Preview text:

lOMoARcPSD|45316467 lOMoARcPSD|45316467 Group 12 | INS 3021 01

VIETNAM NATIONAL UNIVERSITY, HA NOI INTERNATIONAL SCHOOL ---------o0o--------- FINAL REPORT

GLOBAL SUPPLY CHAIN MANAGEMENT ZARA’s Supply Chain GROUP: 12

Course Code: INS 3021. 01 MEMBERS: Ta Bich Ngoc 19071445 Vu Thi Quynh Anh 19071306 Nguyen Tung Lam 20071018 Nguyen Mai Linh 19071407 LECTURER: PhD Tran Cong Thanh Hanoi, December 2022 1 lOMoARcPSD|45316467 Group 12 | INS 3021 01 INDIVIDUAL CONTRIBUTION

Course Name: Global Supply Chain Management

No: ……………………… Course Code: INS 3021. 01 Group No.12 Student No Full name Tasks Contribution ID - About the report 1 Ta Bich Ngoc

19071445 - Zara's supply chain stage 100% - Supply chain design Vu Thi - Zara supply chain management 2 19071306 100% Quynh Anh issues and practices Nguyen Tung 3 20072018 - Forecasting 100% Lam Nguyen Mai - Zara’s overview 4

19071407 - Supply chain strategy. 100% Linh - Supply chain design 2 lOMoARcPSD|45316467 Group 12 | INS 3021 01 TABLE OF CONTENTS

PART A: Introduction................................................................................4

About the report.........................................................................................4

Zara’s Overview.......................................................................................4

PART B: ZARA Supply chain...................................................................5

I. Supply chain stage of Zara...................................................................5

II. Zara’s Lean Supply Chain................................................................7

III. Supply chain design.............................................................................9

PART C: Zara supply chain management issues and practices...........14

I. Relationship management..................................................................14

II. Inventory Management.......................................................................15

III. Reserve Logistics...............................................................................17

IV. Forecasting.........................................................................................18

REFERENCES:........................................................................................21

APPENDIX:...............................................................................................24

SELF ASSESSMENT:..............................................................................28 3 lOMoARcPSD|45316467 Group 12 | INS 3021 01 PART A: Introduction About the report

The purpose of this study is to evaluate and assess Zara's worldwide supply chain

strategy and management priorities. A high-level overview of Zara's supply chain is

given in the article. In order to manage the supply chain sustainably and at the lowest

possible cost, we looked at the challenges the organization faced and how they operated,

and offered suggestions for enhancing Zara's supply chain to make it more effective and ideal. Zara’s Overview

Zara is a Spanish clothing retailer based in Galicia, Spain. Founded by Amancio Ortega

in 1975, it is the flagship chain store of the Inditex group, one of the world's largest

apparel retailers. It has stores in 96 countries and is the flagship brand of the Inditex

Group. Zara is renowned for its ability to develop a new product and get it to stores

within two weeks, while other retailers take six months.

Zara’s mission is to give the customer what they want and give it to them faster than

anyone else. Zara’s vision is to contribute to the sustainable development of society and

that of the environment with which we interact." (Edrawsoft, 2022).

Since Zara is one of the most successful fast fashion brands, they aim to rapidly respond

to the demands of customers at affordable prices, we can see that their business strategy

is vertical integration. It adapts couture designs, manufactures, distributes, and retails

clothes within two weeks of the original design first appearing on catwalks. This is in

stark contrast to the average six months it takes to produce items in the fashion industry.

The company owns its supply chain and competes on its speed to market, literally

embodying the idea of 'fast fashion' (QuickBooks, 2018). 4 lOMoARcPSD|45316467 Group 12 | INS 3021 01

PART B: ZARA Supply chain I.

Supply chain stage of Zara

Zara recently revealed that it will use its physical locations to fulfill internet orders.

The news highlights Zara's prior tactical accomplishments. Zara has put in place a

supply management system that makes use of RFID garment tracking technology to do

this. The technology will connect inventory data across brick-and-mortar stores and

internet fulfillment sites. When traditional fulfillment centers run out of inventory, this

will allow retailers to fill internet orders.

The development also demonstrates Zara's prior efforts to improve supply chain

effectiveness. In less than 25 days, Zara has been able to design, produce, ship, and

sell new clothing. This frees the merchant from having to transport clothing from

Asia and enables them to adapt to rapidly changing consumer tastes (a process which can take many months). (CB Insights, 2018) 5 lOMoARcPSD|45316467 Group 12 | INS 3021 01 1. Input material

Zara's major design headquarters are in Spain, and the company maintains close ties

with its offices and purchasing systems throughout the world, including those in

Hong Kong, Beijing, Barcelona,...

