Preview text:

I. REFRIGERATOR/ COLD STORAGE

● This is the best and most efficient method for commercial storage.

● Eggs for cold storage must be clean, unbroken, and free from fungus and other infections.

● A temperature of 0oC or 30-32oF and relative humidity of 85-90% is

recommended for cold storage of eggs to preserve them for 5 to 8 months.

● For a short period of preservation of 2 to 3 months, eggs can be stored at

10-12oC or 50-55oF with a relative humidity of 60-70%.

● Intact eggs are held at the lowest possible temperature which will avoid

freezing and bursting of the shells.

● It has been observed that intact eggs do not freeze at temperatures between

-1.5oC and -2oC and the relative humidity must not go beyond 90%. II. EGGSHELL TREATMENT

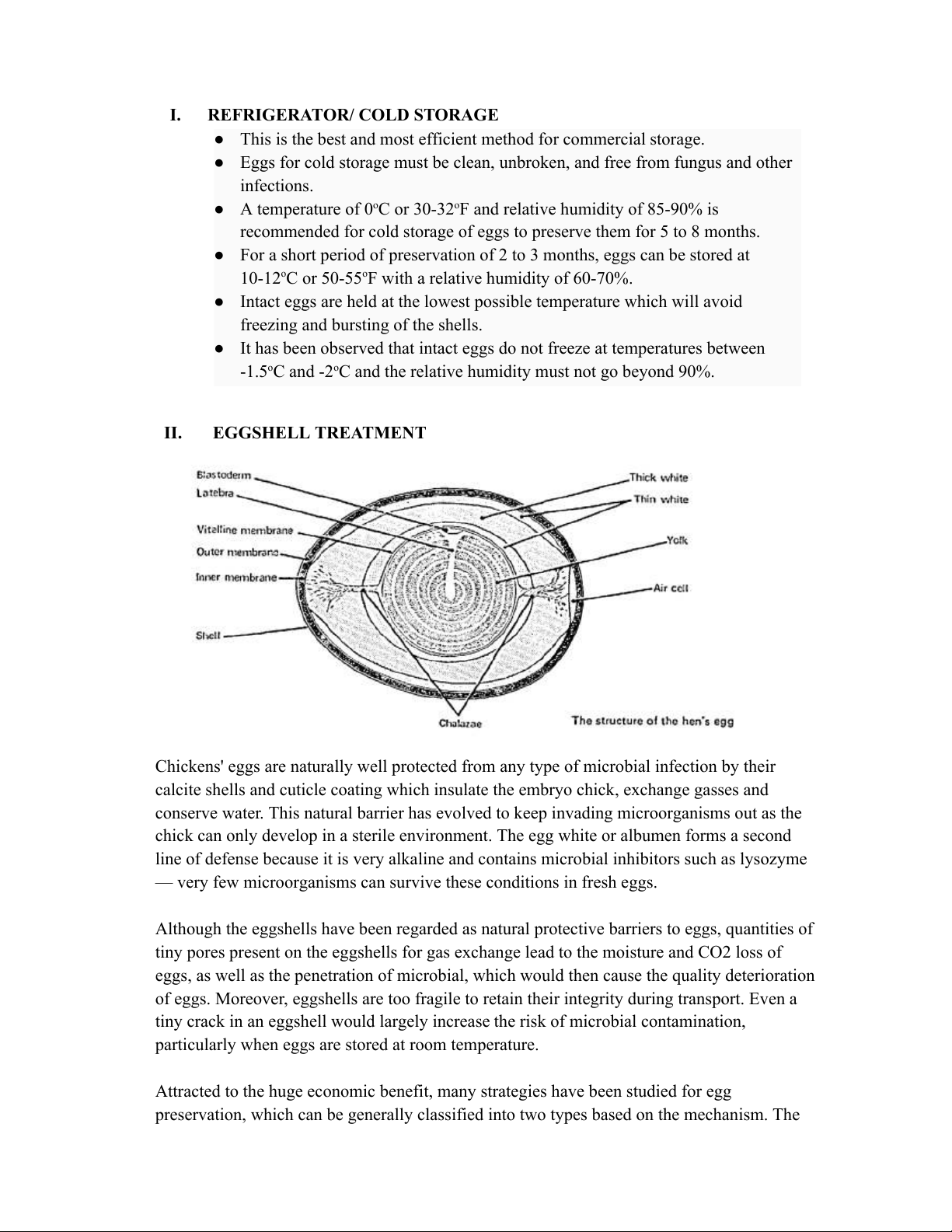

Chickens' eggs are naturally well protected from any type of microbial infection by their

calcite shells and cuticle coating which insulate the embryo chick, exchange gasses and

conserve water. This natural barrier has evolved to keep invading microorganisms out as the

chick can only develop in a sterile environment. The egg white or albumen forms a second

line of defense because it is very alkaline and contains microbial inhibitors such as lysozyme

— very few microorganisms can survive these conditions in fresh eggs.

Although the eggshells have been regarded as natural protective barriers to eggs, quantities of

tiny pores present on the eggshells for gas exchange lead to the moisture and CO2 loss of

eggs, as well as the penetration of microbial, which would then cause the quality deterioration

of eggs. Moreover, eggshells are too fragile to retain their integrity during transport. Even a

tiny crack in an eggshell would largely increase the risk of microbial contamination,

particularly when eggs are stored at room temperature.

Attracted to the huge economic benefit, many strategies have been studied for egg

preservation, which can be generally classified into two types based on the mechanism. The

first one is to deactivate the microorganisms on the eggshells, including techniques such as

ultrasonic treatment [Hình 1], ozone treatment [Hình 2], application of AgNPs-doped paper

egg trays [Hình 3], vacuum packaging [Hình 4], The other one is to seal the pores on

eggshells by coating, which serves as good barrier layers towards water vapor, gasses, and

