Preview text:

lOMoAR cPSD| 58583460 1) Management

- The process of making thing done efficiently (năng suất) and effectively (chất lượng) with people and through people.

2) Four functions of management: - Planning - Organising - Leading - Controlling

3) TQM: Total Quality Management

- A people-focused management system that aims at continual increase customer sastifaction

at continually lower real cost. TQM is a total system approach (not a separate area or program)

and an integral part of high level strategy; it works horizontally across functions and

department, involves all employees, top to bottom, and extends backward and forward to

include the supply chain and the customer chain. TQM stresses learning and adaptation to

continual change as keys to org. success. - The foundation of TAM is philosophical: the

scientific method. TQM includes systems, methods, and tools. The systems permit change; the

system stays the same. TQM is anchored in values that stress the dignity of the individual and power of community action.

- P&G: TQM is unyielding and continually improving effort by people in an orrg, to understan,

meet, and exceed expectations of customers.

- Challenges for quality management:

(1) Data management and analytics

(2) Compliance with regulation

(3) Global supplies change complexity. CHAPTER 2: 4)

Early quality management framework a) Deming

- Deming received a PhD in physics, and trained as a statistician

- Deming worked for Western Electric After WWII, Deming was invited to

Japan Died: December 1993 at the age of 93 lOMoAR cPSD| 58583460

- "How would you like to be remembered?"

- "I probably won't even be remembered. Well, maybe ... as someone who spent his life trying

to keep America from committing suicide" - 14 points off quality management framework:

(1) Create a vision and demonstrate commitment.

(2) Adopt the new philosophy. We can no longer live with commonly accepted levels of

delays, mistakes, defective workmanship.

(3) Cease dependence on mass inspection. Require instead statistical evidence that quality is built in.

(4) Stop making decisions purely based on cost

(5) Improve constantly and forever

(6) Institute modern methods of training on the job.

(7) Institute modern methods of supervision of production workers.

(8) The responsibility of foremen must be changed from numbers to quality.

(9) Drive out fear, so that everyone may work effectively for the company.

(10) Break down barriers between departments. Efforts of team Eliminate numerical goals,

posters, and slogans for the workforce asking for new levels of productivity without providing methods.

(11) Eliminate work standards that prescribe numerical quotas.

(12) Remove barriers that stand between the hourly worker and his right to pride of workmanship.

(13) Institute a vigorous program of education and retraining.

(14) Create a structure in top management that will push every day on the above 13 points. - Synthesized into 4 groups:

(1) Appreciation for a system

(a)Create a vision and demonstrate commitment.

(b)Improve constantly and forever

(c)Institute modern methods of training on the job.

(d)Institute modern methods of supervision of production workers.

(e)Drive out fear, so that everyone may work effectively for the company. lOMoAR cPSD| 58583460

(f) Create a structure in top management that will push every day on the above 13 points.

(2) Understanding Variation

(a)Cease dependence on mass inspection. Require instead statistical evidence that quality is built in.

(b)Break down barriers between departments. Efforts of team Eliminate numerical

goals, posters, and slogans for the workforce asking for new levels of

productivity without providing methods.

(c)Eliminate work standards that prescribe numerical quotas.

(3) Theory of Knowledge

(a)Stop making decisions purely based on cost

(b)Institute a vigorous program of education and retraining. (4) Psychology:

(a)Adopt the new philosophy. We can no longer live with commonly accepted

levels of delays, mistakes, defective workmanship.

(b)The responsibility of foremen must be changed from numbers to quality.

(c)Remove barriers that stand between the hourly worker and his right to pride of workmanship.

- Early quality management framework:

(1) 1 Build awareness of the need and opportunity for improvement.

(2) Set goals for improvement.

(3) Organize to reach the goals (establish a quality council, identify problems, select

projects, appoint teams, designate facilitators). (4) Provide training.

(5) Carry out projects to solve problems. (6) Report progress. (7) Give recognition. (8) Communicate results. (9) Keep score. lOMoAR cPSD| 58583460

(10) Maintain momentum by making annual improvement part of the regular systems and processes of the company. - Four absolute:

(1) Definition: Conformance to requirements (2) System: Prevention

(3) Performance standard: zero defects.

