Preview text:

HO CHI MINH CITY INTERNATIONAL UNIVERSITY

SCHOOL OF INDUSTRIAL ENGINEERING & MANAGEMENT REPORT INTERNSHIP 1

Name: Trần Hải Đăng ID: IELSIU20012 Ho Chi Minh city, Vietnam Month/Year TABLE OF CONTENTS

Students have to report 5 compan

describes ies which ha general inf ve ormation

already visited. Each company student should clarify about as below: I. INTRODUCTION (

company which can get info when company introduce

or find more on internet)

describes what you already observe II. OBSERVATION (

such as production process, checking process,

material flow, ….)

based on what you have learned in school III. ANALYSIS (

then you analysis what you have seen on visiting and

give some improvement ideas)

what lessons you have learned from IV. CONCLUSION ( this visiting) A. INTRODUCTION Table of Contents

A.Introduction…………………………………………….……3

B. General……………………………………………………. …3 C. Company

description…………………………………….….4

1. TBS group-Multi-industry company……………………………

a) Introduction…………………………………………………..….4

b) Observation………………………………………………….…..5

c)Analysis and lesson learned……………………………………...8

2. YAKULT Vietnam……………………………………………...9

a)Introduction……………………………………………………..9

b) Observation…………………………………………………....10

c) Analysis and lesson learned………………………………..….12 3. AJINOMOTO

Vietnam………………………………………………………...13

a) Introduction……………………………………………………13

b) Observation……………………………………………………14

c) Analysis and lesson learned…………………………………...15

4. TRA-SAS Joint Stock Company

company…………………………………………………….…16

a) Introduction……………………………………………………16

b) Observation……………………………………………..…..…17

c)Analysis and lesson learned…………………………………....18

D. Conclusion…………………………………………...20

E. References……………………………………………21

With the goal of strengthening the knowledge and experience of the

students of the Faculty of Industrial Systems Engineering,

internship 1 is an important stepping stone to help students have a

perspective on businesses and their own careers.

During the last summer (2022-2023), we had the opportunity to visit

and experience 4 companies including: YAKULT, AJINOMOTO

(food and chain company) and TBS group, TRASAS (food industry

group) household as well as focusing on logistics).

Under the guidance of the instructors, we were able to visualise and

understand the actual problems of the industry, the relationship

between machines and human resources. This report is intended to

summarise what I have learned after the field trips to self-realise my

knowledge and abilities. Above all, thank you to everyone who has

tried their best to guide students like me this semester. B. GENERAL

This report is about 4 factory companies, respectively:

● TBS group-Multi-industry company (shoes, bags, logistics)

● YAKULT Vietnam (Production of fermented drinks)

● AJINOMOTO Vietnam(Production of spices)

● TRA-SAS Joint Stock Company company( Customs declaration and cargo agent) C. COMPANY DESCRIPTION TBS group 1. INTRODUCTION

-"The world can do it, so we can do it" are the words that Mr.

Nguyen Duc Thuan - who was born in a moneyless family of

teachers, always takes to heart. When he reached adulthood, along with two companions, Nguyen Thanh Son and Cao Thanh Bich,

to found the company TBS group.

In 1992, the Thai Binh shoes No.1 factory was approved to go into

operation. Following the development, factory No.2 was also put

into operation with the mission of focusing on sports shoes. After

the Certificates of Merit for Typical Enterprise in Vietnam Textile &

Garment & Footwear industry awarded by the Ministry of Industry

and Trade in 2009, the company expanded into the handbag industry

in 2011. After more than 30 years of development, the TBS group

has now assembled, enter the international market in many new

fields such as logistics and trade in services.

