Preview text:

Automatic transmission 9G-TRONIC 725.0 System description

– This printout will not be recorded by the update service. Status: 06 / 2013 – Mercedes-Benz Service System description

Automatic transmission 9G-TRONIC 725.0

Daimler AG · Technical Information and Workshop Equipment (GSP/OR) · D-70546 Stuttgart System description A

| utomatic transmission 9G-TRONIC 725.0 1

– This printout will not be recorded by the update service. Status: 06 / 2013 – Information and copyright Product Portfolio

You can also find comprehensive information

on our complete product portfolio in our Internet portal:

Link: http://aersales.mercedes-benz.com Questions and suggestions

If you have any questions or suggestions concerning

this product, please write to us.

Email: customer.support@daimler.com Fax: +49 (0) 69-95 30 73-76 © 2013 by Daimler AG

This document, including al its parts, is protected by copyright. Any further processing or use requires the previous written consent of Daimler AG,

Department GSP/OR, D-70546 Stuttgart. This applies in particular to reproduction, distribution, alteration, translation, microfilming

and storage and/or processing in electronic systems, including databases and online services.

Image no. of title image: P27.00-2391-00

Image no. Poster: P27.10-2501-00

Order no. of this publication: HLI 000 000 12 33 2 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 – Contents Preface 4 Overall system Overview 5 Sectional view 6 Block diagram 8 Technical data 10 Hydraulic diagram 11 Subsystems Electrohydraulic control 13

Shi valve housing and valve block 17 Cover/shi valve housing 18 Rpm sensor system 19 Power transmission/power flow 21 Upshi and downshi 23 Oil supply 24 Driver information 26 Limp-home mode 28 System components Torque converter 29

Torque converter lockup clutch 31 Planetary gear set 32 Multidisk clutch 34 Multidisk brake 35 Park pawl 36 Park pawl control 38 Transmission oil cooling 43

Electric transmission oil pump 44 Oil pan and oil filter 46 Service Information Flashing 47 Special tools Special tools 48 Questions and answers

Questions about the 9G-TRONIC 725.0 automatic transmission 50 Annex Abbreviations 52 Index 53 System description A

| utomatic transmission 9G-TRONIC 725.0 3

– This printout will not be recorded by the update service. Status: 06 / 2013 – Preface Dear Reader,

The system description provides initial information about the

This system description presents the new automatic trans-

new automatic transmission 9G-TRONIC 725.0. The system

mission 9G-TRONIC 725.0. The purpose of this brochure

description is not stored in this form in WIS. The contents

is to acquaint you with the technical highlights of this new

of this brochure are not updated. No provision is made for

transmission in advance of its market launch. This brochure supplements.

is intended to provide information for people employed in

service or maintenance/repair as wel as for aer-sales staff.

We wil publicize modifications and new features in the re-

It is assumed here that the reader is already familiar with the

levant WIS documents. The information presented in this

Mercedes-Benz transmissions currently on the market.

system description may therefore differ from the more up-to-

date information found in the WIS.

In terms of the contents, the emphasis in this system de-

scription is on presenting new and modified components and

Al of the information relating to specifications, equip- systems.

ment and options are valid as of the copy deadline in June

2013 and may therefore differ from the current production

This system description is not intended as an aid for repairs configuration.

or for the diagnosis of technical problems. For such needs,

more extensive information is available in the Workshop Infor-

mation System (WIS) and Xentry Diagnostics. Daimler AG

WIS is updated continuously. Therefore, the information

Technical Information and Workshop Equipment (GSP/OR)

available there reflects the latest technical status of our vehicles. 4 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 – Overview ystem

The automatic transmission 9G-TRONIC 725.0 is an entirely

An increased service life, reduced fuel consumption and ma- rall s

new electronical y control ed automatic transmission with 9

ximum shi comfort are achieved through: ve

forward gears and one reverse gear. The ratios for the gear O

stages are achieved by planetary gear sets. Al the transmis- spread of 9

sion functions and control components for this automatic

transmission are combined in one assembly module. The ful y

integrated transmission control er unit located in the automa-

tic transmission al ows the number of interfaces to the wiring

ditional comfort and dynamic functions

harness in the vehicle to be minimized.

The use of the new ful y integrated transmission con-

The transmission can be subdivided into the fol owing

trol (VGS) system also provides the fol owing additional assemblies: advantages:

dulum and torque converter lockup clutch

influence between various electronic components)

generating the required oil pressure and for guaranteeing

the on-board electrical system, resulting in increased shi

lubrication of shi elements and bearing points quality

red oil pressure and for guaranteeing lubrication of shi

values and quicker evaluation of these measurement

elements and bearing points with the engine off and for values supporting the primary pump

ponents (planetary gear sets, electrohydraulical y actua-

ted park pawl, multidisk clutches and multidisk brakes)

ted ful y integrated transmission control unit Model series Model Engine Transmission Market launch E 350 BlueTEC 212.026 642.852 725.011 09/13 E 350 BlueTEC 212.226 642.852 725.011 09/13 System description A

