Preview text:

HCMC UNIVERSITY OF TECHNOLOGY AND EDUCATION

FACULTY FOR HIGH QUALITY TRAINING PROCESS REPORT

RESEARCH AND TESTING ANTI LOCK BRAKING

SYSTEM AND TRACTION CONTROL SYSTEM OF

HONDA CIVIC 2020 BY MATLAB AND CARSIM SOFTWARE Student name: BUI TRAN NGUYEN KHOA 19145192 CAO CHI TINH 19145002 NGUYEN MINH KHANG 19145188 Course: SPECIAL PROJECT Advisor: Ph.D. NGUYEN MANH CUONG Ho Chi Minh City, June 2022

HCMC UNIVERSITY OF TECHNOLOGY AND EDUCATION

FACULTY FOR HIGH QUALITY TRAINING PROCESS REPORT

RESEARCH AND TESTING ANTI LOCK BRAKING

SYSTEM AND TRACTION CONTROL SYSTEM OF

HONDA CIVIC 2020 BY MATLAB AND CARSIM SOFTWARE Student name: BUI TRAN NGUYEN KHOA 19145192 CAO CHI TINH 19145002 NGUYEN MINH KHANG 19145188 Course: SPECIAL PROJECT Advisor: Ph.D. NGUYEN MANH CUONG Ho Chi Minh City, June 2022

THE SOCIALIST REPUBLIC OF VIETNAM

Independence – Freedom– Happiness --------

Ho Chi Minh City, June 12, 2022 PROJECT ASSIGNMENT

Student name: __________________________

Student ID: ___________________

Student name: __________________________

Student ID: ___________________

Student name:___________________________

Student ID: ___________________

Major: ________________________________

Class: ________________________

Advisor: ____________________________

Phone number: _________________

Date of assignment: _____________________

Date of submission: _____________

1. Project title: _________________________________________________________

2. Initial materials provided by the advisor: ___________________________________

3. Content of the project: _________________________________________________

4. Final product: ________________________________________________________ CHAIR OF THE PROGRAM ADVISOR (Sign with full name) (Sign with full name)

THE SOCIALIST REPUBLIC OF VIETNAM

Independence – Freedom– Happiness --------

Ho Chi Minh City, June 12, 2022

ADVISOR’S EVALUATION SHEET

Student name:______________________________ Student ID:_____________ Major: Automotive Engineering

Project title: Research and Testing the Anti Lock Braking System and Traction

Control System on Honda Civic 2020 by MATLAB and Carsim Software

Advisor: ............................................................................................................... EVALUATION 1. Content of the project:

......................................................................................................................................

...................................................................................................................................... 2. Strengths:

......................................................................................................................................

......................................................................................................................................

...................................................................................................................................... 3. Weaknesses:

......................................................................................................................................

......................................................................................................................................

......................................................................................................................................

4. Approval for oral defense? (Approved or denied)

......................................................................................................................................

5. Overall evaluation: (Excellent, Good, Fair, Poor)

......................................................................................................................................

6. Mark: ………………. (in word.........................................................................)

Ho Chi Minh City, September 19, 2021 ADVISOR (Sign with full name) ACKNOWLEDGEMENT

The authors gratefully acknowledge the valuable supports from Ph.D. Nguyen Manh

Cuong from Ho Chi Minh City University of Technology and Education.

CHAPTER I: OVERVIEW OF CAR BRAKE SYSTEM

1. Purpose and meaning of the topic

Currently, cars have become an important means of transporting passengers and goods

for national economic sectors, and at the same time have become a private means of

transport in countries with developed economies. In our country, the number of people

using cars is increasing, along with the growth of the economy, the increasing density of

cars on the road leads to more and more traffic accidents. Therefore, to ensure the safety

of traffic accidents is one of the most necessary solutions, always concerned by the

designers and manufacturers of cars, where the brake system plays a very important

role. Because of that, now the brake system is increasingly improved, the standards for

the design, manufacture and use of the brake system are increasingly strict and strict.

For students majoring in traffic mechanics, the survey and testing of the brake system is

even more practical. That's why I chose the topic "Surveying, calculating and testing the

ABS brake system on Honda Civic 2020". To solve this problem, first of all, we need to

understand the operating principle, structure of details and parts in the brake system.

Thereby creating a premise for the design and improvement of the brake system to

increase braking efficiency, increase directional stability and guideability when braking,

increase working reliability for the purpose of ensuring movement safety and increasing safety. vehicle performance. 2.

Uses, classifications and requirements of the brake system. 2.1 Uses

The brake system is used to slow down the vehicle until it comes to a complete stop or

reaches a certain speed. In addition, the brake system also ensures to keep the vehicle

stationary during stopping, especially when stopping on a slope. For cars, the brake

system is one of the most important systems, because it ensures the car's safe movement

at high speed, allowing the driver to adjust the speed of movement or stop the vehicle in

the middle. dangerous situations, thereby improving transportation productivity and

safety for people and goods during vehicle operation. 2.2 Classifications

- Classification according to use: + Main brake system + Stop brake system

- Classification according to the position of the brake mechanism + Brake at the wheel

+ Brake at drive shaft (after transmission)

- Classification according to the structure of the brake mechanism 1 + Brake clogs + Brakes + Disc brake

- Classification by mode of drive + Mechanical brake drive + Hydraulic brake drive

+ Pneumatic (vapor) brake drive

+ Combined brake drive (hydraulic + pneumatic) + Power-assisted brake drive 2.3 Requirements

The brake system is an important part of the car that performs "active safety" functions,

so the brake system must satisfy the following requirements:

+Has the highest braking efficiency on all wheels under all circumstances

+Quiet operation to ensure the stability of the car when braking

+Smooth control to reduce the driver's labor intensity

+Has high sensitivity to quickly adapt to dangerous situations

+The brake mechanism has no self-tightening phenomenon

+The brake mechanism must have good heat dissipation

+Has a high and stable coefficient of friction

+Keeping the ratio between the force applied to the brake pedal and the braking

force generated by the brake mechanism

+The system must have reliability, durability and long life

+Streamlined layout for easy adjustment of care and maintenance 3.

