Preview text:

lOMoAR cPSD| 58759230 Steel Structures

Chapter 2 Steel connections Steel connections 1 .Introduction

2 .Welded connections 3. Bolted connections 4. Riveted connections 2 lOMoAR cPSD| 58759230 Introduction 3 lOMoAR cPSD| 58759230 Welded connections Introduction 4 1. Introduction

• Structural members are jointed by means of weld

• Why using welded connections?

o A more efficient use of materials o High speed of

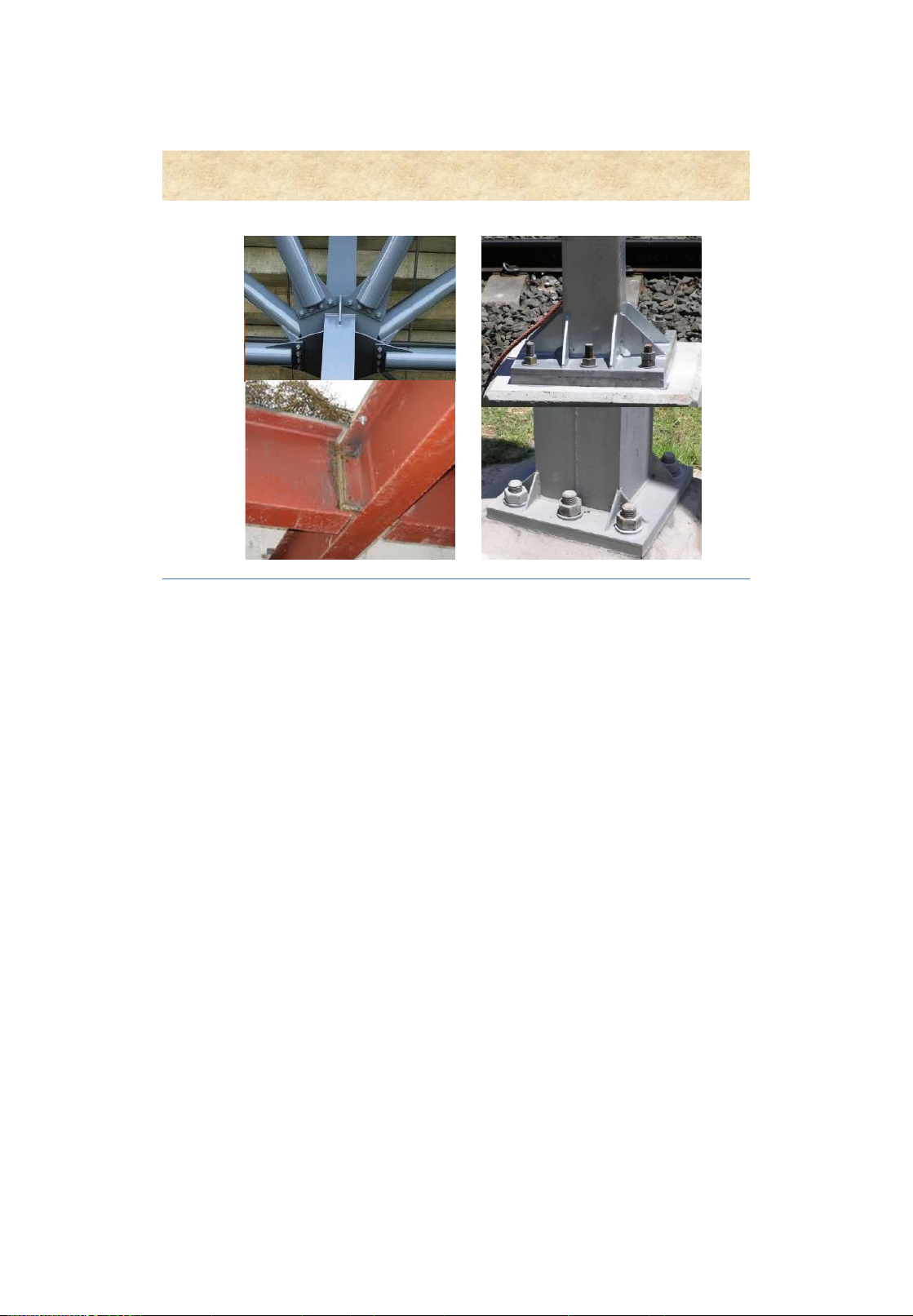

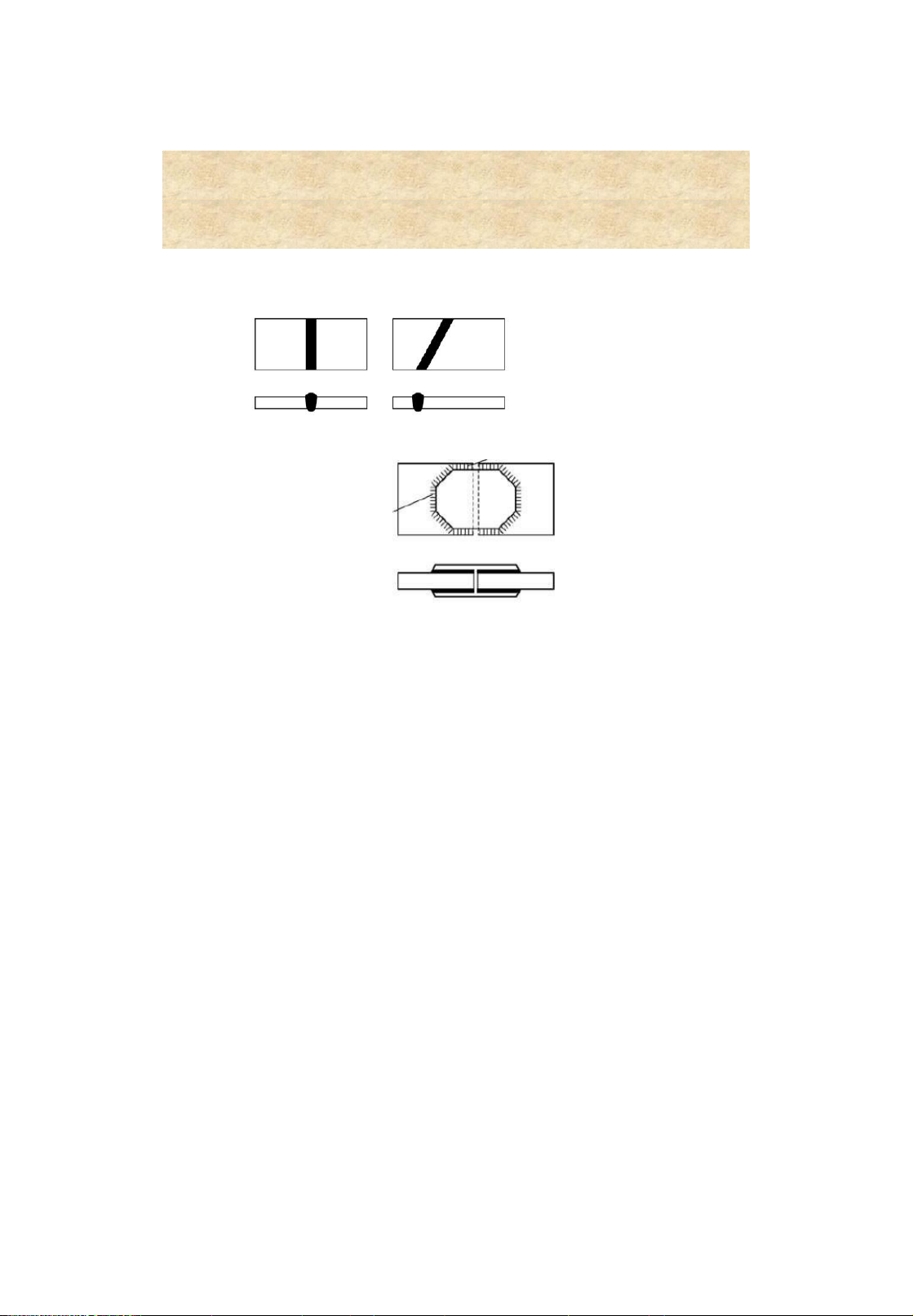

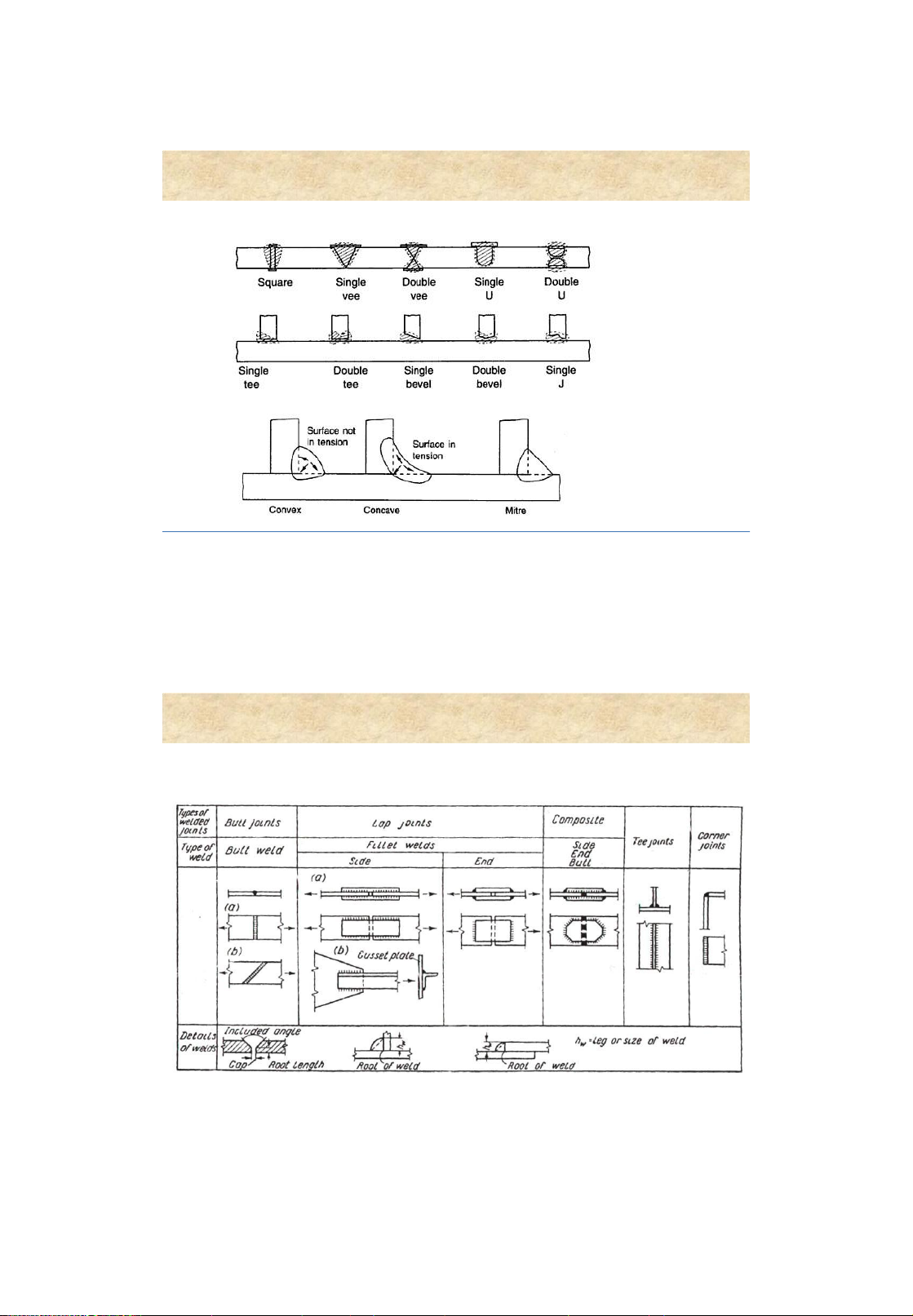