The business buys low-cost raw materials from numerous nations, including Spain,

India, the Middle East,..., with the quantity determined by the proper dyed/undyed ratio.

Undyed fabrics support the brand's ability to adapt quickly and flexibly to each unique Zara campaign.

2. Producing finished goods

The design team at Zara focuses on adhering to existing fashion trends rather than

striving to establish new ones and releases roughly 15,000 new designs annually.

This makes it simpler for Zara to consistently have a source of items and to

occasionally produce in line with trends (without the pressure of new breakthroughs, creating new fashion trends).

The manufacturing process at Zara firmly abides by the Just In Time philosophy; items

are produced in accordance with the appropriate standards, using the appropriate

models, in the appropriate locations, and at the appropriate times. This operational

principle aims to maintain uniform operation by eliminating inefficient procedures. The

production capacity of Zara's factories is always between 85-100%, and can be

increased if necessary to help the company always control the quantity, speed and new

products launched to the market.

3. Storage and distribution operations

Competing retailers' inventories are less than half as Zara. In particular, compared to the

average inventory level of 17–20% maintained by many companies in the industry, the

corporation maintains an inventory level of less than 10%.

More than 450 million products may be handled by Zara's supply chain annually, and

new product models are introduced twice a week. Statistics show that the corporation

can deliver huge volumes of goods to stores in its retail network in Europe within 24

hours and in the Americas and Asia within 40 hours. After delivery, products can be 6 lOMoARcPSD|45316467 Group 12 | INS 3021 01

sold right away to clients.The high, stable production schedule and quick delivery time of

the Zara supply chain help the company to stay close to the needs of its customers.

4. Supplying items to consumers (through the retail chain)

The corporation concentrates on creating and running supply chains, famous and

distinctive display places, and less on public relations and advertising operations.

For this business, the "focal point" of viral communication is its customers. II.

Zara’s Lean Supply Chain

To be successful in the fashion and textile business, it’s hard for most businesses to

predict the demand changes because of the fashion trends and volatile market. The rapidly

changing demand could change in a short time, giving business’s supply chain a

hard time. The way to stay strong and stand out in this business is using Lean in their

supply chain strategy and Zara is a brand that is successful in using it.

1. Pull strategy (Kanban)

One of the Lean techniques for their supply chain is the Pull strategy, or Kanban. Using

a pulling approach helps ZARA reduce the bullwhip effect, avoid over-producing and

over-ordering, the Kanban system keeps small quantities of resources that are needed

and replaces what is used, only when it has been used.

ZARA creates up to 1,000 designs every month based on store sales and current

trends. It monitors how much money customers spend in store to evaluate and

understand which designs are being purchased and then it updates its next designs accordingly (Robinson, 2015).

Zara has used pull as their approach. If the other shops design their own collections and

push them to the other retailers, or their own shops, Zara decided to create what their

customers want. In the saleling, Zara’s store employees always listen to the customers’

feedback and after that, they will tell them to the designer team in Arteixo. They also

produce small batches of new designs to test the interest of consumers and thus decide

what designs to mass-produce (Technology and Operations Management, 2015). 7 lOMoARcPSD|45316467 Group 12 | INS 3021 01 2. Just In Time

Zara, which is famous for setting trends ahead of its competitors, often updates its

clothing designs every two weeks. Zara uses Just-in-Time (JIT) production techniques

to ensure turnaround times as short as possible in order to keep up with this breakneck

pace. JIT is a unique method that, when well designed and implemented, has several

benefits that aren't restricted to cost savings. Zara manufactures a large portion of its

products in-house, with many of its facilities located near the company's headquarters in

Galicia, Spain. It also keeps around 85% of capacity available for any necessary in-

season adjustments, providing for greater flexibility and agility in how and when new

items are introduced. They are able to give their customers the latest fashion every

month by utilizing customer psychology and combining it with a production process

that saves them money and time.

When there are must- have items, or a new fashion trend on the street, Zara’s

designers will get to work as soon as possible. They come up with inventive style,

then bring it to the store while it is still trending. This time, the store managers and

sales employees will communicate with customers, then give feedback to the designers

about what their customers like, what they think about the trend lately,.. This will

create demand forecasting data and it is sent to the designers immediately, so that they

can start to sketch and start to produce a large number and customers will visit to buy.