Structure of disc brakes

Disc brake mechanism is commonly used on passenger cars (mainly on the front

wheels). Recently, this type of brake began to be used on some types of transport and passenger cars.

Disc brakes are of the following types: closed, open, single disc, multi-disc, rotating

housing type, rotating disc, rotating friction ring.

The disc can be a solid disc, a disc with vented slots, a single layer of metal, or a

composite of two dissimilar metals. In automobiles, the main type of open disc is used,

and rarely the rotary shell type is used.

There are two mounting options for clamps: fixed mounting and optional swimming

style mounting. Fixed mounting plan has high rigidity, allowing large driving force to

be used. However, the cooling condition is poor, and the working temperature of the brake mechanism is higher. 2

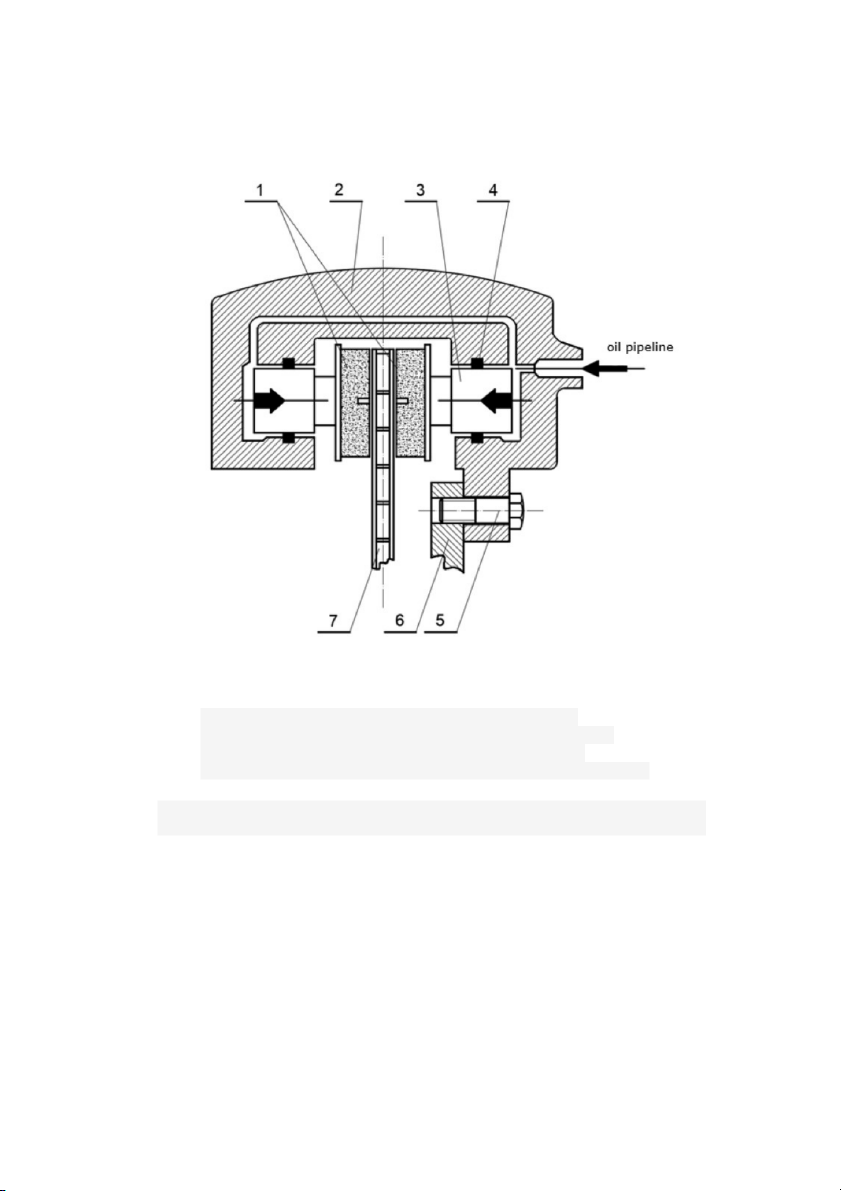

Figure 1 : Structure diagram of disc brake with fixed clamp type. 1. Brake Pads 5. Guide Pin 2. Fixed Clamp 6. Locating Gauze 3. Piston 7. Brake Disc 4. Sealing Ring 8. Shock Absorber Ring

To fix it, you can use the automatic clamp type. The chuck can be split or integrated

with the wheel cylinder and slide on fixed guide pins. Such structures have low 3

stiffness. When the guide pins are deformed, wear and tear will cause the brake pads to

wear unevenly, reduce the braking efficiency and cause vibration. However, it has only

one hydraulic cylinder with twice the length, so the cooling condition is better, the brake

fluid is less hot, the working temperature can be reduced by 30 ÷ 50 ˚C. In addition, it

also allows deep translation of the brake mechanism into the wheel. Thereby reducing

the lever arm acting on the rolling resistance to the vertical cylinder of the guide wheels.

