Preview text:

lOMoAR cPSD| 58794847 Bài tập 1:

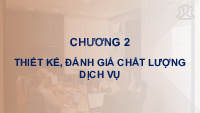

The process to be controlled is a filling operation in a packaging shop where a

powder chemical is filled in bags. The net weight of the chemicals in the filled

bags is to be controlled using control charts so that the average and variability of

the net weight of all the filled bags remain consistent. The data are shown in

Figure 1 on a standard control chart form. In this example, 24 samples of five

bags each were collected at approximately one-hour intervals.

Let’s use the X- and R-charts to control the average and variability of the filling operation.

Figure 1 The net weight of the chemical in the filled bags Bài tập 2:

The data from exercise 1. Calculate the limits for the X and S-charts. Bài tập 3:

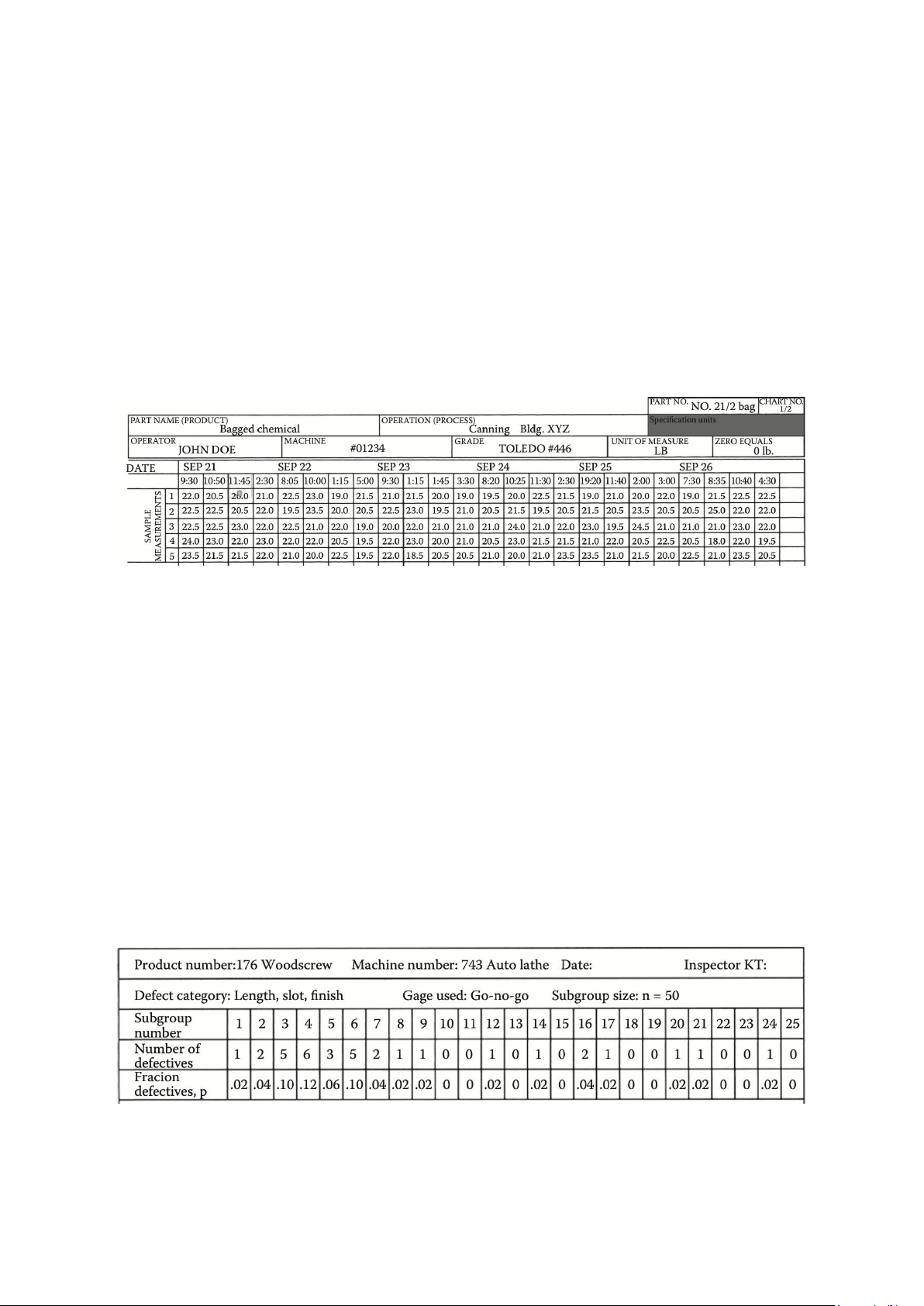

The process was an automatic lathe-producing wood screws. Samples of 50

screws were taken every half-hour, and the screws were gaged for length, the

diameter of the head, and slot position and were also visually checked for the

finish. The number rejected in each sample for any reason was recorded, as shown

in Figure 2. Prepare a control chart (P-chart) to monitor the fraction defectives in the process. Bài tập 4: lOMoAR cPSD| 58794847