(4) Measurement: price of non-confornance.

- Make it clear that management is committed to quality.

- Form quality improvement teams with representatives from each department.

- Determine where current and potential quality problems lie.

- Evaluate the cost of quality and explain its use as a management tool.

- Raise the quality awareness and personal concern of all employees.

- Take actions to correct problems identified through previous steps.

- Establish a committee for the zero defects program.

- Train supervisors to actively carry out their part of the quality improvement program.

- Hold a 'zero defects day' to let all employees realize that there has been a change.

- Encourage individuals to establish improvement goals for themselves and their groups.

- Encourage employees to communicate to management the obstacles they face in attaining their improvement goals.

- Recognize and appreciate those who participate.

- Establish quality councils to communicate on a regular basis.

- Do it all over again to emphasize that the quality improvement program never ends.

- Ishikawa: Professor of engineering at Tokyo University

(1) 1. Quality begins with education & ends with education

(2) The first step in quality is to know the requirements of customers

(3) The ideal state of quality control occurs when inspection is no longer necessary

(4) Remove the root cause, not the symptoms.

(5) Quality control is the responsibility of all workers and all divisions lOMoAR cPSD| 58583460

(6) Do not confuse the means with the objectives

(7) Put quality first and set your sights on long-term profits

(8) Marketing is the entrance and exit of quality

(9) Top managers must not show anger when facts are presented by subordinates

(10) 95% of problems can be solved with simple tools for analysis and problem solving