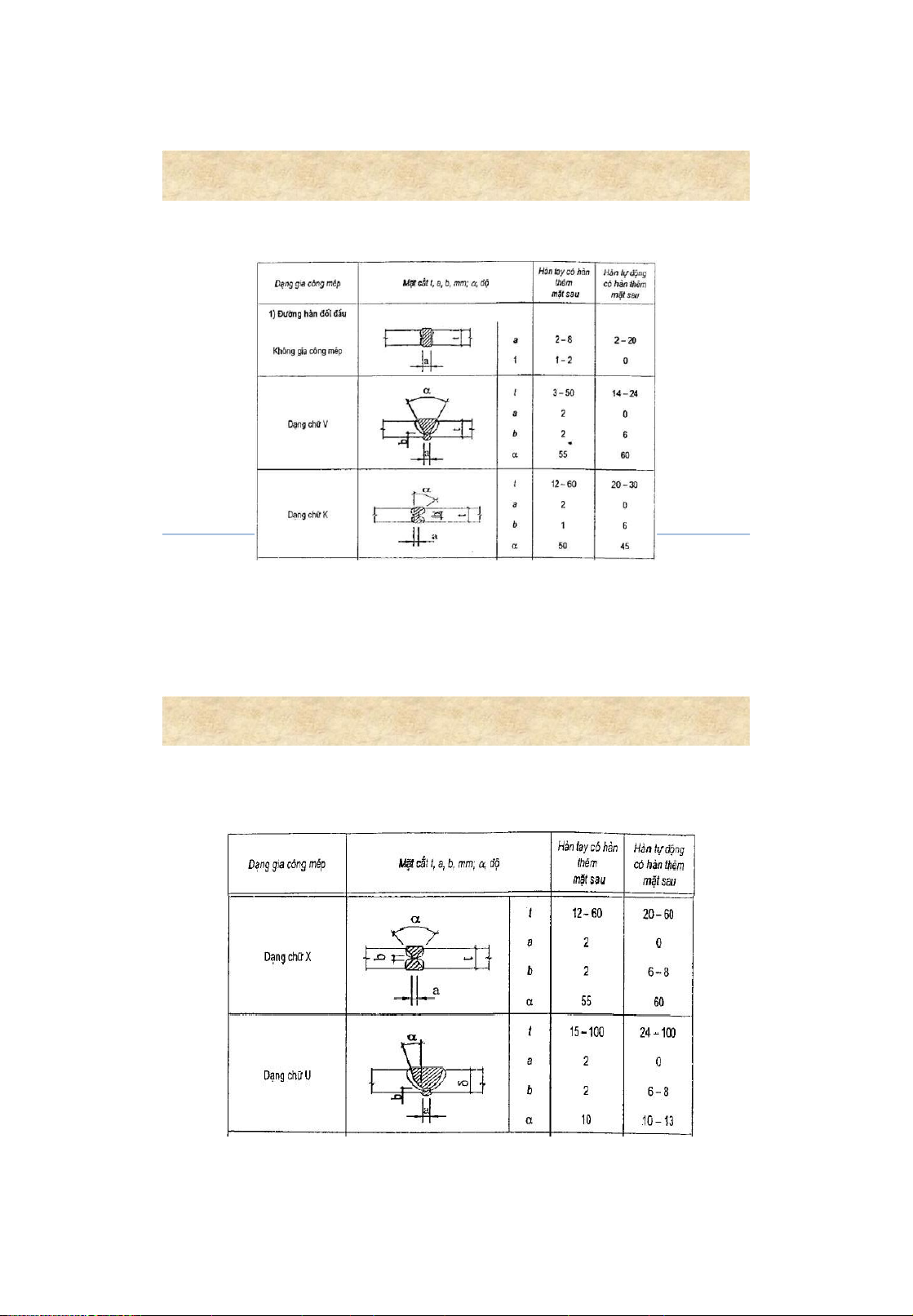

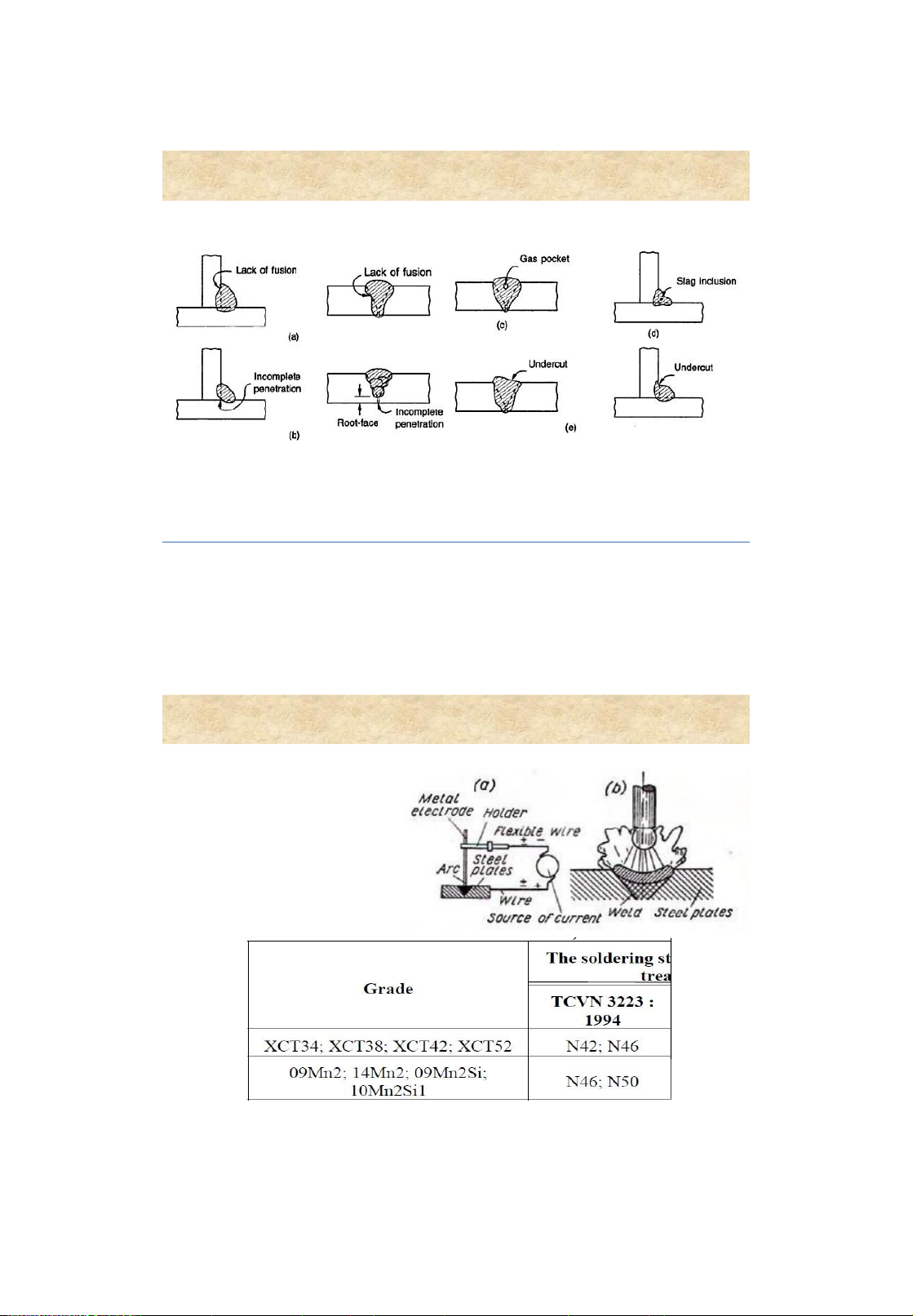

fabrication and erection o Better for fatigue loads, impact loads, and vibrations 5 lOMoAR cPSD| 58759230 Welded connections 2. Types of welds o Butt welds o Fillet welds 6 lOMoAR cPSD| 58759230 Welded connections 2. Types of welds Types of butt welds Types of fillet welds 7 Welded connections 2. Types of welded joints 8 lOMoAR cPSD| 58759230 Welded connections 2. Types of welded joints For butt welds 9 Welded connections 2. Types of welded joints For butt welds 10 lOMoAR