Preview text:

IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

HOCHIMINH CITY INTERNATIONAL UNIVERSITY

SCHOOL OF INDUSTRIAL ENGINEERING & MANAGEMENT REPORT INTERNSHIP 2

Name: Phạm Minh Thắng ID: IELSIU20413

Advisor: Mr. Dương Võ Nhị Anh Ho Chi Minh city, Vietnam October/2023 ACKNOWLEDGEMENT

For completing this report, I would like to first thank the Director of Saigon Co.op has given an opportunity for me to study and work at the

company, allowing me to gain more knowledge and valuable practical experiences about the logistics industry.

I would like to honourably appreciate the Board of Directors and staffs in Saigon Co.op Logistics Co., Ltd. - Binh Duong Satellite Warehouse

for helping, supporting, and imparting practical knowledge and experience, creating favorable conditions for me during more than two months of internship at the enterprise.

The past time has allowed me to learn about the operating procedures at Saigon Co.op's Satellite Warehouse, as well as combining theoretical knowledge

and practical experience. With the knowledge and experience accumulated during the internship, although not much, it has made me more confident about

my career direction in the future. I am grateful to have had the opportunity to work with highly experienced staffs in the company.

Finally, I would like to thank Mr. Duong Vo Nhi Anh for supporting and answering my questions during the internship. Due to my limitation

of practical knowledge during the internship, the completion of this report cannot avoid errors. I am looking forward to receiving comments from you and

the workers in the company to complete the report, and help me to accumulate and improve my knowledge to develop myself more and more. Sincerely thank you! 1 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management CONTENTS 1. Introduction

1.1 General information about Saigon Co.op a. Mission b. History c. Workforce

1.2 General informationa about Saigon Co.op Logistics Company Limited a. Primary function b. Mission 2. Purpose 2.1 Purpose 2.2 Target

3. Business Description 3.1 Operation a. Order receiving b. Order delivery 3.2 Function and role 4. Tasks 4.1 Task assignment 4.2 Job description

a. Receiving orders from stores and supermarkets

b. Carpentry stamp for delivery time, orders that require to be shrink wrapped

c. Handle the order to the warehouse staff for order picking d. Cross validation

5. Analysis and Improvement Suggestion 5.1 Analysis 5.2 Suggestion 2 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management 6. Conclusions 7. References

CHAPTER 1: INTRODUCTION

1.1 General information about Saigon Co.op

Saigon Co.op is one of the leading retailers in Vietnam, committed to the goal of maintaining a prominent position in the market. Saigon Co.op

focuses on the fast and sustainable development of Co.opmart supermarket chain on the basis of meeting the diverse needs and preferences of

customers. The key point of Saigon Co.op's strategy is to constantly strive to diversify retail models, creating a modern and civilized shopping

experience for today's consumers. Saigon Co.op's goal is to bring a convenient and efficient shopping environment by investing in modern facilities,

displaying attractive products and decorating booths in a reasonable way.

In addition to its efforts in the retail sector, Saigon Co.op also focuses on building and strengthening relationships with consumers and large

communities. Enterprises actively participate in activities that bring social benefits, demonstrating their commitment to social responsibility. By

supporting various programs and campaigns related to poverty alleviation, education, health care, and environmental protection, Saigon Co.op aims

to make a positive impact and contribute to the betterment of the communities it serves. This approach not only builds up Saigon Co.op's image into

a responsible business but also fosters trusting relationships and strong loyalty with customers and partners.

Saigon Co.op's ambition is not only to become a leading retailer. Saigon Co.op strives to become a typical organization for the cooperative

business model. Building on a nationwide scale and scale, Saigon Co.op aims to gradually expand its market to new regions, both in terms of scope

and influence. Adhering to the principles of collective ownership, production autonomy and self-responsibility, Saigon Co.op embodies its nature as

a typical cooperative, with democratic decision-making processes and actively engages members in the strategic direction of the company. Through

this method, Saigon Co.op has gained the trust and love of both customers and partners. a. Mission

Saigon Co.op's mission involves increasing its national awareness and reaching new areas, demonstrating their determination to reach and

serve a larger customer base. This approach stems from the company's unwavering belief in the value of understanding and meeting the diverse needs

and preferences of different regions, ensuring that every Co.opmart store meets the specific needs of the local population. By tailoring its services to

specific regions, Saigon Co.op has succeeded in linking up with local communities, establishing trusting relationships and solid loyalty with customers.