- Company: Thai Binh Joint Stock Company

- Factories: 35 factories spread across Vietnam (North, Central, East, West)

- Research Centre: 6 centres specialising in research and development of new products - Distribution: Viet Nam

- Familiar partner of many big brands in the world such as:

Decathlon, Skechers and Wolverine

- Vietnamese company with standard capacity, international vision

- Main consumption markets: Europe, America, Japan

- Current manpower: 17,000 people 2. OBSERVATION

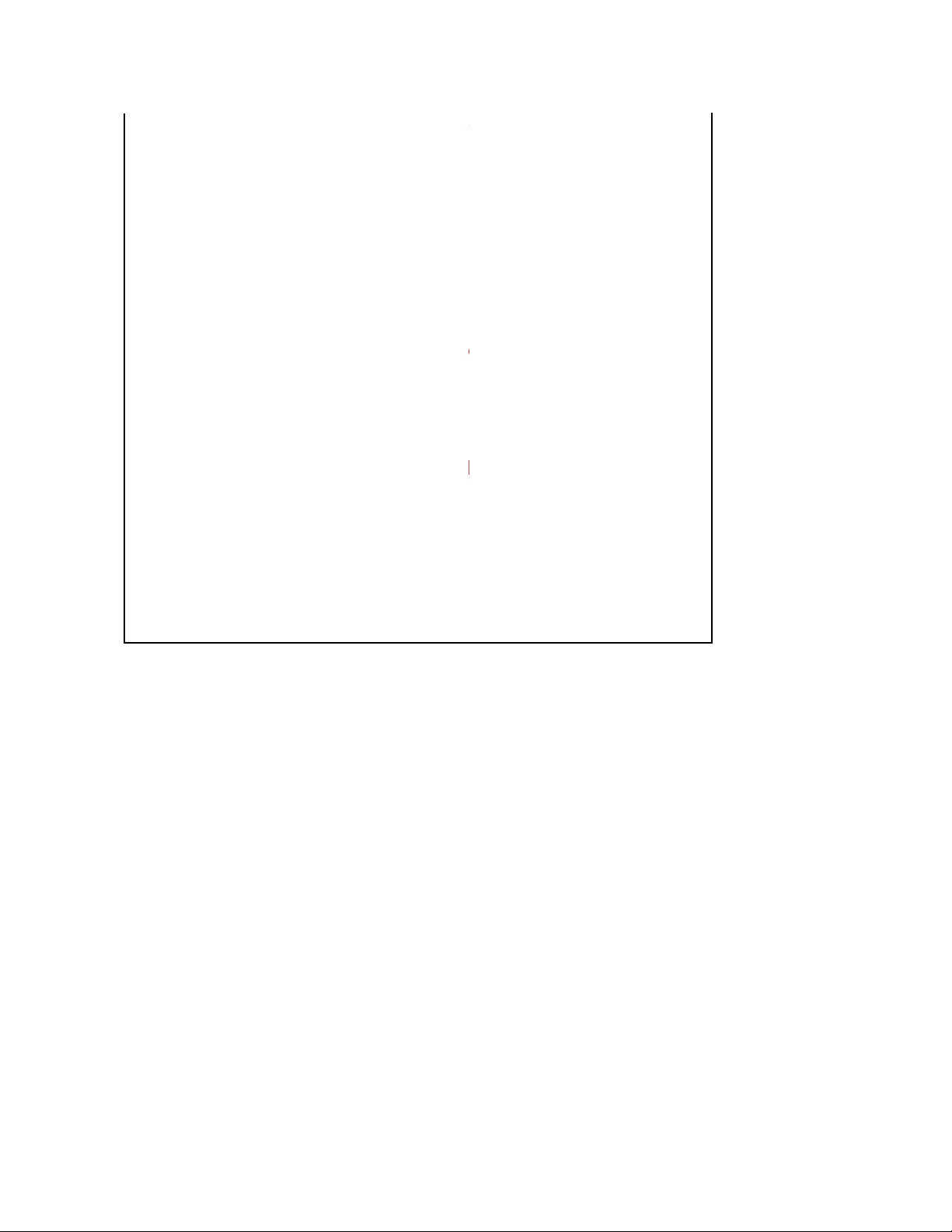

- August 18, 2015, The inauguration ceremony of Warehouse 5

was officially held in Binh Duong

- Total area up to 47,500 m2

❖The process of receiving and checking goods is strictly carried out

according to the following steps:

Step 1(Inbound receiving): Drivers do registration procedures at

the gate Step 2: Staff in the centre will document and verify. The data will be uploaded to the WMS management system

Step 3: The car has been brought into the warehouse,, then the

security guard will check the basic information about the type of

goods and seal it if it is not.