| utomatic transmission 9G-TRONIC 725.0 5

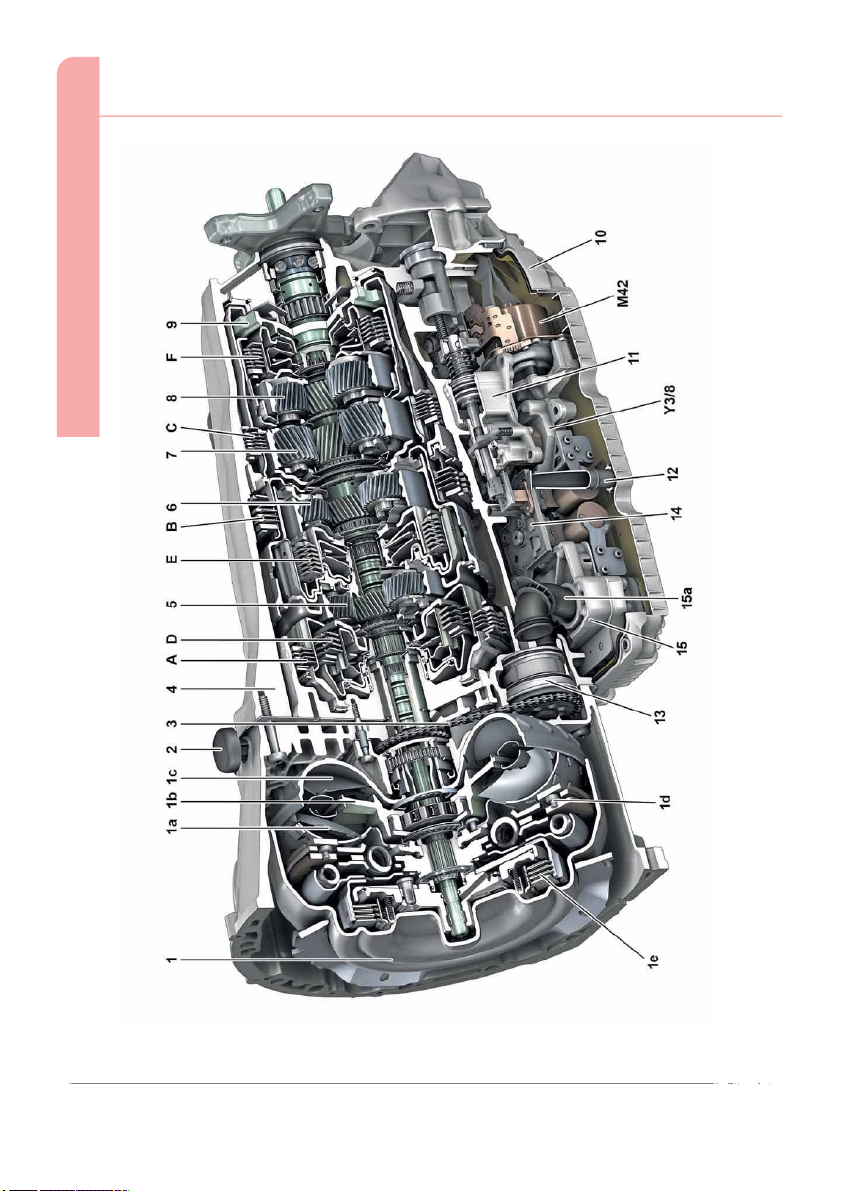

– This printout will not be recorded by the update service. Status: 06 / 2013 – Sectional view ystem rall s P27.10-2467-00 ve O 6 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 – Sectional view ystem rall s ve O il 08 05 06 81 38 27 ion o ransmis- nit rake B rake B rake B lutch K lutch K lutch K ransmiss roler u egrated t ont ultidisk b ultidisk b ultidisk b ultidisk c ultidisk c ultidisk c M M M M M M Electric t pump Fuly int sion c 42 A B C D E F M Y3/8 l S G ipes over ckup lec- aw f V ousing atic ulum hain ake p ousing ousing et 1 et 2 et 3 et 4 for e ark p erter c end erter lo alve h n h n h ody o int ear v utom rive c ear s ear s ear s ear s b heel nd d l g i f a .0 5 onv onv w ousing ube o 2 tary g tary g tary g tary g aw eler rifugal p ilation ump an ump iew ator ent il p il p uide t il p pporting over/sh Torque c Turbine St Imp C Torque c clutch Transmissio vent O Transmissio Plane Plane Plane Plane Park p O Piston h trohydraulic p actuation G O Su C Pressure a ission 7 ional v ct Se transm 1 1a 1b 1c 1d 1e 2 3 4 5 6 7 8 9 10 11 12 13 14 15 15a System description A