Zara changes its apparel designs every two weeks on average; most of its competitors

do so every 10–14 weeks. It is a little bit risky of Zara to have their products from the

factories straight to shelves, this is a priceless strategy. 3. Flexibility

The production of their products is highly flexible. Their seasonal designs are what their

consumers asked for. It allows rapid response after the customers’ demand. Zara’s

fabric before designing are plain and uncolored, Zara is again able to respond to trends or

consumer demands, dyeing the fabrics according to whichever color happens to be on-

season or is required for a particular clothing design (Worldfinance.com, 2015).

Zara produces seasonal-collection every year and sells fresh models all year around.

They adapt their items according to the client's needs, fashion trends and store sales. 8 lOMoARcPSD|45316467 Group 12 | INS 3021 01

Zara is also sensible, if one of their designs does not work out, they will retire it. They

made a thousand designs per month and updated their collections. By making

shipments every two weeks, this quick turnover enables businesses to provide fresh

designs, luring customers in again and time again. 4. Cost

From years to years, Zara always offers unique, high quality, latest fashionable products

to their customers at an affordable price. Zara’s production labor cost in Asia is

quite cheap, compared with inside Spain, for that reason, Zara must therefore offer a

higher price than its rivals who have completely outsourced their manufacture to Asian

nations. Considering what clients are willing to pay, they determine rates based on

geography using a demand-oriented approach.

III. Supply chain design

To take advantage of the fast fashion aspect, Zara follows the vertical integration. It

will help the supply chain run smoothly. By acquiring businesses at different stages of

the chain, Zara is able to maintain better control of the value chain, which means it