Saigon Co.op's striving to achieve the highest standards is reflected in all aspects of the business. A notable point in the commitment of the

business is the relentless pursuit of a modern and civilized shopping experience for customers. Co.opmart stores are thoughtfully designed and

equipped with modern facilities, ensuring convenience, comfort and efficiency. The focus on the modern shopping environment is evident through

spacious aisles, attractive product displays, and well-organized areas, all of which contribute to an enjoyable, entertaining shopping experience for customers. 3 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management b. History

Since the VI Party Congress in 1989, Vietnam's economy has undergone a significant shift from a subsidy mechanism to a socialist-oriented

market economy. As a result, outdated cooperative economic models face enormous challenges and fall into crisis, forcing mass dissolution. In this

context, on 12/5/1989, the People's Committee of Ho Chi Minh City had a policy to restructure the Management Board of the City Commercial

Cooperative into the Ho Chi Minh City Union of Commercial Cooperatives.

Saigon Co.op was established with two main functions: directly managing business activities and coordinating and mobilizing the cooperative

movement. Saigon Co.op operates under a cooperative economic model based on the principles of collective ownership, autonomy in production and

business activities, self-responsibility.

From 1992 to 1997, when the country's economy experienced significant growth, foreign investment capital poured into Vietnam, forcing

businesses to actively and creatively seize business opportunities and learn management methods from foreign partners. Realizing the need to increase

development resources, Saigon Co.op has conducted joint ventures and associations with foreign companies. As one of the few enterprises in the city

licensed for direct import and export, Saigon Co.op has made great progress in import and export activities. These efforts have brought significant

results, enhancing Saigon Co.op's reputation and position in the domestic and international markets. 4 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

An important milestone in this period was the opening of the first supermarket in Co.opmart supermarket chain, Co.opmart Cong Quynh, on

09/02/1996. This achievement has been achieved through cooperation with international cooperation movements from Japan, Singapore, and Sweden.

Accordingly, a new era of modern retail business, in line with the development trend of Ho Chi Minh City, has opened, marking an important stage in Saigon Co.op's journey. Year Event

Co.opmart Can Tho, the first supermarket in the province, was established. 2002 5 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management 2007

The establishment of Saigon Co.op Joint Stock Companies (SCID and SC IMEX). Also, Saigon Co.op have taken a part in

the foundation of Vietnam Development Association (VDA).

The launch of safe and convenience food stores, Co.opFood. 2008

Develop a television market called HTV Co.op. 2010

Co.opmart changes its brand, and applies a new brand regconition. 2012

Opened Co.opXtraplus at Thu Đuc, TP.HCM 2013 2014

Established SenseCity operated SCID. This mall showcases a modern shopping space that integrates a variety of products and services. 2016

Launched the modern department store chain Co.op Smile. Co.op Smile aims to modernize the traditional department store

model in Vietnam, providing customers with quality products at competitive prices. 6 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

Officially launched Sense Market, a combination of traditional market elements and modern facilities. Sense Market meets the

shopping and entertainment needs of domestic and international customers. 2017

Launched the 24h convenience store model Cheers as the result of many years of cooperation between Saigon Co.op

(Vietnam) and NTUC FairPrice (Singapore). 2018 2019

Saigon Co.op has made great strides in the retail industry, pioneering the introduction of the first high-end supermarket

chain model in Vietnam called Finelife, celebrating 30 years of establishment and successfully acquiring Auchan Vietnam.

Saigon Co.op continues to promote retail models with the goal to become the most reliable supplier and retailer of Vietnam. 2020- 2023 c. Workforce

The success and growth of Saigon Co.op is achieved thanks to the deep awareness and consistency in promoting the collective strength of its

staff. With more than 80% of employees being young people, the company has shown its commitment to exploiting and innovating with fresh 7 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

perspectives that the younger generation brings. Currently, Saigon Co.op boasts an immense workforce consisting of more than 10,000 individuals,

demonstrating its ability to create significant employment opportunities and contribute to Vietnam's overall economic development.

In recent years, Saigon Co.op has continuously introduced positive changes in human resources and policies for employees, demonstrating its

enthusiasm to build a dynamic and progressive working environment. The company places special emphasis on quality in all aspects of talent

management, from recruitment to training and placement. By applying rigorous selection processes and targeted training programs, Saigon Co.op

ensures that its workforce has the skills and knowledge it needs to thrive in the retail industry.

A notable aspect of Saigon Co.op's workforce structure is the localization of employees at Co.opMart supermarkets across provinces. While

the company initially increased the number of employees, most of the workforce is now employed locally. This strategy not only creates employment

opportunities for individuals in the community but also fosters a deeper understanding of the needs and preferences of local clients. In addition, the

recruitment of seasonal workers, mainly students, at Co.opMart supermarket gives students valuable practical experience and the opportunity to

acquire practical knowledge in the retail environment.