| utomatic transmission 9G-TRONIC 725.0 7

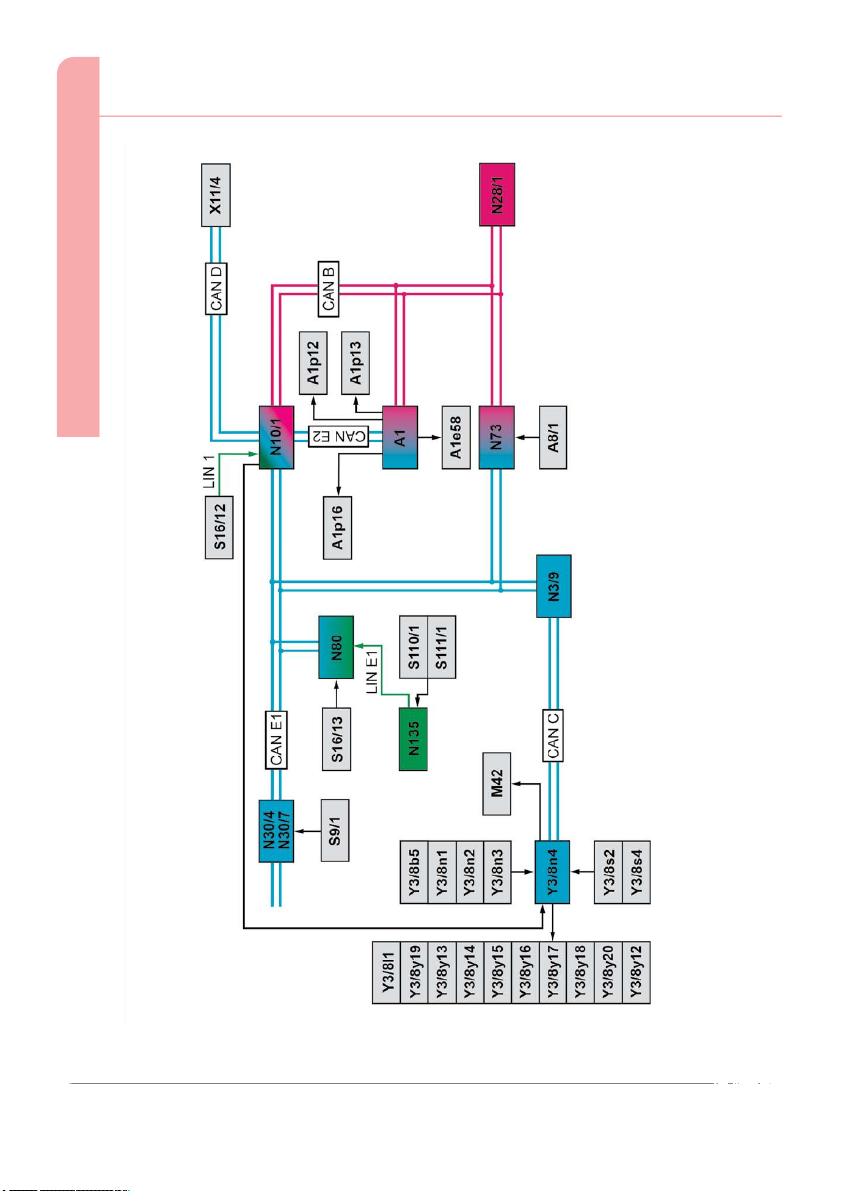

– This printout will not be recorded by the update service. Status: 06 / 2013 – Block diagram ystem rall s P27.19-2626-00 ve O 8 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 – Block diagram ystem rall s ve O o- o- rol s rol s olenoid ckup ont ont id rake c rake c erter lo ressure s 05 06 p onv oleno id B id B ultidisk b ultidisk b orking leno leno clutch s y17 M y18 M y19 W y20 Torque c Y3/8 Y3/8 Y3/8 Y3/8 o- 81 38 27 o- pm utton sion nshi ensor pera- ensor rol s ube m s ensor lectronics e b lever ow pshi ctor sion r ransmis- em ont r pm olenoid K olenoid K olenoid K nit itch T olenoid pm s nit il t w ressure ransmis n mod onne s r n o osition s rol s rol s rol s olumn t heel e LEC heel d heel u enso r p rake c c rol u w ht s l li heel r rol u l p tic t w w ransmis ha egrated t ont ont ont 08 ont T SE stic c aw w l t r ont enso aw id EC id B eering utoma IR eering eering iagno erna utput s lutch c lutch c lutch c ultidisk b St dule c Steering rake lig B A transmissio D St button St button D Pressure s Park p Turbine Int senso O Fuly int sion c Transmissio ture s Park p soleno leno 2 3 b5 l1 n1 n2 n3 n4 s2 s4 y12 Lubricating y13 C y14 C y15 C y16 M 80 135 /1 6/1 6/1 10/1 11/1 11/4 N N S9 S1 S1 S1 S1 X Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 ith on- il ith isplay S) nit w rogram ode tability IC ck c IN ontrol LU N de d ion o 50 (Trailer nit (w l L P O rol u odule sis indicator isplay N ion c E 5 IC ion lo luster ey N A A 1 2 ane nit ont D ability P N rol u ISTR nit c n mo O N N N p c O (except c lectronic S ont nt IN elay m St ig iagno A A icator tion d ter k A nt L ransmiss rol u M r nit d rain C stic C ecognit ISTR m E ont ith C SA nd nit rume ine rume rol u I c (w S) ear ind ultifunc erior C rive t iagno hassis C hassis C eering D Inst Eng lamp G M Transmissio Transmit Int D D C C Inst St Electric t pump C Front fuse a Trailer r unit hitch)) Electronic cont (233) D Premiu Program c code (233) D PLU Electronic trol u iagram d 1 2 B C D E E 1 N N N N N 1 E lock A A A A A 42 3/9 10/1 28/1 30/4 30/7 73 B 1 1e58 1p12 1p13 1p16 8/1 A A A A A A C C C C C LIN LIN M N N N N N N System description A

