Preview text:

Conquering Shelf-life Issues of Chocolate

Ingredients, processes, packaging and ambient conditions all

affect shelf life. Understanding and controlling these factors

will help to ensure product quality and encourage repeat purchases. Marlene Stauffer Blommer Chocolate Co.

All foods are perishable by nature.

minerals and vitamins. It is an intimate mix-

Numerous changes can take place in foods

ture of solid particles suspended in fat.

during processing and storage. Conquer-

Chocolate is very shelf stable due princi-

ing shelf-life issues in confections can be

pally to the unique properties of cocoa.

challenging, to say the least. This paper

Chocolate contains cocoa butter and, some-

will define shelf life and discuss issues

times, milk or milk fat. It has a fast flavor

directly impacting shelf life, such as for-

release and melts at body temperature.

mulation, manufacturing, storage and dis-

Cocoa solids contain a natural antioxidant Marlene Stauffer is

tribution, and then discuss possible reme-

in the form of tocopherols, and cocoa but- the director of quality dies to overcome these issues.

ter breaks down to inoffensive short-chain assurance/research

fatty acids.As a result, most chocolate prod- and development at Blommer Chocolate WHAT IS SHELF LIFE?

ucts can be classified as medium- or long- Company. She has

life products. Compound coatings contain

The shelf life of a food product is the period been with Blommer

vegetable fat, have a slower flavor release since 1982.

of time during which it will retain accept-

and can be heat resistant. When adding

able appearance, aroma, flavor and texture.

inclusions and making candies using choco-

Key elements of shelf life for the confec-

late, shelf-life factors can be altered and

tioner are microbiological safety, eutetics,

categorized into two main classes:

bloom, migration (fat or moisture), loss of

• Those which are inherent in the product texture and rancidity.

itself and cannot be prevented by pack-

Chocolate is a high-energy foodstuff with aging alone.

a complex nutritional profile, containing

• Those which are dependent on the envi-

fat (either cocoa butter or, if it is a confec- ronment and may be controlled.

tionery coating, vegetable fat), carbohy-

In a perfect world, making mouthwatering

drates and protein. It does provide some

confections today and selling them tomor- ➤

The Manufacturing Confectioner • February 2007 47

Conquering Shelf-life Issues of Chocolate The formulation

row is ideal, but many factors influence

syrup solids than sucrose solids in chosen for a

how these candies get to our consumers, caramel. confection can

such as raw material availability, season- Moisture directly impact how

ality, distribution and consumer demand.

• Moisture migration can occur when a

Microbiological safety is critical in con- well the flavor and

drier inclusion comes in contact with a

fectionery products. Raw nuts may con- texture are

higher-moisture piece, causing the tex-

tain pathogens; products must therefore ture to become more hard. maintained.

be processed and stored to prevent this.

• Keeping a meltaway smooth upon stor-

Milk may contain listeria, making it crit-

age may require actual tempering of

ical to avoid moisture and condensation.

the chocolate with the added fat before going further in the process.

A raw-material and finished-product test-

ing program needs to be in place to mon- Fat Migration

itor your environment and products

• Everything likes to come to equilib-

going out the door. A hold/release pro-

rium — a balanced state or unchanging

gram will prevent any products from get- system. ting out of your control.

• Center fats will rise to the surface, soft-

ening chocolate and hardening the cen- FORMULATIONS ter.

• Consult your specialty fat supplier to

The formulation chosen for a confection

formulate the correct fat for your

can directly impact how well the flavor recipe.

and texture are maintained. Let’s look

• Milk fat is often added to dark choco-

at a few examples to see what impacts

late to provide protection against shelf life.

bloom, delaying the transformation

from form V to form VI (the highest

Eutetics/Softening of a Coating melting polymorphic form).

• Eutetics could occur, decreasing shelf

life and causing the product to bloom, Oxidative Rancidity

with the possibility of fat deterioration

• Oxidative rancidity can occur relatively

when incompatible fats are blended

rapidly when high-fat centers or roasted together in a formula.

nuts are used in a formulation.

• Cocoa butter and palm kernel oil are

• Centers may not be completely coated

not compatible and will cause soften-

when using nuts, exposing the choco-

ing and eutetics when mixed together,

late and nuts to the possibility of bloom. even in small quantities.