cPSD| 58759230 Welded connections 3. Weld defects 11 Welded connections 4 . Welding processes Arc welding

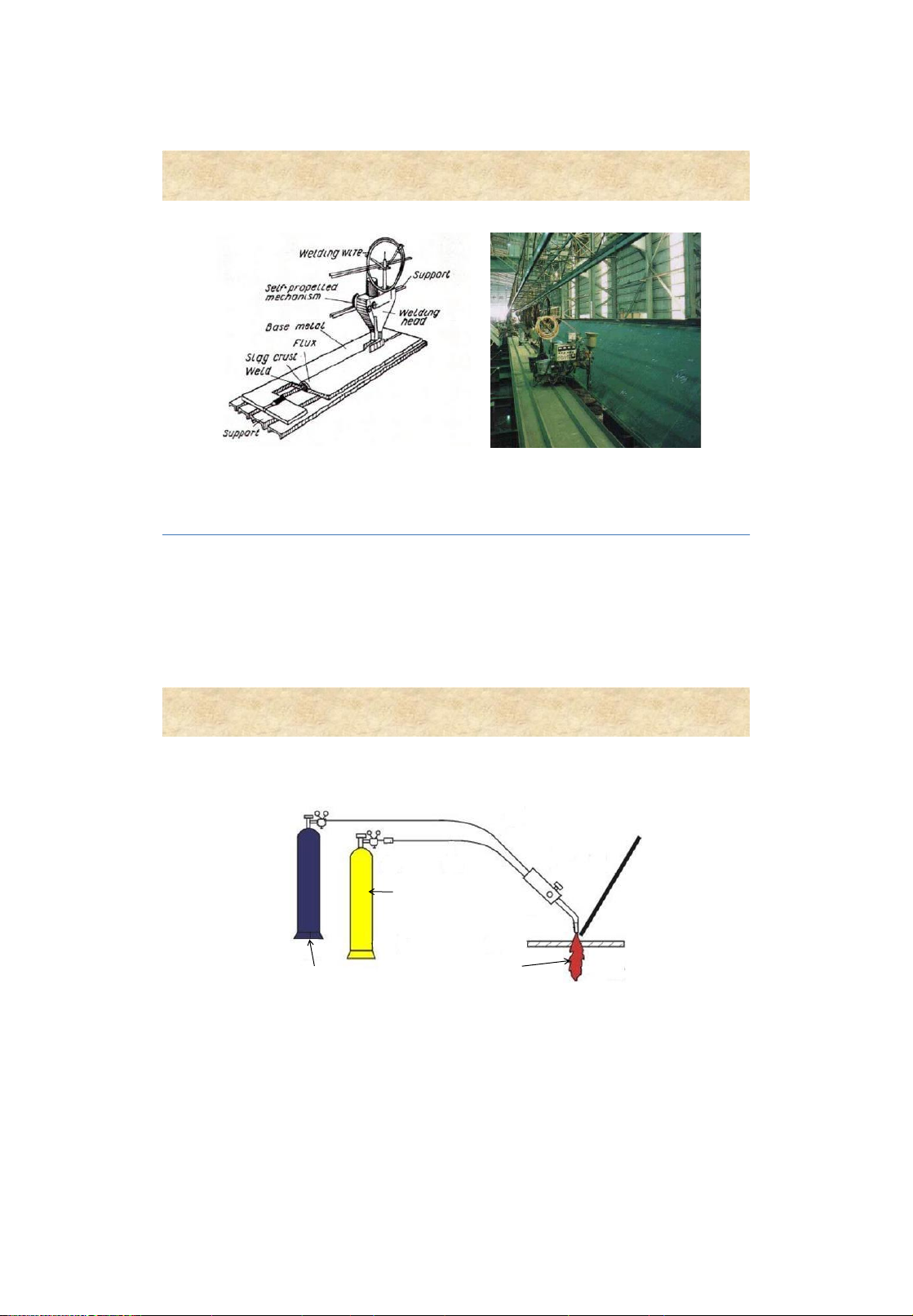

( manual welding ) Types of electrode 12 lOMoAR cPSD| 58759230 Welded connections 4. Welding processes

Automatic and semi-automatic welding 13 Welded connections 4. Welding processes axetylen oxy 3200 o C Gas welding 14 lOMoAR cPSD| 58759230 Welded connections 5 . Design strengths of welds Butt welds

o Compressive strength f wc = f o Tensile strength f wt = f (or 0.85f) o Shear strength f wv = f v ( 0 ,58f )