| utomatic transmission 9G-TRONIC 725.0 9

– This printout will not be recorded by the update service. Status: 06 / 2013 – Technical data ystem rall s ve Automatic transmission Unit 725.011 O Designation W9A 700 Shi mechanism 9-speed, automatic Number of ratios 9+R Gear ratio spread 9.150

Weight of automatic transmission (including kg 94.8 (with OM 642)

torque converter and transmission oil)

Automatic transmission fluid (yel ow/gold) l approx. 10 GTL Max. rpm 1st to 7th gear rpm 7000 8th gear rpm 5900 9th gear rpm 5000 Overal length mm

644...649 depending on joint flange and torque converter Starting device Hydraulic torque converter Max. input torque Nm 700 Transmission ratio A (B08) ¹ B (B05) ² C (B06) ³ D (K81) ⁴ E (K38) ⁵ F (K27) ⁶ 1st gear 5.503 2nd gear 3.333 3rd gear 2.315 4th gear 1.661 5th gear 1.211 6th gear 1.000 7th gear 0.865 8th gear 0.717 9th gear 0.601 Neutral position "N" - Reverse gear "R" -4.932 ¹ Multidisk brake B08 ² Multidisk brake B05 ³ Multidisk brake B06 ⁴ Multidisk clutch K81 ⁵ Multidisk clutch K38 ⁶ Multidisk clutch K27 10 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 – Hydraulic diagram ystem rall s P27.00-2392-00 ve O System description A