Recognizing the important role of attracting and retaining highly qualified employees, Saigon Co.op attaches great importance to its

remuneration policy. By offering competitive salaries, benefits, and career development opportunities, the union strives to attract top talent and

nurture loyalty and commitment in its workforce. Saigon Co.op's remuneration policy is an important motivating factor, ensuring the union has a

highly skilled and dedicated team to promote success.

1.2 General information about Saigon Co.op Logistics Company Limited

Date of foundation: 11/10/2016

Address: Street 10, Di An, Binh Duong, Vietnam

Phone number: 028 38 360 – 21230 Work hour: 24/7 Main areas of activity: •

Saigon Co-op Logistics Co., Ltd. is in charge of logistics transfer, warehouse, supply goods to retail chains: Co-op Xtra, Co-op Mart,

Co-op Foood, Co-op Smile, Cheers. •

In addition, SC Logistics also handles logistics for the sale retail for joint venture stores, grocery FMCG products such as: 8 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

confectionery, chemicals, daily utensils. a. Primary function

Strive to maintain its position as the leading retailer in Vietnam on the basis of sustainable development and supermarket chains

Co.op Mart, Co.opFood, Co.opSmile, Cheer,... efforts to diversify civilized and modern retail models. At the same time, they constantly

strengthens the close relationship with consumers and the community. The main function of Saigon Co.op Logistics Co., Ltd. is in charge

of logistics, warehousing, and transportation of goods for business stores.

In addition to the supermarket chain that is meeting consumer demand, in order to develop a system of small stores to serve

consumers, the company was formed to supply goods according to the needs of display and sale, limiting inventory. b. Mission

Rationally utilize labor, assets and capital, ensure economic efficiency, comply with the provisions of the Law on Accounting and

the Law on Statistics and fulfill obligations to the state budget. To fulfill obligations towards employees, ensure that employees participate

in the management of the Company in accordance with the provisions of the Labor Code. Perform other obligations as prescribed and the Company's Charter.

Vision of Saigon Co.op: Striving to maintain as the leading retailer in Vietnam on the basis of fast and sustainable development

of Co.op supermarket chain, striving to diversify civilized and modern retail models. At the same time, they constantly strengthens the

close relationship with consumers and the community. Building Saigon Co.op to become a typical cooperative organization of stature and

scale operating nationwide and gradually reaching out to the region, always trusted and trusted by customers and partners.

Core values: Always satisfy customers and aim for perfection. Saigon Co.op is the beloved home of its employees.

Mission: Meet the daily consumption needs of customers. Always bring convenience to customers, safety and added value.

Contribute to improving people's lives and developing Vietnam's retail industry. 9 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management CHAPTER 2: PURPOSE 2.1 Purpose

The internship at Saigon Co.op serves many goals with different purposes. The internship mainly aims to provide students with a

deeper understanding of logistics and its practical application in the current work context. By participating in the day-to-day operations at

Saigon Co.op, I have the opportunity to gain first-hand experience and gain valuable insights into logistics modeling, supply chain management,

and its impact on the economy as a whole.

The main purpose of the internship is to learn how Saigon Co.op Logistics Company operates and operates its warehousing

system. This includes managing products stored in warehouses such as receiving goods, sorting goods, continuously checking the expiry date

of products, processing orders of chain stores and supermarkets. In addition, ensuring smooth delivery to chain stores is also an important part,

from picking, checking to shipping needs to be done accurately and quickly. Through the above activities, I have understood the role and

importance of operating the warehouse system in logistics activities.

Finally, the internship aims to promote the development of social skills. I have had the opportunity to enhance my ability to

communicate, teamwork and solve problems by working in a dynamic and fast-paced environment. Interacting with the experienced staff at

Saigon Co.op helps me to build valuable relationships and establish networks that will benefit them later in life. 2.2 Target

During the internship, there are several important goals, providing a holistic learning experience and growth for students. Firstly,

the internship aims to bridge the gap between the theoretical knowledge gained in the classroom and its application in a practical work

environment. Provide opportunities for students to gain hands-on experience and witness firsthand how concepts and theories are applied in a professional setting.

Second, internships serve as a foundation for students to develop and perfect essential professional skills. These skills include

communication, teamwork, problem-solving, adaptability, and time management. By actively participating in the internship process, students

can hone these skills through real-life situations, working alongside experienced professionals, and handling challenges in daily work. This

process enhances students' competence and confidence, preparing them for later careers.

Furthermore, the internship process allows students to explore their strengths, interests, and career aspirations. Through exposure

to different departments, students gain a better understanding of the roles and responsibilities of each department, allowing students to make

informed decisions for their career path.

