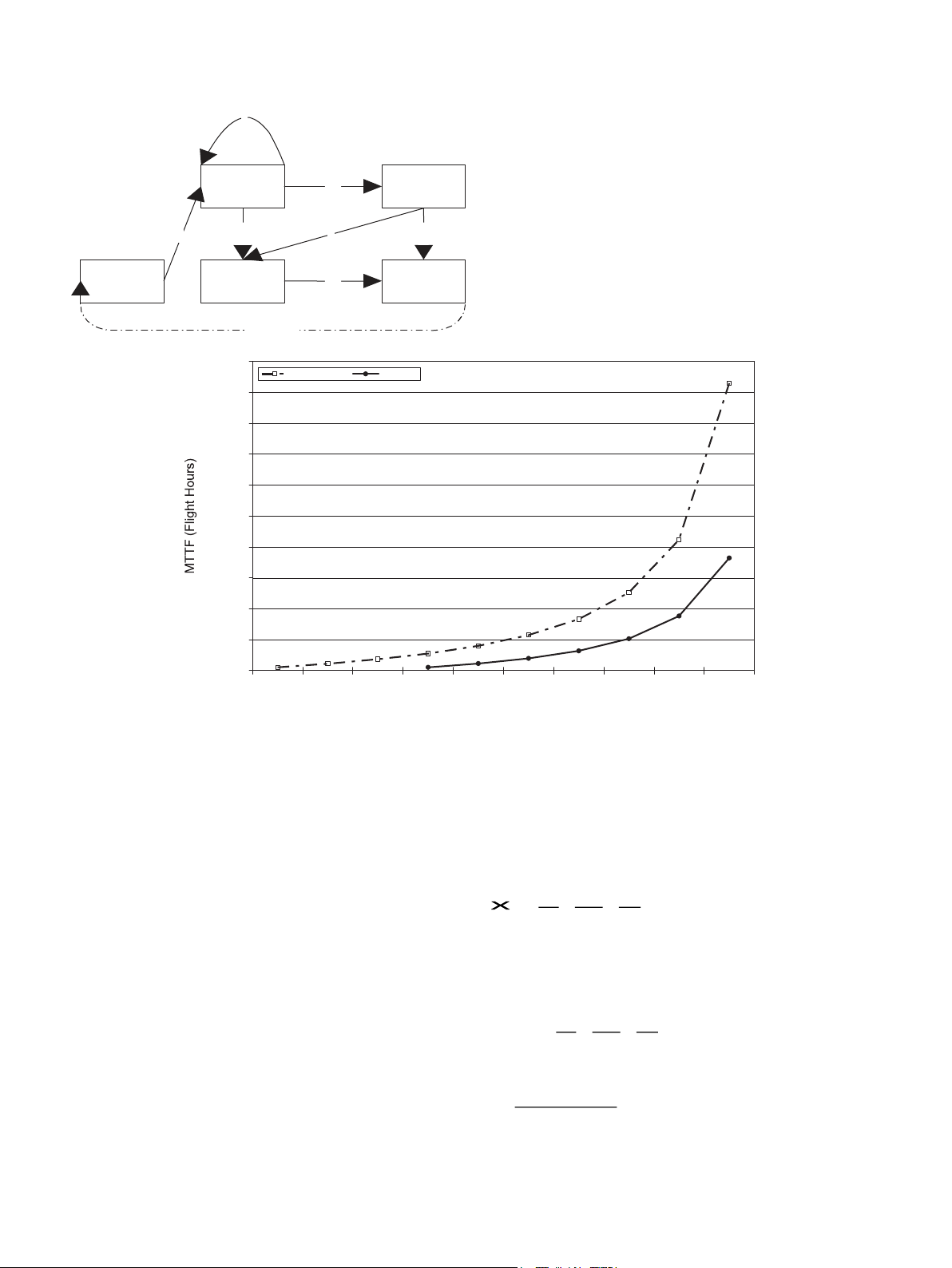

Performing sensitivity analysis, Fig. 9 depicts the relationship of the cooling pack

used for maintenance optimization based on limited failure strategy. Also, we

and the RAM air reliability with the mean time to failure of the ECS. The

can perform sensitivity analysis for MTTF and STTF of the ECS system that

reliability improvement of two warm–cold standby subsystems from 0.89 to

can be obtained from Eqs. (3) and

0.98 can improve the mean to failure. However, reducing the probability of CC,

CHEs, and HF links has no significant effect in improving MTTF. c

In Fig. 10, the flow graph has five nodes (state) and seven links (transition). If

one considers a dummy link from end node ‘E’ to start node ‘S’ with

transmittance 1/W, where W is the equivalent of the flow graph, the flow graph

becomes a closed flow graph. The flow graph has the following four loops: 1 b 2

transmittance of loop I (L1) ¼ abf/W,

transmittance of loop II (L2) ¼ abeg/W, a d e f

transmittance of loop III (L3) ¼ adg/W,

transmittance of loop IV (L4) ¼ c. S 3 g E

To find the equivalent of the flow graph, the topological Eq. (1) must be equal to zero: 1 /W ‘ ‘ ‘ ‘ ‘ ‘ 100000 Cooling packs RAM Air 90000 80000 70000 60000 50000 40000 30000 20000 10000 0 0.89 0.9 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 Reliability of the subsystem

Fig. 9. Mean time to failure of ECS. Fig. 10. Flow graph.