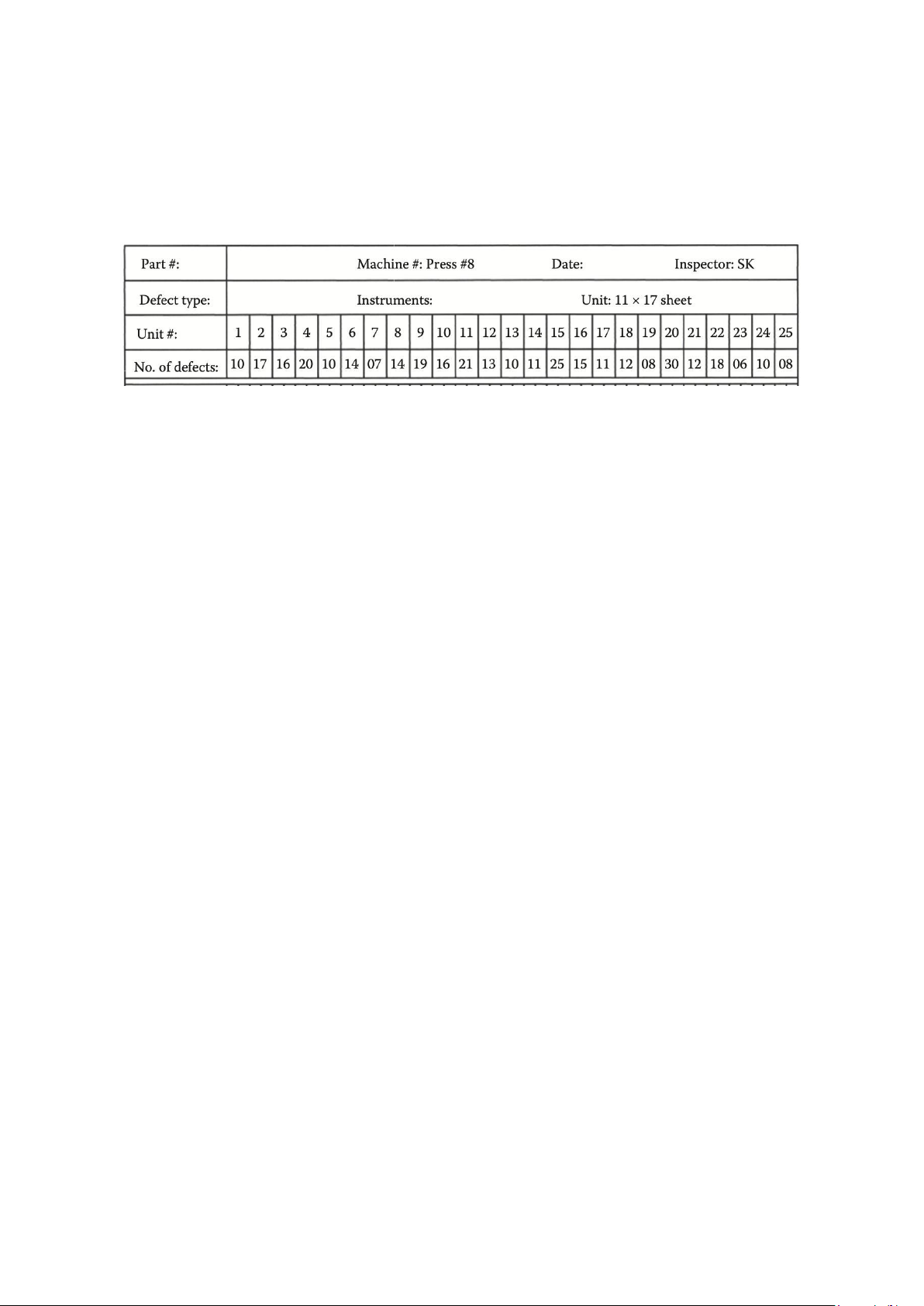

The process is a laminating press that puts plastic lamination on printed art sheets,

which are later cut and finished into a credit card-type product. The number of

defects such as bubble, tear or chicken scratches on the laminated sheets is to be

controlled by counting the number per sample sheet. Prepare a control chart (C-

chart ) to control the defects per sheet.