In addition, internships aim to promote interns' sense of professionalism and workplace behavior. By participating in a

professional working environment, I have learned the importance of punctuality, respect, responsibility and work ethic. These qualities are

essential for success in any professional environment and are highly valued by employers. Internships provide opportunities for students to

demonstrate and hone these qualities, thereby enhancing their employability and future prospects.

Finally, an internship is an opportunity that connects students with employers. Allowing students to establish connections and 10 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

develop relationships with professionals in the field of logistics. These relationships can provide mentorship, guidance, and potential future

employment opportunities. Communicating during an internship can expand a student's network, open up new opportunities, and give students

a competitive edge in the job market. 11 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

CHAPTER 3: BUSINESS DESCRIPTION 3.1 Operation a. Order receiving

The order schedules of stores in Co.op's chain are broken down into days of the week, and stores in the same district will have

the same order schedule together on the same day. In addition, different stores will have different pickup schedules, mostly in the morning,

noon, and evening; However, stores must make orders and close orders to be sent to the warehouse before 10 am every day so that the

warehouse can quickly process and prepare the goods for delivery.

On the part of the Order processing Department, they will receive and close orders through the order management system. From

there, create an order picking file containing the necessary information such as SKUs, the number of rows to be composed, specifications and

the number of bales to prepare. Each order will also specify the date and time of closing the order, ensuring accuracy and standards in the order picking process.

An important part of this process is the role of the Executive Board. After the order bill is generated, the Management Board will

proceed to record the time of issuance of order, the ID of the staff who composes the goods and the number of order issued. This not only helps

to keep track of employee productivity and performance, but also ensures that there is no loss of goods during transportation and picking. b. Order delivery

The first step starts from receiving orders from supermarkets through the order management system. The order information will

be updated into an Excel file, including the ID and name of the supermarket, the date and time of the order. In particular, the Excel file also

contains important informations such as the number of tons and the number of blocks of cargo, which is the foundation for creating a booking plan.

After receiving Excel file with the order plan, the manager will use this information to plan the booking for each day and night.

These plans will be sent to the Logistics Department, where specifications and quantification of the number of vehicles needed to transport the

goods will be carried out. Information about vehicle type, number of vehicles and vehicle departure time will be notified to the garage via

email or direct call, especially in case of urgent booking.

When the transport vehicles (such as large trucks) arrive at the warehouse, the receiving and control process will be carefully

carried out. The security guard will record the license plate number and information about the supermarket based on the schedule from the

dispatch room. If the truck arrives one hour earlier than scheduled, it will be asked to park outside to wait until the time of loading. However,

for small vehicles, vehicles will be allowed to directly enter the dispatch area and notify their readiness to load goods to the dispatch room.

After the goods have been inspected and exported to the vehicle, the storekeeper will forward the relevant invoice to the dispatch

office. This invoice will clearly state information about freight forwarding and be attached to the cargo truck when leaving the warehouse and

moving to different supermarkets. All of these steps together make up a coherent and organised process to ensure that goods are transported

and distributed efficiently, while meeting the requirements and timing of supermarkets. 12 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management 3.2 Function and role

Transportation Management: Saigon Co.op's Logistics Department is responsible for coordinating and managing the process

of transporting goods from suppliers to warehouses and distribution centers of the company. Shipping involves tasks such as designing efficient

shipping routes, selecting the right mode of transportation, and ensuring timely delivery of products to meet customer needs, working closely

with suppliers, transporters, and internal stakeholders to optimize delivery schedules, minimize delivery time and reduce shipping costs.

Saigon Co.op is able to maintain its agile and reliable supply chain through efficient management of these transportation processes.

Last-mile delivery management: Last-mile delivery is an important aspect of Saigon Co.op's logistics activities, focusing on

the last part of the process of transporting products to the end customer. Last mile delivery is responsible for ensuring that products are delivered

accurately and in a timely manner to designated delivery locations, which may include homes, businesses, or retail stores. This process involves

managing delivery staff, coordinating delivery schedules, and using appropriate vehicles. In addition, there is monitoring delivery performance,

resolving customer queries and providing exceptional service. Saigon Co.op enhances customer satisfaction and strengthens its competitive

position by streamlining last-mile delivery.

Warehouse management: Warehouse management includes efficient handling, storage and arrangement of goods at Saigon

Co.op's warehouses and distribution centers. Warehouse managers monitor inventory levels, implement appropriate storage systems, and

optimize warehouse layouts to facilitate efficient movement and retrieval of products. By using inventory management techniques, such as

Just-in-Time (JIT) and First-In-First-Out (FIFO), Saigon Co.op ensures accurate inventory turnover and minimizes inventory retention costs.