microorganisms. The most widely studied coating materials are oil, proteins, biopolymers, etc. 1. EGG CLEANING 1.1. Dry cleaning:

This was the recommended practice before the development of sanitizing compounds

capable of maintaining washing water and equipment in a condition so that wet cleaning

methods could be used. The simplest dry cleaners are hand abrasive blocks to scratch the dirt

or stain from the shell surface. Abrasives were put on mechanically rotated wheels so that

eggs could be rapidly cleaned by holding individual eggs against the rotating abrasive

surface. Although mechanical equipment for dry cleaning shell eggs was developed it has

been made obsolete by wet cleaning procedures.

The disadvantage of dry cleaning is the weakness of the shell. 1.2. Wet cleaning

For the clean appearance of eggs, washing is a more effective and simplest method for

removing dirt and stains from the shell surface. The egg wash water temperature needs to be

at least 11℃ higher than the egg temperature. The temperature differential between the eggs

and wash water is also critical, as a difference of more than 10℃ results in an increased

number of thermal cracks due to the expansion of the contents of the egg. In older eggs with

enlarged air cells, thermal checking is not a serious problem. Also, a water temperature of at

least 35℃ is needed for adequate cleaning. By not recycling water and by giving careful

attention to the temperature difference between eggs and washing Water eggs can be cleaned

with a minimum of hazard to quality. Disadvantage:

There is a possibility of remaining bacterial penetration of the shells, with resultant rotten

eggs. A temperature difference of more than 10℃ results in an increased number of thermal

cracks due to the expansion of the contents of the egg.

Cold eggs subject to hot water will expand too fast and crack the shell (expansion checks) on

the other hand the interior contents of eggs that have been washed in hot water and then

rinsed by immersion in cool water contract and aspirate bacteria through the shell. The

organisms multiply and the eggs spoil.

Modern egg washers are designed to minimize the above conditions by spraying water, rather

than immersing them using a sanitizer in water along with detergent for cleaning them using

rinse water warmer than the wash water, and finally dry the eggs with hot air.

