Preview text:

lOMoAR cPSD| 59085392

C. Industrial and Environmental Biotechnology

1. Genetically Modified Bacteria for Biofuel Production

1.1 Engineering Microorganisms for Ethanol Production

Ethanol is one of the most widely used biofuels, primarily produced through the fermentation of

sugars by microorganisms. Traditional ethanol production relies on Saccharomyces cerevisiae (yeast),

but genetic engineering has enabled the development of more efficient strains. For instance:

Enhanced Sugar Utilization: Genetically modified Saccharomyces cerevisiae can now ferment both

hexose and pentose sugars, which are abundant in lignocellulosic biomass (e.g., agricultural waste).

This expands the range of feedstocks and reduces competition with food crops.

Tolerance to Inhibitors: Lignocellulosic biomass often contains inhibitory compounds that hinder

fermentation. Engineered strains with improved tolerance to these inhibitors have been developed, increasing ethanol yields.

1.2 Engineering Microorganisms for Biodiesel Production

Biodiesel, a renewable alternative to diesel, is typically derived from plant oils or animal fats.

However, genetically modified microorganisms offer a more sustainable and scalable production method:

Microbial Lipid Accumulation: Microalgae and bacteria like Escherichia coli have been engineered to

overproduce lipids, which can be converted into biodiesel. For example, introducing genes for fatty

acid biosynthesis pathways has significantly increased lipid yields.

Waste-to-Fuel Conversion: Some GMMs can utilize industrial waste streams, such as glycerol from

biodiesel production, as a carbon source for lipid synthesis, creating a circular economy. lOMoAR cPSD| 59085392