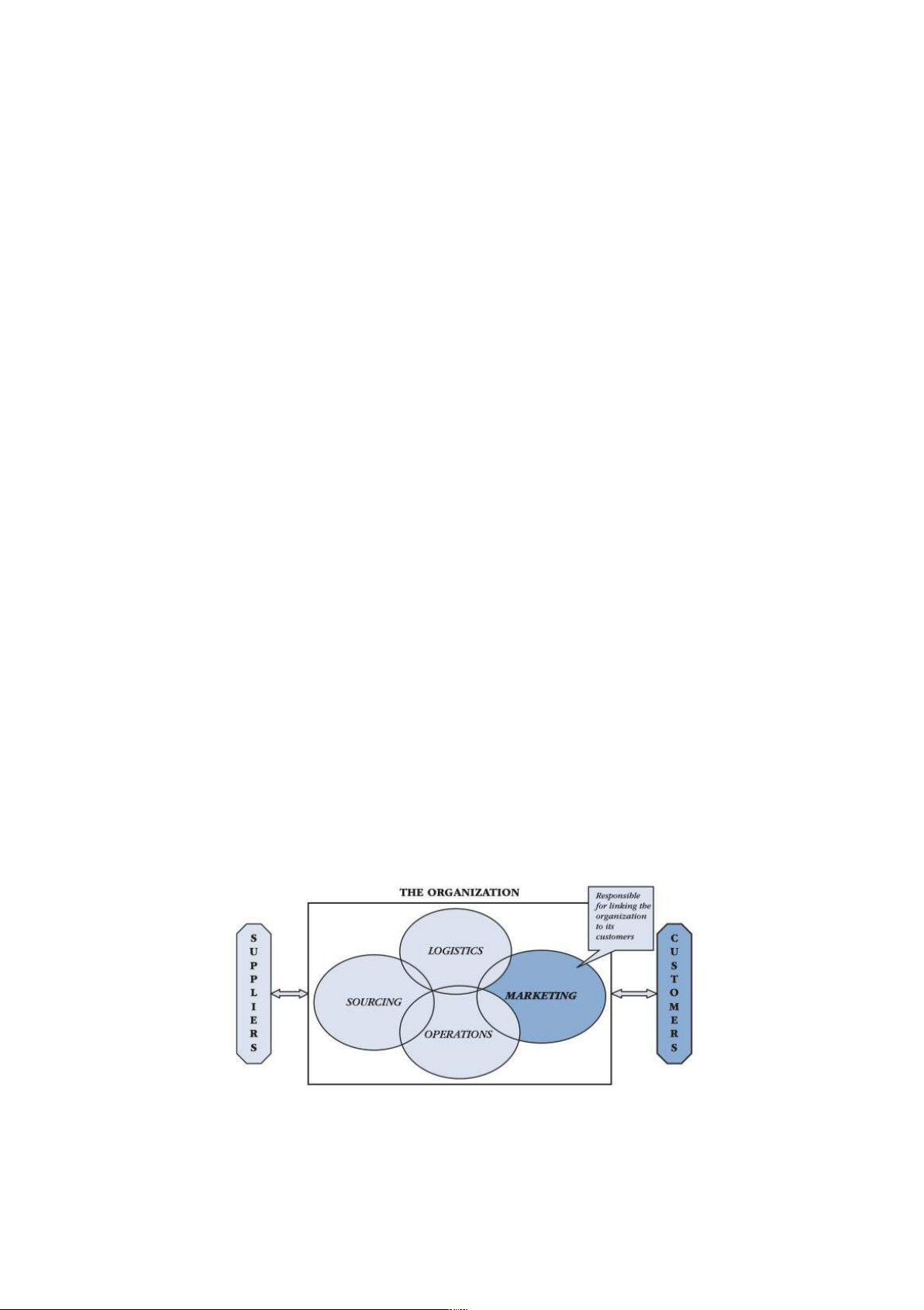

can react quickly to shifting consumer demands (Thomasnet.com, 2020). 1. Marketing

The Marketing Function (Nada R. Sanders, 2018).

With the dramatic introduction and the crowded fast fashion market, it will be hard for

fashion brands to stand out, and Zara made it. Zara understands their market segment 9 lOMoARcPSD|45316467 Group 12 | INS 3021 01

and what their target customers and from that, they can make them different from their competitors.

Zara’s market segmentation is diversity, they have products for men, women, kids.

Their products do not stop at clothes. Beside clothes, they also have home products,

accessories, etc. Zara provides a significantly larger assortment of styles and designs

with over 450 million products per year, compared to average retailers. They focus on

their modern design and they assure its inventory is always refreshed for its clients.

Without outsourcing the manufacture, Zara is ready to quickly react to market changes

and fashion turns. The production and distribution time are also reduced, Zara tries to

have trending products for sale as fast as possible. Clothes in the stores are kept short,

this will keep customers coming back to the store and trying to buy before it is sold

out. Zara keeps their expense in the promotion and advertising low to achieve balance,

and maintain the competitive advantage of low prices (Edrawsoft, 2022).

Zara also does its marketing through distribution channels. Zara distribution strategy

is one of the key elements behind its quick response strategy. Zara has outlets in 86

countries, including Europe, United States, Middle East and Asia. In 2012, Inditex, the

parent company of Zara claimed US$20.7 billion of total sales, out of which Zara

contributed 66 percent that is US$13.6 billion sales, which is a huge success (hussain1108, 2015).

Zara focused mainly on opening new stores and word of mouth. Their key

promotion strategy is based on experience, exclusivity, affordability, and

differentiation. They understand women, their main target customers. 2. Retailing Operation

Currently Zara has about 1,763 stores worldwide. After 5 years of entering the

Vietnamese market, Zara currently only has a system of stores in two major cities of

Vietnam: Hanoi and Ho Chi Minh City.

To rapidly match changing customer’s needs, Zara practices total control of the retail-

chain through forward integration and retaining ownership of 90% of its stores (Sull &

Turconi, 2008). Zara uses franchise only in risky countries or in countries where wholly 10 lOMoARcPSD|45316467 Group 12 | INS 3021 01

owned stores are not allowed to operate (Tokatli, 2008). However, Zara’s franchise

agreements are usually designed as a 5-year contract with fees of 5-10% of total sales

and Zara always reserves the right to either buy out the franchisee or open wholly

owned stores during that contract period. This arrangement allows Zara to experiment

markets in new countries without bearing significant financial risk (Caro & Martínez-

de-Albéniz, 2015). Given that consumers increasingly choose to purchase online for the

best deals, Zara's plan to expand its retail space may be in jeopardy at this

point."Consumers are changing their shopping habits. Instead of going to sub-stores,

they are more likely to shop online but still value flagship stores with good locations,"

said Alistair Wittet, head category manager European investment at Comgest - one of

20 investors of Inditex. A modest change in retail orders, for instance, can result in wide

variation in orders as it reaches the factory while being transmitted through wholesalers

and distributors (Whang & Lee, 1998). Additionally, it gives Zara more sway over retail

inventories in terms of product mix, pricing and quantity offered and other factors. The

level of control achieved allows Zara to set the pace at which products and information flow (Edmondson, 2003).