Step 4: Cargo handling, verification and labelling

Step 5: WMS records the location of each package

Step 6(Pick and pack processing): Goods are passed through the check code scanning area Step 7: Reseal new packing Step 8(Outbound loading): Check empty containers according to CT-PAT .'s seven- step process Step 9: Container Sealing

(Including customer and supplier). Seal photo take

Step 10: Cargo deliver to terminal

3. ANALYSIS and LESSON LEARNED

In the context of many changes in the economy of Vietnam and the

world, the implementation and signing of new-generation free trade

agreements such as CPTPP, EVFTA, and RCEP bring many

advantages and challenges for businesses. Vietnam.

Logistics costs of TBS logistics compared to developed countries in

the world are still too high. This is because industries and

infrastructure do not have close links and mutual support. This leads

to a decrease in the competitiveness of Vietnamese goods in the

international market. The next issue we can mention is the quality of

human resources. TBS logistics as well as other logistics companies

in Vietnam are always in a shortage of high-quality human

resources, making it difficult to compete with foreign enterprises in

terms of scale and uniformity.

Once the opportunities and challenges have been identified, there

must be clear code improvement steps:

● Focus on perfecting the system of regulations, mechanisms

and policies related to logistics

● Prioritise resources to improve infrastructure and promote logistics development

● Government support is needed in policies and financial

priorities from the Ministry of Industry and Trade to help

businesses develop peace of mind.

● The most important thing is to strengthen training, raise

awareness and quality of human resources. Yakult company 1. INTRODUCTION

- The origin of the Yakult company was

when Dr. Minoru Shirota successfully

isolated and cultured a new strain of

lactic acid bacteria, Lactobacillus

casei Shirota. In 1935, the Yakult

company first commercialised in the

Japanese market. In 1955, Yakult

Honsha Company was established.

The research centre was established in Kyoto. In 2007, Yakult

came to the Vietnam market, the factory in Binh Duong

officially went into operation one year later. As of 2022,

Yakult is present in 38 countries on multiple continents. - Company: Yakult Honsha

- Product: Fermented beverages, food and cosmetics

- Distribution: 38 countries (Asia, Europe, South America, North America and Australia)

- Research Centre: 2 Yakult microbiology research institutes located in Japan and Belgium