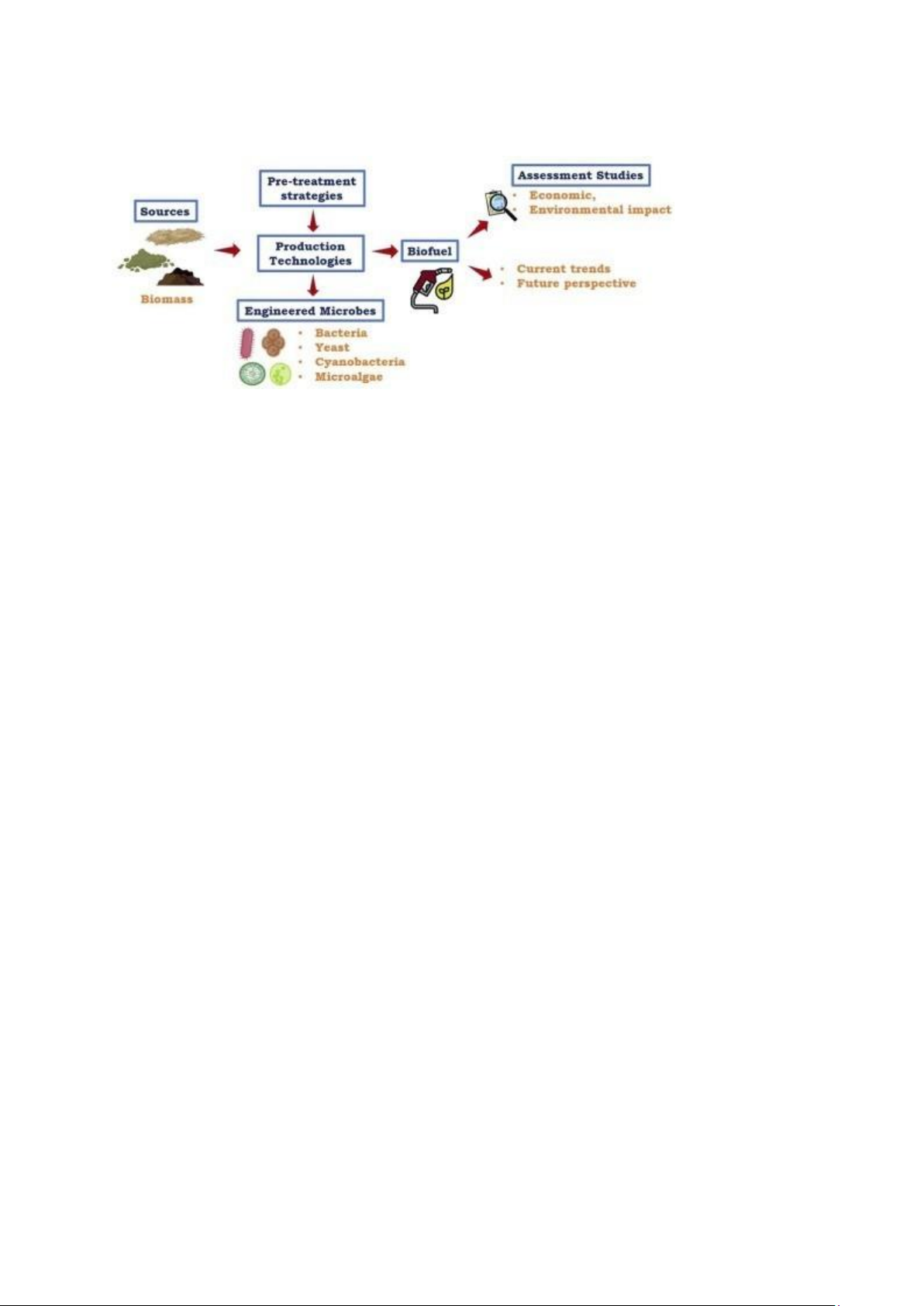

The figure summarizes various microorganisms that have been genetically engineered to enhance

biofuel production, detailing the specific biofuels or precursors they produce.

Figure. Biofuel energy production has been significantly increased from almost 0 TWh to around 500

TWh in 33 years from 1990 to 2023 due to OurWorldinData lOMoAR cPSD| 59085392

1.3 Advantages of Microbial Biofuel Production

Sustainability: Reduces reliance on fossil fuels and lowers greenhouse gas emissions.

Versatility: Can utilize non-food feedstocks, minimizing competition with food supplies.

Scalability: Fermentation-based processes are highly scalable and adaptable to industrial settings.

