Preview text:

1. THEORETICAL BASIS (HALIN + MOON)

1.1. What is business operation management? What

does a business operate?

Operations management (OM) is the set of activities that create

value in the form of goods and services by transforming inputs into outputs.

Business operations refer to the activities and tasks that

organizations use to produce goods and services. This includes

planning, organizing, staffing, leading, and controlling various aspects of organization Essential functions:

Marketing: identify the needs and wants of the market, and

find the most suitable marketing methods.

Production/Operations: transform inputs into outputs (or

create products) for the purpose of creating added value to provide to customers.

Finance/Accounting: collect, process and report financial activities of the Enterprise.

1.2. Administrator need to do?

Managers must apply management processes to be able to operate

well organizations and businesses. To do this successfully, managers need to: Planning Organizing Staffing Leading Controlling

1.3. Importance of Operations Management

Operations management refers to the discipline of overseeing and

controlling the various activities within an organization. It ensures

efficient production processes, optimal resource utilization, and,

ultimately, the achievement of desired business goals.

Additionally, operations management involves planning,

organizing, and supervising the entire production timeline, from

input to output.*(https://emeritus.org/in/learn/what-is-operations- management/)

Operations management is one of three major functions of any

organization, we want to study how people organize

themselves for productive enterprise.

We want and need to know how goods and services are produced.

We want to understand what operations managers do.

1.4. The main influence of business operation in the organization

Operational issues include production scheduling and control,

inventory management, quality control and inspection, traffic and

materials handling, and equipment maintenance policies. Build a

management operation, launched the product line of coca cola

company. Operations management focuses on carefully managing

the processes to produce and distribute products and services.

Usually, small businesses don’t talk about “operations

management”, but they carry out the activities that management

schools typically associate with the phrase “operations

management.” Major, overall activities often include product

creation, development, production and distribution

(https://www.ukessays.com/essays/business/project-report-

operation-management-in-coca-cola-company-business- essay.php)

Strengthening a consumer-centric portfolio through strategic acquisitions

Transforming and modernizing marketing through one

global marketing network partner:After an extensive review in

2021, the company named WPP as its global marketing network

partner. WPP will play a key role in executing a new marketing

model to drive long-term growth for the company’s global portfolio of brands.

Further embedding sustainability into the business,

including a new packaging target:*The company’s

environmental, social and governance (ESG) goals are embedded

in operations and serve as key drivers of growth.

PROCESS STRATEGY (chap 7) (HALIN)

1. Product focus strategy

The Coca-Cola Company sells the products form of soft drinks

include beverage concentrates and syrups, with major beverage

products. Business has more than 300 beverage brands all over

the world with a major to be Coke, Fanta, Lift, Sprite, Frutopia

100% Fruit Juice, and Powerade. The Coca-Cola Company

Beverages its packages into plastic bottles of sizes 2 liters, 1.25

liters, 600ml and 300ml. these are also available in aluminium

cans of 375ml. Coca-Cola is the most well-known trademark,

recognized by 94 percent of the world population. Business was

very successful and has an excellent reputation.

*In all our processes we minimize our environmental impact and

consider sustainability in our value chain - from sourcing raw

materials and manufacturing the end product to distributing it to our customers.

Coca-Cola employed CSC (a consultancy firm) to outsource a large

portion of their production to modern streamlined supplier.

To produce our products, we use water, sweeteners, sugar,

beverage concentrate and glass, aluminium, PET resin or carton

packaging plus energy for the overall manufacturing process.

The transformation process for Coca-Cola is highly multi-faceted

due to the high variety of products being offered by Coca-Cola and

the vastness of the company's operations. Some of the inputs

required include ingredients or materials such as water, colourant,

acidulous, sweeteners, preservatives, flavouring and caffeine.