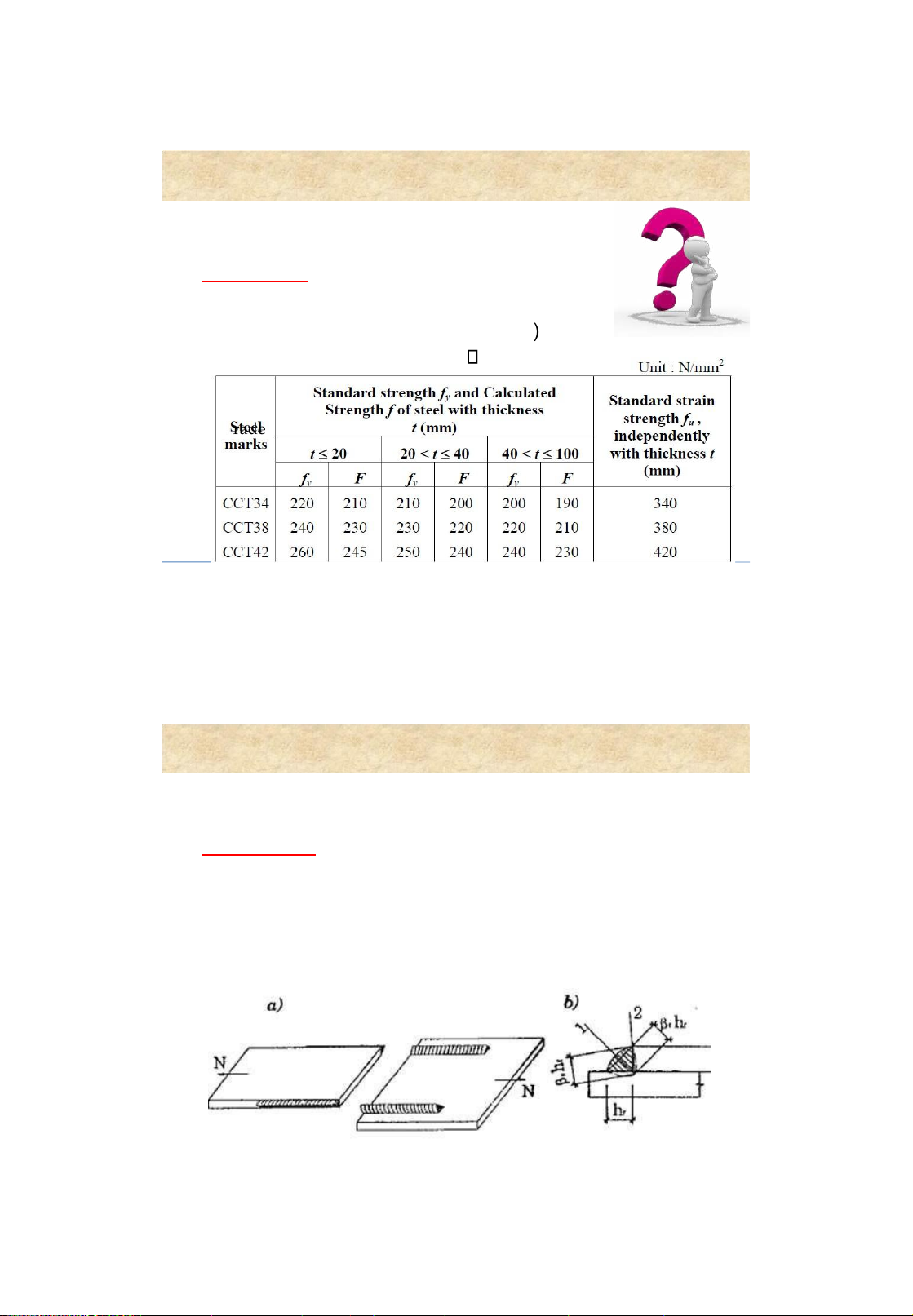

Strengths of materials corresponding to Steel different thickness t Ultimate Steel grade strength f u grade f f f 15 Welded connections 5. Design strengths of welds Fillet welds

o Shear strength (fracture plane 1) fwf (TCVN3223-1994)

o Shear strength (fracture plane 2) fws = 0.45fu

❖ fu - the standard ultimate strength of steel in tension lOMoAR cPSD| 58759230 Welded connections 16 5. Design strengths of welds Fillet welds

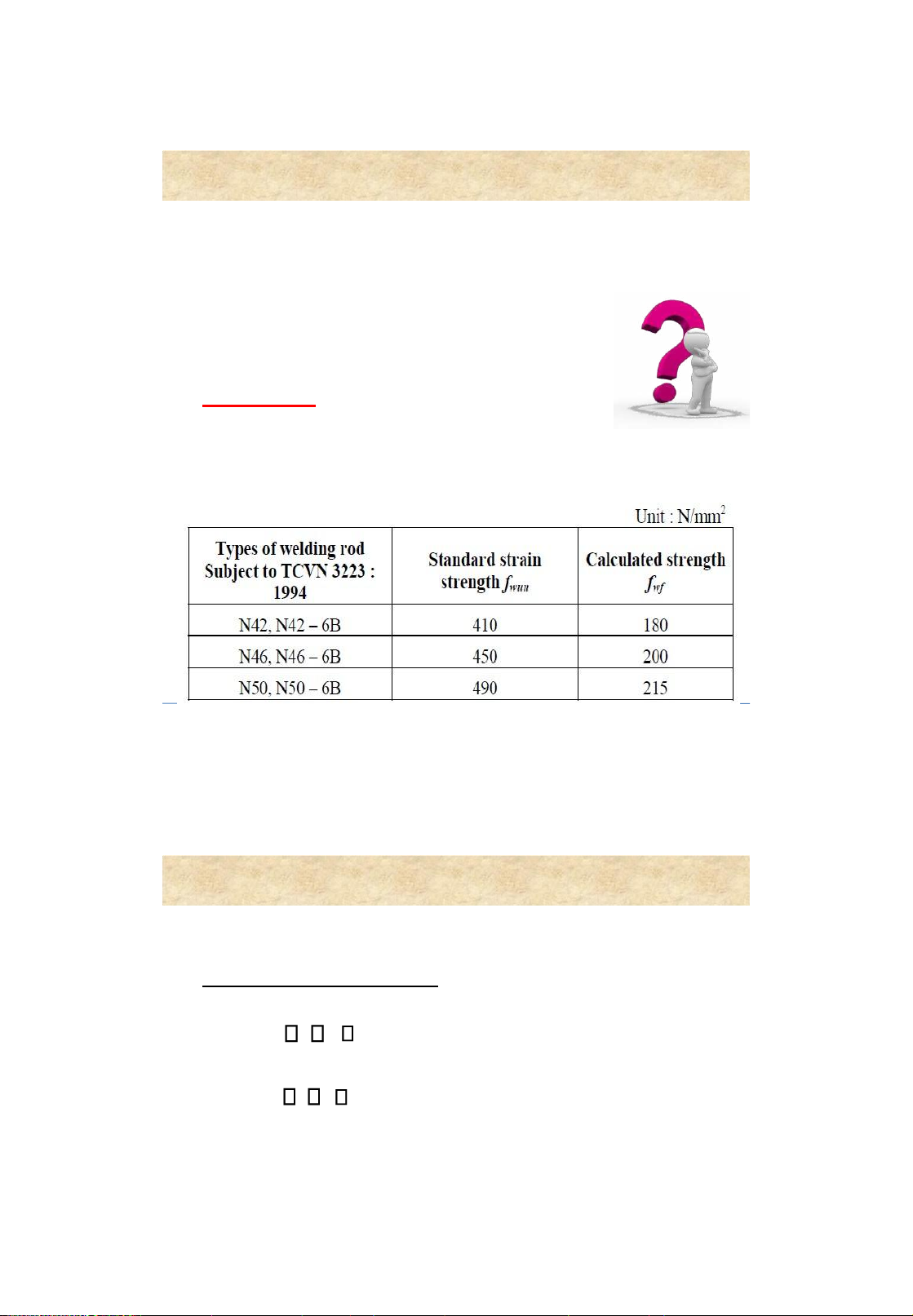

o Shear strength (fracture plane 1) fwf (TCVN3223-1994)

