Preview text:

HOCHIMINH CITY INTERNATIONAL UNIVERSITY

SCHOOL OF INDUSTRIAL ENGINEERING & MANAGEMENT REPORT INTERNSHIP 1 Name: Mai Nguyễn An ID: IEIEIU20120 Ho Chi Minh city, Vietnam 8/2022 1 TABLE OF CONTENT

A. INTRODUCTION …………………………………….. 3 B. COMPANY I. YAKULT

1. Observation………….………………………….... 3

2. Analysis………………………………………….. 6 II. AJINOMOTO

1. Observation ……………………………………... 6

2. Analysis………………………………………….. 9 III. TBS Group

1. Observation……………………………………… 9

2. Analysis…………………………………………. 10 IV. TRASAS

1. Observation……………………………………... 10

2. Analysis…………………………………………. 11

C. CONCLUSION ……………………………………..... 12

D. REFERENCE………………………………………… 12 2 A. INTRODUCTION

Internship 1 is required of all School of Industrial Engineering & Management

second-year students. It is essential for students to help them get used to their

future jobs and to help them comprehend firms in a range of industries. Because of

the School, we have many opportunity to speak with and tour various

manufacturing companies across a range of sectors, including food, transportation, electronics, and warehousing.

In this internship, we travel to four of the best businesses in the import-export,

beverages, food, spices, and other industries. When we visit, a guilder will show us

through the main area of the factory, explain their production method and why they

are so proud of their product, discuss the business, and answer any questions we

may have. After internship I, we are required to create a report outlining the results

of our site visits. But given the limited time and lack of expertise I have now, my

report may be filled with mistakes. I would want some instructor feedback so that I

may gain more experience and understanding of the real jobs that are available in a variety of industries.

Finally, I'd want to express my gratitude to the Industrial and System Engineering

Department for all of their assistance and support throughout the internship. I genuinely appreciate it. B. COMPANIES I.YAKULT 1. Observation a. Overview

Yakult is the first fermented milk beverage in the world. Lactobacillus casei

Shirota is a probiotic bacteria that was first found in 1930 by Japanese

researcher Minoru Shirota. The product is sold by Yakult Honsha, which has

its headquarters in Tokyo. A 65-milliliter pack (2.3 fl oz; 2.2 fl oz US) of milk

bottles contains five bottles.

Yakult Vietnam was established on June 26, 2006, with a total investment of

roughly VND 400 billion from Yakult Honsha of Japan (80%) and the Danone

Group of France (the remaining 20%). (the remaining 20 percent ). 20% of the 3

total Yakult Vietnam first opened its doors in August of 2007. Yakult products are

widely available in supermarkets and retail shops throughout Vietnam.

Yakult is also delivered directly to clients' homes in Ho Chi Minh City, Hanoi,

Hai Phong, Dong Nai, Binh Duong, Da Nang, Nha Trang, and Vinh through the

Yakult delivery system - Lady.

Yakult's goal is to improve people's health all over the world and to continue

to make new discoveries in a variety of fields in the days and years ahead and

develop into a well-liked and recognized organization that never abandons its

purpose of assisting people and society further. b. Production process Dissolving tank

In the dissolving tank, heated water between 50 and 55° C is used to dissolve the

skim milk powder and create a milky solution. Culture Tank

The milky solution is moved from the dissolving tank to the culture tank and

sterilized there. After that, it will be chilled to 37°. Once the quantity of L. casei

strain Shirota reaches an optimum concentration, the culture starter, L. casei strain

Shirota, from the seed tank will be introduced to the tank to ferment the solution

until the solution transforms into curd form, or culture foundation. Storage tank

Before being delivered to the storage tank, the culture base will pass through a

homogeniser (a high pressure machine) to create a fine texture. The concentrated 4

Yakult is made in the storage tank by combining the culture foundation with sterile

sugar syrup, which is then refrigerated to 5° C. Mixing Tank

Transferred to the mixing tank, the concentrated Yakult will be diluted with sterile

water. For flavor-infused Yakult, natural flavors and authorized coloring will be

added at this point. The diluted liquid will then be transported to the filling tank. Bottle molding machine

The molding machine produces plastic bottles at a rate of 7000 bottles per hour. A

clean air blower then transports these polystyrene bottles down a conduit and into the storage tank. Selector machine

The empty bottles will be moved from the storage tank to the selection machine,

where they will be placed upright before being sent to the printing device. Printing machine

On the empty bottles, the printing device will utilize red instant-dry ink to print the

Yakult logo, the ingredients used, etc.