| utomatic transmission 9G-TRONIC 725.0 11

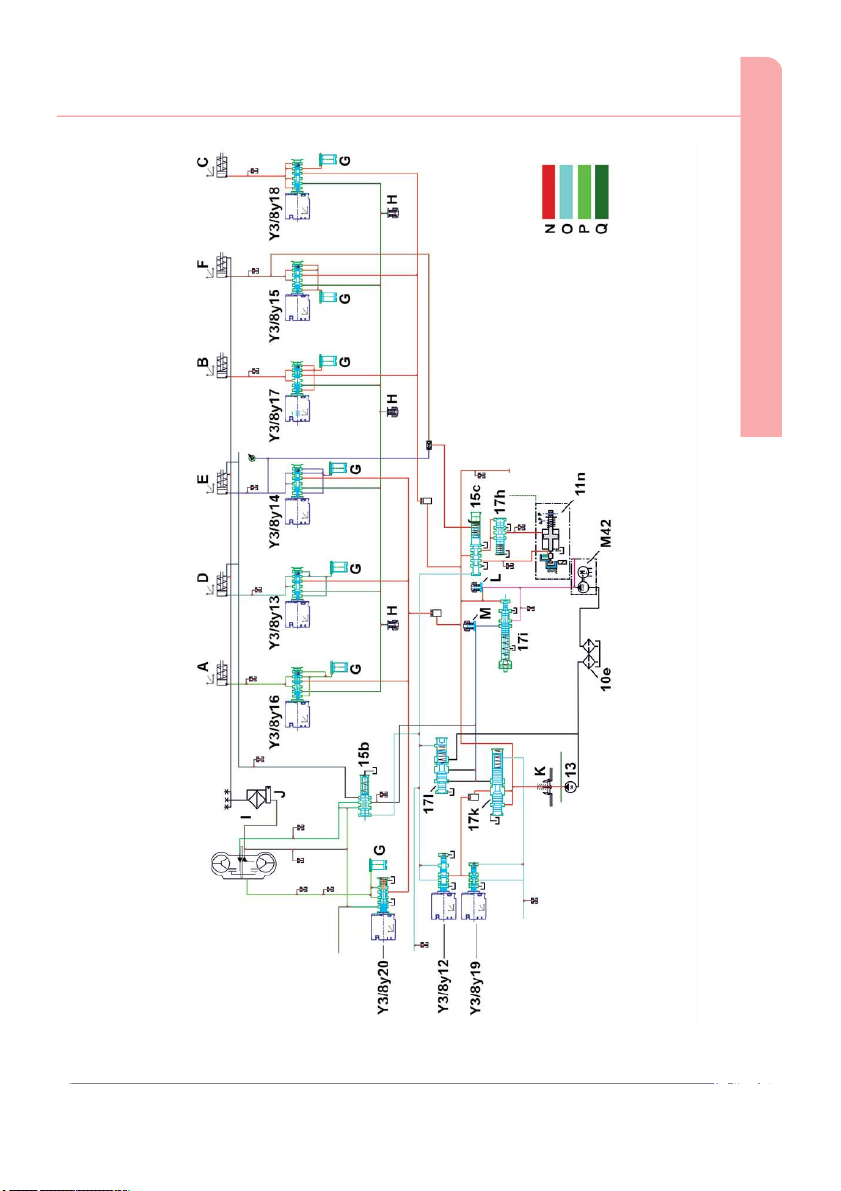

– This printout will not be recorded by the update service. Status: 06 / 2013 – Hydraulic diagram ystem rall s ve O 81 38 27 o- o- o- il rol s rol s rol s olenoid ckup ion o olenoid K olenoid K olenoid K ont ont ont ressure ressure id p p rol s rol s rol s rake c rake c rake c erter lo ransmiss ressure s ont ont ont 08 05 06 p onv oleno ressure id p id B id B id B i lutch c lutch c lutch c ultidisk b ultidisk b ultidisk b orking Lubricating Sh Electric t pump soleno leno leno leno clutch s y12 Lubricating y13 C y14 C y15 C y16 M y17 M y18 M y19 W y20 Torque c 42 P Q M Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 Y3/8 hi egula- ostat atic p p egulating alves heck an 81 38 27 um um egulating 08 05 06 v herm lectric lectric utom il p alve ooler il t dule v il p il p ressure s ressure r f a o alve ark r p p rake B rake B lutch K n c n o n o n o o v hi rake B lutch K lutch K olding .0 nd l mo ressure r ressure c ressure ressure 5 hi ot P p p alve to e alve to e p 2 aw ump ark s alve er v rol p iagram il filter a il p oost s ot P orking ultidisk b ultidisk b ultidisk b ultidisk c ultidisk c ultidisk c amp orking heck v heck v orking ont O Park p O B Park/N valve N Lubricating valve W valve Lubricating ting M M M M M M D Pressure h Transmissio Transmissio W valve C transmissio C transmissio W C ission 7 ydraulic d H transm 10e 11n 13 15b 15c 17h 17i 17k 17l A B C D E F G H I J K L M N O 12 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 – Electrohydraulic control s

Fully integrated transmission controller unit

Special features of fully integrated transmission ubsystem

The ful y integrated transmission control er unit is connected controller unit S

to the CAN network of the vehicle and evaluates the inco-

The automatic transmission was conceived as a compact

ming signals and requests from other control units, actuating

transmission unit for north-south instal ation. Particular at-

the internal actuators accordingly depending on this informa-

tention was paid to ensuring that al components which are

tion. It also evaluates the signals of the sensor system and

involved in the gearshi, lubrication and control processes

forwards them to the associated control units.

are integrated in the transmission.

The ful y integrated transmission control unit actuates the

The special features of the ful y integrated transmission con-

fol owing actuators and/or performs the fol owing functions trol er unit are:

depending on the sensor and CAN input signals:

grated transmission control er unit

pressure and position sensors) is part of the ful y integra-

ted transmission control er unit

in the ful y integrated transmission control er unit

System description | Automatic transmission 9G-TRONIC 725.0 13

– This printout will not be recorded by the update service. Status: 06 / 2013 – s Electrohydraulic control ubsystem

Shi pressure, lubricating pressure and working Shi pressure S pressure

The shi pressure (oil pressure in the multidisk clutch or mul-

The oil pressures are separated into:

tidisk brake) is derived from the working pressure.

The respective solenoid influences the position of the asso-

ciated regulating valve. In turn, the position influences the oil

pressure prevailing in the multidisk brake or multidisk clutch.

The shi pressure thus depends on the geometry of the res- Working pressure pective regulating valve.

The oil pressure produced by the primary pump is converted

into working pressure by the working pressure regulating Electric transmission oil pump valve.

The electric transmission oil pump provides the hydraulic

The level of working pressure depends on the position of the

system's oil supply when the internal combustion engine is

regulating valve and therefore on its geometry.

switched off. It is actuated through the ful y integrated trans- mission control unit.

The position of the working pressure regulating valve is influ-

enced by the working pressure solenoid to match the load

and gear. Al other oil pressures required for transmission

control are derived from the working pressures. Lubrication pressure

At the working pressure regulating valve excess oil is diverted

to the lubrication pressure regulating valve and from there

used in a regulated manner for lubrication and cooling of

mechanical transmission parts and the torque converter. In

addition, the oil pressure in the torque converter is limited via

regulation of the lubrication pressure. b Note

The actively control ed lubricating pressure reduction

function causes a reduction in drag and thus reduces fuel consumption. 14 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 – Electrohydraulic control s ubsystem S P27.60-3652-00