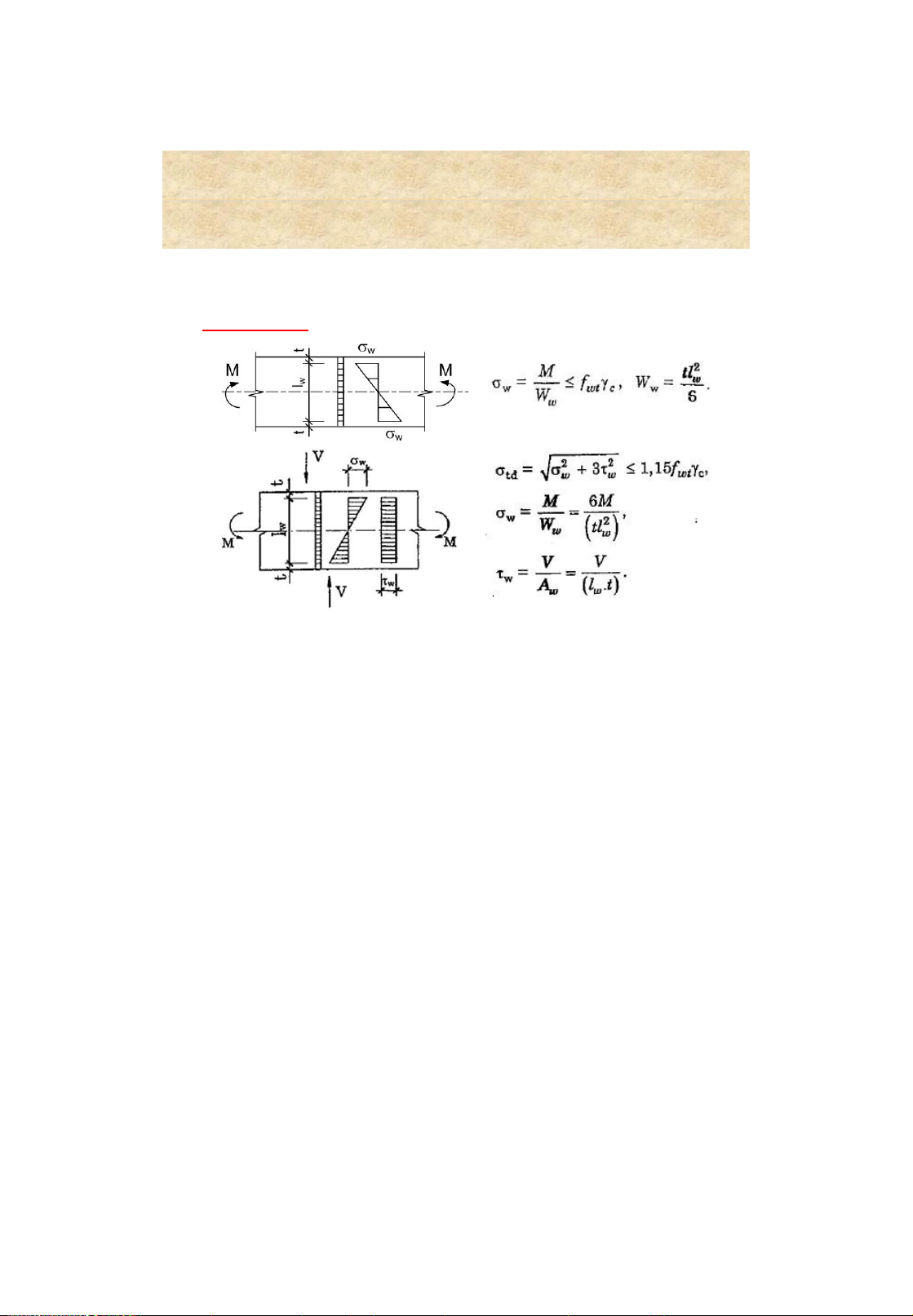

o Shear strength (fracture plane 2) fws = 0.45fu Types of electrode Normal tensile Design strength, strength, f wun f wf 17 Welded connections 6. Design of butt welds

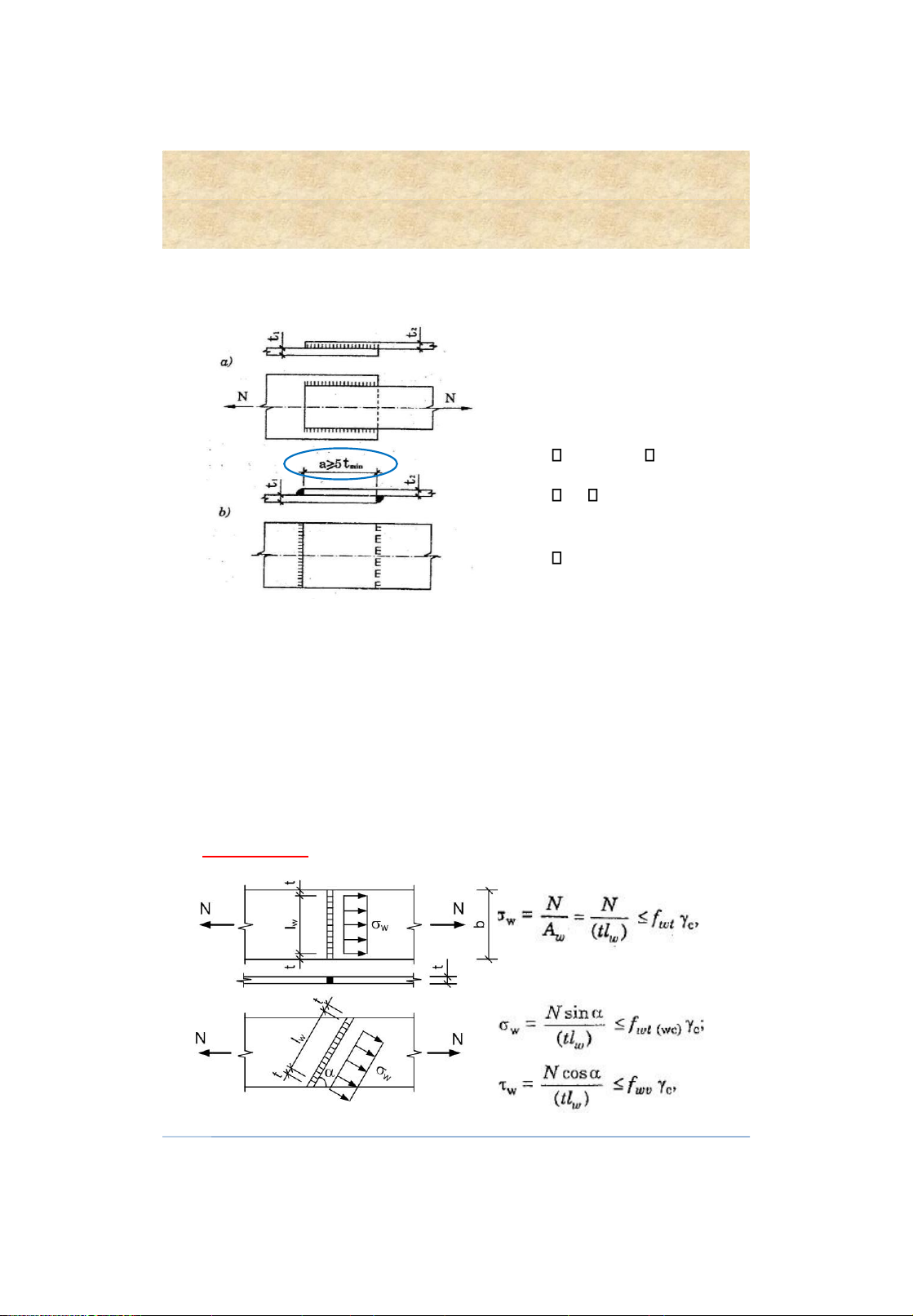

Strength requirements o Welds subjected to normal

stress w c.fwt wc( ) o Welds subjected to shear

stress w c.fwv o Welds subjected to normal and shear stresses lOMoAR cPSD| 58759230 Welded connections

wtd 2 3 2 1,15 c.fwt

The effective area of the weld Aw=t x lw, where t and lw are the

effective thickness and length of the weld lw = l - 2t 18 7. Design of fillet welds Strength requirements

o For section 1: ( f .hf lw)

wf c.fwf o For

section 2: ( s.hf lw)