Machine for filling, capping, and sealing

The printed bottles will be sent from the printing device to the filling device, which

can fill 30,000 bottles with Yakult per hour. At this point, aluminum foil bearing

the date "Use-by-date" is used to cap and seal the bottles. Packing machine

The final Yakult will be packaged in polypropylene shrink-wrapped single bottles

or packs of five bottles. A crate containing 100 bottles of the same flavor is

packaged with the single bottles. Regarding the Yakult 5-bottle pack, it will either

be packaged in a single flavor or a variety of flavors. We'll additionally pack a box

with these Yakult 5-bottle packs. The conveyor belt will move all of the containers

holding the Yakult to the cold room. Cold room

The final products are always preserved in the best condition possible before

distribution by being kept chilled in the cold room at a temperature of 5° C. Distribution

The Yakult that was kept in the cold room is now prepared for delivery by chilled

trucks to the following suppliers.

Supermarkets, retail and convenience stores, vending machines, schools, and

exports to Brunei are all examples of direct sales.

Home Delivery, which is door-to-door delivery facilitated by Yakult lady agents, is

mostly used in public housing complexes. 5 2. Analysis

The system at Yakult is extremely well thought out, giving the corporation an

excessive amount of control over manufacturing, and there are hardly any faulty

items. Modern automation and technology are used in the workplace, which requires less physical labor.

Engineers run the chain at a rate of around 8 to 10 engineers each hour at the

facility, which employs a little more than 50 employees in total. Without a hitch

and with little to no delay, the surgery was completed.

Modern, imported Japanese machinery makes up the entirety of the factory.

Although the facility has a daily production capacity of 800,000 bottles, it is

currently only producing 300,000 bottles daily to meet Vietnamese consumer demand.

While importing machinery that is entirely Japanese will assist assure

higherquality goods, it can also result in significant import expenses. Cleaning the

equipment is not worth it since it will not perform at its best if it is not operating at

full capacity, which will result in maintenance expenditures. II. AJINOMOTO 1. Observation a. Overview

Ajinomoto Vietnam Company, founded in 1991, is a 100% foreign-owned

subsidiary of the Ajinomoto Group of Japan, with an initial investment of more

than $8 million USD. Over the course of its 30-year history, the company has

consistently grown, expanded its business network, and boosted its product manufacturing capacity.