• Stale or cardboardy flavor can also

• A general rule of thumb is to not mix occur.

more than 4 percent of the fat with

cocoa butter when manufacturing a compound coating. MANUFACTURING

Whether confections are manufactured by Graining

hand or using factory equipment, condi-

• In a caramel, graining can occur if all

tions must be maintained to maximize shelf

the sugars are not dissolved before com-

pletion of the cooking cycle. At least

life. For moulded pieces, one must use prop-

25 percent moisture in the caramel pre-

erly tempered chocolate in room-temper-

mix and heating to 160° to 180°F while

ature moulds that pass through a cooling

agitating can aid in this process.

tunnel to set the product for shrinkage and

• A rule of thumb is to have more corn

easy demoulding. Good mould design and ➤

48 February 2007 • The Manufacturing Confectioner

Conquering Shelf-life Issues of Chocolate

consistent moulding procedures will min-

• If a piece has an uneven surface to coat, Confections do not imize potential problems.

this could cause the center to be like temperature

During enrobing a center is passed

exposed, creating conditions for variation and reduced shelf life.

through a curtain of chocolate or com- prefer constant

pound coating and then over a bottomer

• Incorrect viscosity may also alter cov-

erage rate as well as increase feet temperature and

to coat the bases. Sometimes bases are

formed at the base of each piece. humidity during

coated with a compound coating first to storage.

aid in integrity or to prevent fat migra- Cooling

tion, and then enrobed with chocolate.

• Chocolate and compound require dif-

Pieces can also be double enrobed to

ferent cooling tunnel conditions.

ensure extra coating if the center is vul-

–Chocolate needs to be cooled gently

with moderate air flow (55° to 60°F).

nerable to softening or leakage, or difficult

–Compound coatings are best cooled

to coat. If enrobed centers are cooled too

in colder tunnels (40° to 45°F) because

rapidly, the chocolate could crack; if

they spontaneously solidify in a stable

cooled too slowly, it could end up discol- crystal form.

ored and soft. The big issue is that this

• All tunnels should warm to nearly room

problem may not be apparent right away

temperature at exiting to prevent con-

and could emerge later in the distribution densation.

process or when your customer purchases the product. PACKAGING AND STORAGE ISSUES

Packaging types will have a great influ- Solid Chocolate

ence on the stability of the confectionery Temper

product over time.The goal is to keep fla-

• Improperly tempered chocolate will

vor and texture in and moisture or off-fla-

continue to stabilize after the product is

vors out. Moisture can cause cracking of,

wrapped and has left the factory, which

may lead to soft texture and the appear-

for example, pretzels coated with choco- ance of fat crystals or bloom.

late and could make them soggy. Milk

• Lack of contraction (shrinkage) in a

chocolate is more susceptible to flavor

mould for product releases can be due

degradation if packaging is not controlled. to improper tempering.

There are many types of packaging mate-

• Dull appearances, poor snap and long

rials such as polypropylene, metalized or

set times can be from improper tem-

multilayered films. Packaging suppliers pering.

are excellent resources for the best type of Moulding

packaging for a specific product.

• Improperly designed moulds can lead

Following are some things to take into to poor-quality products. consideration:

• Warm moulds can delay onset of crys-

• Heat sealing — be careful if shrink film- tallization.

ing is used; this could cause bloom due to excessive heat.

• Cold moulds can expose chocolate to

premature cooling, forming incorrect

• High-moisture pieces may lose and trap crystals.

moisture. This could cause molding if

tight packaging is being used. Some- Enrobing

times wax paper is the best option due

• If centers are too warm, they can detem- to its semi-permeability. per the chocolate.

• Packaging material could cause off- ➤

The Manufacturing Confectioner • February 2007 49

Conquering Shelf-life Issues of Chocolate White chocolate is

odors and off-flavors from inks used,

preserve freshness and halt center oil

the type of material in the packaging

migration. Care must be taken with especially

and from where the packaging has been

delicate shells so they do not crack susceptible to light- stored.

during the rewarming process. This induced

• The Robinson test can be used to eval-

must be carefully controlled to pre- degradation of

uate if packaging materials are a source

vent condensation from forming on flavor due to its

of off-flavors. Place a folded piece of the products. lack of natural

the packaging material (20 cm × 22 cm)

• Compound coatings would be more antioxidants.

along with 15 grams of grated choco-

heat resistant than chocolates mainly

late in a sealed jar. Place the jar in the Exposed nut pieces

due to higher melting points with some

dark at room temperature (20°C/68°F) would also be

compound coatings and the fact that

at 75 percent rh (if needed, add satu- susceptible to light- they do not require tempering.