ws c.fws

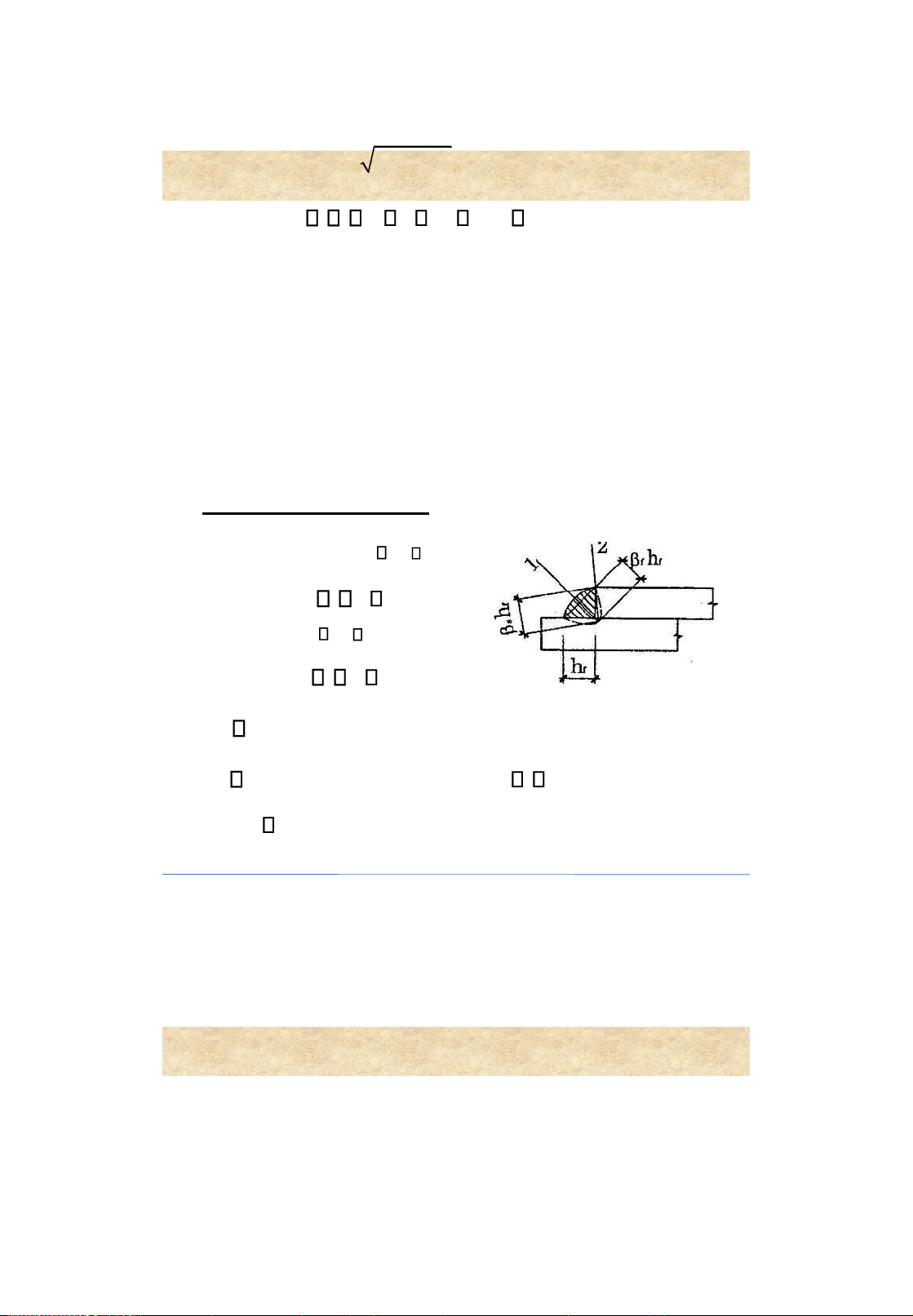

wf - shear stress on section 1

ws- shear stress on section 2 l w l

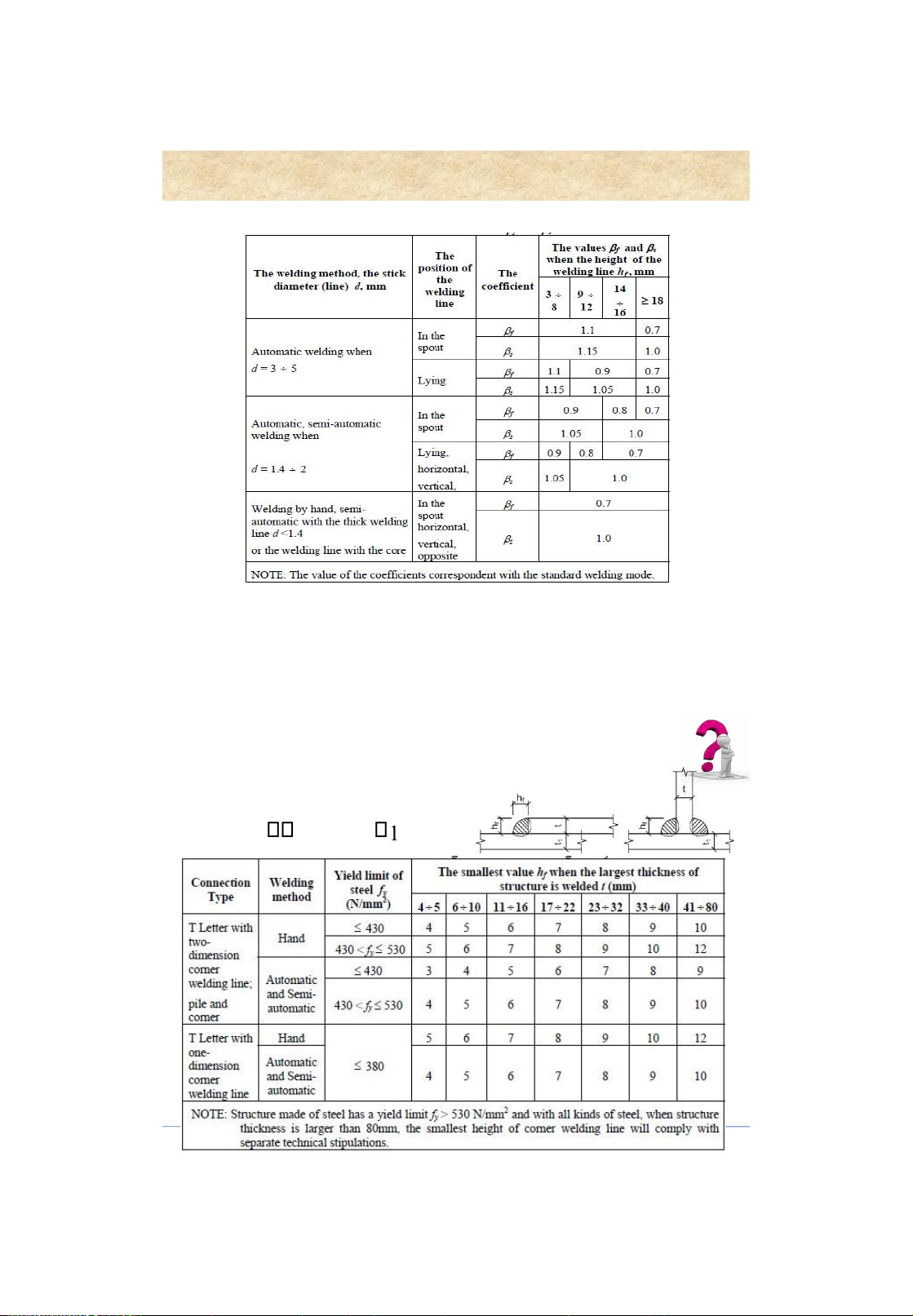

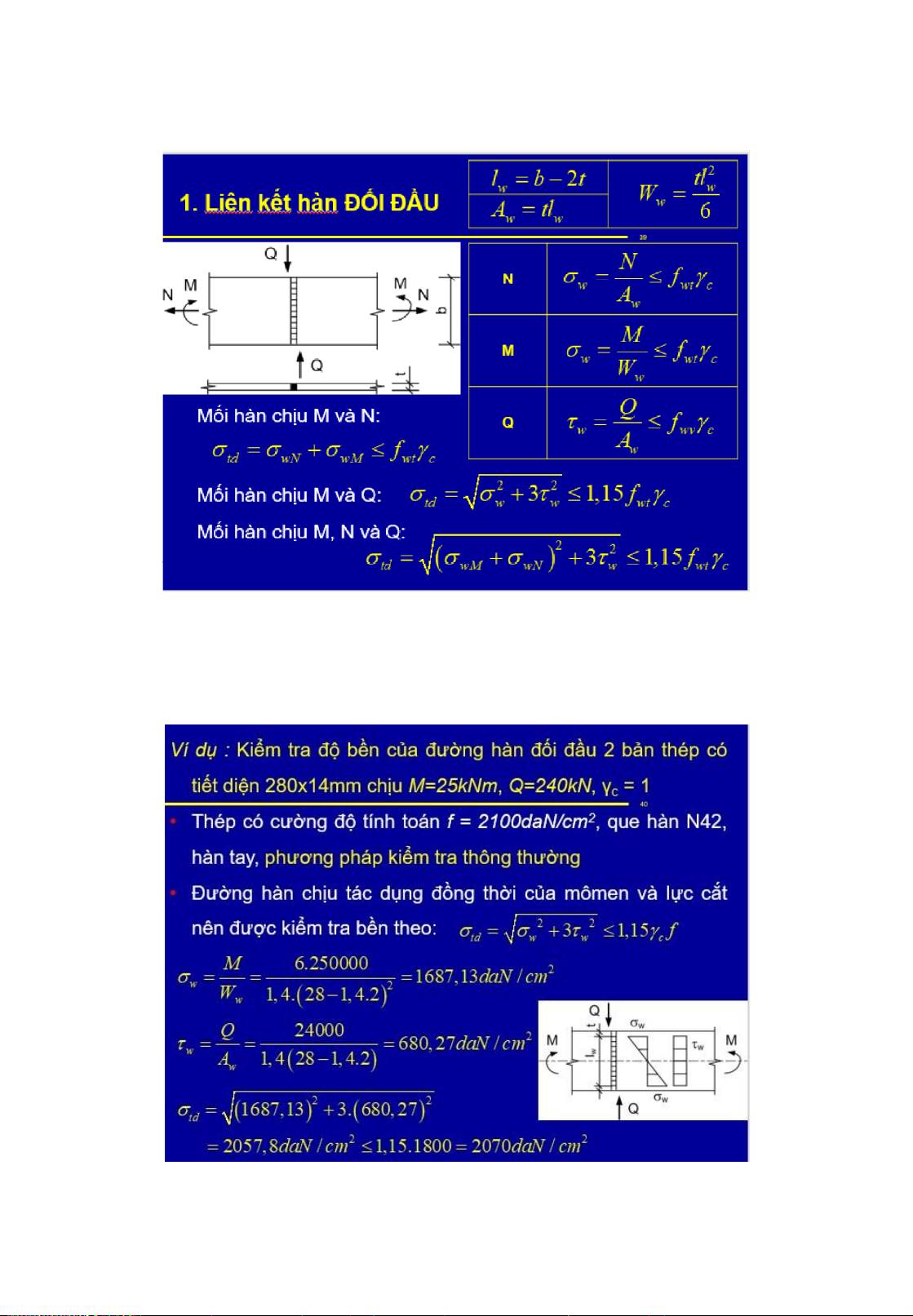

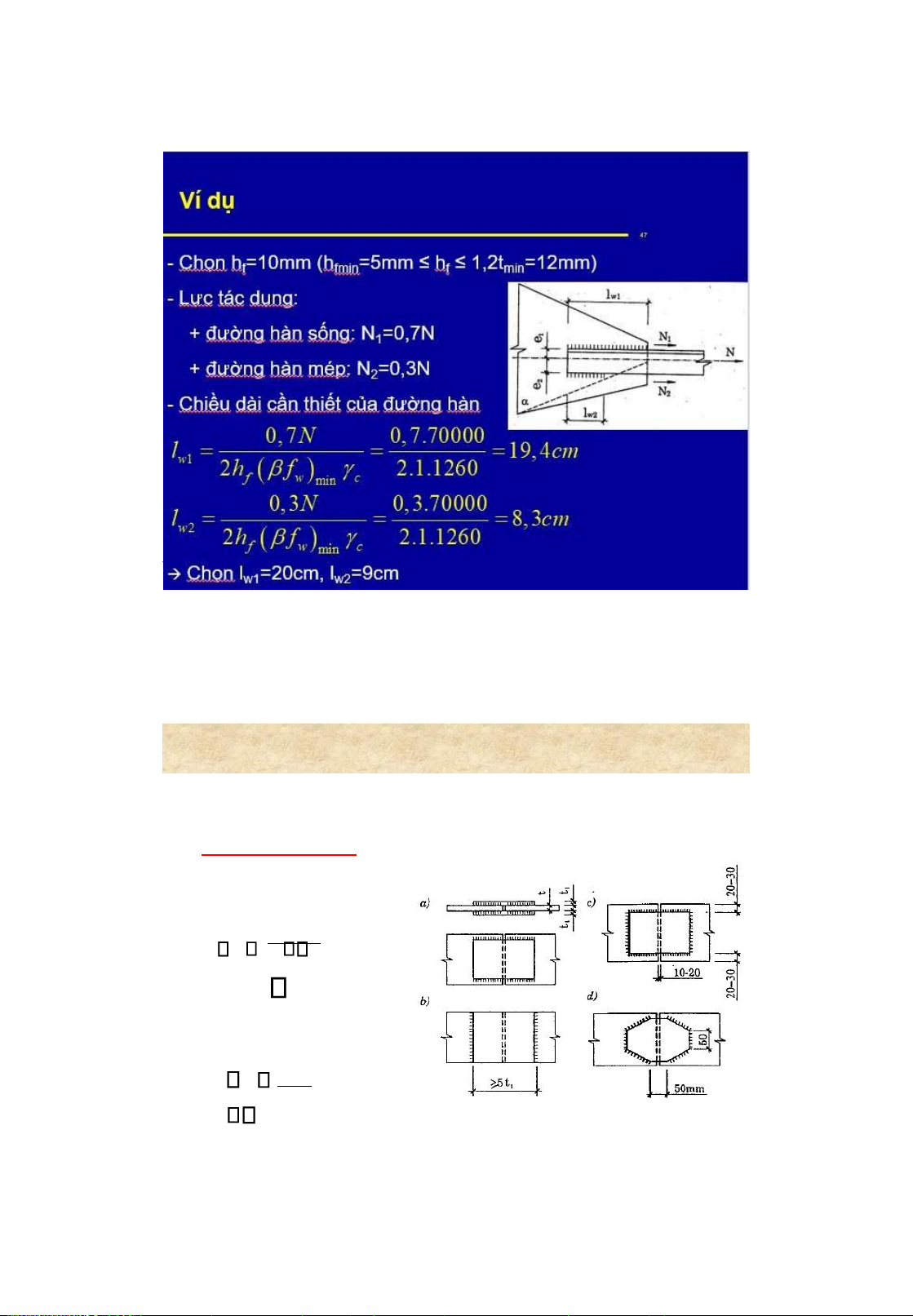

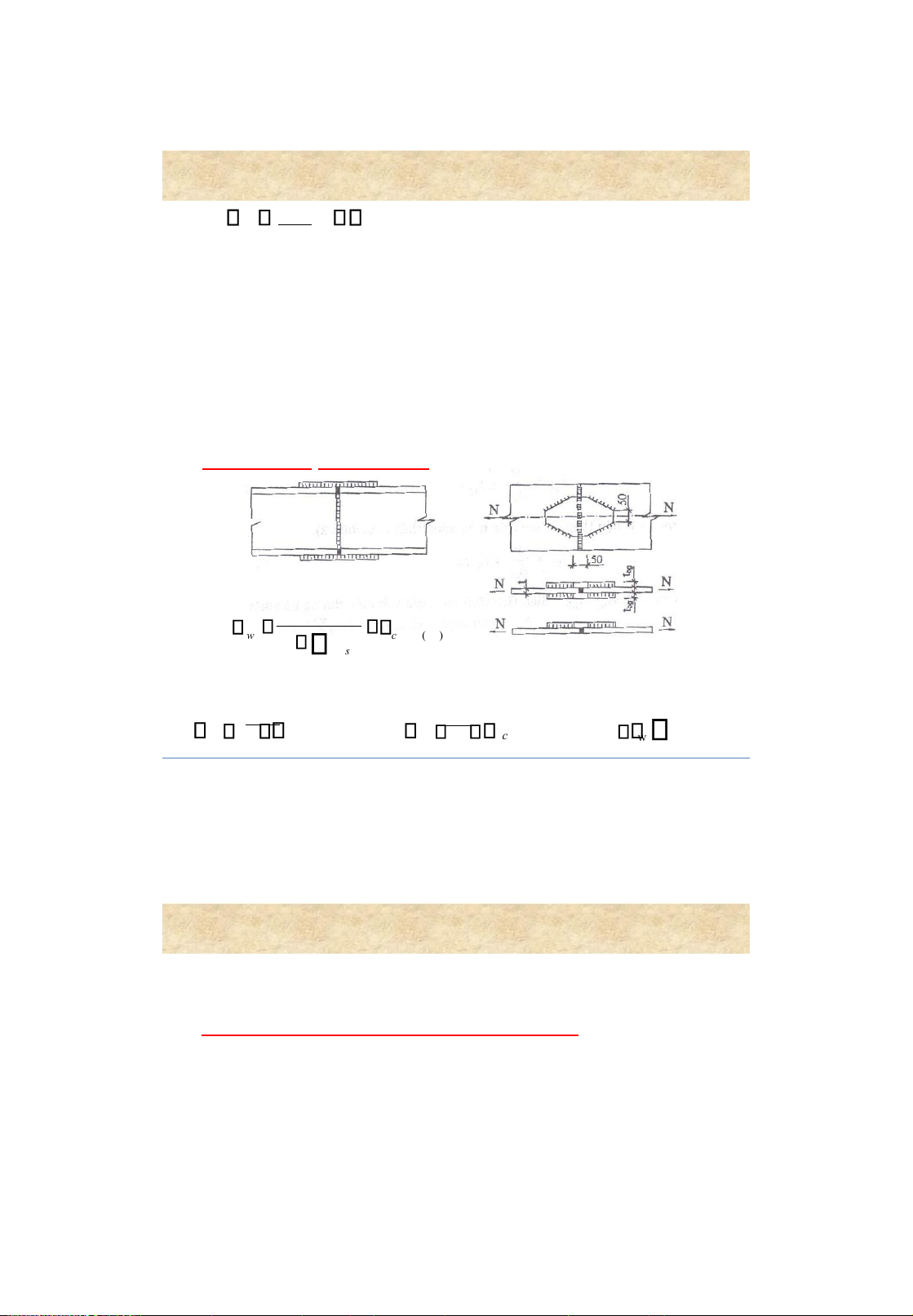

10 mm - effective length of the weld 19 Welded connections lOMoAR cPSD| 58759230 Welded connections 7. Design of fillet welds 20 7 . Design of fillet welds h h h f min f f max 1 ,2 tmi n 21 lOMoAR cPSD| 58759230 Welded connections Welded connections 7. Design of fillet welds • lw 4hf and lw 40mm • lw 85 fhf : for side fil et welds • a 5 tmin 22 8. Worked examples Butt welds 23 lOMoAR cPSD| 58759230 Welded connections Welded connections 8. Worked examples Butt welds 24 lOMoAR cPSD| 58759230 25 Ch.3 Steel Connections LTK 26 lOMoAR cPSD| 58759230 Welded connections 8. Worked examples