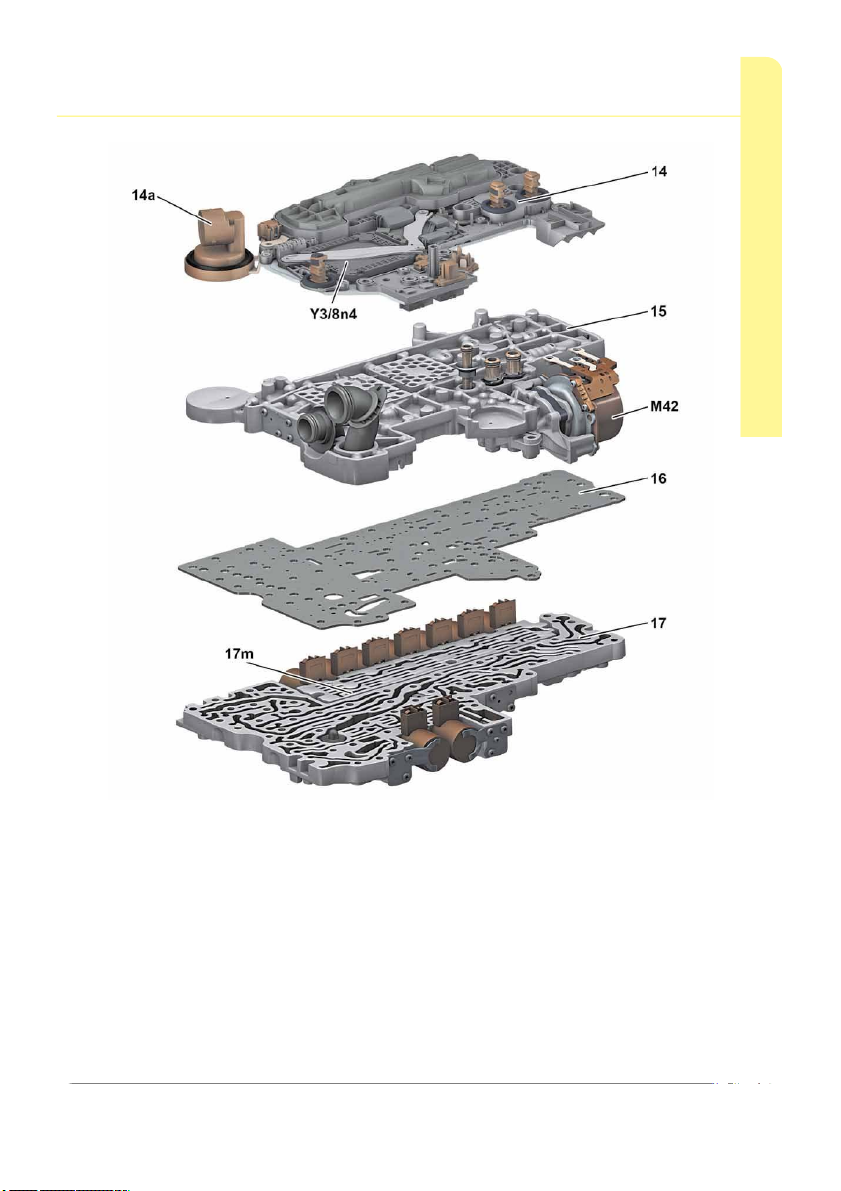

Exploded view of electrohydraulic actuator (EHS) 14 Supporting body of VGS 14a Transmission connector 15 Cover/shi valve housing 16 Intermediate panel 17 Shi valve housing 17m Valve block M42 Electric transmission oil pump Y3/8n4