Material for packing is also part of the inputs for Coca-Cola; these

include glass. plastics bottles, bottle tops, bottle caps and rubber

for the inside of bottle caps. Other inputs include information and

clients such as consumer knowledge of what the demands are and

which products will satisfy these needs. There is a lot of research

that must be done beforehand regarding market trends and needs

for specific products before the manufacturing process begins. In

"Analysis Of The Transformation Process For Coca-Cola: Summary

Essays" we will research and analyze of process, trends and needs of market.

Coca-Cola uses mass production for their products. Many would

argue that Coca- Cola uses continuous production, however

continuous implies that there is little variety in the type of

products. Coca-Cola actually make over 3500 different products.

The volume of products produced by Coca-Cola rival the

production capacity of most companies (with over 1. 8billion

drinks consumed per day) but the vast variety is why their

production is deemed to be mass rather than continuous.

Due to the high variety of products offered, Coca-Cola cannot

make use of Fixed- position layout nor line flow layout as all the

different products have different ingredients and packaging. Since

the products are all beverages, process layout does not make

sense as products are not grouped together. The only viable

option is therefore the cellular or hybrid layout. This also makes

sense as products can be classified by ingredients required or by

packaging design. Items with similar ingredients will be made

together whilst products will similar packaging will be packaged together.

The mantra “Fewer, focused and future-minded” is guiding The

Coca-Cola Co.’s approach to new product innovation.