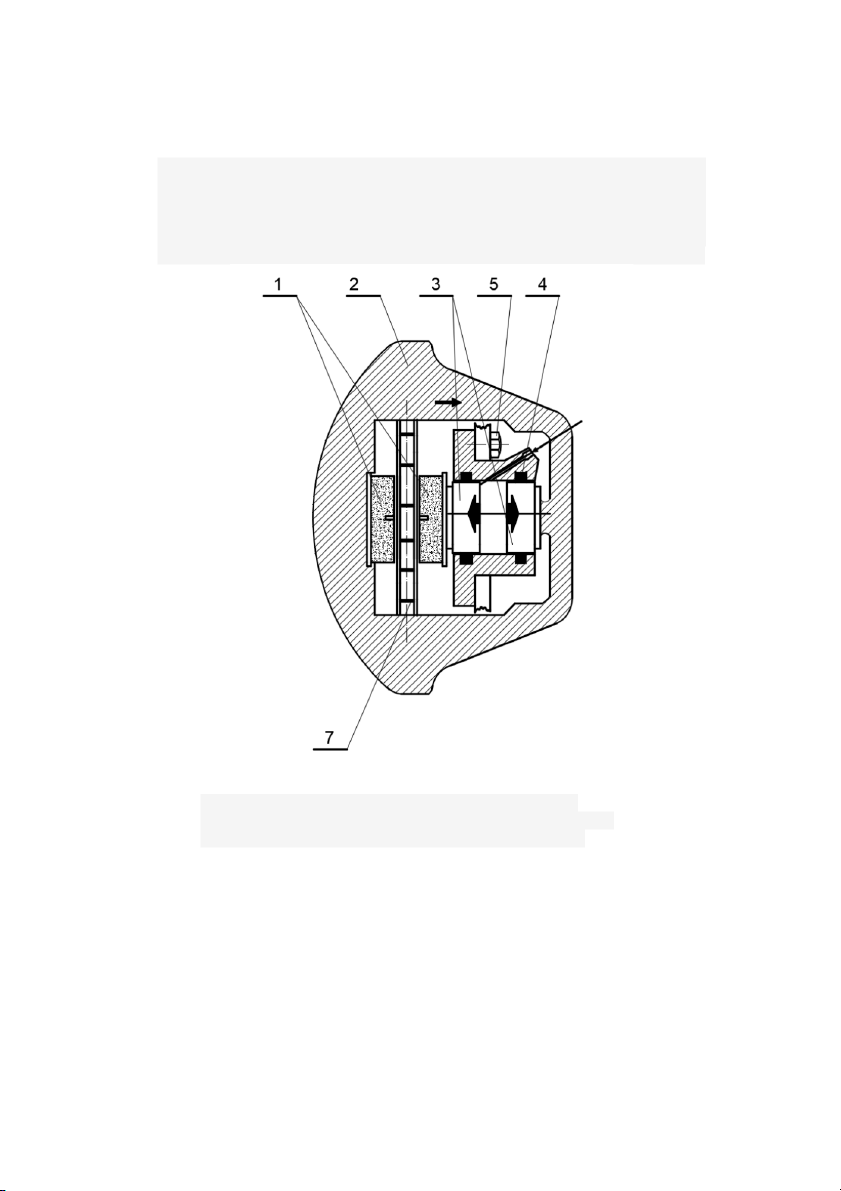

Figure 2: Structural diagram of disc brake with automatic clamp type - fixed cylinder 1. Brake Pads 5. Guide Pin 2. Fixed Clamp 6. Locating Gauze 3. Piston 7. Brake Disc 4 4. Sealing Ring 8. Shock Absorber Ring

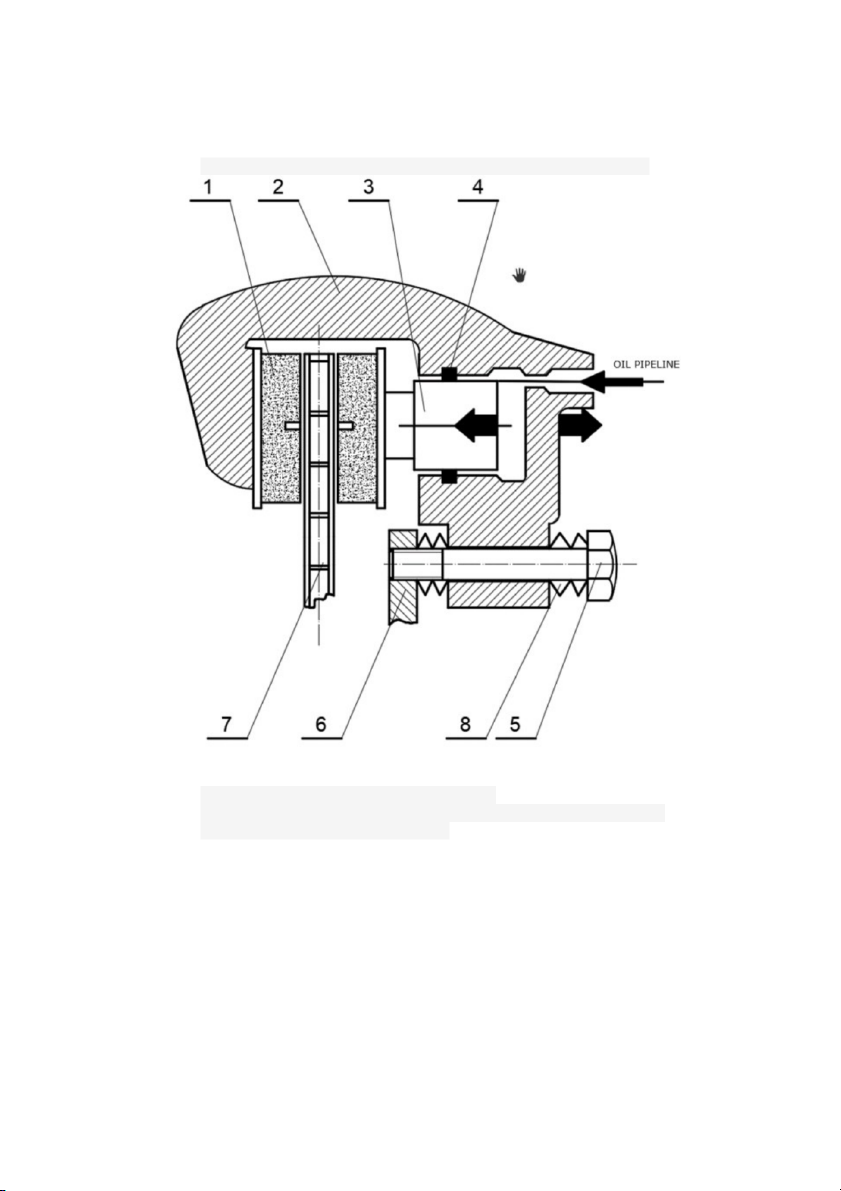

Figure 3: Some causes of brake failure and consequences 1. Brake Pads 5. Hydraulic oil line 2. Fixed Clamp

6. Direction of Displacement Piston and Clamp 3. Piston 7. Guide Pin 5 4. Sealing Ring 8. Ventilation Grooves 9. Brake Disc -

Advantages of disc brake mechanism compared with drum-hoop brake mechanism

+ Able to work with a small gap of 0.05 ÷ 0.15 mm, so it is very sensitive, reduces

the delay time and allows to increase the gear ratio.