Zara places the stores in prime locations that attract a voluminous flow of upscale

shoppers in the most high-profile commercial areas, often including landmark buildings

in the premier shopping streets and upscale shopping centers around the world. The

average size of the stores is 1200-1,376 square meters and carries about 40,000 units of

inventory. Shop floors are designed to be spacious and therefore the product density of a

typical Zara store is 28 units of inventory per square meter while traditional retailers

usually have between 32 and 43 units of inventory per square meter. Zara erected a

three-story store in the charming downtown area of Bilbao, a sizable city in northern

Spain, complete with stone pillars and chandeliers hanging from the roof. three smaller

stores were closed, along with marble and vibrant glass windows.

3. Internal Manufacturing and Outsourcing 3.1. Outsourcing

With the vertical integrated, Zara is helped to reduce risk and maintain better control of the

value chain, and easily to shifting consumer demands. Zara outsourcing is minimal, 11 lOMoARcPSD|45316467 Group 12 | INS 3021 01

it helps Zara control everything from design to display to shipping, allowing it to gather

valuable data at every stage (Thomasnet.com, 2020).

Zara outsources the fashion products to original design manufacturers in countries that

are near each other. This will help to compress order- to- delivery lead times (Gereffi &

Memedovic, 2003; Tokatli, 2008). By using outsourcing, Zara can quickly cancel the

out of trend products and avoid inventory backlogs and product markdowns that are a

regular drain on profit (Tokatli, 2008). To compare production in Europe and Asia,

Europe’s labor is higher than Zara by about 15- 20%, Asia countries are far but the

labor cost is cheaper and crowder. Zara procures the more price-sensitive but less time-

sensitive basic category apparel products by outsourcing total production processes to

OEM production/full package sourcing networks located in distant sources such as

China, Bangladesh, India, Pakistan, Vietnam and Cambodia where labor wage rates are

lower and order-to-delivery lead times are significantly longer compared to

local/proximate sourcing (Ferdows et al., 2004; Inditex Annual Report, 2005).

3.2. Internal Manufacture

The internal manufacturing is performed by 11 fully owned plants, most of them

positioned in and around Zara’s headquarters in Arteixo, Northern Spain (Amed &

Abnett, 2015) and (Inditex Annual Report, 2017). The manufacturing facilities are

automated and only perform in the capital-intensive initial production like fabric

dyeing; pattern design using CAD; creating layout of pattern pieces, cutting fabric by

automate knives and lasers aided by computer aided manufacturing (CAM). These

machines can calculate how to position the layout of pattern pieces on the marker

efficiently and quickly on computer screens to map out the individual parts for a

garment on the fabric. The machine thus minimizes fabric waste while cutting over 100

layers of cloth at single cut (Ghemawat & Nueno, 2006; McAfee et al., 2007).

After the fabrics are cutted, it will be sent to a network of more than 400-450 partner

factories located nearby the Inditex-owned factories in Galicia and Portugal to perform

the labor intensive assembly/sewing operations. Zara attentively monitors their

partner’s operation to safeguard quality, conformity with labor laws, and above

all else adherence to the production schedule. Zara and its subcontractors are generally

long-term and as such Zara collaborates with its subcontracting partners by providing 12 lOMoARcPSD|45316467 Group 12 | INS 3021 01

technology, logistics and financial support. After that, the partner factories then bring

back the assembled items to Zara’s factories, where each piece is inspected for

quality control during ironing, given a machine-readable tag and packaged. The

finished products are then dispatched on hangers grouped by model and size, through

part of the 211 km network of rails to Zara’s Arteixo distribution center. Completed

products procured from external suppliers are also sent directly to the distribution

center. Zara implements a sampling methodology to ensure quality for the incoming

products (Ghemawat & Nueno, 2006).

4. Logistics and Distribution

Logistics entails the free circulation of commodities from production units to target 1

customer for total satisfaction. It incorporates the integration of information, movement

of goods, stocking, storage, casing, and safety (Gelder & Woodcock, 2003). Zara has

successful logistics that totally commits to the customer's satisfaction. The effectiveness

of time and location are enhanced by its logistics. The business makes sure that clothing

is sent from its production facility in a timely manner to different outlets throughout the

world. It takes into account the constantly shifting fashion and trends that affect the

textile sector, enduring the constantly shifting consumer needs. Depending on the

requirements and market niche of that particular region, the logistics department

considers supplying different retailers with a variety of supplies. The company's

manufacturing operations are described in the following details: Instead of focusing on

low prices and cheap labor, Zara competes on flexibility and agility. Compared to the

average labor cost in Asia, which is roughly 0.40 euros per hour, they employ about

3,000 people in manufacturing operations in Spain at an average cost of 8.00 euros per

hour. Flexible manufacturing systems are used in the Spanish Zara facilities to facilitate

quick operational changes: 50% of all items are manufactured in Spain, 26% in the rest

of Europe, 24% in Asia and Africa.