The warehouse management department also collaborates with other departments, such as purchasing and sales, to forecast demand, plan for

peak periods, and optimize warehouse space utilization. Through efficient warehouse management, Saigon Co.op can optimize warehouse

operations, reduce costs and maintain inventory accuracy. CHAPTER 4: TASK 4.1 Task Assignment

During the time at Saigon Co.op, I was assigned to participate in the Order Processing Department, which is responsible for

managing the receipt of orders from the stores, updating orders into the system, printing orders and assigning them to warehouse staff to

prepare goods for shipping, checking the prepared package and enter information into the system.

During my internship in the Order Processing department, I was able to perform the following jobs: •

Receiving orders from stores and supermarkets •

Carpentry stamp for the delivery time, and orders that require to be shrink wrapped •

Handling picking orders to pickers 13 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management •

Enter package information after cross-checking into the system 4.2 Job description

a. Receiving orders from stores and supermarkets

Every day, the warehouse will receive orders from stores in a district, in which: Co.op Food will send orders through Excel files

containing order codes, Co.op Smile will place orders on their system and synchronized through the warehouse's system. What needed to do

is to enter each of the above order codes into the warehouse's order management system and allocate each order on the system. After

completing the above work, the staff will send an email back to the stores to notify that the warehouse has successfully received the order.

b. Carpentry stamp for delivery time, orders that require to be shrink wrapped

Each different store and supermarket has its own delivery time, mainly at 3 periods: morning, noon, and evening. Therefore, Order

Processing Department also takes care of stamping the delivery time on top of the order. The work is done by stamping the carpentry "Morning

trip", "Noon trip", "Evening trip" corresponding to each time of morning, noon, and evening.

In addition to stamping the time of delivery, the order that needs to be wrapped in shrink film will also be stamped with the

carpentry stamp "CH shrink wrap" on the order bill so that the warehouse staff can conduct shrink wrapping when preparing the goods for

transportation to the store. The shrink wrap helps to fix the goods on the pallet, avoiding the case of falling goods leading to loss, or spilling

when moving to ensure the safety of the goods.

c. Handle the order to the warehouse staff for order picking

After creating the application and printing out the picking orders, those picking orders will be brought to the warehouse and

handled to the picking staff to prepare the goods. Picking work will usually begin at 11 p.m. until 4 p.m.

When distributing a ticket to the picker, the composing staffs will state the employee ID, and the order issuer will write that employee ID in

the corresponding order item on the order compose tracking Excel file containing the information of the order and the productivity of the

compiler. Normally, the ticket delivery staff will only distribute orders from 1 single store to the picker in one picking to avoid the case of

confusing orders of one store to another. In addition, when distributing tickets, it is also necessary to prioritize the heavy weighted orders

such as spring water barrels, soft drinks, milk, beer, etc. to male picking staff so that the operation goes smoothly.

After the picker completes a picking batch and takes the goods to the cross-checking area, they will return to the ticket

distribution site to receive the picking slip for the next batch. Each time such a compose order is received, the productivity of the staff 14 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

composing on the Excel file will increase based on the number of order picked. The picker will continue to repeat the picking process until

the productivity reaches 100% or more and has completed his work. d.Cross validation

After the Cross-checking Department has completed checking the packages prepared by the staff compared to the order, the

order processor will go to the cross-checking area and pick up those cross-checked orders and enter the information into the system. In

addition to entering cross-checked order information into the warehouse management system, it is also necessary to enter information into an

Excel file named "Order cross-validation sheet” . The information entered will include: picking date, code of the picked order, picking staff

ID, numbers of cross-checked order, cross-checking staff ID, cross-checking agent, and total SKU line.

CHAPTER 5: ANALYSIS AND IMPROVEMENT SUGGESTION 5.1 Analysis

Saigon Co.op's Satellite Warehouse supplies retail stores including Cheers, Co.op Food and Fineline. The noteworthy point of

the warehouse involves a single order picking system in which the goods are not taken in pallets or bales, but are taken individually, usually

one or several items. This level of detail during order fulfillment provides a high level of flexibility in picking, allows precise customization

of customer orders, and enables efficient inventory management. While this approach allows for more flexible order fulfillment, it carries the

risk of human error during manual picking. Relying on staff to select items can lead to inaccuracies in the execution of customer orders and

can affect overall operational efficiency.