Ful y integrated transmission control unit System description A

| utomatic transmission 9G-TRONIC 725.0 15

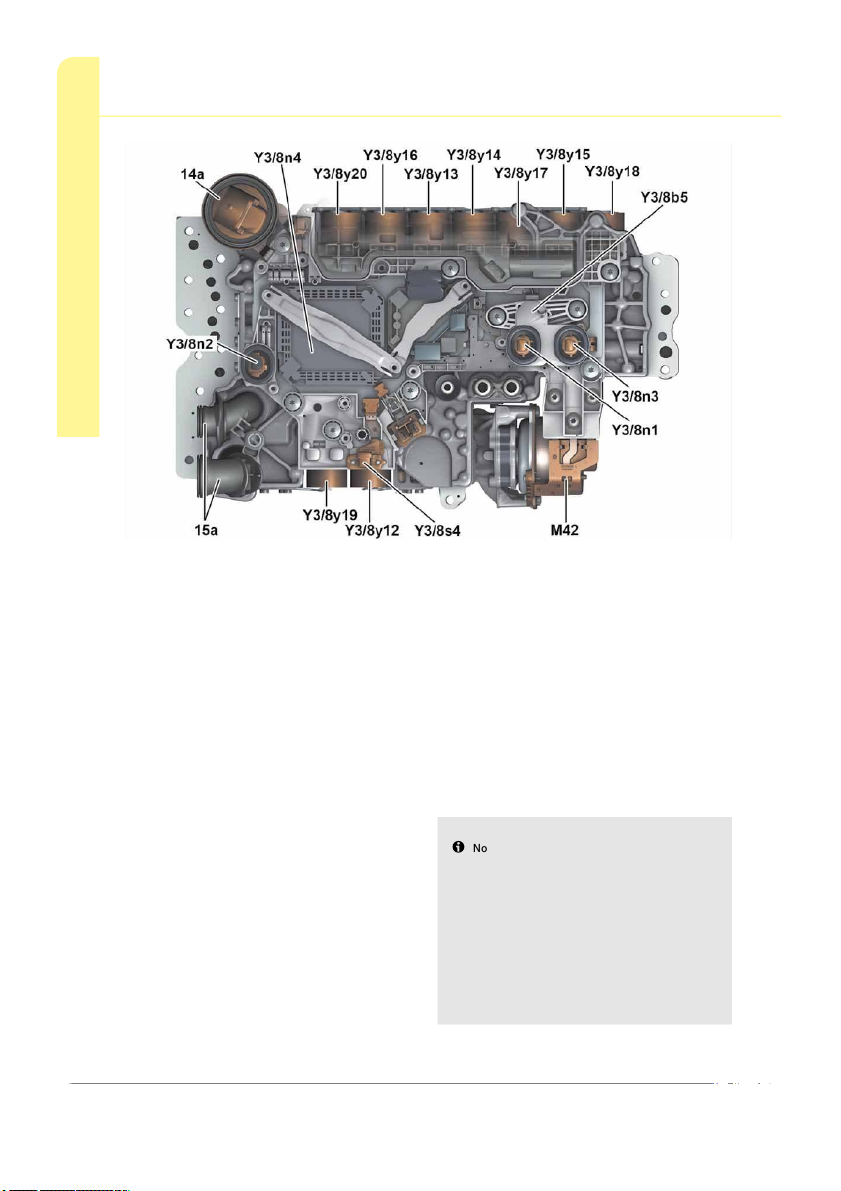

– This printout will not be recorded by the update service. Status: 06 / 2013 – s Electrohydraulic control ubsystem S P27.19-2624-00 Components of EHS 14a Transmission connector Y3/8y13 Clutch control solenoid K81 15a Pressure and intake pipes Y3/8y14 Clutch control solenoid K38 M42 Electric transmission oil pump Y3/8y15 Clutch control solenoid K27 Y3/8b5 Pressure sensor Y3/8y16

Multidisk brake control solenoid B08 Y3/8n1 Turbine wheel rpm sensor Y3/8y17

Multidisk brake control solenoid B05 Y3/8n2

Internal transmission rpm sensor Y3/8y18

Multidisk brake control solenoid B06 Y3/8n3 Output sha rpm sensor Y3/8y19 Working pressure solenoid Y3/8n4

Ful y integrated transmission control unit Y3/8y20

Torque converter lockup clutch solenoid Y3/8s4 Park pawl position sensor Y3/8y12 Lubricating pressure solenoid b Note

The rpm sensors are permanently connected to the

ful y integrated transmission control er unit and can- not be replaced individual y. 16 System description A

