Preview text:

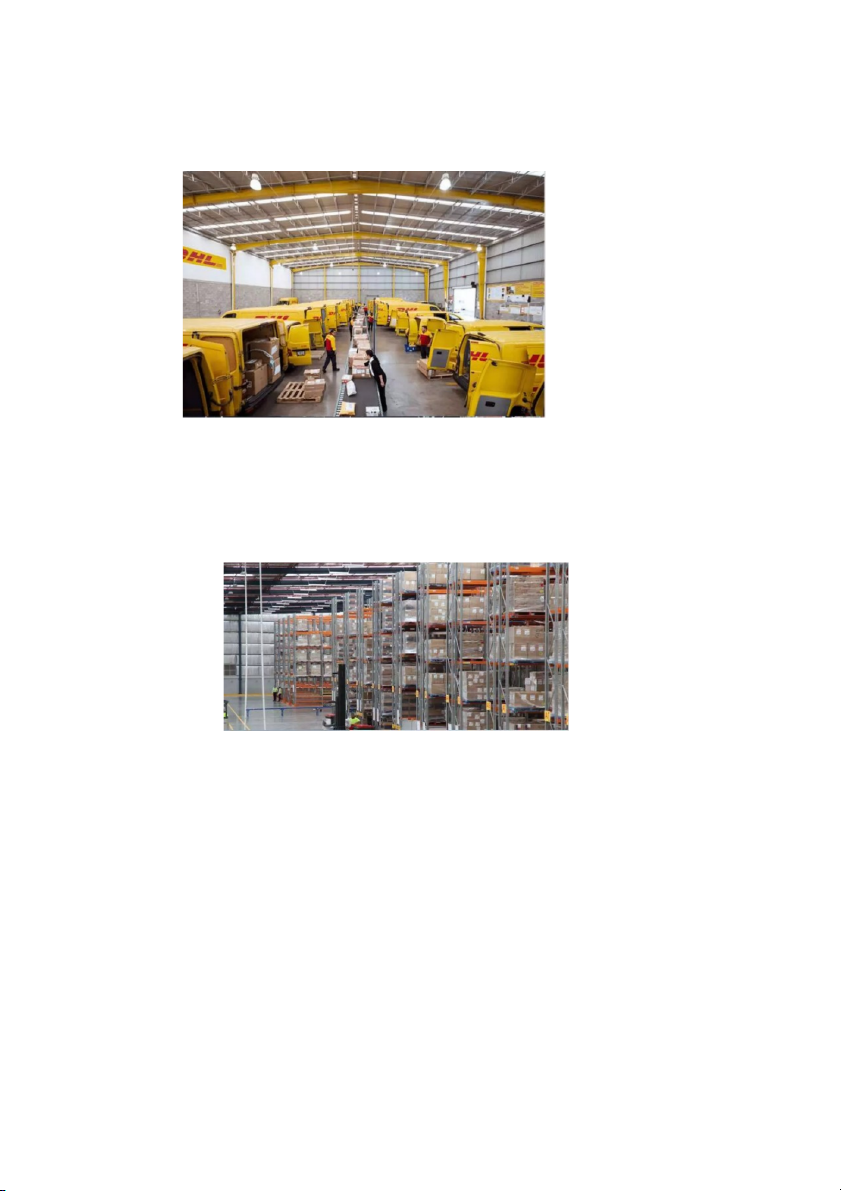

2.1.1. Cross docking:

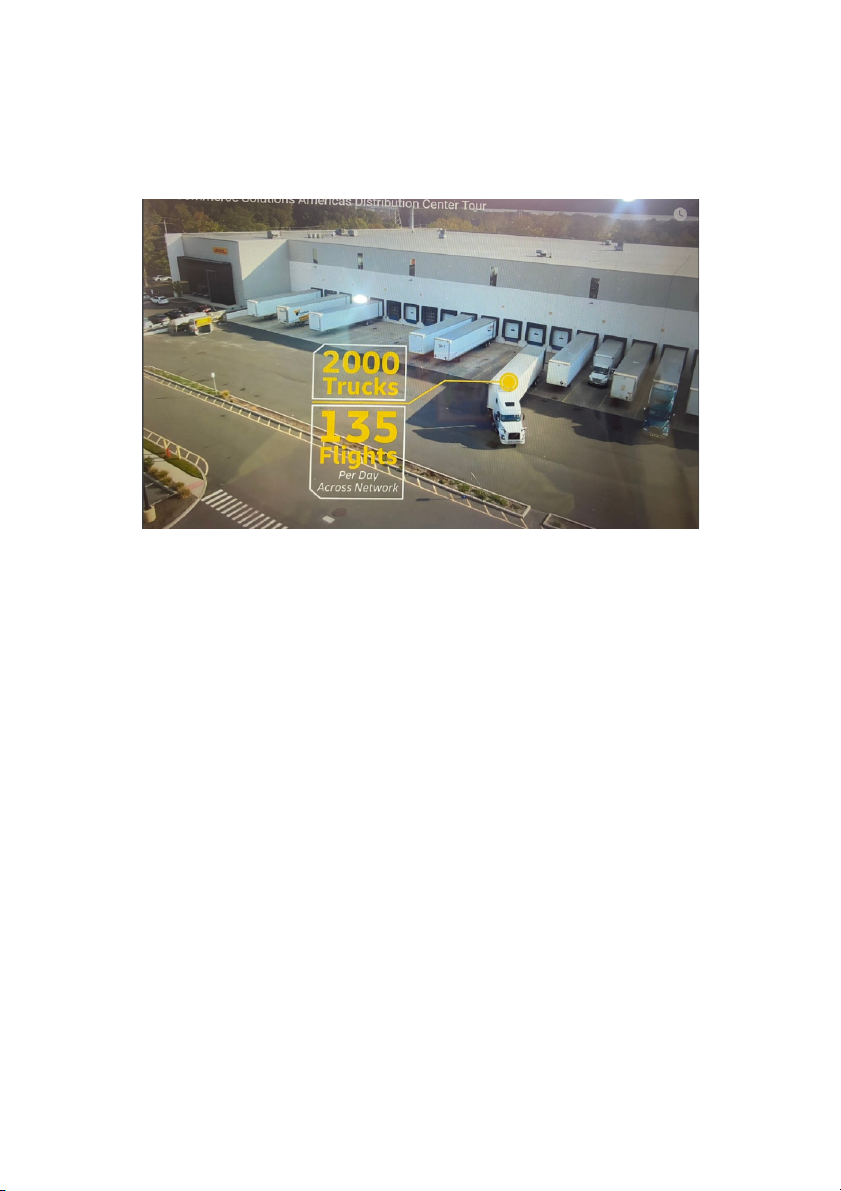

Pictures: DHL’s cross docking

DHL’s company have 64 dock doors to handle all of our inbound and outbound

truck. 95 trailers,2000 trucks come in and out on a daily basis pallet are offloaded and the