Due to Zara's robust distribution network, products may be delivered to its European

stores in less than 24 hours and to its American and Asian locations in under 40. The

Cube and the company's headquarters are both in northwest Spain, which is the region's

center for manufacturing. However, they went with a location that is more centrally

positioned for its primary distribution and logistical hub. That facility is situated in a

sizable logistics hub built by the Spanish government in Zaragoza. Suppliers deliver raw 13 lOMoARcPSD|45316467 Group 12 | INS 3021 01

materials to Zara's production facility. After that, finished clothing is removed from

the Cube and delivered to the Zara logistics center in Zaragoza. From there, they are

transported by truck and by airplane.

PART C: Zara supply chain management issues and practices

I.Relationship management 1. Issues

Lack of Supplier Relationship Management brings Zara under fire. Reports from major

publications, such as Newsweek, have accused Zara of not paying its employees.

Stakeholders and advocates for human rights have expressed their displeasure with this. (Newsweek, 2017) 2. Practices

Managing supplier relationships - and ensuring procurement and sourcing activities are

completed ethically - is now more important than ever. Zara's trust-based and power-

based relationships with suppliers have allowed the company to operate with virtually few inventory in the process.

“According to the AP news agency, one of the factories owned by a Turkish Zara

company, Bravo, has been accused of not paying employees on time, if any” (Kaye,

2017). Zara customers find notes from unpaid employees inside their clothes. This lack

of relationship management regarding these external entities has once again put Zara in the hot seat.

In 2017, Zara signed an agreement with the International Labor Organization to

develop "best practices" in its factories and working conditions. However, just a month

later, these accusations surfaced and Zara did not make any public statements regarding

the allegations about their activities in Bravo factories. 3. Recommendations

Zara takes the fact that suppliers and manufacturers are the foundations of any business

extremely seriously and cares equally for its suppliers and producers. It effectively 14 lOMoARcPSD|45316467 Group 12 | INS 3021 01

protects the human rights of workers who toil away to make those stylish garments a

reality. Zara's long-term business model contributes to the development and prosperity

of its suppliers. As a result, it has a favorable impact in a number of countries. Zara

also works to promote international labor conventions. It demonstrates how the

corporation not only cares about its customers, but also for its suppliers and producers.

After all, Zara would be nothing without its employees at all levels.