Ajinomoto Vietnam Company now has two representative offices in Ho Chi

Minh City and Hanoi, as well as two manufacturing factories, including the

Ajinomoto Bien Hoa Factory, which has been in operation since 1991, and the

Ajinomoto Long Thanh Factory, which has been in operation since 2008. The

construction of the third machine, which is located in Long Thanh, began in

2016. The organization also has three significant distribution facilities and 6

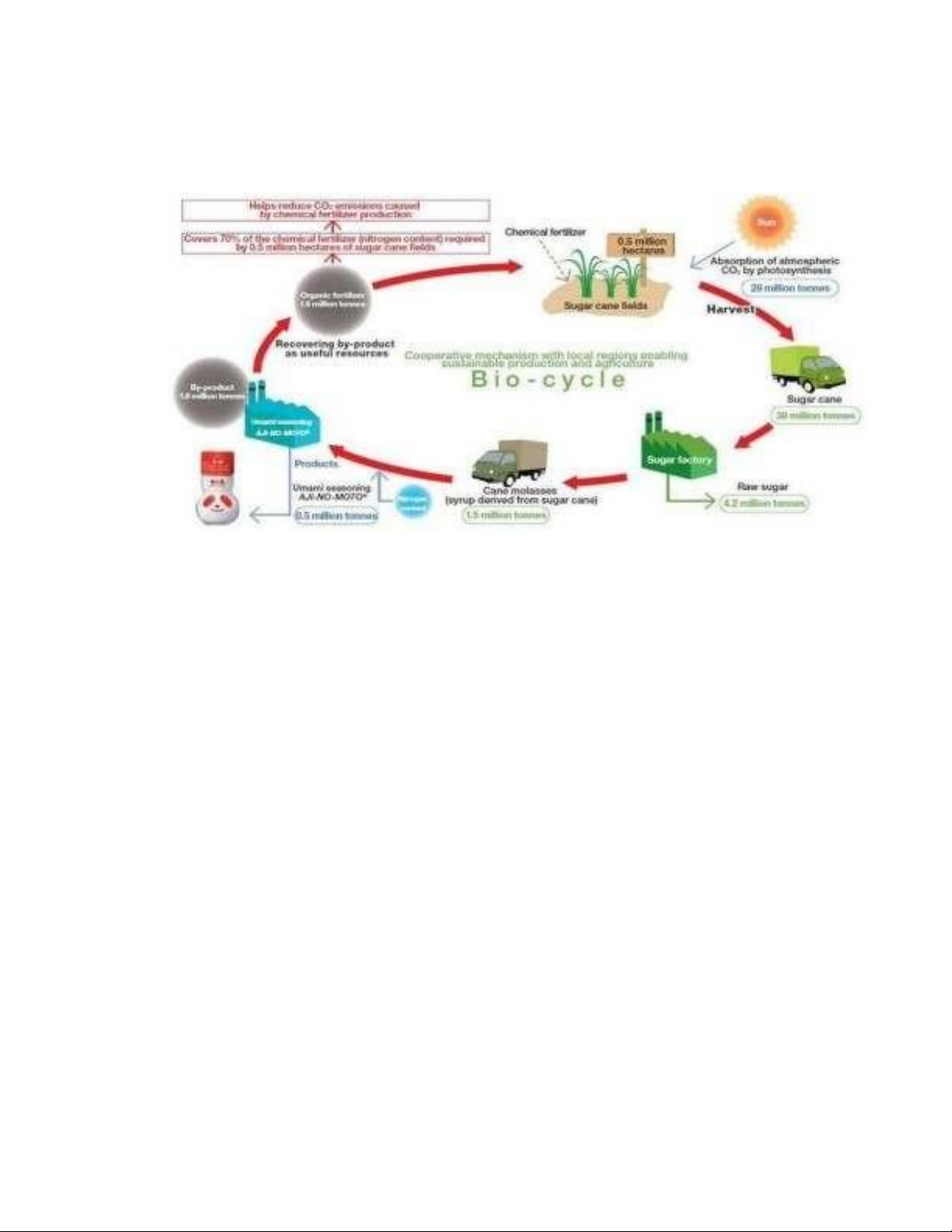

branches distributed over 63 regions. The Ajinomoto Vietnam Company employs a total of 2,300 people. b. Production process

Step 1:Materials are handled in step one. Molasses and cassava starch, which are

used to create sugar solutions, are the primary ingredients of the business. After

being heated-sterilized, raw materials and additional nutrients are added to fermentation tanks.

Step 2: A fermentation technique is used to manufacture glutamic acid. The

acidification process isolated the glutamic crystalline cubic from the fermentation broth.

Step 3: Crystallization allows for the recovery of glutamic acid. By acidifying the

environment of the fermentation broth, glutamic acid crystallized.

Step 4: Monosodium glutamate is created from glutamic acid. Monosodium

glutamate is created when sodium hydroxide solution is added to the crystalline

glutamic acid block (used in food). For use as a food flavoring, monosodium

glutamate has the benefits of being soluble and long-lasting in storage. Step 5:

Cleaning the monosodium glutamate solution. The surface of activated carbon has

a lot of microscopic pores, which helps it absorb pollutants. As a result, the

contaminants are eliminated, and the monosodium glutamate solution is left clear and pure.

Step 6: Monosodium glutamate crystallizes in step six. Drying concentrates the

cleaned monosodium glutamate solution, resulting in the formation of crystalline monosodium glutamate. 7

Step 7: The monosodium glutamate crystals are dried in step seven. In a closed

system, the crystals are rotated, vibrated, and heated.