receiver verifies the shipper’s Bill off Landing

2.1.2. DHL’s Bonded Warehouse:

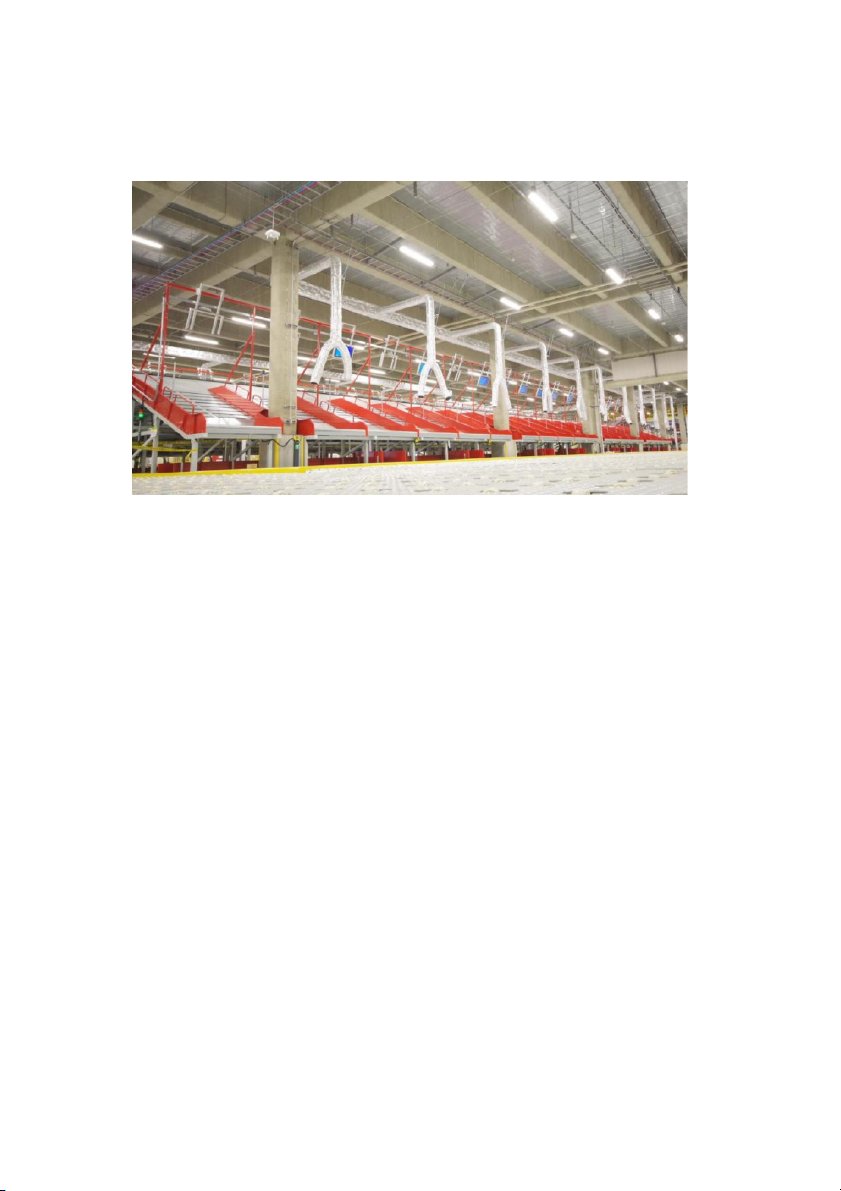

Pictures: DHL’S Bonded Warehouse

DHL invest a brand new 25,000 sq m hub in Segro Park Coventry Gateway, located

south of Coventry Airport. DHL will also feature secure bonded storage and customs

capabilities to support international e-commerce, a 48-door cross-dock facility and state-

of-the-art mechanisation, allowing automatic sortation of mixed-sized and weight items

through high-speed sortation equipment.

Pictures: DHL Toyoko Distribution center

DHL Tokyo Distribution Center (TDC) is currently situated, the new DHL Express

Tokyo Gateway is accessible from the Narita International Airport, Haneda Airport, and

Tokyo’s business districts. The new Osaka Distribution Center will increase shipment

processing capacity by more than 50%.