+ The pressure is evenly distributed over the surface of the brake pads, so the brake pads wear evenly.

+ Simple maintenance since no clearance adjustment is required.

+ The axial and self-balancing forces should allow their values to be increased to

achieve the required braking effect without being limited by the deformation

conditions of the structure. Therefore, disc brakes are compact in size and easy to arrange in the wheel.

+ The braking effect is independent of rotation direction and more stable.

+ Better cooling conditions, especially with the rotating disc type. -

Disadvantages of disc brake mechanism compared to drum-hoo brake mechanism:

+ Sensitive to dirt and difficult to seal.

+ Open type brake discs are easily oxidized and dirty, causing the brake pads to wear quickly.

+ High working pressure makes the brake pads easy to crack and scratch.

+ It is often necessary to use vacuum boosters to increase driving force, so when the

engine is not working effectively, the brake performance is low and it is difficult

to use them to combine as a stop brake. -

Structural characteristics of the main details and parts:

+ Brake disc: usually made of cast iron. Solid discs are 8 - 13 mm thick. Ventilated

slotted disc 16 - 25 mm thick. The coupling disc can have an aluminum or copper

core and a friction surface – gray cast iron.

+ Clamp: usually cast in wrought iron.

+ Hydraulic cylinders: cast aluminum alloy. To increase wear resistance and reduce

friction, the working surface of the cylinder is chrome plated. When the cylinder is

made of aluminum alloy, it is necessary to reduce the heating temperature of the

brake fluid. One of the ways to reduce the temperature of brake fluid is to reduce

the contact area between the piston and the brake shoe or to use pistons made of non-metallic materials.

+ Brake pad bodies: the place where the piston presses up is made of sheet steel.

+ Friction plate: of open disc brake pads usually have a surface area of about 12 -

16% of the disc surface area, so disc cooling conditions are very favorable. 6

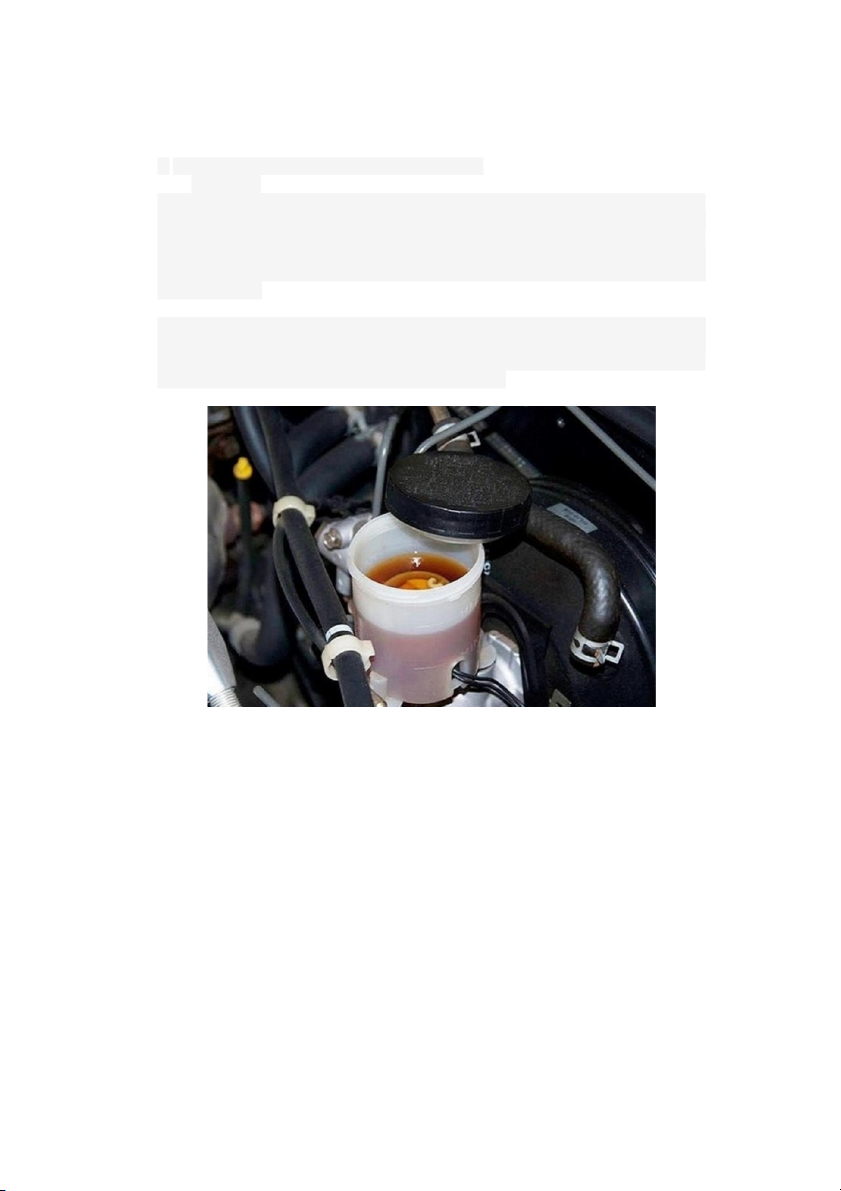

4. Some causes of brake failure and consequences 4.1 Causes

One of the most common causes of “brake failure” accidents is a loss of brake fluid

pressure. The brake is operated by hydraulic pressure inside the system. Therefore, if

there is a leak of brake fluid in the brake fluid line or brake cylinder, the brake system

will not have enough pressure to perform the deceleration. When a serious leak occurs,

the brake fault light will light up to warn you and the vehicle will not be safe to operate in this condition.