(11) Data without variation are false fata

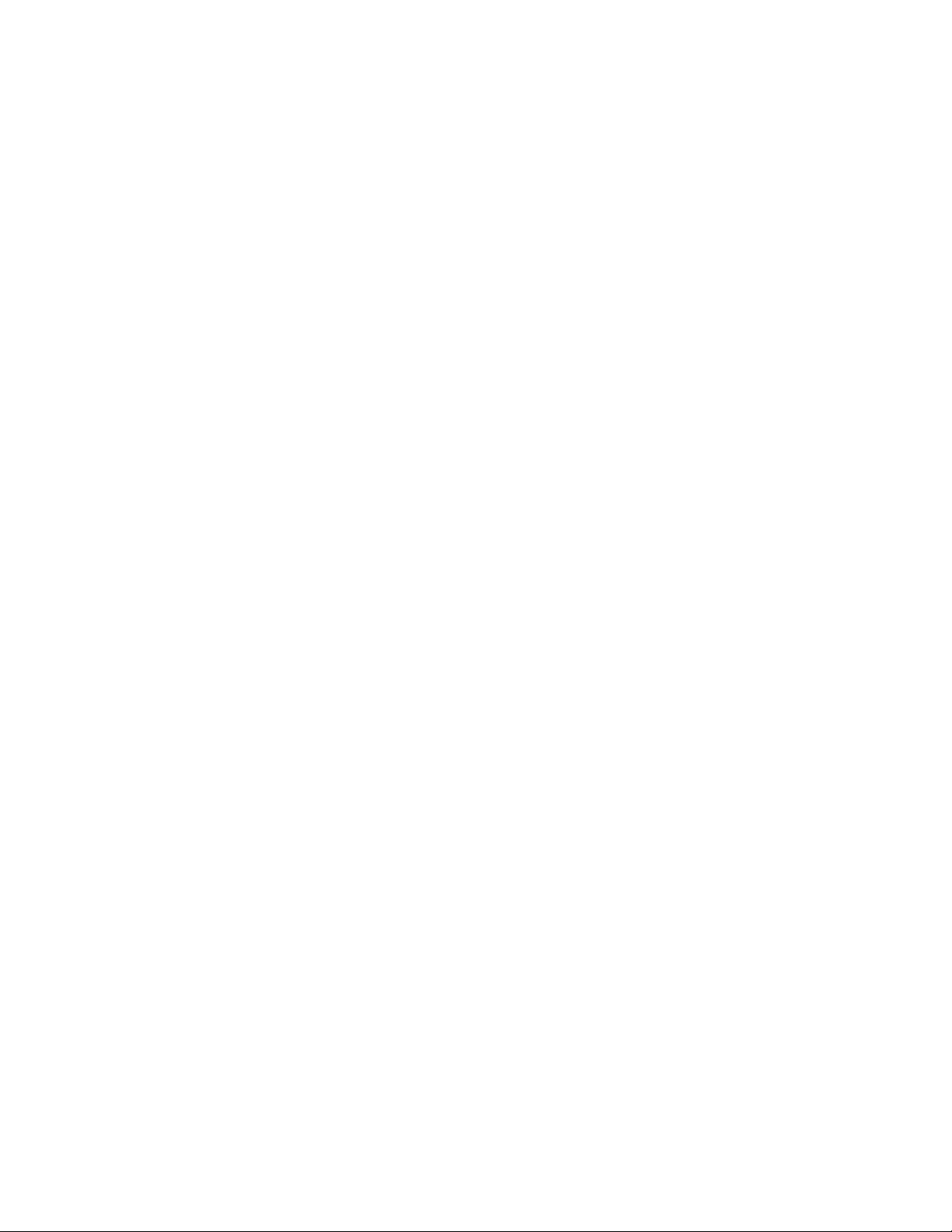

- Prevention cost (chi phí phòng ngừa): bao gồm chi phí trực tiếp và gián tiếp liên quan đến các

hoạt động được triển khai để ngăn ngừa lỗi xảy ra như: Huấn luyện và đào tạo nghề, nghiên

cứu thử nghiệm, xem xét sản phẩm mới,…

(1) Establishing Product Specifications (2) Quality Planning

(3) New Product Development and Testing

(4) Development of a Quality Management System (QMS) lOMoAR cPSD| 58583460 (5) Proper Employee Training

- Appraisal cost (chi phí thẩm định): bao gồm chi phí kiểm tra, thử nghiệm gắn liền với việc đánh

giá sản phẩm đã hoàn thành và thẩm duyệt.

(1) Incoming Material Inspections (2) Process Controls (3) Check Fixtures (4) Quality Audits (5) Supplier Assessments

- Internal Failure Cost (IFC: Chi phí lỗi nội bộ): liên quan đến các lỗi được tìm thấy trước khi sản

phẩm hoặc dịch vụ đến tay khách hành. VD: Sản phẩm hư hỏng và phải sửa chữa, máy móc

hỏng do bảo trì không đúng cách, … (1) Excessive Scrap (2) Product Re-work

(3) Waste due to poorly designed processes

(4) Machine breakdown due to improper maintenance

(5) Costs associated with failure analysis

- External Failure Cost (EFC: chi phí lỗi bên ngoài): liên quan đến các lỗi được tìm thấy sau khi

khách hàng nhận được sản phẩm hoặc dịch vụ. VD: Chi phí bảo hành, chi phí sửa chữa, xử lý

khiếu nại của khách hàng,… (1) Service and Repair Costs (2) Warranty Claims (3) Customer Complaints

(4) Product or Material Returns (5) Incorrect Sales Orders (6) Incomplete BOMs

(7) Shipping Damage due to Inadequate Packaging

- Ex: Cost that may occurs at FTU

(1) Student complaint handling: Xử lí khiếu nại

(2) Curriculumn development and review lOMoAR cPSD| 58583460

(3) Regular Accreditation and Audits

(4) Alumni Dissatisfaction and Negative Publicity - Quality mgt principles: (1) Customer focus

(a)Organizations depend on their customers and therefore should understand

current and future customer needs, should meet customer requirements and

strive to exceed customer expectations. (b)Principles:

(i) Researching and understanding customer needs and expectations

(ii)Ensuring that the objectives of org. are linked to customer needs and expectations

(iii) Communicating customer needs and expectation through the org.