2.1.2. Warehouse Management System ( WMS ): 2.1.2.1. Internet of Things:

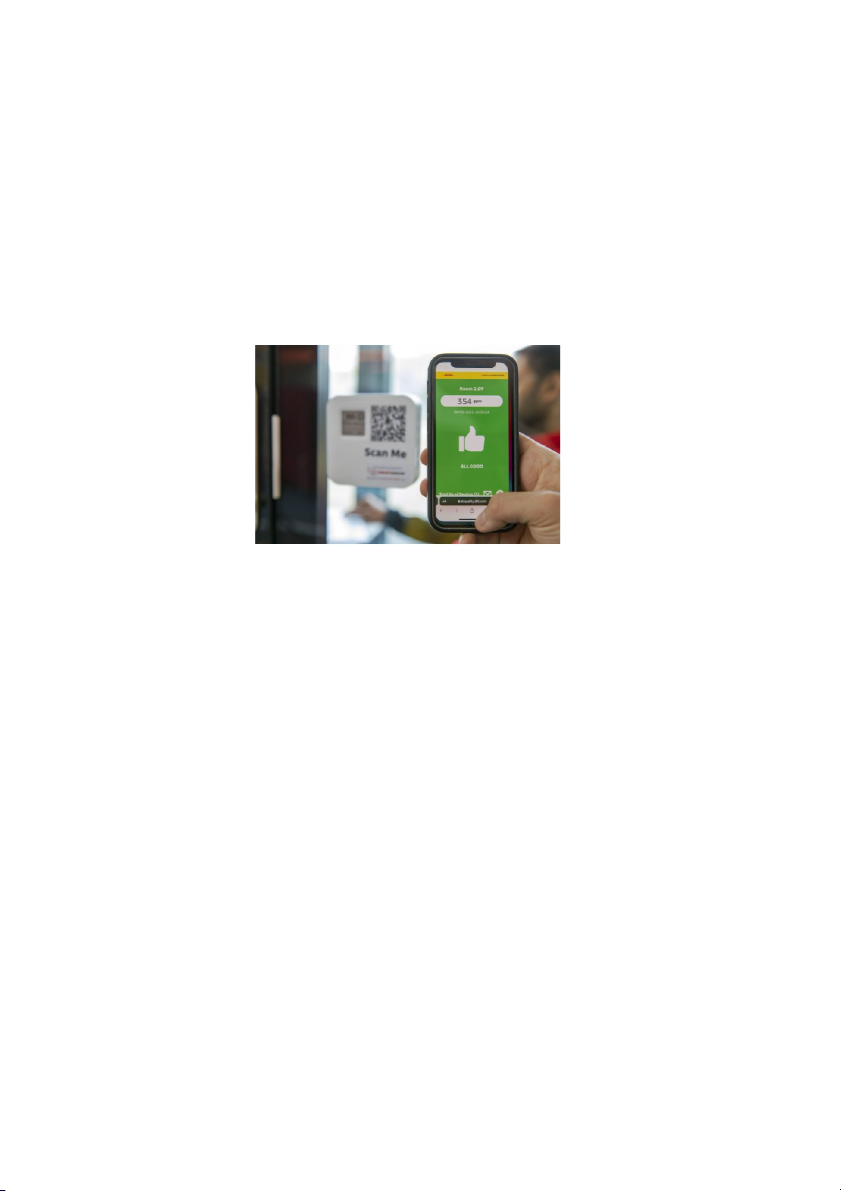

Pictures: DHL is using Internet of Things

The internet of things is a technology that allows us to add a device to an inert object (for

example: vehicles, plant electronic systems, roofs, lighting, etc.). IoT measure

environmental parameters, generate associated data and transmit them through a communications network.

The Internet of Things (IoT) has made full supply chain transparency - shipment

visibility, asset tracking, and condition monitoring - more possible than ever. As network

telecommunication systems speed up and expand reach, sensors are becoming

increasingly more affordable, thus making the potential for realizing new operational

efficiencies through a dedicated IoT strategy boundless.

Shipment monitoring for security and loss prevention:

Pictures: Prevent loss of goods

Iot can now monitor items as they move around a warehouse or distribution center as

well as across the entire supply chain.

Devices using GPS technology have been around for a long time, but it’s only recently

that they have the capabilities to add real value to logistics. Small sizes, long battery

lives, and strong signal strengths have made them a perfect solution for quality control

and loss prevention in small package shipping. Today’s devices come in all shapes and

sizes and can detect temperature, humidity, light, vibrations, etc.