The order processing department also encountered a number of problems that caused work progress to be delayed, among which

can be mentioned when taking cross-checked order bills from the warehouse to the office to enter the data. Normally, the staff of the Order

Processing Department have to go directly to the warehouse to collect the bills and have to time the when to collect themselves; Therefore,

when the cross-checked orders are too many but still no one comes out to pick them up, the warehouse staff has to bring those bills into the

office themselves. As a result, the work of warehouse staff is stagnant, the same happens with Order Processing staff when there is no one to pick up the ticket. 5.2 Suggestion

Although satellite warehouses have demonstrated the ability to manage goods efficiently, however, there is still a reliance on

manual processes. To further improve, satellite warehouses can use manual warehouse management practices combined with advanced

technological advances such as the use of robots in picking goods that can speed up workflows and reduce the possibility of human error,

thereby improving the productivity of the warehouse. Possible measures include:

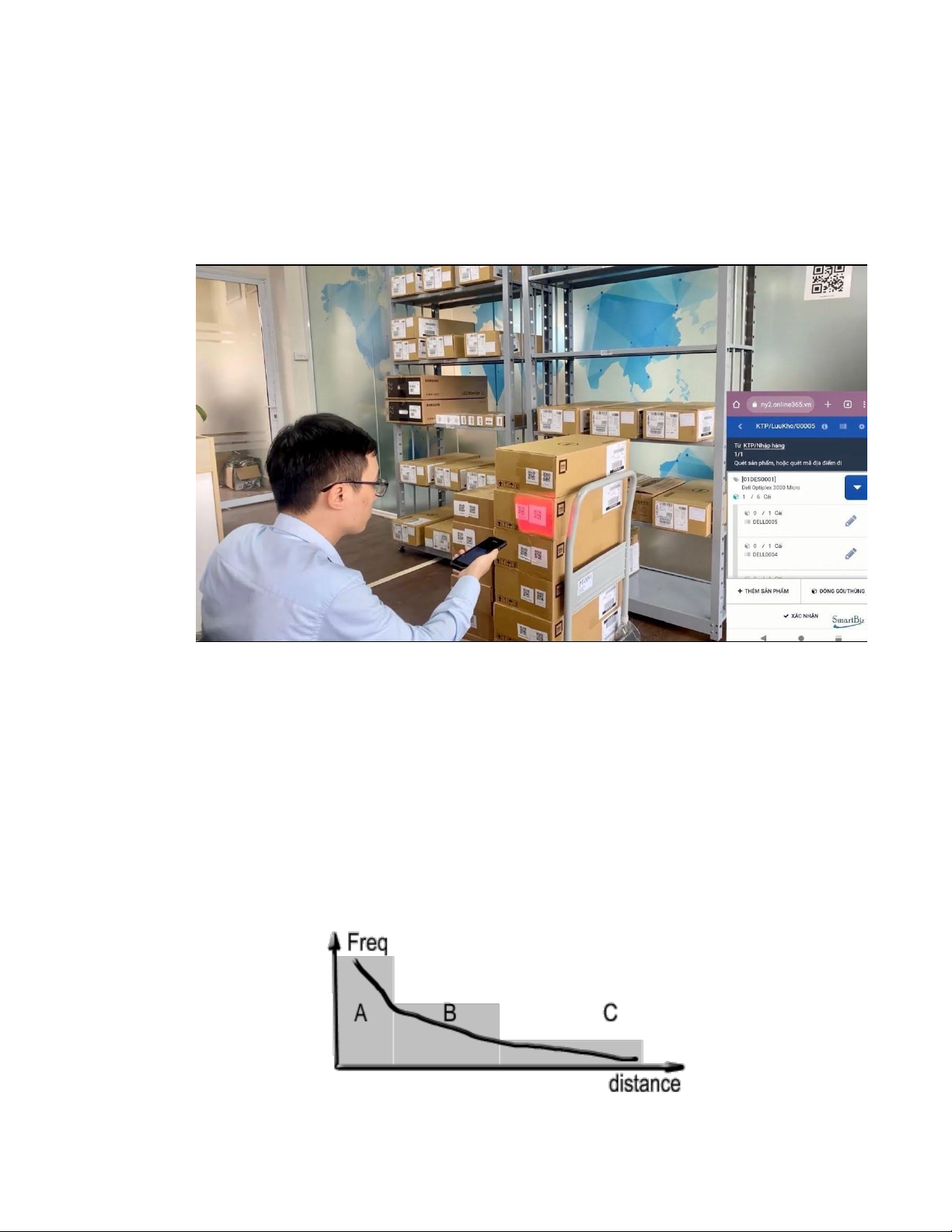

Application of QR technology in picking: The application of QR code technology to compose orders needs to be planned and

executed thoroughly. Training programs should be provided to warehouse staff to ensure seamless and efficient integration when using QR

codes. The adoption of QR codes will not only improve the speed and accuracy of picking, but also reduce paper usage, contributing to 15 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

warehouse environmental sustainability efforts. When the staff need to import/export warehouses, employees just need to select the

import/export order on the machine and scan the QR code on the product. The software will record the quantity and automatically create

import/export orders on the software without employees having to use import/export orders as before. The warehouse inventory only needs 1

scan of the QR code, the system will automatically record the quantity and create a warehouse inventory sheet, allowing reference with the

inventory on the software to compare between inventory and reality.