(iv) Measuring customer satisfaction and acting on the results

(v)Systematically managing customer relationship

(vi) Ensuring a balanced approach between satisfying customers and other interested parties (2) Leadership

(a)Leaders establish unity of purpose and direction of the organization. They

should create and maintain the internal environment in which people can

become fully involved in achieving the organization's objectives (3) People involvement

(a)People at all levels are the essence of an organization and their full involvement

enables their abilities to be used for the organization's benefit (4) Process approach

(a)A desired result is achieved more efficiently when activities and related

resources arre managed as a process (5) System approach

(a)Identifying, understanding and managing interrelated processes as a system

contributes to the organization's effectiveness and efficiency in achieving its

objectivesContinuous improvement.

(6) Continuous improvement lOMoAR cPSD| 58583460 (7) Factual approach:

(a)Effective decision makings arre bassed on the analysis of data and imformation

(8) Mutual benefit to supplier relationship.

(a)An organisation and its suppliers are interdependent and a mutually beneficial

relationship enhances the ability of both to create value.

CHAPTER 3: QUALITY MANAGEMENT TOOLS

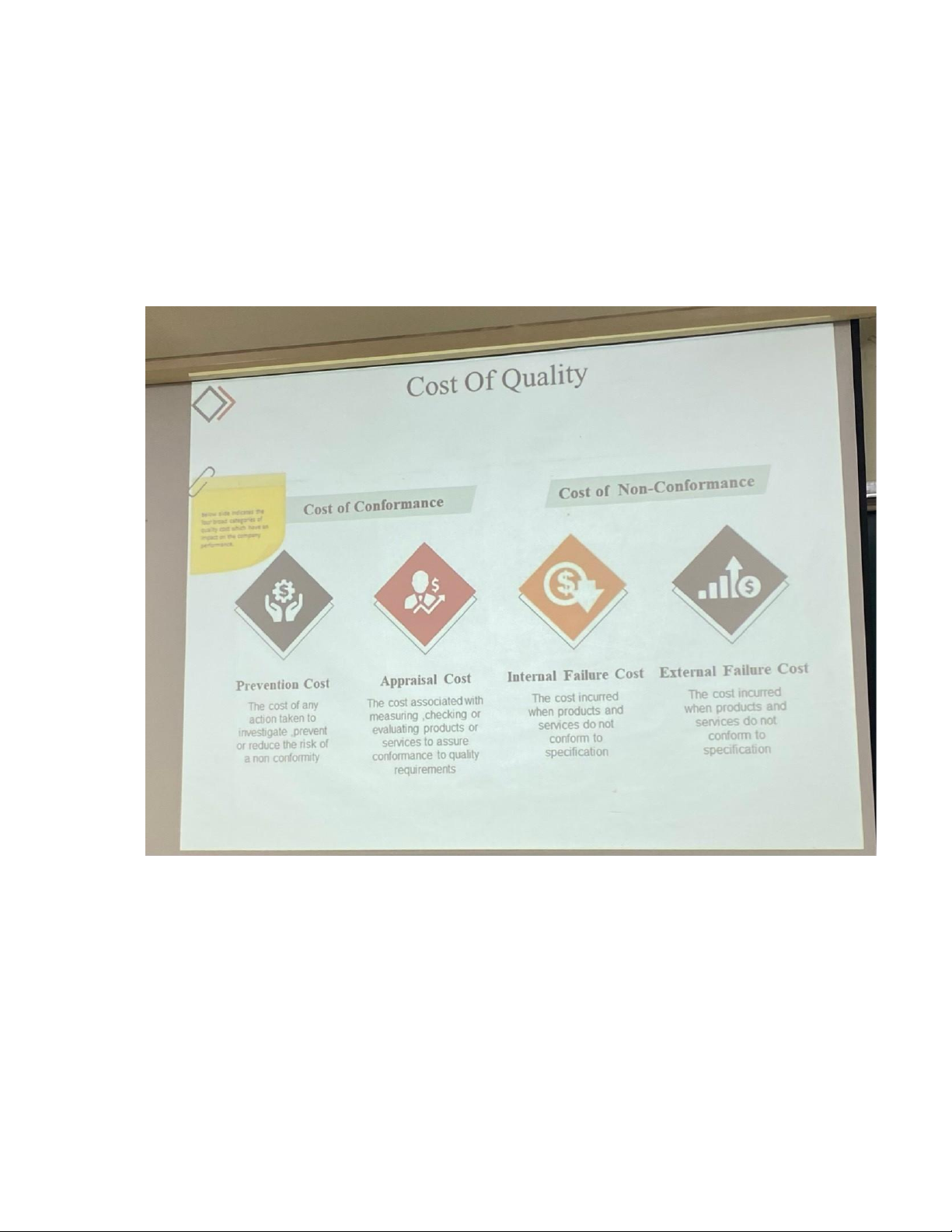

1) Quality management system. a) ISO 9000

- Aim: assure purchasers that quality meets their requirement

- Via documents, ISO assures that quality is built into a process and is achieved

- Amongst other things it ensures that an organization has a quality policy, that procedures are

standardized, that defects are monitored, that corrective and preventative action systems are

in place, and that management reviews the system lOMoAR cPSD| 58583460

- The ISO9000 family of standards consists of four primary standards: IS09000, ISO9001, ISO9004 and ISO19011

(1) ISO9000: Fundamentals and Vocabulary (2) ISO9001: Requirements

(3) ISO9004: Guidelines for Performance Improvement (4) ISO19011: Guidelines on

Quality and Environmental Auditing - Limitations:

(1) Lack of flexibility and perceived restrictions on creativity

(2) Lack of relevance to the real needs of the business

(3) The time and resources needed in writing procedures and training

(4) The bureaucracy involved in documentation and accreditation.

(5) The cost involved in achieving IS09001 registration and then maintaining it