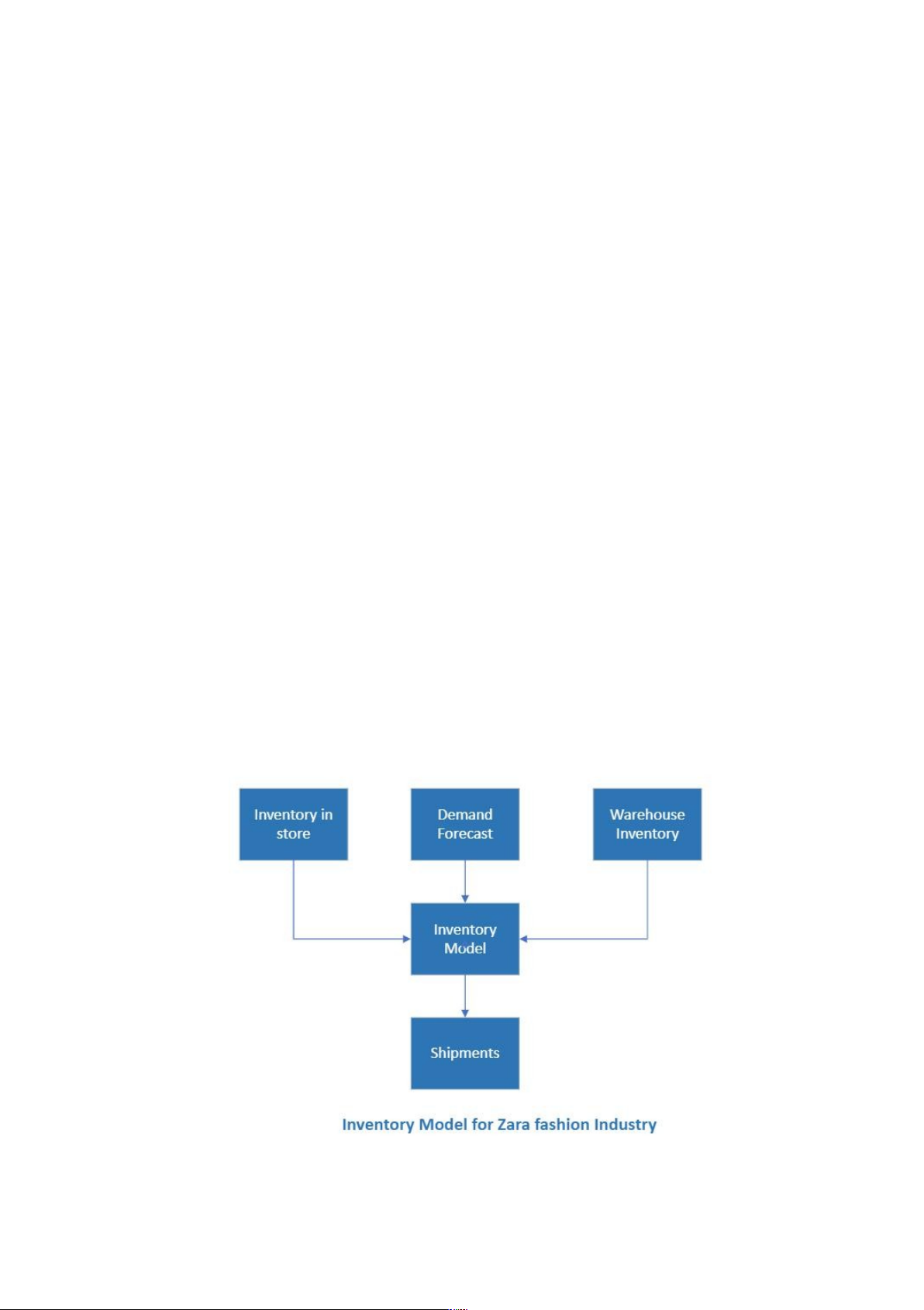

II. Inventory Management 1. Issues

When applying lean production, Zara faces inventory management issues that mean

improving their supply chain and running it in a short time (about 15 days/new product)

while controlling operating and inventory costs as low as possible. 2. Practices

This model is used to minimize the cost to determine the purchasing as well as repairing

of lot sizes, predicts the sales in the store throughout the replenishment period, reduces 15 lOMoARcPSD|45316467 Group 12 | INS 3021 01

the shipment time, boosts the proportion of time that the products of Zara spend

on exhibit in their lifecycle. Thus, regarding competitors, Zara's inventory level is the lowest.

Firstly, Zara launches only small batch productions (lean concept) in order to reduce the

risks of producing something the customer doesn’t want. Thus, they reduced the

number of unsold clothes and practiced less markdowns than the others which increased the profit margin.

Moreover, Zara employs postponement for instance half of the products are undyed

until the last moment to select the color. That method decreases the components stock

and avoids forecasting mistakes.

Furthermore, it sometimes occurs that a product is sold well in one country but not in

another one, Zara uses reverse logistics by moving stocks from a store to another one

in order to place this product in a country where the sales will be higher. Stores place

orders twice a week and they don’t keep stock in the stores which decreases the stock

level as well. They can do that because of the speed of replenishment (within 24 hours in European countries). 3. Recommendations

Quick response (QR) began in the apparel industry as a response to JIT practices of the

auto industry. Zara should continue to develop a QR strategy that is based on shortening

the lead time from product design to store display because it allows the supply chain to

enter the seasonal sales cycle with a small initial inventory allocation at the retailers,

observe early sales patterns, generate a posterior demand distribution, and choose the

optimal replenishment quantity to maximize expected profits given the posterior

distribution. In this manner, Zara's planned stock-outs become a marketing advantage,

and they also avoid inventory obsolescence costs by quickly responding to changes in the marketplace.

Zara should be more careful about the way it deploys the latest IT tools to facilitate

information exchanges and apply advances of Technologies to produce more in less

time. A small change in retail orders can result in wide fluctuations in factory orders

after it's transmitted through wholesalers and distributors. In an industry that 16 lOMoARcPSD|45316467 Group 12 | INS 3021 01

traditionally allows retailers to change a maximum of 20% of their orders once the

season has started, Zara lets them adjust 40-50% => Zara can avoid costly over

production and the subsequent sales and discounting prevalent in the industry III. Reserve Logistics

The Zara organization makes some improvement in their supply chain and lastly they go

for reverse logistics of their clothes to become more sustainable. 1. Issues

Zara’s customers return products to different locations around the world

=> The collection and redemption process to reuse, recycle or refurbish old products takes time and is complicated. 2. Practices

Zara uses reverse logistics by moving stocks from a store to another one to place them

in a country where the sales will be higher, buying their old clothes for a small price

to reuse or organizing the reverse logistics for the returning parcels and re-introducing

them back to the commercial circuit.