Lap connection with side welds 1 N . ; kNN 2 (1 ). kN 27 Ch.3 Steel Connections LTK 28 lOMoAR cPSD| 58759230 Ch.3 Steel Connections LTK 29 Welded connections 8. Worked examples Lap connection For straps str N c fstr Astr For welds wf N c.fwf Awf lOMoAR cPSD| 58759230 Welded connections ws N c.fws Aws 30 8 . Worked examples Composite connection For butt welds N w c f ( wcwt ) A s A tr

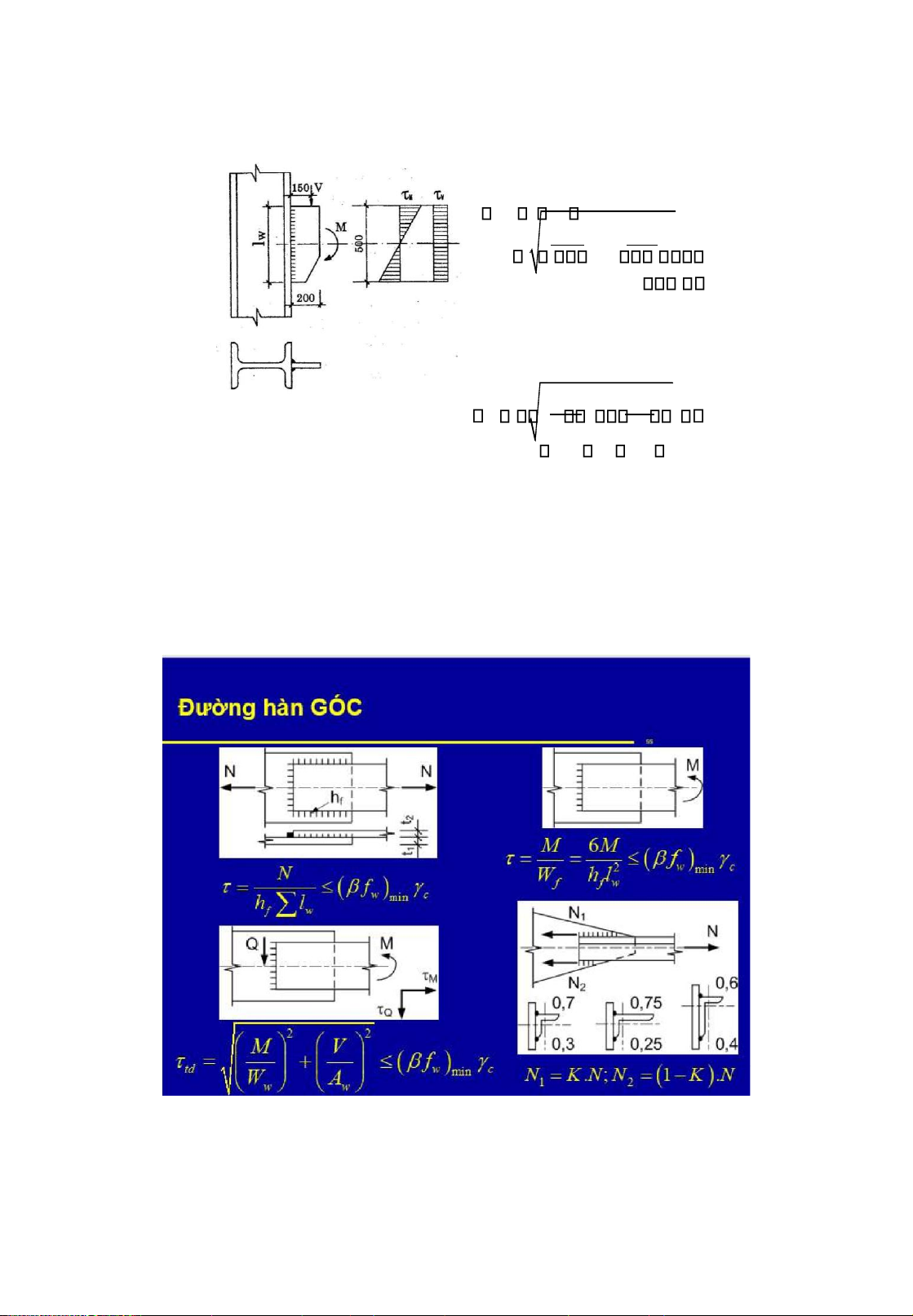

For fillet welds connecting the straps and the steel plates N N wf str .f c wf ws str .cf ws str N w A str wf A ws A 31 Welded connections 8. Worked examples

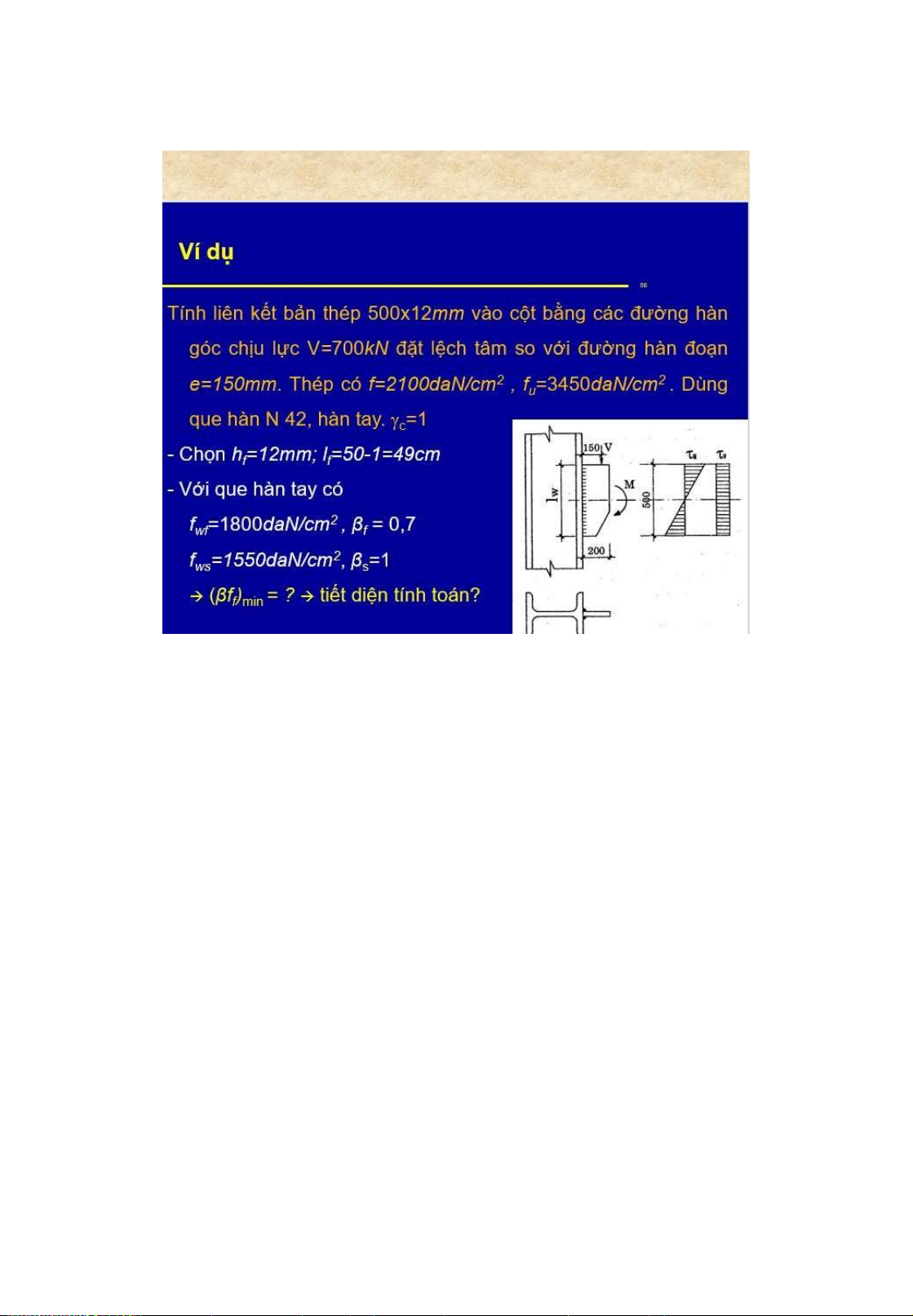

Connection under shear and moment lOMoAR cPSD| 58759230 For section 1 M 2 V 2 wf Wwf Awf c fwf For section 2 ws M 2 V 2 c wsf Wws Aws 32 Ch.3 Steel Connections LTK 33 lOMoAR cPSD| 58759230 Welded connections Ch.3 Steel Connections LTK 34