- Yakult's General Philosophy: Longevity, Preventive Medicine, Reasonable Price

- Current manpower: approximately 29,000 people 2. OBSERVATION

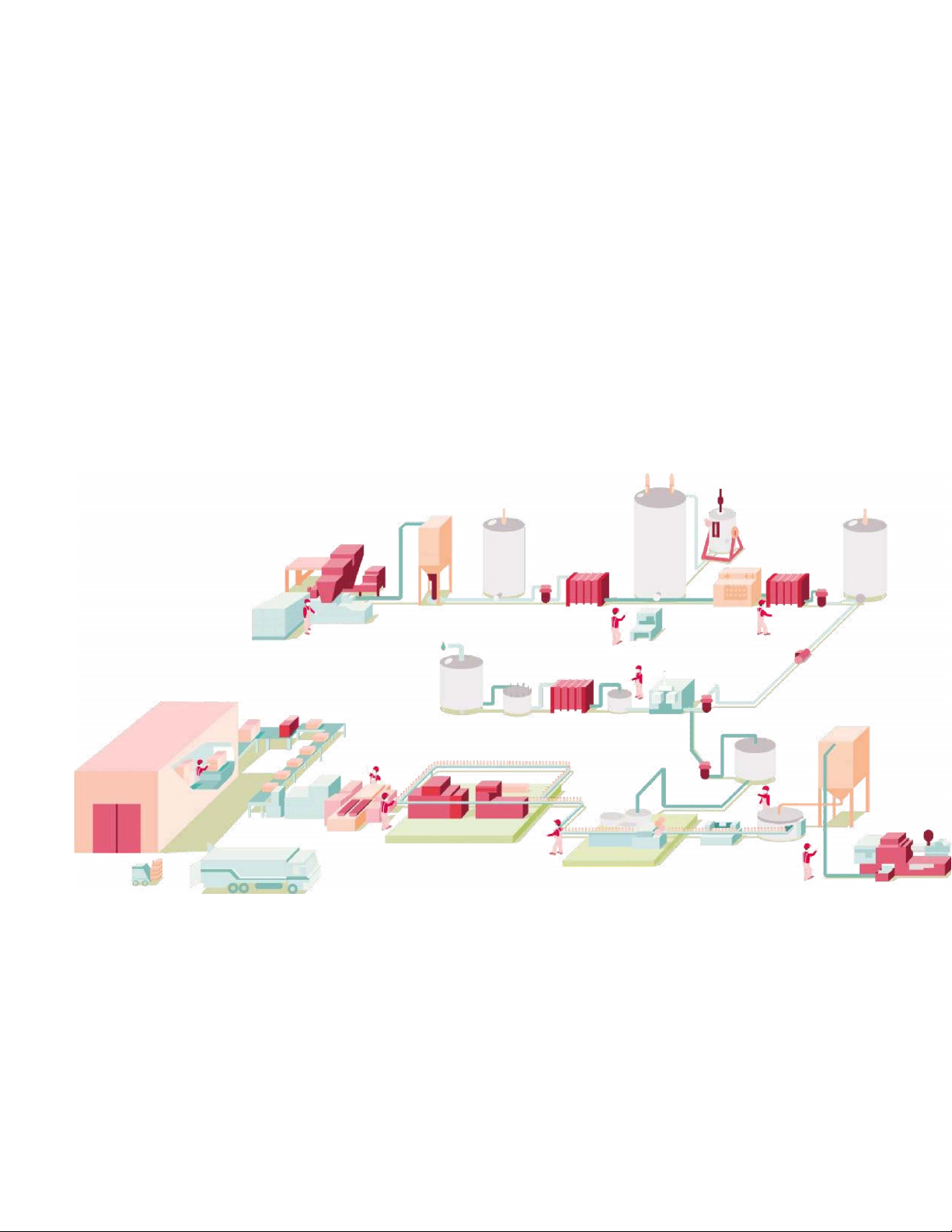

Step 1: Prepare ingredients (skimmed milk powder, glucose sugar, white sand sugar)

Step 2: Dissolving tank: Dissolve the mixture of skimmed milk

powder, glucose sugar, white sand with hot water

Step 3: Sterilisation equipment: Sterilise milk, sugar water at high temperature

Step 4: Fermentation tank: Inoculate

Yakult yeast into a sterilised milk bath

to produce billions of beneficial

bacteria (Assimilated mixture)

Step 5: Homogenizer: The milk after

being fermented is pumped through the homogenizer for anabolic fermentation

Step 6: Then the milk will be put

through the water treatment system and sterilised water tank

Step 7: Milk will be put into the

packing machine into 10 batches 1 carton

Step 8: The product will be stored in cold storage below 10 degrees

Celsius for 1 to 2 days to check before reaching consumers.

Step 9: Refrigeration trucks bring Yakult to the warehouses of large

supermarket chains for distribution to individual supermarkets.

3. ANALYSIS and LESSON LEARNED

Modern, closed technological process from raw materials to

finished products, good infrastructure according to Japanese

technology. Hygiene is very good. Processes of waste treatment,

fermentation, production of probiotics are operated with high

technology under very strict hygienic conditions.

Yakult is available in most supermarkets and stores, and has a home

delivery system called Yakult Lady. The company's staff guides and

gives presentations on the production process to the packaging and

preservation in detail. Here, we can see the discipline, working style

and high sense of responsibility of a workshop of just over 100

people. Yakult not only focuses on product profits, but also cares

about quality and consumer health

As a product related to human health, Yakult Co., Ltd. must have a

scientific organization system, effective in product quality and

production quantity. The workshop works with automatic equipment

and modern machinery, so it does not need too many workers.