rated salts to create a high humidity) induced rancidity.

for 48 hours. The flavor can then be

evaluated as compared to a standard, DISTRIBUTION

and specific requirements can be devel-

oped as to how much flavor pickup is

All of the hard work of maintaining the

acceptable for the specific product.This

product to this point would be for nothing

would be approximately equivalent to

if the product is not transported and dis- nine months of shelf life.

tributed in conditions similar to how it is

Storage of confections is critical to main-

stored. Refrigerated trucks, controlling

taining the original flavor and texture

the product on docks and storage in the

when the piece is fresh. Confections do

distribution centers will all influence how

not like temperature variation and pre-

well the product will hold up until it

fer constant temperature and humidity reaches consumers.

during storage, distribution and getting

the product to the store shelves. It can be What Needs to Occur?

difficult to control what happens.

• During warm months, refrigerated

Ideal storage conditions would be in a

sealed or locked containers would be

cool, dry environment, away from off- required.

odors, at 55° to 70°F at 60 percent rela-

• Distribution systems must handle con-

tive humidity — some say as high as 70 fectionery products correctly.

percent. Note: relative humidity is the

• Light in display cases can influence the

amount of moisture in the air that could

quality of a confection — white choco-

then be absorbed by the product.

late is especially susceptible to light-

induced degradation of flavor due to its Points to Consider:

lack of natural antioxidants. Exposed

• During the fat phase of a confection, it

nut pieces would also be susceptible to

is partially solidified.At this point it will light-induced rancidity.

either continue to solidify or remain

• Infestation can also occur during trans-

liquid depending on how the product

porting and distribution. Examining is stored.

transporting vehicles and keeping the

• If products are stored at too low of a

temperature controlled greatly helps

temperature, condensation can form

eliminate this concern. Sealed packages

and create sugar bloom when coming

can deter insects from trying to pene- back to room temperature.