Check the brake fluid tank, if the oil level is too low, it means there is a serious brake

fluid leak, need to check the entire brake system to find out where the leak is and fix it.

Leaks have many causes, but if the brake fluid level is too low, it means that the rubber

seal in the brake system is broken or the oil line is rusty.

Figure 4: Brake fluid in hydraulic drive

The brake lines are made of copper and can corrode quickly in some special places,

after a period of time will wear out and have poorer quality than other places on the oil

pipe, so the brake fluid will leak. rust and the vehicle may lose its brakes. 7

If the brake pedal is not effective, there may be air in the system. At this time, it is

necessary to vent the brake system to remove air bubbles. Sometimes it can also be

because the piston inside the master cylinder is damaged.

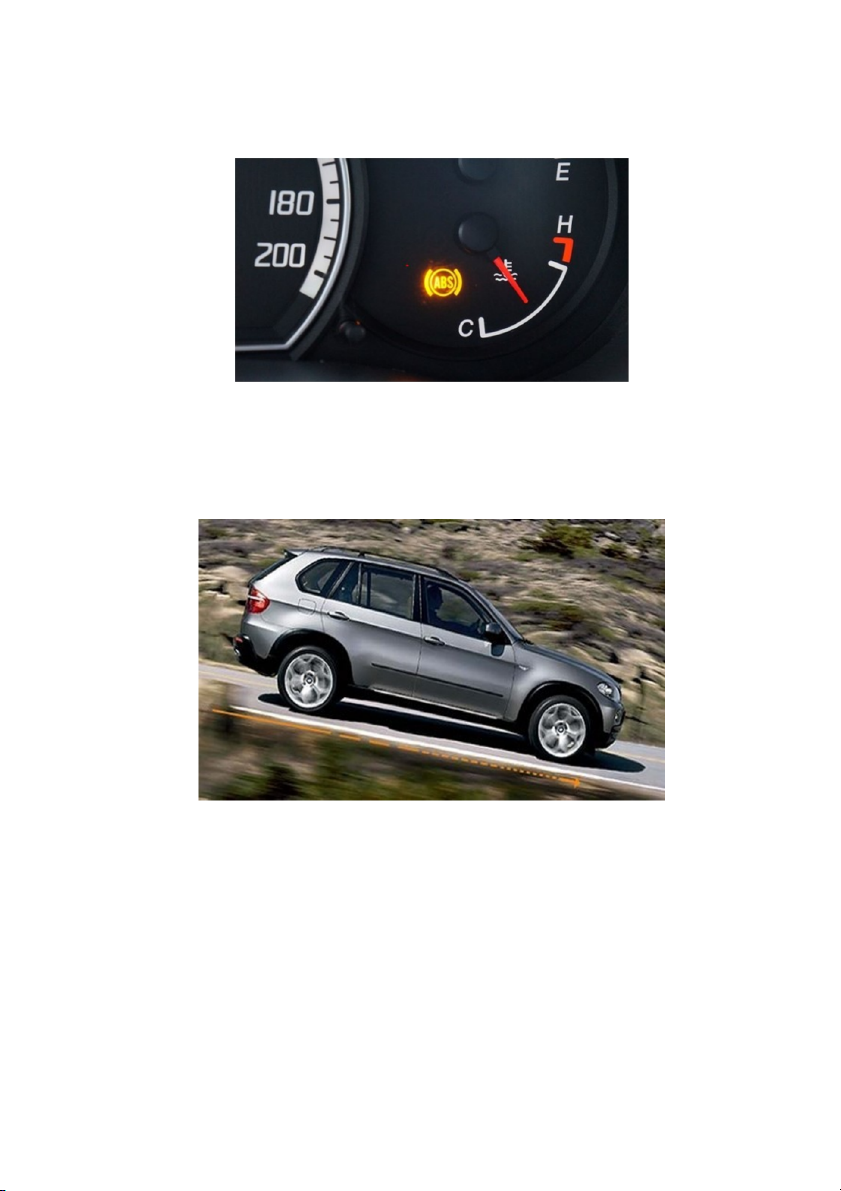

Figure 5: Low oil pressure indicator light

Another possible cause of brake failure is a faulty ABS controller. Due to the leak, the

internal pressure drops and the brake pressure cannot be transferred when the brake is

applied. Contamination inside the brake fluid can also enter the control unit and prevent

the intake and exhaust valves from opening and closing, causing the brakes to fail. 8