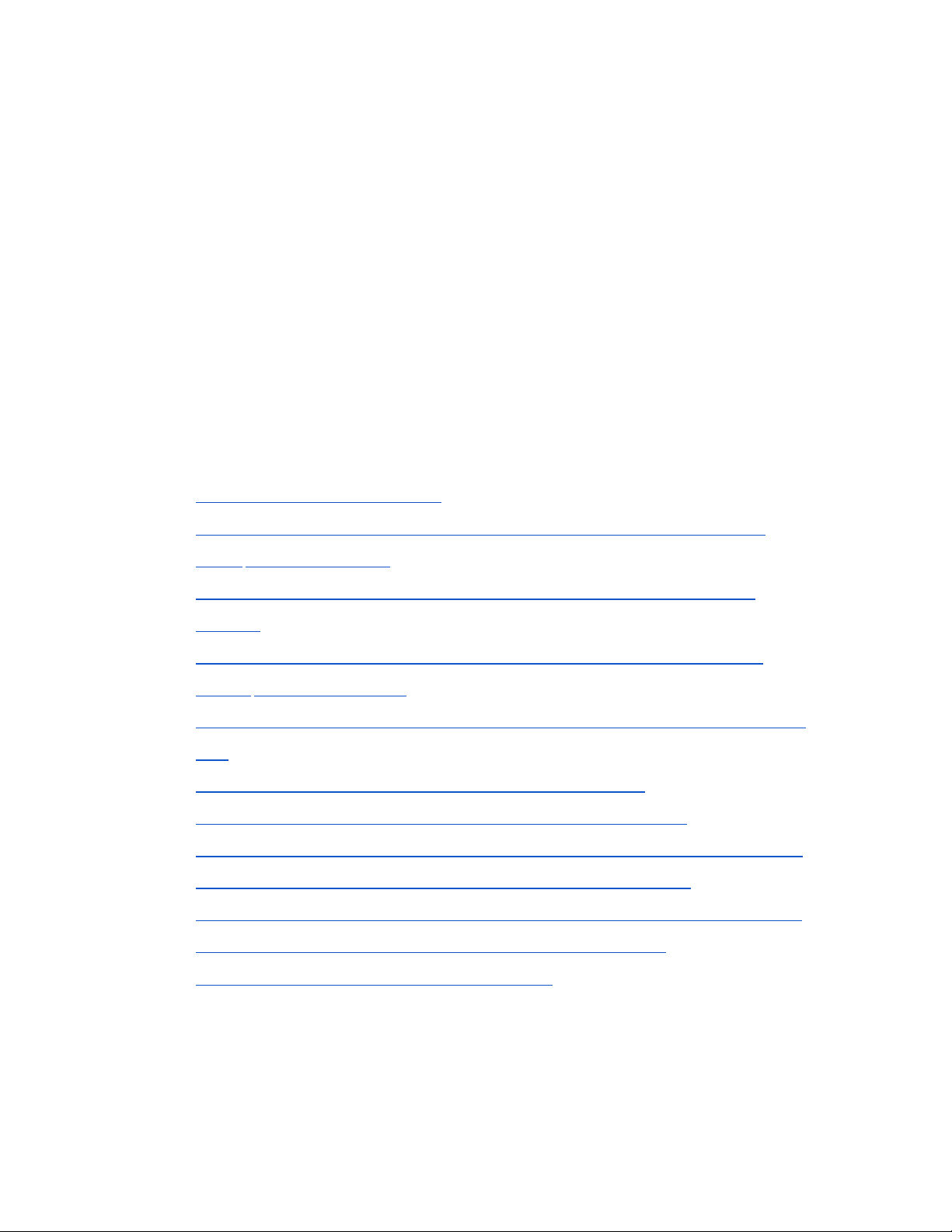

ABC sorting strategy: During peak picking hours of warehouses, implementing an ABC sorting strategy can be a highly

effective solution to manage the flow of goods and ensure smooth operations. This method involves sorting products based on importance

and demand, which in turn allows the warehouse to prioritize and allocate resources more efficiently. Category "A" will include items that

are in high demand, need immediate attention, and should be easily accessible near the front of the warehouse. Category "B" includes items

in medium demand, while category "C" includes items with low demand. By strategically placing "A" items near the loading and unloading

area, pickers can speed up the picking process during peak hours. In addition, implementing real-time tracking systems can support optimal

level control. This solution not only helps reduce congestion and disruption during peak periods, but also simplifies the entire workflow,

ensuring essential items are always ready to respond to customer needs in a timely manner. 16 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

