Preview text:

lOMoAR cPSD| 58097008 A) • Total Revenue (TR) Equation:

TR=Price per unit×QTR = \text {Price per unit} \times QTR=Price per unit×Q

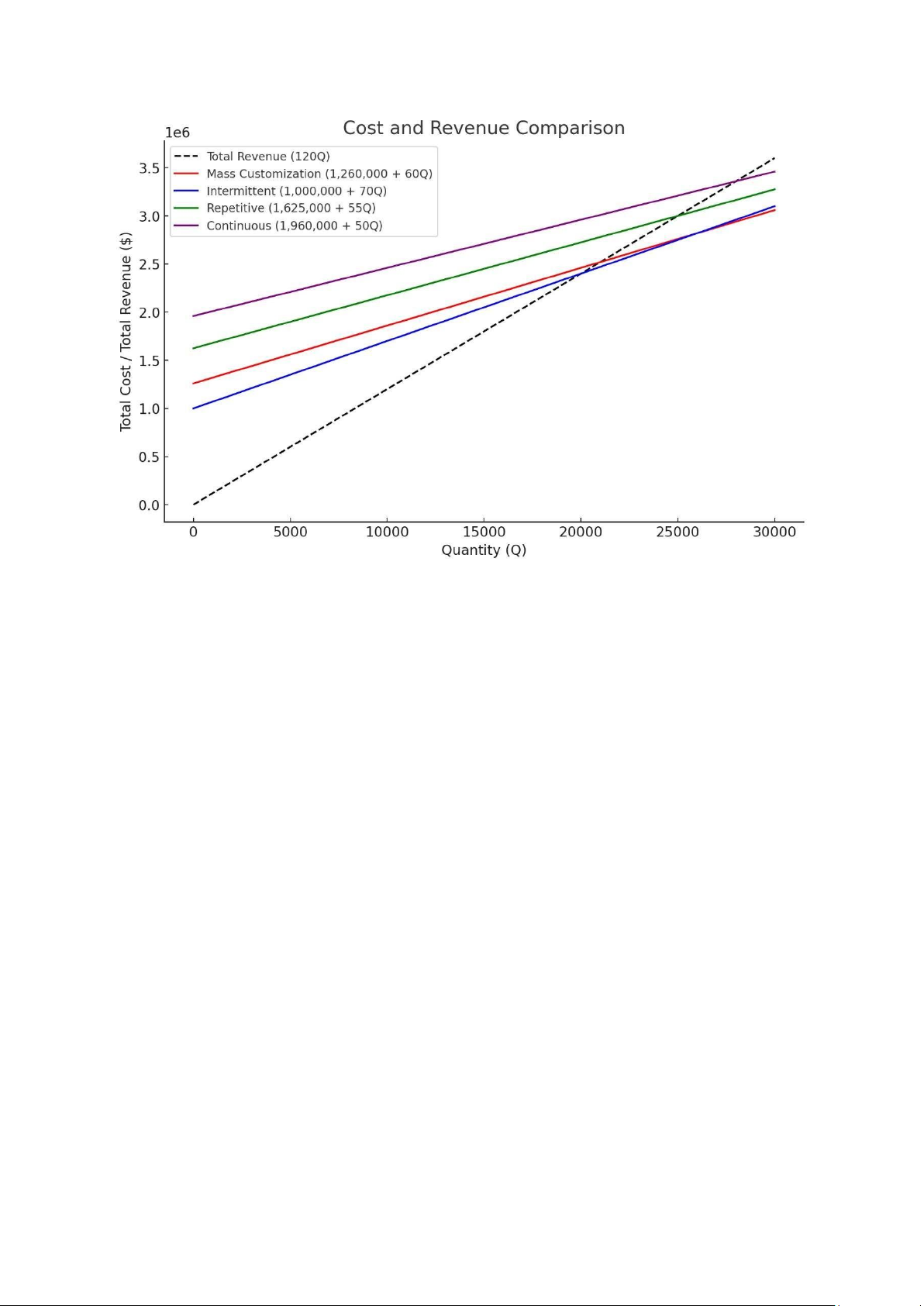

Given that the Maxistand sells for $120 per unit, we get: TR=120QTR = 120QTR=120Q •

Total Cost (TC) for each process type:

TC=Fixed Cost+(Variable Cost per Unit×Q)TC = \text{Fixed Cost} + (\ text{Variable Cost per Unit} \times Q)TC=Fixed Cost+

(Variable Cost per Unit×Q) where:

Variable Cost per Unit=Labor+Material+Energy\text{Variable Cost per

Unit} = \text{Labor} + \text{Material} + \ text{Energy}Variable Cost per

Unit=Labor+Material+Energy Let's compute the total variable costs for each process type: Fixed Process Type Variable Cost per Unit Cost Mass

$1,260,0 30+18+12=6030 + 18 + 12 = Customization 00 6030+18+12=60

$1,000,0 24+26+20=7024 + 26 + 20 = Intermittent 00 7024+26+20=70

$1,625,0 28+15+12=5528 + 15 + 12 = Repetitive 00 5528+15+12=55 Continuous

$1,960,0 25+15+10=5025 + 15 + 10 = 00 5025+15+10=50

Thus, the Total Cost (TC) equations are:

o Mass Customization: TC=1,260,000+60QTC = 1,260,000 +

60QTC=1,260,000+60Q o Intermittent: TC=1,000,000+70QTC = 1,000,000 +

70QTC=1,000,000+70Q o Repetitive: TC=1,625,000+55QTC = 1,625,000 +

55QTC=1,625,000+55Q o Continuous: TC=1,960,000+50QTC = 1,960,000 + 50QTC=1,960,000+50Q

We will plot Total Revenue (TR) along with the Total Cost (TC) for all four process types. I'll generate the graph now. lOMoAR cPSD| 58097008 B)

A cross-over point is where two cost functions are equal:

Fixed Cost1+(Variable Cost1×Q) =Fixed Cost2+(Variable Cost2×Q)\ text{Fixed Cost}_1 +

(\text{Variable Cost}_1 \times Q) = \text{Fixed Cost}_2 + (\text{Variable Cost}_2 \times

Q)Fixed Cost1+(Variable Cost1 ×Q)=Fixed Cost2+(Variable Cost2×Q)

Let's compute the cross-over points between different process types.

Step 4: Interpretation of Cross-Over Points

The cross-over points indicate where one process becomes more costeffective than another. Key findings: •

Mass Customization vs. Intermittent: Q=26,000Q = 26,000Q=26,000 •

Intermittent vs. Repetitive: Q=41,667Q = 41,667Q=41,667 •

Intermittent vs. Continuous : Q=48,000Q = 48,000Q=48,000 •

Repetitive vs. Continuous : Q=67,000Q = 67,000Q=67,000

Since the projected demand is 24,000 units, we choose the Intermittent Process because it

has the lowest cost at this quantity. C) lOMoAR cPSD| 58097008 Profit is given by:

Profit=Total Revenue−Total Cost\text {Profit} = \text{Total Revenue} - \ text{Total

Cost}Profit=Total Revenue−Total Cost For 24,000 units, we calculate the profit for each process:

\text{Profit} = 120(24,000) - \text{Total Cost} \]

The calculated profits at 24,000 units are: • Mass Customization: $180,000 •

Intermittent: $200,000 (Highest Profit) • Repetitive: -$65,000 (Loss) • Continuous: -$280,000 (Loss)

Thus, Intermittent Process is the best choice for maximizing profit at the given demand