TP ¼ 1 X Li þ X X Li Lj X X X Li Lj Lk þ ¼ 0 i¼1 i j i j k

(4) based on changing the reliability of the subsystems, and transition

elements. For future work, one may extend the multilayer flow-graph for

where the first-order loop (i.e., Li) is composed of only one loop and the second-

evaluating different reliability scenarios.

order loop (i.e., Li Lj) is composed of the product of two disjointed loop ‘i’ and

‘j’. These disjointed loops ‘i’ and ‘j’ have no intersection in their nodes and links.

Similarly, the ‘n’thorder loop can be defined as a product of ‘n’ disjoint loops. Acknowledgments

For example, the transmittance of the first-order loops in Fig. 10 is given by 4

The authors would like to express their sincere appreciation to abf abeg adg

anonymous referees for the constructive comments, which enhanced the

Li ¼ þ þ þ c (9) W W W quality of the paper. i¼1

and there is no second-order loop, because the loops are not disjointed.

Thus, by substituting the transmittance of the first-order loop into the TP Eq. Appendix A

(1), and setting the remaining terms equal to zero, we obtain abf abeg adg

Fig. 10 presents a flow-graph model composed of nodes and links

associated with transmittance (i.e., a, b, etc.) representing states, transition

TP ¼ 1 þ þ þ c (10) W W W

process and transition parameters, respectively.

By equating TP equation equal to zero, we obtain

This closed flow graph has the following basic properties:

abf þ abeg þ adg only one start node, W ¼ (11) only one end node, 1 c

at least one path from the start to the end nodes,

Therefore, the equivalent of the flow graph in Fig. 10 is a singlenode flow

topological equation describing the relationship between path

graph with the transmittance of Eq. (11) where each link transmittance is the

transmittance of a closed flow graph is equal to zero.

product of its probability and its momentum generating function. For example,

in Fig. 2, the transmittance of the link between node ‘2’ and node ‘3’ denoted

by ‘e’ is equal to P23 Rt estf23ðtÞdt. References

[1] Dhillon BS, Rayapati SN. Common-cause failure and human error modeling of redundant

systems with partially energized standby units. Reliab Eng 1987;19:1–14.

[2] Aven T. Availability formulae for standby systems of similar units that are preventively

maintained. IEEE Trans Reliab 1990;39(5):603–6.

[3] She J, Pecht MG. Reliability of k-out-of-n warm standby system. IEEE Trans Reliab 1992;1(2):50–9.

[4] Dhillon BS, Yang N. Human error analysis of a standby redundant system with arbitrarily

distributed repair times. Microelectron Reliab 1993;33(3):431–44.

[5] Pham TG, Turkkan N. Reliability of a standby system with beta-distributed component lives.

IEEE Trans Reliab 1994;43(1):71–5.

[6] Subramanian R, Anantharaman V. Reliability analysis of a complex standby redundant

system. Reliab Eng Syst Saf 1995;45:57–70.

[7] Dhillon BS, Yang N. Probabilistic analysis of a maintainable system with human error. J Qual Maint Eng 1995;1(2):50–9.

[8] Aven T, Optal K. On the steady state unavailability of standby systems. Reliab Eng Syst Saf 1996;52:171–5.

[9] Sridharan V, Mohanavadivu P. Some statistical characteristics of a repairable, standby,

human and machine system. IEEE Trans Reliab 1998;47(4): 431–5.

[10] Mahmoud MAW, Esmail MA. Stochastic analysis of a two-unit warm standby system with

slow switch subject to hardware and human error failures. Microelectron Reliab 1998;38:1639–44.

[11] Zhong YL. An optimal geometric process model for a cold standby repairable system. Reliab

Eng Syst Saf 1999;63:107–10.

[12] Ke J, Wang K. The reliability analysis of balking and reneging in a repairable system with

warm standbys. Qual Reliab Eng Int 2002;18:467–78.

[13] Motta SB, Colosimo EA. Determination of preventive maintenance periodicities of standby

devices. Reliab Eng Syst Saf 2002;76:149–54.

[14] Utkin LV. Imprecise reliability of cold standby systems. Int J Qual Reliab Manage 2003;20(6):722–39.

[15] Seo JH, Jang JS, Ba DS. Lifetime and reliability estimation of repairable redundant system

subject to periodic alternation. Reliab Eng Syst Saf 2003; 80:197–204.

[16] Zhang T, Xie M, Horigome M. Availability and reliability of k-out-of-(M+N)-G warm standby

systems. Reliab Eng Syst Saf 2006;20(6):722–39.

[17] Azaron A, Katagiri H, Kato K, Sakawa M. Reliability evaluation of multicomponent cold-

standby redundant systems. Appl Math Comput 2006;173:137–49.

[18] Jayabalan V, Chaudhuri D. Optimal maintenance and replacement policy for deteriorating

system with increased mean downtime. Naval Res Logistics 1992;39:67–78.

[19] Pritsker AAB, Happ WW. GERT: Graphical evaluation and review technique:

Part I: fundamental. J Industrial Eng 1966;17(5):267–74.