trate through folds or bore through

• Be careful when freezing candies to packaging. ➤

50 February 2007 • The Manufacturing Confectioner

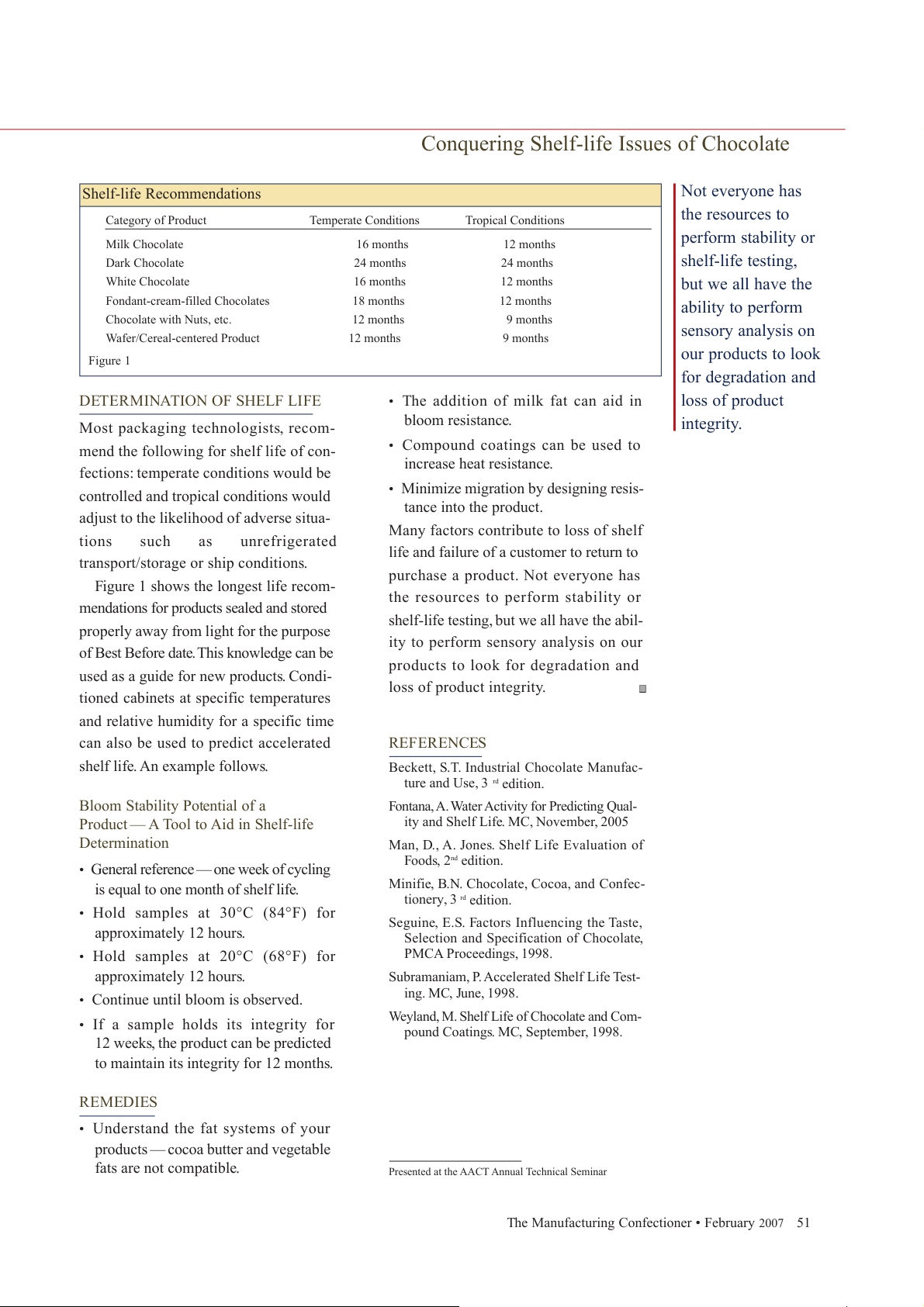

Conquering Shelf-life Issues of Chocolate Shelf-life Recommendations Not everyone has the resources to Category of Product Temperate Conditions Tropical Conditions perform stability or Milk Chocolate 16 months 12 months Dark Chocolate 24 months 24 months shelf-life testing, White Chocolate 16 months 12 months but we all have the

Fondant-cream-filled Chocolates 18 months 12 months ability to perform Chocolate with Nuts, etc. 12 months 9 months sensory analysis on Wafer/Cereal-centered Product 12 months 9 months our products to look Figure 1 for degradation and DETERMINATION OF SHELF LIFE

• The addition of milk fat can aid in loss of product

Most packaging technologists, recom- bloom resistance. integrity.

mend the following for shelf life of con-

• Compound coatings can be used to increase heat resistance.

fections: temperate conditions would be

controlled and tropical conditions would

• Minimize migration by designing resis- tance into the product.

adjust to the likelihood of adverse situa-

Many factors contribute to loss of shelf tions such as unrefrigerated

life and failure of a customer to return to

transport/storage or ship conditions.

purchase a product. Not everyone has

Figure 1 shows the longest life recom-

the resources to perform stability or

mendations for products sealed and stored

shelf-life testing, but we all have the abil-

properly away from light for the purpose

ity to perform sensory analysis on our

of Best Before date.This knowledge can be

products to look for degradation and

used as a guide for new products. Condi- loss of product integrity. ■

tioned cabinets at specific temperatures

and relative humidity for a specific time

can also be used to predict accelerated REFERENCES

shelf life. An example follows.

Beckett, S.T. Industrial Chocolate Manufac- ture and Use, 3 rd edition. Bloom Stability Potential of a

Fontana,A.Water Activity for Predicting Qual-

Product — A Tool to Aid in Shelf-life

ity and Shelf Life. MC, November, 2005 Determination

Man, D., A. Jones. Shelf Life Evaluation of Foods, 2nd edition.

• General reference — one week of cycling

is equal to one month of shelf life.

Minifie, B.N. Chocolate, Cocoa, and Confec- tionery, 3 rd edition.

• Hold samples at 30°C (84°F) for

Seguine, E.S. Factors Influencing the Taste, approximately 12 hours.

Selection and Specification of Chocolate,

• Hold samples at 20°C (68°F) for PMCA Proceedings, 1998. approximately 12 hours.

Subramaniam, P. Accelerated Shelf Life Test-

• Continue until bloom is observed. ing. MC, June, 1998.

Weyland, M. Shelf Life of Chocolate and Com-

• If a sample holds its integrity for

pound Coatings. MC, September, 1998.

12 weeks, the product can be predicted

to maintain its integrity for 12 months. REMEDIES

• Understand the fat systems of your

products — cocoa butter and vegetable fats are not compatible.

Presented at the AACT Annual Technical Seminar

The Manufacturing Confectioner • February 2007 51