(6) Perceived by small companies to be only applicable to large companies.

(7) Considered by those companies who have mature TQM approaches to be of no value.

Chapter 6: QUANLITY MANAGEMENT IN SERVICE lOMoAR cPSD| 58583460 1) Service. a) Def -

Philip Kotler: " A service is an act of performance that one party can offer to another that

is essentially intangible and does not result in the ownership of anything. Its production may or

may not be tied to a physical product." -

A service is a type of product. Service is always the result of an activity or interaction

between a service supplier and a customer and can take many forms.

b) Characteristics of service.

- Typically intangible: there is usually little or no tangible evidence to show once a service (e.g.

investment advice, consultation with a doctor) has been performed. (Thường thì có rất ít hoặc

không có bằng chứng hữu hình nào để chứng minh khi một dịch vụ (ví dụ như tư vấn đầu tư,

tư vấn với bác sĩ) đã được thực hiện.)

- Production and consumption: simultaneous; the service may not be separable from the

person of the seller, and the customer may be involved in the service performance (e.g. legal

advice, hair-dressing). Thus, the service process, including staff at the customer interface,

becomes integral to service quality. (Đồng thời, dịch vụ có thể không tách rời khỏi người bán,

và khách hàng có thể tham gia vào quá trình thực hiện dịch vụ (ví dụ như tư vấn pháp lý, cắt

tóc). Do đó, quá trình cung cấp dịch vụ, bao gồm cả nhân viên giao tiếp trực tiếp với khách

hàng, trở thành một phần không thể tách rời của chất lượng dịch vụ)

- Heterogeneity: variability often exists in services as a function of labour inputs and non-

standardization of delivery, and so the use of quality standards in the conventional sense is

more difficult. (Sự biến đổi thường tồn tại trong các dịch vụ như một hệ quả của đầu vào lao

động và tính không tiêu chuẩn hóa trong quá trình cung cấp, do đó việc áp dụng các tiêu chuẩn

chất lượng theo cách thông thường trở nên khó khăn hơn)

- No inventory: Many services cannot be stored to meet fluctuations in demand (e.g. a doctor's

time, hotel rooms, purchase of shares in a privatization issue). Companies need to develop

systems to manage supply and demand. (Nhiều dịch vụ không thể được lưu trữ để đáp ứng sự lOMoAR cPSD| 58583460

biến động trong nhu cầu (ví dụ như thời gian của bác sĩ, phòng khách sạn, mua cổ phần trong

một đợt tư nhân hóa. Các công ty cần phát triển các hệ thống để quản lý cung và cầu.) - Ownership.