Step 8: Weighing and packaging the monosodium glutamate crystals. The Ajinomoto MSG is this. Upstream process

The production of MSG follows a typical bioprocess flow. One typical bioprocess

flow is fermentation. When sugar's acids are released, fermentation occurs. To

avoid the detrimental consequences of consuming excessive amounts of sugar, the

sugar is then introduced gradually. Scaling Up: At the beginning of the process,

glutamate is kept in separate shaking flasks. They are at full volume.

During fermentation, oleic acid is added to the mixture. The temperature is set at

33 degrees. Throughout the process, the temperature is increased and lowered until

Monosodium Glutamate is created. Downstream

Fermentation is a method for eliminating unwanted components during

downstream extraction. The product is then held at 20°C for two days to allow

crystallization. After that, the product is dissolved in water to create monosodium

salt, which is the final step in polishing. They subsequently solidified, and before usage, they were let to dry.

The Process of Waste Treatment of AJINOMOTO VIETNAM

Ajinomoto Vietnam has put in place an environmental management system based

on the ISO 14001: 2004 standard as well as initiatives to better and protect the

environment, including the reduction of waste water and solid waste, air pollution,

energy conservation, and 100% waste recycling. These initiatives all contribute to

the effective use of natural resources to support business and production activities.

All of the company's manufacturing plant waste is therefore categorized for

recycling; plastic trash is transferred to facilities for recycling plastics; and

industrial waste, after being decanted of the valuable parts, is sent to sophisticated

treatment systems using microbiological and deposition procedures. When visiting

the wastewater treatment facility, which Ajinomoto Vietnam meticulously invested

in, there is no unpleasant smell; rather, there is just the smell of molasses sugar,

and fish may survive in the water after being handled. Ajinomoto Vietnam received

a long-term "Green brand" award from the Vietnam Union of Science and

Technology Associations for its efforts to protect the environment.

To guarantee a secure and top-notch working environment, Ajinomoto Corporation

carries out thorough quality control in compliance with the HACCP Standard,

GMP Standard, Food Defense Standard, and other Ajinomoto Quality Assurance

System (ASQUA) requirements. Every stage of manufacturing, from obtaining raw 8

ingredients to combining, cooking, filling, and packaging, is handled with care in

addition to following the right procedures and educating the personnel on

appropriate behavior. the top in terms of cleanliness, security, and quality. Each

phase goes through a number of tests and inspections depending on the kind of

material used and the characteristics of the finished product.

Ajinomoto Corporation is boosting food safety assurance in an effort to reduce the

risk of deliberate contamination in the Group's worldwide supply chain. As shown

in the image below, they include creating a healthy company culture based on

relationships of trust with workers, updating and enhancing physical components

like manufacturing equipment, and software components like quality standards and processes. 2. Analysis

Students learn more about the production process for Ajinomoto goods such

Ajinomoto powder, Aji-ngon nut powder, and Ajinomoto doughnuts during the

factory visit. The corporation's operations, storage, shipping, and packaging are

also emphasized. The students also learn more about Ajinomoto's initiatives to

advance shared values in society and develop a greater grasp of the spiritual ideas

and message that the company hopes to convey to its clients. III. TBS GROUP 1. Observation a. Overview

TBS was established in 1989 and has seen many ups and downs in its growth.

Milestones show the company's maturity in each phase and increasingly integrate

Vietnamese businesses lower down the global value chain. TBS makes investments

and expands in six key industries: trade and services, port and logistics, real estate,

footwear, and handbags. Every sector has important milestones and

accomplishments that greatly contribute to the long-term success of the business. b. Production process

from manufacturing to warehouse process 9 Check-in

Security officers record the driver's license plate, the job number, the date, the

time, and the cargo information; the warehouse sets up the waiting area; and the cargo truck pulls up. Documents Verification

Once a passenger has checked in, the driver transfers them to the waiting area

where the driver or business representative examines the documents to ensure that

they are in line with the company's stated plan. Physical Goods Inspection

Personnel assigned to documentation are sent out to examine and receive the cargo.

The real shipment is thoroughly examined and then sent to the warehouse if everything is in order. 2. Analysis

The success and expansion of the organization depend in large part on the

development of its human resources, which are valuable assets and tactical tools.