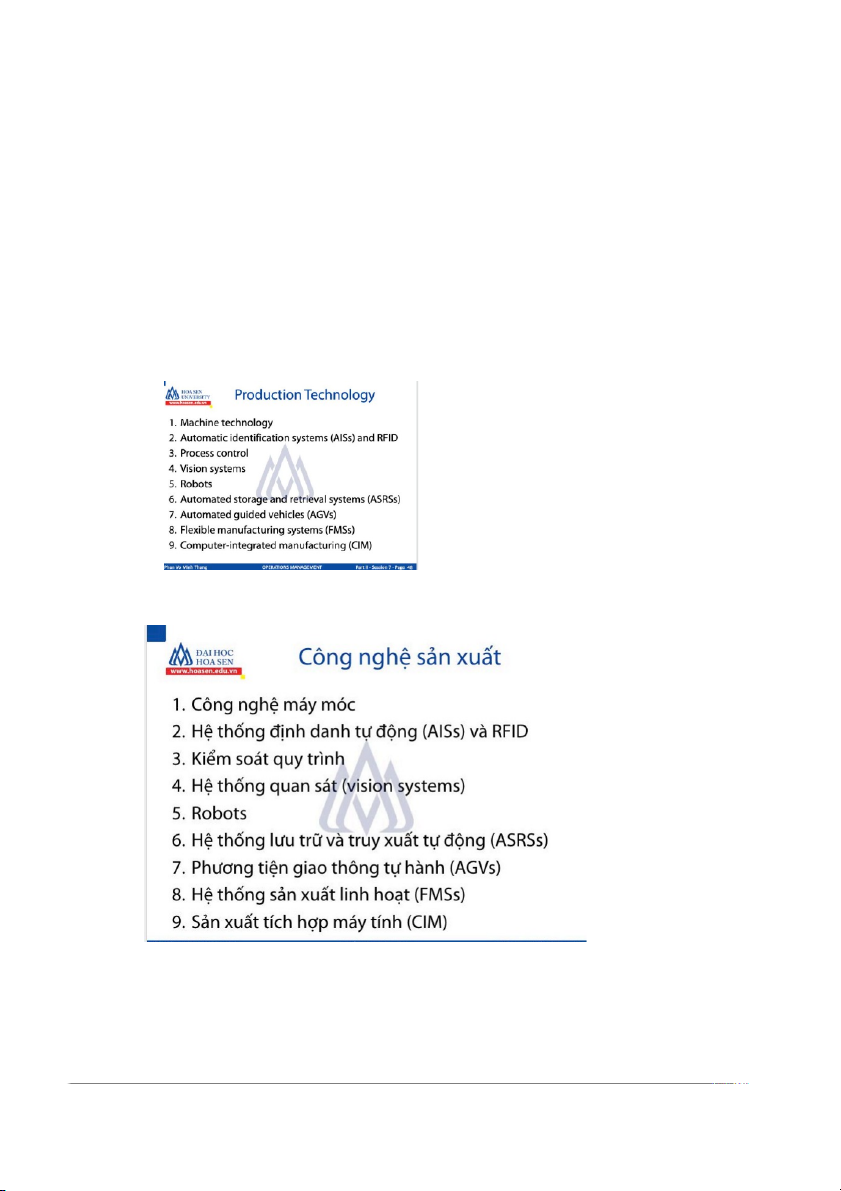

1.5. Value stream mapping

https://www.internationaljournalssrg.org/IJME/2018/Volume5- Issue1/IJME-V5I1P101.pdf

The lean method has the potential to increase Coca-Cola’s

production by shortening lead times and increasing profitability

(Milewski, 2022). An increase in productivity might be

accomplished by reducing waste and any other inefficiencies

which are likely to occur when the bottler and the retailer phases

related to supply chain management system interacts, which is

now under investigation within the Company. The combination of

this factor with the excellent quality of the Company’s goods

results into maximum efficiency and profitable organization.

Coca-Cola system and value chain. (The Coca-Cola Company, 2018). Customer Order:

Identify the starting point of the value stream, which is typically a

customer order for Coca-Cola products. Order Processing:

Map the steps involved in processing the customer order,

including order entry, verification, and communication. Raw Material Acquisition:

Outline the steps in obtaining raw materials required for

production, such as water, sweeteners, flavorings, and packaging materials. Manufacturing Process:

Detail the steps in the production process, from mixing ingredients to bottling and packaging. Quality Control:

Identify points in the process where quality checks and inspections

are performed to ensure product quality. Distribution:

Map the steps involved in transporting finished goods from the

manufacturing facility to distribution centers. Inventory Management:

Include information on how inventory is managed throughout the

process, from raw materials to finished goods. Retailer Distribution:

Highlight the steps involved in delivering products from

distribution centers to retailers. Customer Delivery:

Map the final steps in delivering products to the end customer,

which may involve distributors, retailers, or direct delivery. After-Sales Service:

Include any post-sales activities, such as customer support,

returns, and recycling initiatives.

1.6. Equipment & Technology 1. Equipment Vending machine Fountains Coca cola freestyle Cooler Technology:

Technology is an important part of the transformation process of

any product and Coca-Cola is no different. The Coca-Cola

Company are constantly looking to improve their products through

the integration of the newest technology. This comes in the form

of trying to reduce energy consumption, trying to be more

environmentally conscious and of course constrain costs.

“We have been working with technology partners for many years

to develop the right technologies to create a bottle with 100%

plant-based content—aiming for the lowest possible carbon

footprint—and it’s exciting that we have reached a point where

these technologies exist and can be scaled by participants in the value chain,”

The second breakthrough technology, which The Coca-Cola

Company co-owns with Changchun Meihe Science & Technology,

streamlines the bMEG production process and also allows for

flexibility in feed stock, meaning more types of renewable materials can be used.

1.7. Crossover chart (math)

Our system operates through multiple local channels.

The primary way that our products reach the marketplace starts

with Coca-Cola, which manufactures and sells concentrates,

beverage bases and syrups to bottling operations. Coca-Cola also

owns the brands and is responsible for consumer brand marketing

initiatives. Our Coca-Cola bottling partners manufacture, package,

merchandise and distribute final branded beverages to our

customers and vending partners, who then sell our products to consumers.

A. 7.000 tỷ -> 350 tỷ (China)

B. 3.000 tỷ -> 900 tỷ (Vietnam)

C. 1.000 tỷ -> 740 tỷ (UK) A - B 7000 + 350.V1 = 3000 + 900.V1 => V1 = 7.27 B - C 3000 + 900.V2 = 1000 + 740.V2 => V2=-12.5