- Quality measurement

2) Model of excellence for service - Products:

(1) Excellent (e.g PC Business) - Deliver systems:

(1) Excellent (IBM man – Dell) - Service mindset: 3) 3 rules of service

- S = P – E (Satisfaction = perception (cảm nhận) – expectation)

- First impression is the most important - Focus on tangible feature of service. 4) Sequal

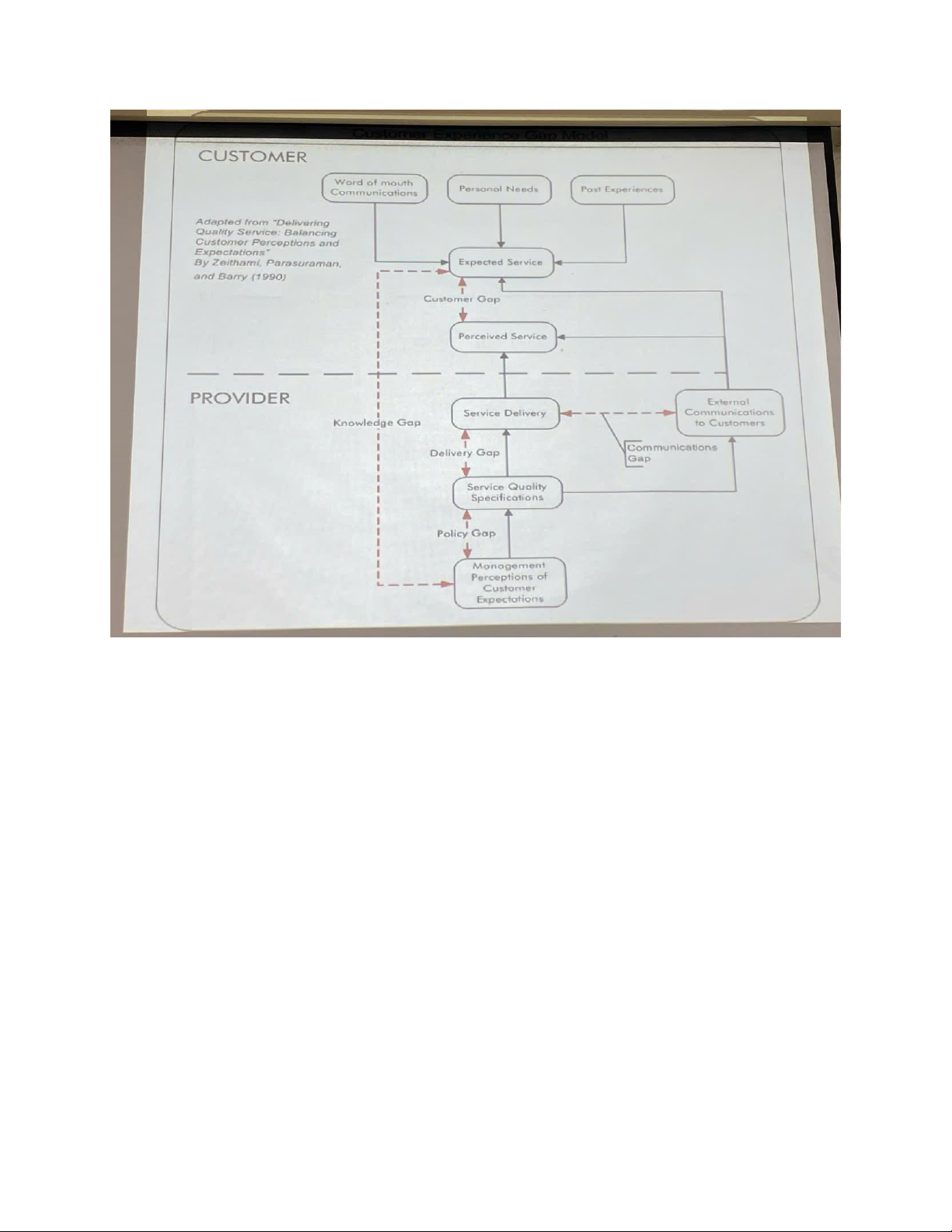

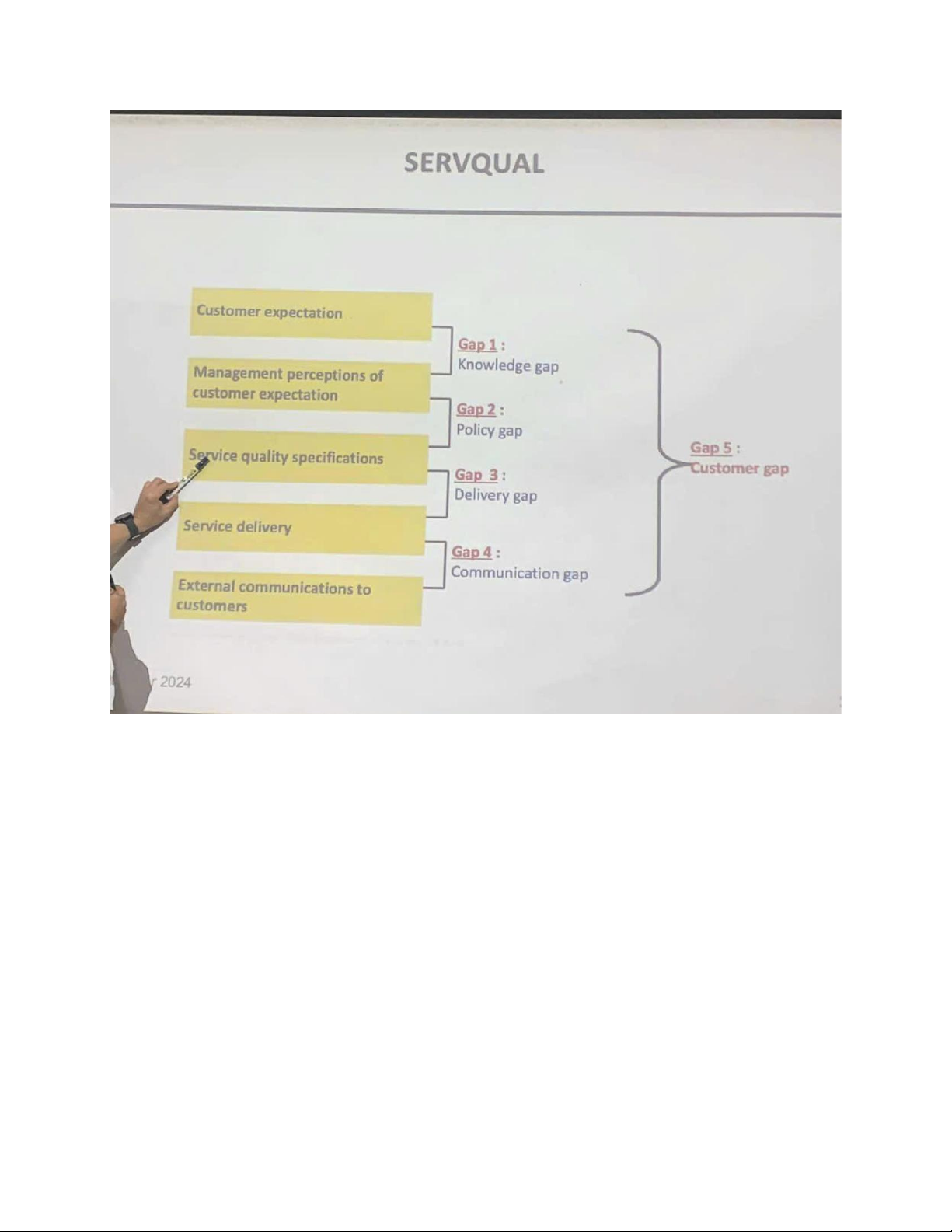

- Parasuraman: Gap model shows difference between customer perception and customer expectations (Satisfaction)

- SERVQUAL (service quality gap model) is a gap method in service quality measurement, a tool

that can be used by Product Manager across all industries.