The business will also continuously collaborate with clients, partners, and

employees to help TBS flourish and share benefits as well as to keep innovating as

a foundation for development. As a commitment of duty to the nation, community,

society, and workers, contribute to a better life and society.

During their internship at TBS, students gained knowledge of the corporate model

of logistics, supply chain management, shipping, and storage, including its

organizational structure, technical approach, and phases. The company's brothers

and sisters are also always willing to help and support me. As a consequence,

students have gained knowledge on a wide range of subjects, including production

company professional abilities as well as TBS' current problems and difficulties.

After completing my internship with the company, I'd like to provide some

recommendations for the company's further success. For long-term growth and

cooperation, the organization should make a concentrated effort to keep current

clients, re-engage previous clients, and recruit new ones. IV.TRASAS 10 1. Observation a. overview

The Maritime Transport and Services Joint Stock Company (TRA-SAS) was

founded in 1996 and is one of Vietnam's leading logistics and supply chain service

providers. TRA-SAS is known as a strategic partner in logistics services in many

Industrial Parks, industrial infrastructure, and large-scale business projects

throughout Vietnam, with its forerunner being the Shipping and Marine Services

Enterprise under TRACIMEXCO - Ministry of Transport. TRA-SAS is proud to

be an enterprise that has grown significantly, fast, and firmly in various industries

after over 25 years of establishment and development. TRA-SAS is now regarded

as one of the most powerful firms in the sector of customs clearance, as well as a

freight forwarding agent for the majority of the world's shipping corporations. b. Production process

The delivery order (D/O) is collected by TRASAS employees together with the

original shipment receipt, B/L, and letter of introduction from the firm to the

shipping agency. Only the reference will get the delivery order in a bill surrender

or telex release scenario. If the B/L is postpaid, there will be an extra fee. Only if

they are accessible based on the charges already paid will the document fee,

tracking expenses, and other fees be paid (prepaid). TRASAS generates a set of

documents to receive the objects after receiving a D/O. The customs declaration

process is an important one that calls for staff members to act professionally and carefully. 2. Analysis

By putting a strong emphasis on customer satisfaction and service, the firm aims to

assist all workers in achieving their goals and encouraging them to always take

responsibility for their work. Relationships that TRASAS has established with

important company stakeholders have helped in service delivery. Due to

established connections with multiple shipping lines, each firm may bargain for

favorable price for its range of products, for instance. Because each company is

only strong in a few areas, the business is laser-focused on utilizing its partners'

abilities along their most lucrative paths.

Despite the drawbacks of the warehouse system, TRASAS did not invest enough

time and effort in creating its own.

Students can learn about logistics, global commerce, and the fundamentals of

shipping and forwarding in this discipline. As a result, a professional logistics

firm's expansion depends on investing in professional personnel development. 11

The network is unstable or information is lost to the outside world as a result of

network failures. Office gear and equipment that are frequently damaged or

outdated waste time and money and slow down business operations. C. CONCLUSION

I was able to see how my academic knowledge was put to use thanks to the visit.

How to carry things quickly and cheaply. which direction to arrange the items in

the inventory and label them for quick delivery. The conveyor for the wrapping

lines cannot stop moving quickly enough to receive payment for the hours worked.

In light of the enormous demand, ensuring that the system can function while

being transported continually is crucial.

In the plant, I have observed expansive and effective conveyors with the new level.

as an improved version of the models that we created for the Introduction to

Industrial Engineering and Systems course. I can learn about their design and

experience from that and use it in the future. After all, this topic has potential to

influence the future. This aids ISE students in understanding the process through

which their knowledge will be utilized in the next assignments.

I am grateful to the lecturers and professors at the ISE Department for not only

teaching us but also for planning the fantastic internship trip that forced us to

conduct additional research and experiments. I hope that the Department continues

to grow in order to provide more opportunities and support for the next generation of students. D. REFERENCES http://yakult.vn

https://www.ajinomoto.com. vn/

https://www.trasas.com.vn/vi/ve-chung-toi.html

http://www.tbsgroup.vn THANKS FOR READING! 12