In fact, as the clothes are fast-fashion items, basically, they quickly become “has-

been”. Zara could buy their old clothes for a small price to reuse the material. Zara

could create a closed loop by bringing back the products from the point of consumption

to the point of origin. Both Zara and customers would be winners. For sure, this

solution is hard to implement. If Zara organizes the reverse logistics for the returning

parcels and re-introducing them, The returned package needs to be opened and checked,

the clothes probably ironed, refolded and repacked. Then they need to be sent back to the usual logistic flow.

In short, dealing with ‘revitalizing’ clothes implies a cost (in money and time). Time

devoted to returning shipping, revitalizing clothes, and introducing the items again to

logistic-commercial flow means losing the freshness of trendy products, which have

‘‘expiration date’’ approach by the minute. This is especially troublesome in the case of Zara. 17 lOMoARcPSD|45316467 Group 12 | INS 3021 01 3. Recommendations

In the long-term,Zara should work with third party transportation suppliers who are

close to its retail locations and are knowledgeable with the local transit infrastructure.

They will know the best way for faster delivery when having a product transported in

a local location that may have traffic jams or geographical difficulties. Furthermore,

buyers who are interested in Zara items and want to buy in quantity can choose a third

party to provide things to them as quickly as possible. In addition, Zara should widely

promote the campaign to recall old products for recycling in parallel with the launch of

a new collection to attract and stimulate buying psychology. IV. Forecasting 1. Overview

Zara's method is reactive, responding to market demand before it happens, which gives

Zara the possibility of planning ahead for styles and quantity. Zara forecasting strategy

focuses on responding to customer demands in a timely and cost-effective manner.

Zara's strategy also focuses on acquiring and provides the company with the vital

information it needs to stay competitive. They are quick on tech innovation and

even quicker on customer reactivity.

Trend forecasting allows Zara to keep close tabs on its customers’ desires in real

time. Customer’s demand is their priority . Besides, they want to ensure that the

right product is available in the right place at the right time. This strategy helps the

company to reduce costs and boost sales. Specifically, the forecasting process takes

into account both the internal and external factors that can affect consumer demand (McCann & Husmini, 2017). 2. Issues

Zara is quite active in releasing collections every few weeks. This way ensures to

keep customers coming back and keep designers aware of client feedback and

demand. However, it puts the burden on the inventory due to shortages and out-of-

stock situations (Mollard, 2020). They have difficulties making short-term forecast 18 lOMoARcPSD|45316467 Group 12 | INS 3021 01

judgments since they have to process large amounts of quantitative data such as initial

stock shipments to retailers, inventory replenishment, liquidation pricing, and supplier

purchase quantities. Furthermore, these choices are sometimes in the hands of a few

professionals. If they depart, it will create serious problems for the organization (Clegg, 2015).

Zara lags behind in AI-powered trend forecasting. They are unable to extend their

significant market share in e-commerce as a result of this (Gosselin, 2020). Actual e-

commerce demand is different from offline demand. It made product planning, design

development, garment production, and resource sharing

problematic. This results in higher production costs and autonomous development

while still consuming supplier capacity (Song, 2021). 3.

Zara implement forecasting

By forecasting trend behaviors and obtaining the data it can help merchandising and

planning teams align with design teams to adjust quantities, this will help Zara to focus

more on other strategies like reducing the amount of time for introducing new products .

Trend forecasting can be a practical way for Zara’s collection planning strategy. Zara’s

Quantitative analysis of social channels deep dives into consumer needs, and

this technology can predict trends up to one year in advance.

Zara's demand forecasting tends to be customer-centric, it helps Zara sustain and retain

competitive advantages over other rivals. Sales tracking data allows Zara to cater to its

customers with new trends and eliminate designs that do not appeal to customers. They

collect real-time data from e-commercial and store it through PDA , POS , RFID tag, and SKU’s.

To deal with qualitative data problems, Zara has developed Operations Research

and Information Technology divisions. These will find ways to deal

with the input data and use the optimization model to give the most accurate

forecast results (Clegg, 2015). Zara’s design team looks at sales data from stores

around the world to forecast what will be top-selling items and adjust

designs accordingly. They also receive qualitative feedback from in-store employees .

Moreover, collecting real data is helpful to forecast the amount of quantities and price

points for the new designs (Uberoi, 2017). To solve the problems of 19