Figure 6: When the ABS controller fails, the light will warn

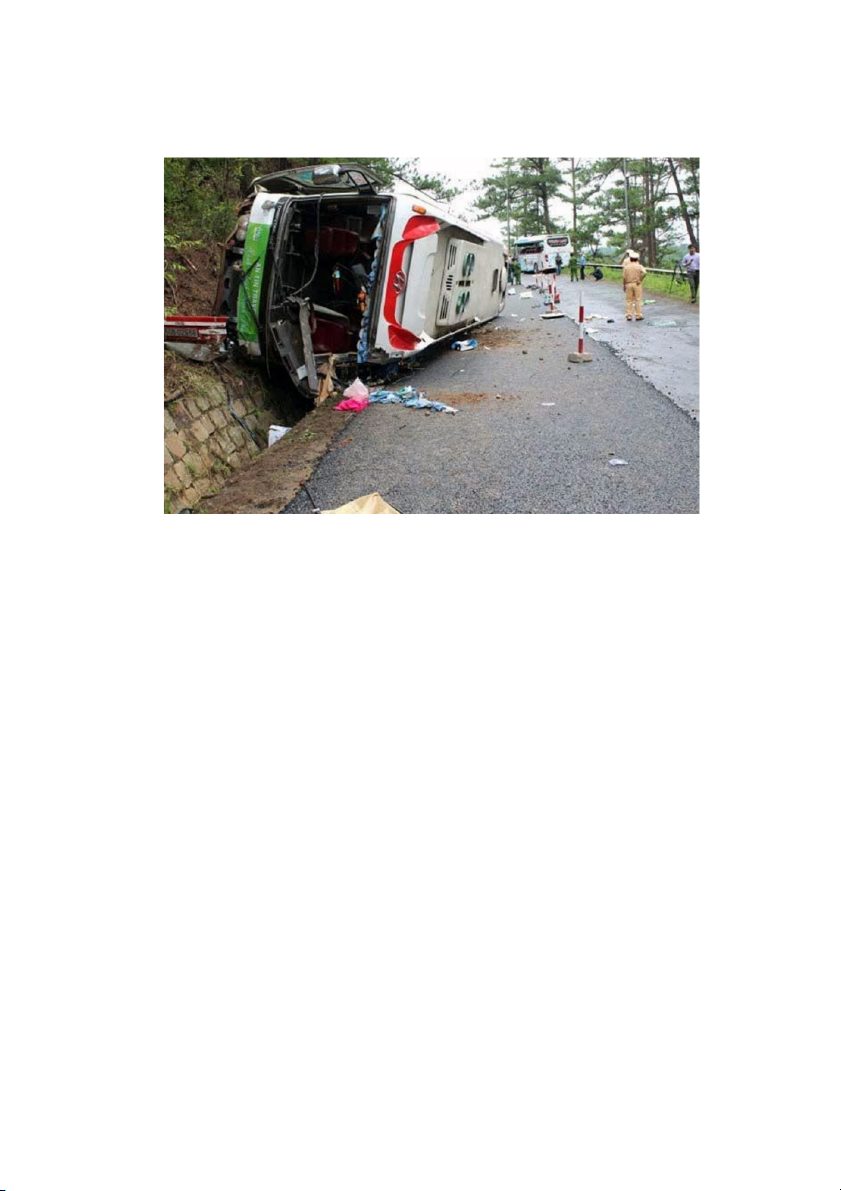

The cause of brake failure can also be caused by the driver, that is, pressing the brakes

continuously for a long time (usually when the vehicle is going downhill on a pass)

causes the brake pads to burn, leading to ineffective braking. To avoid this, the driver

should not apply the brakes for a long time, instead can use the engine to reduce the

vehicle's speed (by engaging in low gear).

Figure 7: The car goes downhill on the pass 9 4.2 Consequences

Some unexpected accidents related to brake failure, loss of control

Figure 8: The bus lost its brakes and rolled many motorbikes at the red light 10

Figure 9 : Passenger car lost the brake

The brake is the part that helps the vehicle decelerate to reduce motion. However, after

many accidents, the question often arises, why does the brake lose its effect? Is it

because of the driver or the quality of the car?

In theory, the car may not be properly maintained, have technical errors such as lack of

brake fluid, full oil in the master cylinder, broken wheel axles, gas entering the brake

fluid... leading to brake failure. do not eat or lose the effect completely.

But for drivers, the habit of going downhill or going up a high pass, the driver checks

the brakes incorrectly, goes downhill and drifts the throttle... to slow down is extremely

dangerous. This causes the brake pads and brake fluid to heat up. High temperatures can

soften the gasket at the master cylinder, allowing brake fluid to escape when the driver

applies the brake. This causes the braking system to lose its effect or in other words, lose the brakes.

To solve this problem, first of all, we need to understand the operating principle,

structure of details and parts in the brake system. Thereby creating a premise for the

design and improvement of the brake system to increase braking efficiency, increase 11

directional stability and guideability when braking, increase working reliability for the

purpose of ensuring movement safety and increasing safety. vehicle performance. It is

for these reasons that I have chosen this topic.

CHAPTER II: INTRODUCE ABOUT HONDA CIVIC 2020

1. The Overall of Honda Civic 2020

In the Vietnamese market, the Honda Civic model right after its launch has always

received positive feedback from consumers. Over 10 generations, this small sports C-

class sedan has quickly entered the list of Top 10 best-selling cars of all time, Honda

Civic has become a typical representative of Honda, in terms of agility, in terms of

flexibility and especially in terms of reliability.