Picture : Cold chain monitoring

IoT device now keeps track of the temperature

Covid-19 pandemic has put IoT to the test – and it passed. BioNTech announced its

vaccine needed to be transported at -70°C, it was up to logistics companies to develop

solutions to provide end-to-end visibility

IoT devices record and report conditions based on customer requirements, with the

system flagging deviations detected.

Picture: Facility condition monitoring

Monitoring environmental conditions: Monitoring a facility was a manual and time-

consuming process. IoT devices are now connected using low-powered wide-area

networks (LPWANs), transmitting information in real-time to a central platform and the customer. RFID: Picture: RFID

Smart Sensor RFID: Monitors temperature data during the course of transportation. RFID

can be used in air, sea, land transportation without restriction because it is a passive

device based on RFID technology. The data can be analyzed in retrospect via the online

Web Portal and are available 24/7 world wide. WHM:

Pictures: DHL’s Warehouse Management

WHM ease the complex storage and distribution management as it integrates with the

framework of ERP to support the basic processes in warehouse areas. Barcode : Picture: Barcode

Barcode located on all customer goods and it is optical and electronically readable

respentation of information that consists of various widths or parallel lines and spaces.

Three types: 2-D Codes 3- D Code 4-D Code.

2.2.2. Material Handling System: Dock shelter and Dock Lever: Picture: DHL Dock Shelter

21 complete loading bays with swing lip dock levellers, sectional overhead

doors & curtain dock shelters. Including sectional overhead doors in 4 level access ramps. Picture: DHL dock Level

DHL transports 40 million pounds of freight and 2 billion shipments a year, with 76,200

vehicles and more than 250 aircrafts. The company employs over 530,000 people worldwide Folklift:

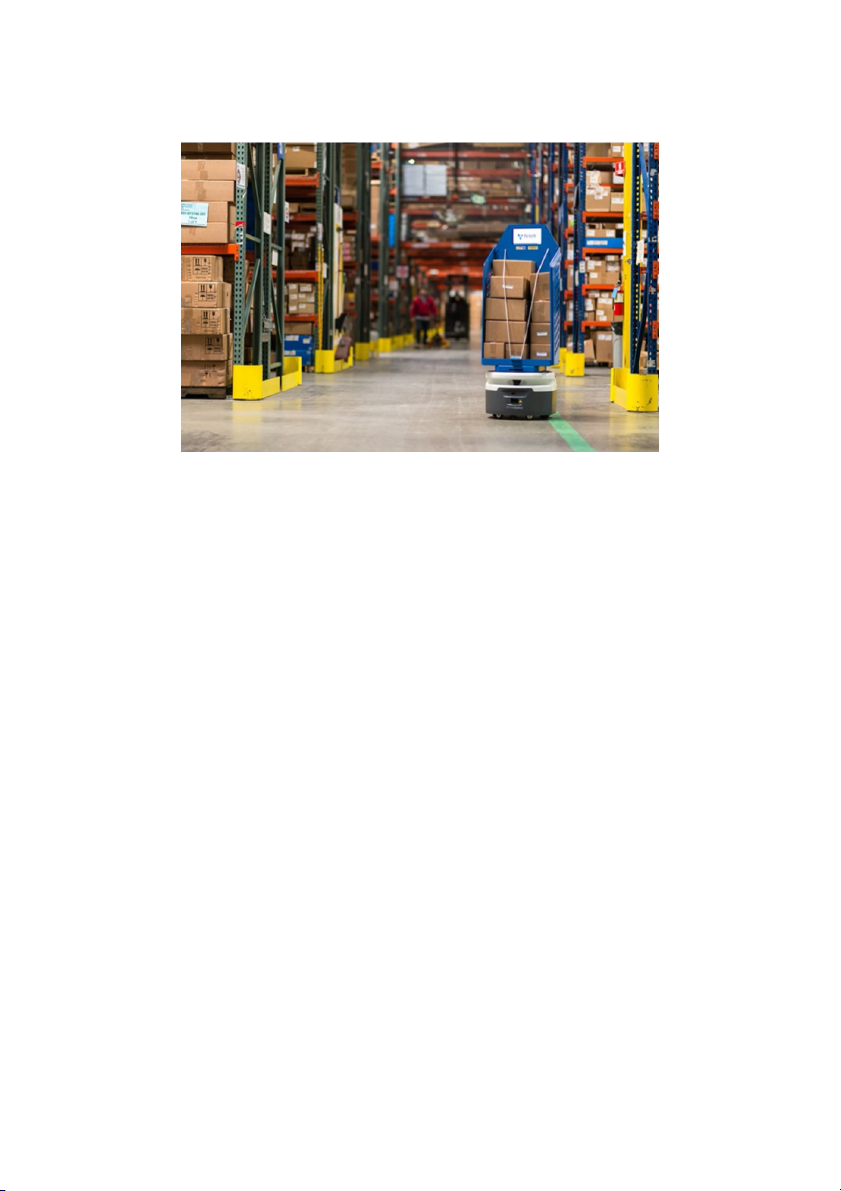

Pictures: DHL Automatic FolkLift

DHL Supply Chain, the contract logistics arm of Deutsche Post DHL Group, is further

accelerating the commercial deployment of autonomous forklifts and pallet movers in its

more than 1,500 warehouses worldwide, focusing on sites in labor-tight markets across

Europe, the United Kingdom, Ireland and North America. Autonomous pallet movers can

handle both horizontal and vertical movements of palletized goods, making them

especially useful in sectors such as consumer, retail or automotive that are characterized

by full-pallet handling. The deployment is part of DHL Supply Chain's Accelerated

Digitalization agenda, a strategy for commercializing and scaling innovative solutions and new technologies.

Autonomous forklifts take over the picking, put-away and replenishment of full pallets in

warehouses, reducing the number of manual pallet transfers without requiring significant

changes in warehouse infrastructure. Such forklifts can easily reach DHL’s highest

warehousing racks at heights of more than 10 meters and can handle all kinds of pallets,

stillages and other unit load storage equipment. Pallet: Pictures: DHL uses Pallet

Wooden barrels and crates were once the de facto standard of storing and transporting

goods, but moving them was a labor intensive and inefficient task. Shippers had to find a

better way to easily stack and transfer huge amounts of goods quickly.

Pallets are equipment for loading goods. Products are stacked up and evenly arranged on

the pallet before they are secured together by cling wrap or other means. The forks of the

forklift are then inserted into a cavity between the top and bottom platforms of the pallet,

before being raised to lift and move as a single unit. Scan:

DHL’s employees use a barcode scanner to read the barcode. Conveyor: Picture: DHL Conveyor

DHL Express plans to install a unique automated conveyor belt for palletised items in its

new Leipzig terminal in order to speed up processing times. The conveyor system

is part of the €150m development of a second terminal at its

European hub that will see the freight processing capacity increase

by 50% to more than 15,000 shipments per hour.

To improve processing time, the intergrator will install a track

system that will be able to transport ‘non-conveyable items’ from

one end of the terminal to the other.

2.3. Warehouse Layout and Product flow options: Picture: DHL warehouse Layout

DHL uses centralized Bonded warehousing and distribution centers. The warehouses are

divided in 2 parts such as: receiving, storage. The storage model used by DHL prevent

fire and explosion in the warehouse, protect the goods in the warehouse safely.

All DHL’s warehouses are Bonded to pushing out the payment of custom duties until the

goods are released from the bonded warehouse pushing out the payment of custom duties

until the goods are released from the bonded warehouse. Reference:

https://www.dhl.com/global-en/delivered/digitalization/the-value-of-iot-in-supply-

chains.html#:~:text=IoT%20delivers%20transparency%20and%20resilience&text=A%20tour%20through

%20the%20DHL,a%20commodity%20but%20a%20constant.

https://www.loading-systems.com/markets-solutions/logistics/dhl