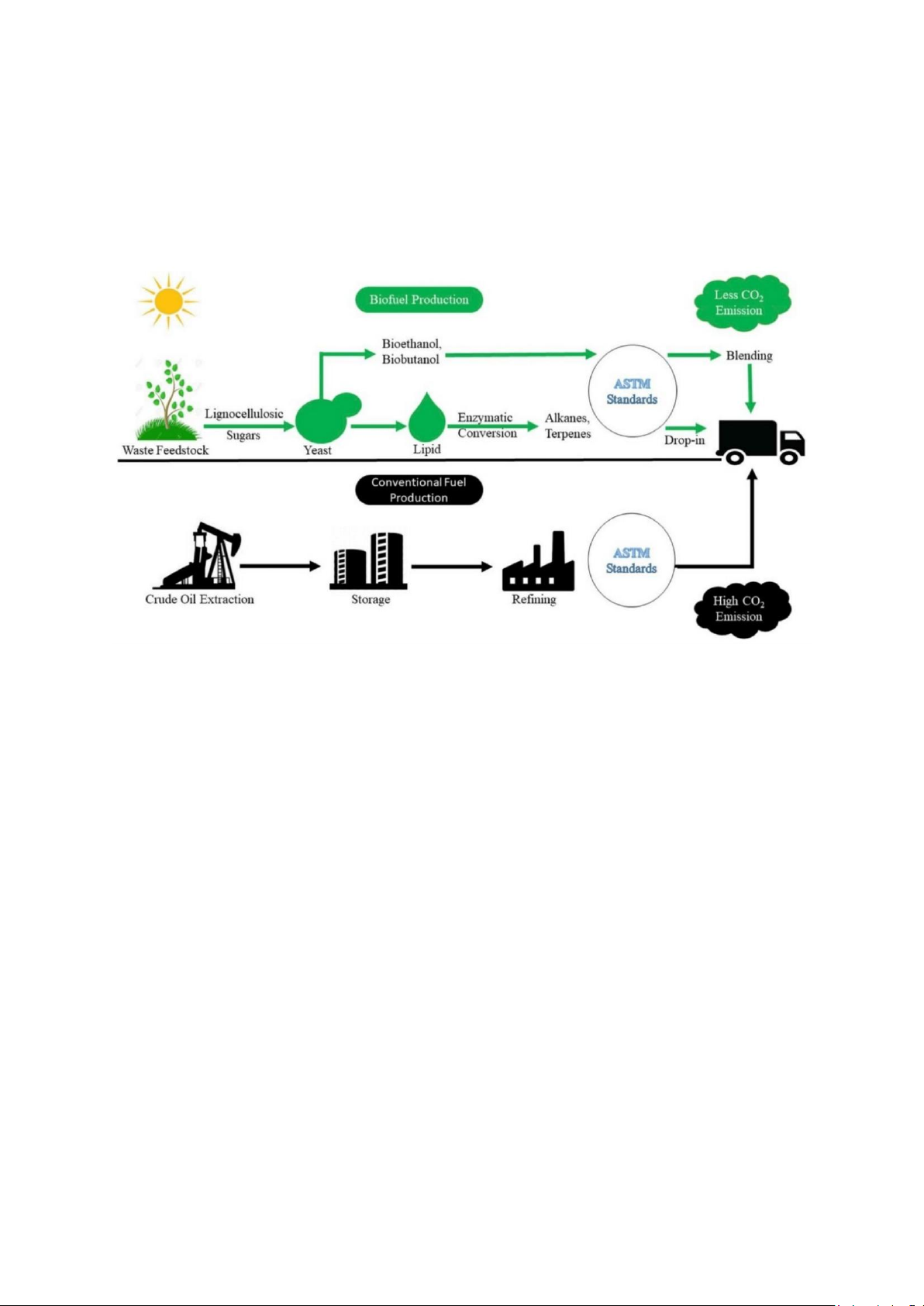

Figure.Conventional oil and biofuels net production pathways

2. Biodegradable Plastics from Genetically Engineered Bacteria

2.1 Polyhydroxyalkanoates (PHAs): A Green Alternative to Petroleum-Based

PlasticsPolyhydroxyalkanoates (PHAs) are a family of biodegradable polymers produced

by bacteria as energy storage molecules. Genetically engineered bacteria, such as

Cupriavidus necator and Pseudomonas putida, have been optimized for high-yield PHA production:

Genetic Modifications: Introducing genes for PHA biosynthesis and deleting competing pathways

have significantly improved production efficiency.

Feedstock Flexibility: GMMs can produce PHAs from a variety of carbon sources, including

agricultural waste, molasses, and even carbon dioxide. 2.2 Applications of PHAs lOMoAR cPSD| 59085392

Packaging: PHAs are used to produce biodegradable packaging materials, reducing plastic waste in landfills and oceans.

Medical Devices: PHAs are biocompatible and used in sutures, drug delivery systems, and tissue engineering scaffolds.

Agriculture: PHA-based films are used as biodegradable mulch films, eliminating the need for plastic removal after harvest.

2.3 Challenges and Future Directions

Cost: PHA production is currently more expensive than conventional plastics due to high fermentation and purification costs.

Scalability: Optimizing large-scale production processes is essential for commercial viability.

Public Awareness: Increasing consumer awareness and demand for biodegradable plastics can drive market adoption.

3. Bioremediation Using Genetically Modified Microorganisms 3.1 Oil Spill Cleanup

Oil spills pose significant threats to marine ecosystems and human health. Genetically modified

bacteria, such as Alcanivorax borkumensis, have been engineered to degrade hydrocarbons in oil spills:

Mechanism: These bacteria produce enzymes like alkane hydroxylases and cytochrome P450, which

break down complex hydrocarbons into simpler, less toxic compounds.

Field Applications: GMMs have been successfully deployed in oil spill cleanup operations,

demonstrating their effectiveness in real-world scenarios. lOMoAR cPSD| 59085392

3.2 Heavy Metal Detoxification

Heavy metal contamination in soil and water is a major environmental concern. Genetically modified

microorganisms, such as Pseudomonas aeruginosa and Bacillus subtilis, have been developed to detoxify heavy metals:

Biosorption: GMMs can adsorb heavy metals onto their cell surfaces, effectively removing them from the environment.

Enzymatic Transformation: Some GMMs produce enzymes that convert toxic heavy metals into less

harmful forms. For example, mercury can be transformed into volatile elemental mercury, which is less toxic.

3.3 Advantages of Microbial Bioremediation

Cost-Effectiveness: Microbial bioremediation is often more affordable than traditional methods like

excavation and chemical treatment.

Eco-Friendliness: GMMs offer a natural and sustainable approach to environmental cleanup.

Targeted Action: Genetic engineering allows for the customization of microorganisms to target specific pollutants. Reference:

Source: | List of microorganisms producing biofuels or the precursors for