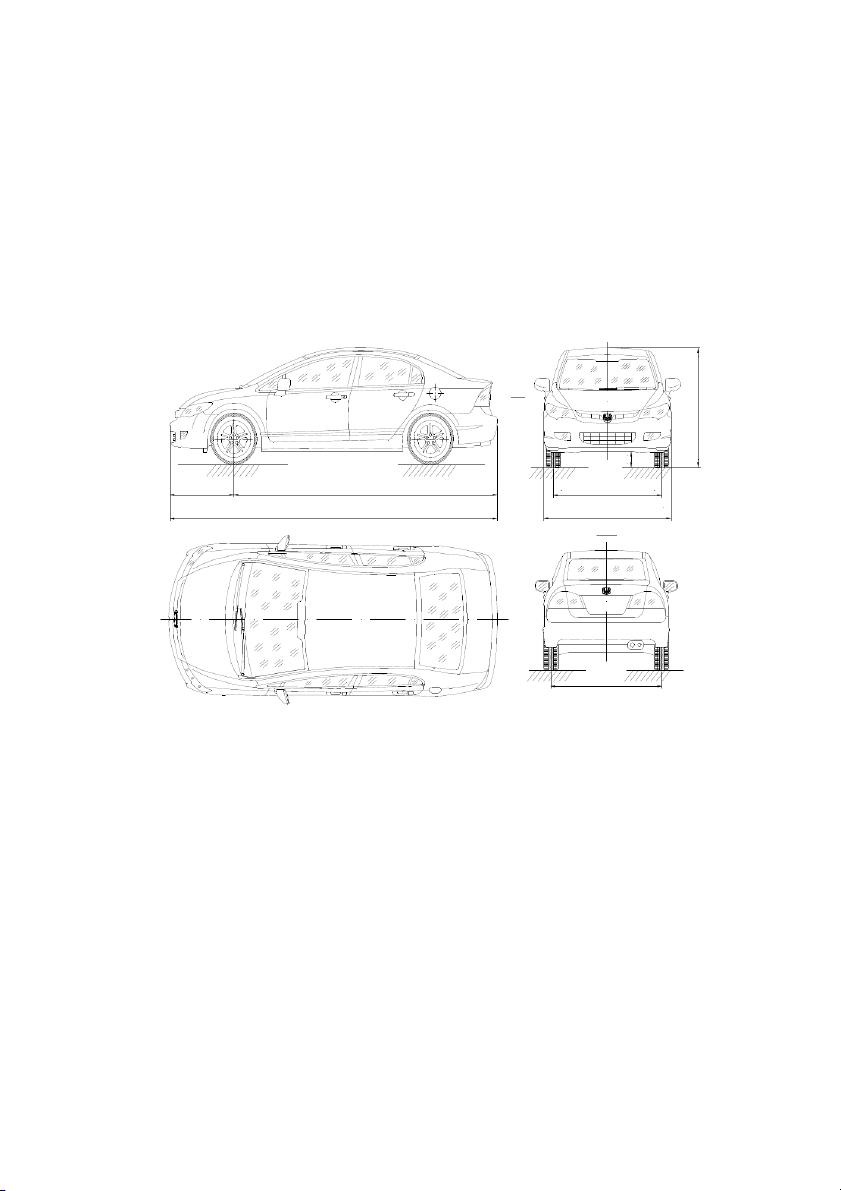

Figure 10: The exterior appearance of the Honda Civic 2020

Unconventional styling with solid lines but still emotional flexibility along with high-

class details, gives Civic a youthful, modern and sportier appearance than ever. In

particular, the aerodynamic design style also helps to complete the fuel efficiency and quietness of the cabin. 12

This is the most spectacular makeover ever of this small sedan. With an all-new

fastback design, the most powerful turbo engine in the segment, and many safety-

driving assist technologies are notable points in this version.

In Vietnam, Honda Civic is being distributed with 03 versions, which are the standard

Civic 1.8E CVT with naturally aspirated gas, the turbocharged Civic 1.8G CVT and the