Incorporating robots into picking processes: By incorporating robots into picking processes, satellite warehouses can

significantly reduce human-caused errors, improve order accuracy, and speed up the entire picking and packaging process. These robots can

be programmed to navigate the warehouse seamlessly, determining the optimal route to pick up items. This technology not only speeds up the

order fulfillment process but also ensures consistent and accurate order retrieval. Moreover, deploying robots to pick goods can also reduce

pressure on employees during peak periods, allowing employees to focus on more complex tasks that require human judgment and

decisionmaking, reducing the accident rate compared to using conventional manual picking methods.

About the problem of the Order Processing Department: The above problem can be solved simply by installing in the cross-

checking area a notification system for the Order Processing Department. With the mentioned system, every time the cross-counting slip is

full, the cross-checker just presses the notification button and the Order Processing staff will pick it up by themselves, no need to bring the bill

into the office themselves. The Order Processing Department also does not need to time to collect the bill anymore, so that they can rest assured

and focus on the task at hand. In general, installing a system for the Cross-Checking Department to notify the Order Processing

Department to collect order bills helps the work of both parties to be smooth, smooth, and not stagnant. CHAPTER 6: CONCLUSION

During my internship at Saigon Co.op, I have gained valuable insights and knowledge that contribute to my personal and professional

development. First, I learned about the complex operation of warehousing management and its pivotal role in ensuring the smooth flow of goods and

materials. Through practical experience, I have witnessed various workflows such as transportation, import and export, warehouse management, and

inventory control. This practical exposure has given me a deeper understanding of supply chain operations and the importance of effective supply chain management.

I have also identified areas that need to be improved for my personal development. One of the main weaknesses is my communication and

collaboration skills in a teamwork environment. Since logistics activities involve coordination and interaction between different stakeholders, 17 IS047IU VNU-International University Engineer Internship

School of Industrial Engineering & Management

effective communication is essential to ensure smooth collaboration and the achievement of common goals. This experience highlighted the

importance of engaging in active group discussion, actively seeking feedback, and continually improving students' communication skills to foster

better collaboration in future professional settings.

The internship has provided me a comprehensive understanding of logistics processes in a warehouse system environment in practice, allowing

me to witness the practical application of theoretical concepts learned in my coursework. The experience at Saigon Co.op has given an overview of

logistics and ignited my passion to pursue a career in this field.

In short, the internship at Saigon Co.op is a valuable and enriching experience. Factors that I gained during this trip include a deep

understanding of logistics, witnessing the company's adaptability, and learning about effective warehousing management. In addition, I have

identified areas for improvement, especially in communication and teamwork. Overall, the knowledge and experience gained from this internship

aligns with my goals, reinforces the interest in logistics and prepare me with valuable skills for future logistics endeavors. REFERENCES •

http://www.saigonco-op.com.vn/ •

https://tuoitre.vn/sau-34-nam-doanh-thu-saigon-co-op-tang-hon-30-000-lan- 20230 511223521997.htm •

https://giaiphaperp.vn/quy-trinh-quan-ly-kho-vat-tu-hang-hoa-voi-qr-code- barcode/ •

https://vnexpress.net/hon-ba-thap-ky-dong-hanh-cung-nguoi-tieu-dung-cua- saigon- co-op-4603951.html •

https://omisell.com/vi-vn/blog/huong-dan-xay-dung-quy-trinh-quan-ly-kho-hang- hoa/ •

https://als.com.vn/tim-hieu-ve-he-thong-kho-bai-o-viet-nam •

https://kecongnghiep.vn/thuc-trang-he-thong-kho-bai-o-viet-nam/ •

https://intechvietnam.com/tin-tuc/tin-cong-nghe/cong-nghe-robot-trong-nha-kho-

cho-phep-logistics-thong-minh-hon-va-tiet-kiem-chi-phi-hon-535/ •

https://vuletech.com/8-cong-nghe-ap-dung-trong-tu-dong-hoa-nha-kho-hien-nay/ •

https://www.abivin.com/vi/post/phan-tich-abc-quan-ly-ton-kho •

https://www.sapo.vn/blog/phan-tich-abc-va-xyz 18