Due to the limited number of workers, Yakult factories always need

to train their own human resources AJINOMOTO 1. INTRODUCTION - In 1908, professor Kikunae

Ikeda succeeded in finding the

sodium salt extracted from the ash solution of kelp in the

laboratory—what later became known as Umami. In 1909, he

established a joint venture to start the business of AJI-NO-MOTO® MSG, the

world's first umami seasoning. The origin of Ajinomoto

Corporation stems from the ideal: "Eat well, live well".

With the strength in the field of amino acids, Ajinomoto

Group is focusing on the main product lines: food, biological

products and pure chemicals, pharmaceuticals. - Company: Ajinomoto Vietnam.

- Factory: 119 factories distributed

throughout 27 countries around the

world (2 factories in Vietnam)

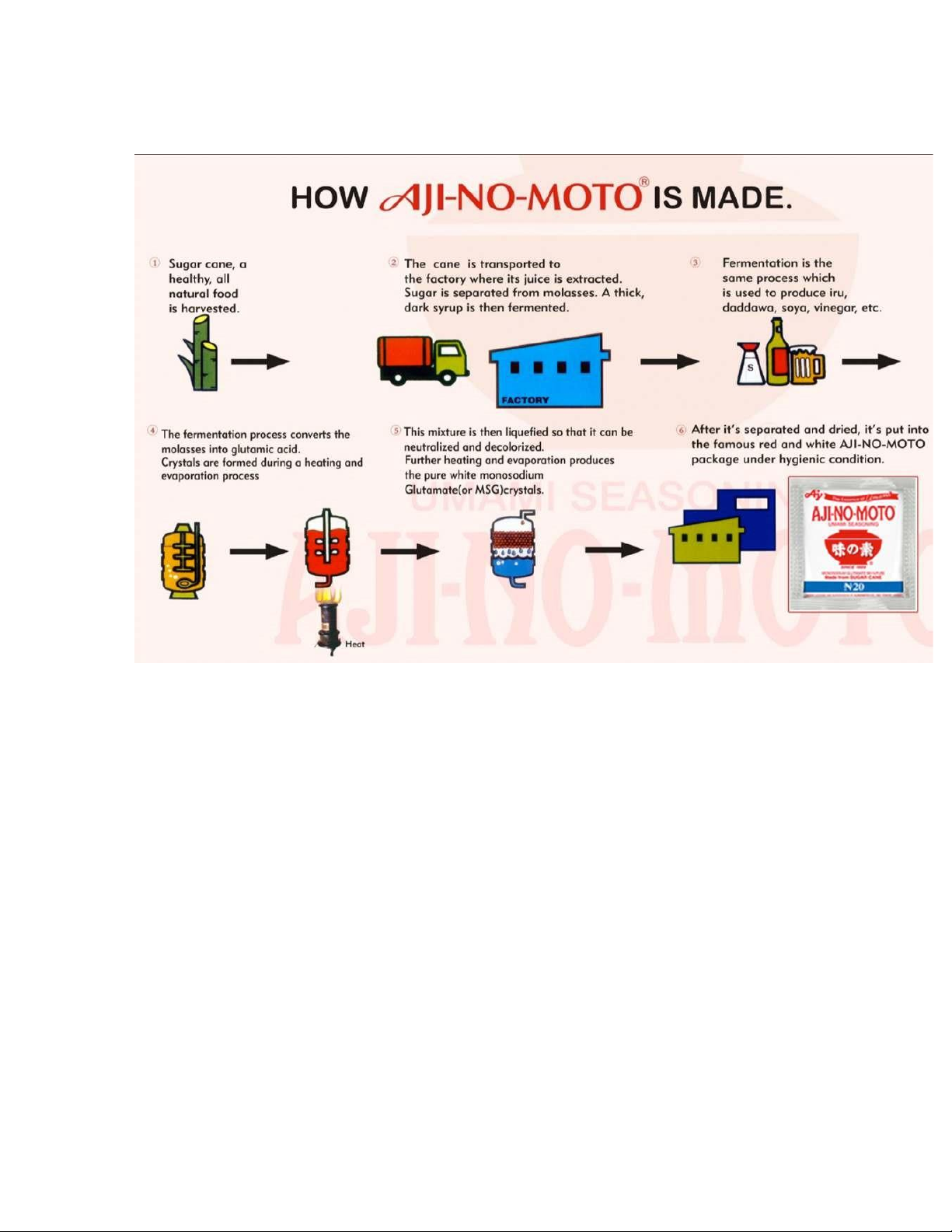

- Product: spices, soy sauce, cosmetics, pharmaceuticals... 2. OBSERVATION

Step 1: Use corn or cassava to make ingredients

Step 2: Glutamic acid is created through a fermentation process

Step 3: Then the glutamic acid is isolated through crystallisation

Step 4: Glutamic acid is made into monosodium glutamate

Step 5: MSG solution will pass through a tank to clean

Step 6: At this stage, MSG will be crystallised

Step 7: The MSG crystals will be dried

Step 8: MSG will be put into the machines for dosing, marking and packing

Step 9: MSG packages are ready to be shipped to supermarkets and consumers.

3. ANALYSIS and LESSON LEARNED

Ajinomoto pays great attention to hygiene as their workers are put

on protective gear and disinfected many times

Because they rely on automatic production lines (almost closed),

workers here only do simple jobs such as unloading goods and

checking product stamps. It is very likely that the chain will have to

stop when there is a small problem. In addition, due to the crystallisation of monosodium

glutamate, cleaning large tanks

becomes difficult and expensive. Need to improve more modern machines TRA-SAS

1. INTRODUCTION - Company:

Tracimexco Chains and Agency Services J.S Company : TRA-SAS - January 26, 1996, Sea Transport and Marine Services Enterprise was established on the basis of VIETRANSTIMEX Transport Enterprise, under VIETRANSTIMEX Corporation - Ministry of Transport

- Then on January 15, 2006: Converting Sea Transport and

Maritime Services Enterprise to Maritime Transport and

Services Joint Stock Company. This event is an important

milestone, marking a new turning point in the development direction of TRA-SAS.