- Developed by Parasuraman, Zeithalm and Berry in 1985 lOMoAR cPSD| 58583460 lOMoAR cPSD| 58583460

- The Customer Gap: The Gap between Customer Expectations and Cu stomerPerceptions

- Expectation: what the customer expects according to available resources

(1) Influenced by cultural background, family lifestyle, personality, demographics,

advertising, experience with similar products and information available online

- Customer perception: totally subjective:

(1) Based on the customer's interaction with the product or service.

(2) Perception is derived from the customer's satisfaction of the specific product or service

and the quality of service delivery.

- The Knowledge Gap: The Gap between Consumer Expectation and Management Perception lOMoAR cPSD| 58583460

(1) Managers are not aware or have not correctly interpreted the customer's expectation in

relation to the company's services or products.

(2) Companies are trying to meet wrong or non-existing consumer needs.

(3) In a customer-orientated business, it is important to have a clear understanding of the consumer's need for service.

(4) To close the gap: will require comprehensive market research.

- The Policy Gap: The Gap between ManagementPerception and Service Quality Specification

(1) This gap reflects management's incorrect translation of the service policy into rules and guidelines for employees

(2) This can include poor service design, failure to maintain and continually update their

provision of good customer service or simply a lack of standardisation.

(3) This gap may see consumers seek a similar product with better service elsewhere.

- The Policy Gap: The Gap between ManagementPerception and Service Quality Sp ecification

(1) This gap reflects management's incorrect translation of the service policy into rules and guidelines for employees

(2) This can include poor service design, failure to maintain and continually update their

provision of good customer service or simply a lack of standardisation.

(3) This gap may see consumers seek a similar product with better service elsewhere.

- The Delivery Gap: The Gap between Service Quality Specification and Service Delivery

(1) Exposes the weakness in employee performance.

(2) Firms may specify the service required but have subsequently failed to train their

employees, put good processes and guidelines in action.

As a result, employees are ill equipped to manage consumer's needs.

- The Communication Gap: The Gap between Service Delivery and External Communications

(1) Promises through advertising media and communication raise customer expectations.

(2) When over-promising does not match the actual service delivery, it creates a communication gap.

(3) Consumers disappointed because the promised service does not match the expected

service and consequently may seek alternative product sources. This gap may see

consumers seek a similar product with better service elsewhere. lOMoAR cPSD| 58583460

- Measuring service quality: (Sử dụng cho midterm):

(1) By the early 1990s: RATER model

(2) Reliability: the ability to perform the promised service dependably and accurately

(a)Providing service as promised

(b)Dependability in handling customers' service problems

(c)Performing services right the first time

(d)Maintaining error-free records

(3) Assurance: the knowledge and courtesy of employees and their ability to convey trust and confidence

(a)Keeping customers informed about when services will be performed

(b)Prompt service to customers

(c)Willingness to help customers

(d)Readiness to respond to customers' enquiries

(4) Tangibles: the appearance of physical facilities, equipment, personnel and

communication materials Empathy: the provision of caring, individualized attention to customers (a)Modern equipment

(b)Visually appealing facilities

(c)Employees who have a neat, professional appearance

(d)Visually appealing materials associated with service

(5) Responsiveness: the willingness to help customers and to provide prompt service

(a)Giving customers individual attention

(b)Employees who deal with customers in caring fashion

(c)Having the customers' best interest at heart

(d)Employees who understand the needs of their customers (e)Convenient business hours

(f) Employees who instill confidence in customers

(g)Making customers feel safe in their transactions

(h)Employees who are consistently courteous

(i) Employees who have the knowledge to answer customer questions