high-end Civic 1.5RS CVT Turbo. 2. Honda Civic Overview 2.1

Overview of Honda Civic cars A 6 41 1 33 1 974 2700 1537 4648 1799 Theo A 1553

Figure 11: Overall diagram of Honda Civic car 13

2.2 Technical characteristics of the vehicle

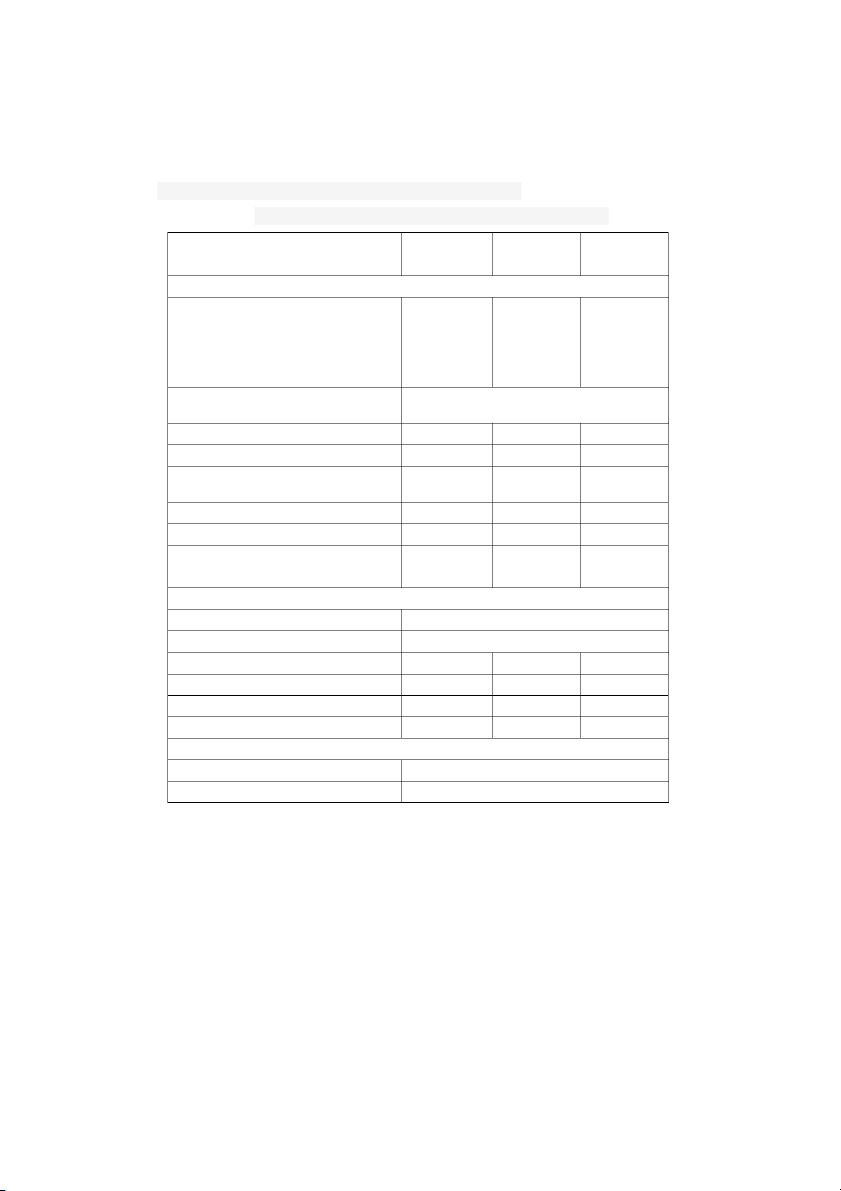

2.2.1 Honda Civic specifications are listed in the table 1

Table 1: Basic technical parameters of Honda Civic 2020 CIVIC 1.8 CIVIC 1.8 CIVIC1.5 CATEGORY E G RS TRANSMISSION ENGINE 1.8 SOHC i- 1.8 SOHC 1.5L VTEC i-VTEC DOHC ENGINE STYLE 4 cylinders 4 cylinders VTEC in line 16 in line 16 TURBO valves valves (CVT) EARTH DREAMS TRANSMISSION TECHNOLOGY Cylinder capacity (cm3) 1.799 1.799 1.498 Maximum power (Hp/rpm) 139/6.500 139/6.500 170/5.500 220/1.700- Maximum torque (Nm/rpm) 174/4.300 174/4.300 5.500 Fuel tank capacity (litre) 47 47 47 Fuel system PGM-FI PGM-FI PGM-FI Acceleration time from 1 to 10 10 8.3 100km/h (giây) SIZE/WEIGHT Length x Width X Height (mm) 4.648 x 1.799 x 1.416 The standard long (mm) 2700 Tire size 215/55R16 215/55R16 235/40R18 Lazang (inch) 16 16 18 Ground clearance (mm) 133 133 133 Minimum turning radius (m) 5.3 5.3 5.3 BRAKING SYSTEM Front brake Disc brake Rear brake Disc brake 2.2.2 Engine 14

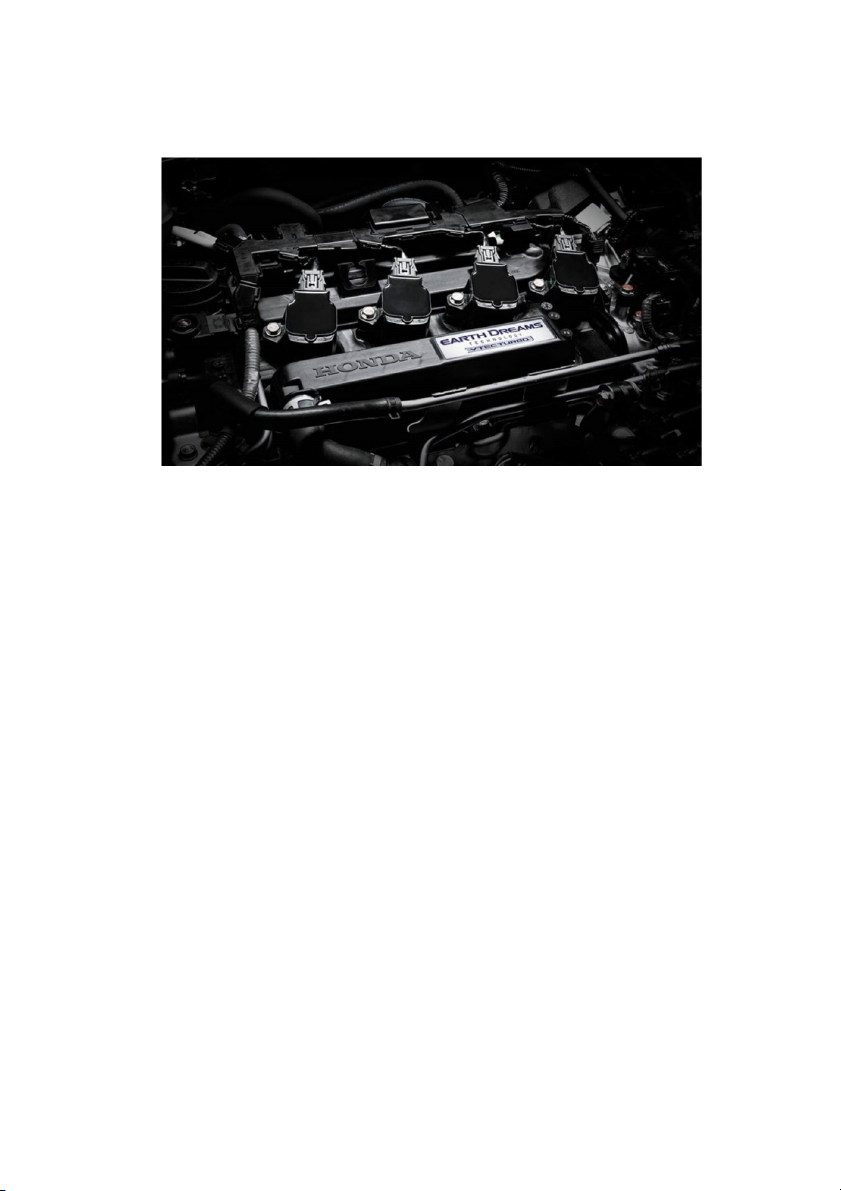

Figure 12: Engine on Honda Civic 2020

The first engine block equipped on the standard versions Civic 1.8E & Civic 1.8G is a

naturally aspirated 1.8 SOHC i-VTEC engine, 4 cylinders, 16 valves. This engine block

delivers a maximum power of 139 (hp) at 6,500 rpm (rpm), along with a maximum

torque of 174 (Nm) at 4,300 (rpm). Comes with a CVT automatic transmission using

Honda's Earth Dreams technology. In versions 1.8E & 1.8G naturally aspirated with

electronic fuel injection, Civic will own a maximum speed of 200 (Km/h), with

acceleration time from 0 - 100 (Km/h) within just 10 (seconds), a pretty impressive number.

The second engine block equipped on the two high-end Civic 1.5RS versions is the

famous 1.5L DOHC VTEC TURBO turbocharged engine of the 10th generation. The

maximum power that this machine brings is 170 (hp). at 5,500 rpm (rpm), maximum

torque is 220 (Nm) at 1,700 - 5,500 rpm (rpm). This Honda Civic 1.5RS version is

supported by CVT gearbox, Earth Dreams Technology application. Like the 1.8E and

1.8G versions, the 1.5RS version has a maximum speed of 200 (Km/h), but with faster

acceleration, from 0 to 100 (Km/h) only takes 8.3 (seconds), an impressive number.

VTEC TURBO is a new generation of Honda's breakthrough turbocharged engine that

helps the car achieve two factors simultaneously: strong performance and outstanding

fuel economy - Overcoming the disadvantages of traditional turbocharged engines when 15