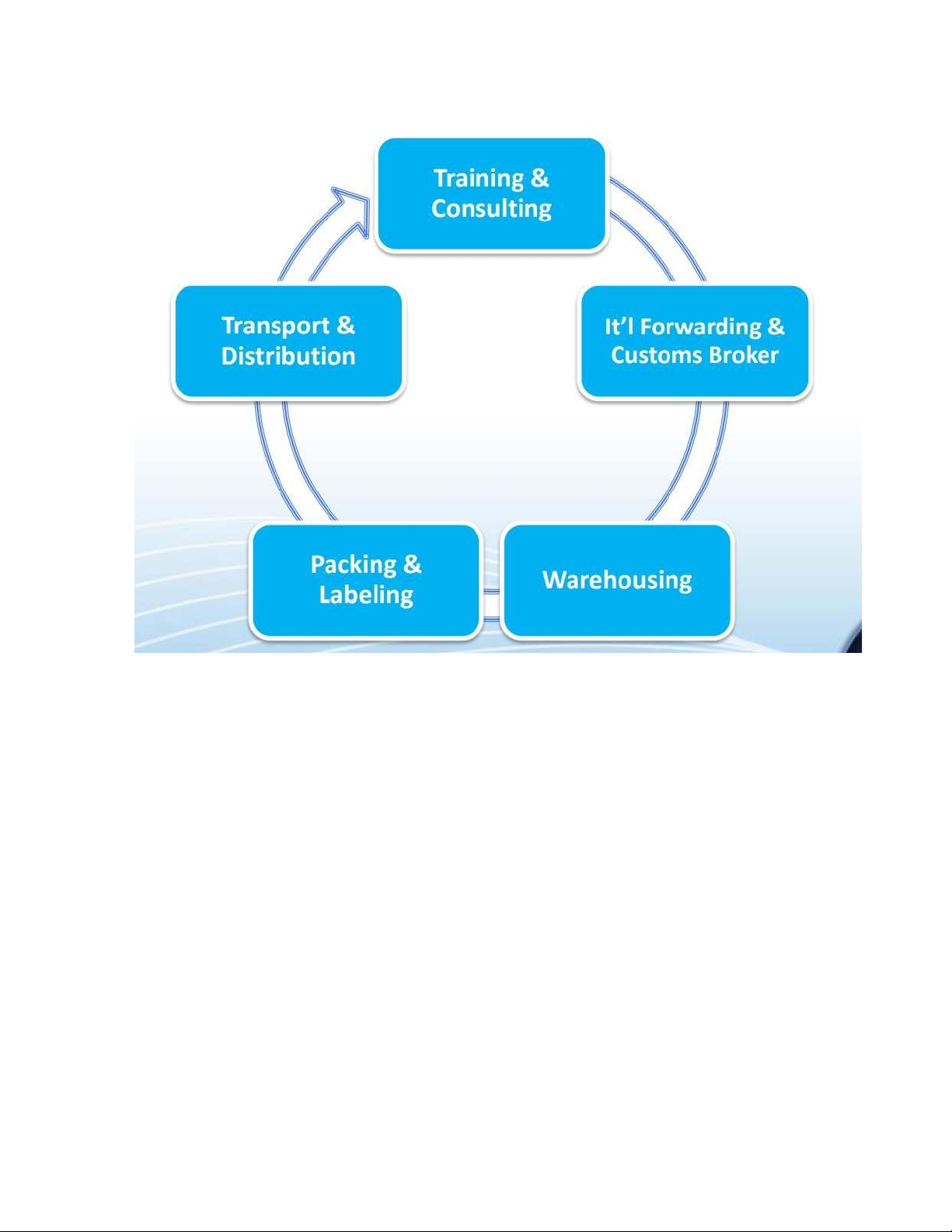

- TRA-SAS Motto: <The time is faster than you think= - ACTIVE FIELDS: - 1.Customs Clearance Agent - 2.Distribution Centre

- 3.Chemical and Dangerous Goods Warehouse Service - 4.Entrusted Service - 5.Transport Service

- 6.International Forwarding Agent. 2. OBSERVATION

Total Construction Area: 16,818 m2 - Storage area: 12,000 m2 - Capacity: 12,000 tons

SCOPES OF SERVICES IN DANGEROUS GOODS INCLUDES 5 FACILITIES:

Group of goods: Group of gases, group of flammable liquid goods,

group of flammable solids, group of oxidising goods, group of

pesticides, group of corrosive substances and other goods such as

motorcycle engines, surface lightening solution after copper plating, etc

Groups of goods are classified

according to different separate

storage areas with corresponding

preservation methods, meeting strict

standards as well as each specified commodity group.

The warehouse is invested and fully

equipped with security surveillance

camera systems, automatic fire

alarms, automatic water spraying and foaming systems to ensure

goods safety and fire prevention.

3. ANALYSIS and LESSONS LEARNED

-TRA-SAS has many advantages in terms of policies and capital

sources when the forerunner of the company belongs to the Ministry

of Industry and Trade. Understanding the need for hazardous

chemicals in the industry is essential, TRA-SAS has built a

hazardous chemical warehouse in Dong Nai province (16.000 square meters).

However, the company has human limitations. Because chemicals

are a profession that requires a lot of knowledge and care, the

company always takes time to train its staff. In addition, the

chemical warehouse takes up a huge area, while it cannot be

combined with other household items. This is an expensive investment

The company needs to always improve the level of workers, take

safe steps in transporting chemicals and soon replace them with

modern machines to optimal costs and compete with other countries in the region. D. CONCLUSION

Thanks to the enthusiastic guidance of the instructors, as well as the

perseverance of the guides in each place we visited, we had the

opportunity to observe the production processes in practice. ,

packaging, strict inspection of food, chemicals, and so on. There are

concerns that I always wonder about when I read theory in the

university lecture hall, which have now been solved relatively.

However, due to the limited time, this article is compiled from the

knowledge gained during the trip, the answers of the guides and

information and videos online about the companies, so it cannot

avoid certain shortcomings. One last time, thank you to those who have accompanied this course.