A general recommendation is to handle shell eggs at less than 10℃ at all times. 2. Oil treatment:

Oil coating preserves the egg by forming a thin film on the surface of the shell and thereby

sealing the pores. The treatment should preferably be given within a few hours of lay to retain

better internal quality. Washing and subsequent coating preserve eggs much better than

coating alone. The oil used must be odorless, colorless, and free from fluorescent materials.

Light mineral oil of food quality is normally used. Vegetable oil such as groundnut oil mixed

with 0.0125% BHT is a good sealing agent. Mineral oils of food grade are less susceptible to

oxidative changes during storage. Eggs can either be dipped in oil or sprayed with it. 3. Immersion in liquids

Under village conditions, liquids like lime water and water glass are very useful. This is an

old method of preserving the quality of shell eggs, especially for home use. In lime sealing,

one liter of boiling water is added to one kg of quick lime. The fluid is brought to room

temperature, and 4-5 liters of cold water, and 250g of table salt are added to it. On the

mixture setting down the solution is strained. The eggs are immersed in thin clear fluid for

16-18 hours and then taken out. Eggs are dried at room temperature and transferred to filler

flats. The eggs can be stored for 3 to 4 weeks at room temperature.

The preservative effect of lime water is partially due to its alkalinity. It deposits a thin film of

calcium carbonate on the eggshell and partially seals the pores.

The water glass is prepared by diluting 1 part of sodium silicate with 10 parts of water and

the eggs are left immersed over right in the water glass. It deposits a thin precipitate of silica

on the surface of the eggshell, possesses intrinsic antiseptic properties, and does not impart odor or taste to the eggs.

When started at 1℃ to 3℃, the water glass preserved eggs were comparable to fresh eggs in

all attributes. The egg can be stored at 13 - 15℃ for six month 4. Thermal processing:

This includes flash heat treatment, thermostabilization, and simultaneous coating.

a) Flash heat treatment: the immersion of eggs in boiling water for 5 seconds. This

resulted in eggs with superior storage characteristics at storage temperatures of either 5℃ or 21 .

℃ Immersion for only 3 seconds in boiling water was effective in reducing

bacterial spoilage in fresh eggs.

b) Thermostabilization: This involves immersion in hot water or oil for sufficient time to kill

the embryo in fertile eggs and stabilize the thick albumen. The time and temperature

suggested are 60℃ for 14 minutes. Simultaneous oil treatment and thermostabilization

complement each other in maintaining the inner quality of the egg. Advantages: ● Eggs are pasteurized. ● Eggs are defertilised

● Eggs have better keeping quality Disadvantage:

● The danger of cooking eggs.

● Requires lab instruments to control heat. ● Time-consuming. ● Expensive. III. LIQUID EGG

Cracked or sub-standard eggs are preserved commercially by drying or freezing for use in

the food industry. At home, we can successfully freeze eggs for use in baking, for omelets

or scrambled eggs, etc. Fresh eggs cannot be frozen in the shell because they crack and

become 'gluey' due to dehydration and changes in the albumen proteins. Hard-boiled eggs

are also disappointing after freezing because they become leathery and sometimes have an

open 'weeping' texture. Eggs for freezing should be broken and whisked lightly.

Alternatively, yolks and whites can be separated and frozen in suitable quantities for later

use. The quality of frozen yolks or whole eggs is improved by the addition of either salt or

sugar which stops the yolk from coagulating — recommended quantities are ½ tsp. salt or

1 tsp. caster sugar for every 2 yolks or 1 egg. These packs should be labeled for use in

savory or sweet dishes. Egg whites need no additives to preserve their texture and will

whip satisfactorily after thawing. All egg products stored in the freezer will keep for up to

ten months. When required the eggs should be thawed quickly at room temperature or

under running, cool water to prevent coagulation and thickening.