| utomatic transmission 9G-TRONIC 725.0

– This printout will not be recorded by the update service. Status: 06 / 2013 –

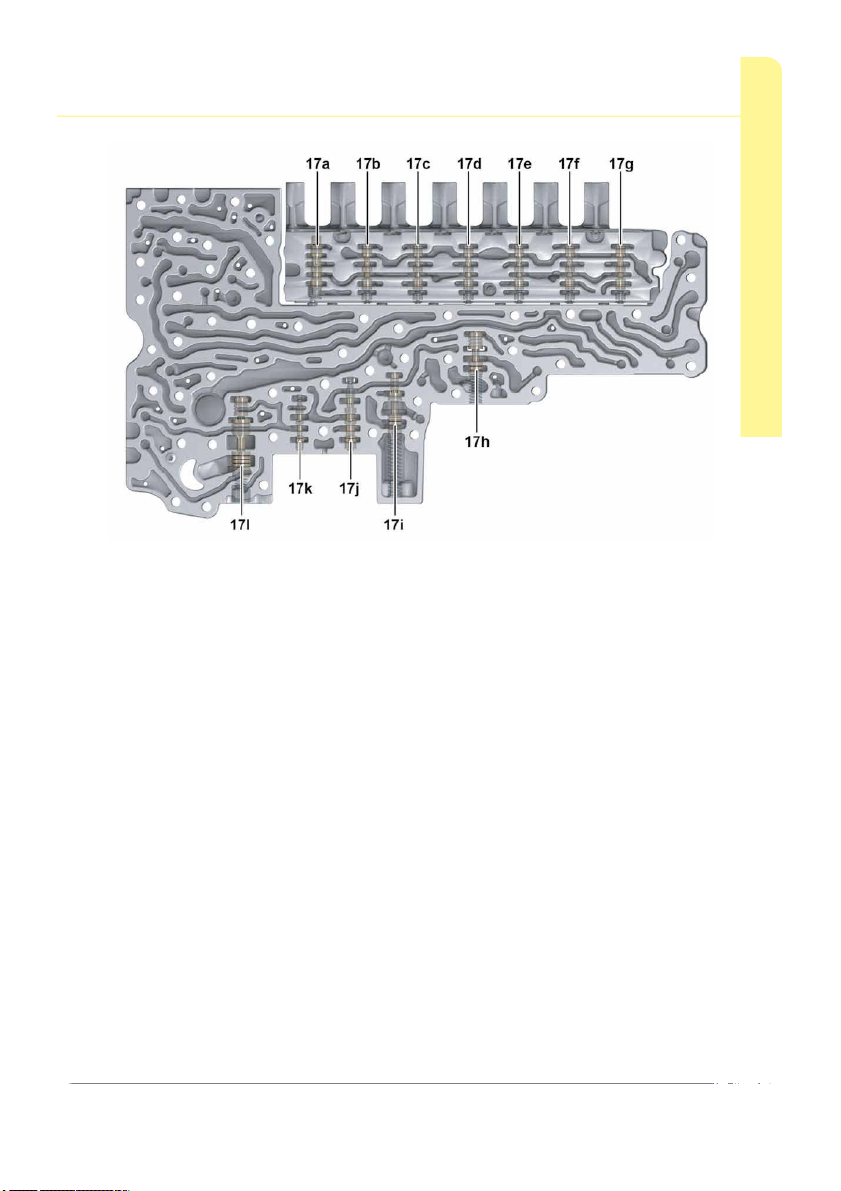

Shi valve housing and valve block s ubsystem S P27.35-2013-00 Shi valve housing 17a WÜK regulating valve 17g Brake regulating valve B06 17b Brake regulating valve B08 17h Not Park shi valve 17c Clutch regulating valve K81 17i

Lubricating pressure shi valve 17d Clutch regulating valve K38 17j

Lubricating pressure solenoid regulating valve 17e Brake regulating valve B05 17k

Working pressure regulating valve 17f Clutch regulating valve K27 17l

Lubricating pressure regulating valve System description A

| utomatic transmission 9G-TRONIC 725.0 17

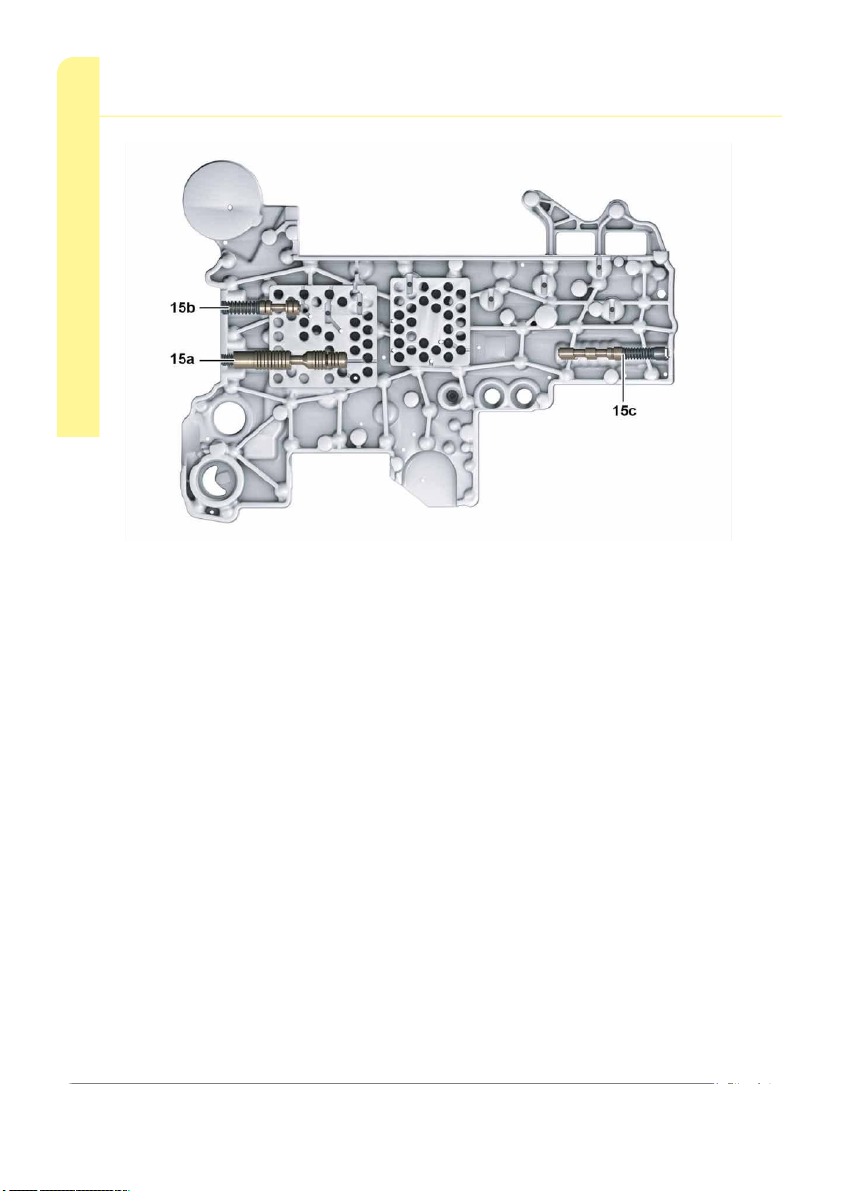

– This printout will not be recorded by the update service. Status: 06 / 2013 – s Cover/shi valve housing ubsystem S P27.10-2468-00 Cover/shi valve housing 15a

Working pressure regulating valve 15b

Boost shi valve (supports centrifugal oil cover fil ing) 15c Park/Not Park shi valve 18 System description A

| utomatic transmission 9G-TRONIC 725.0

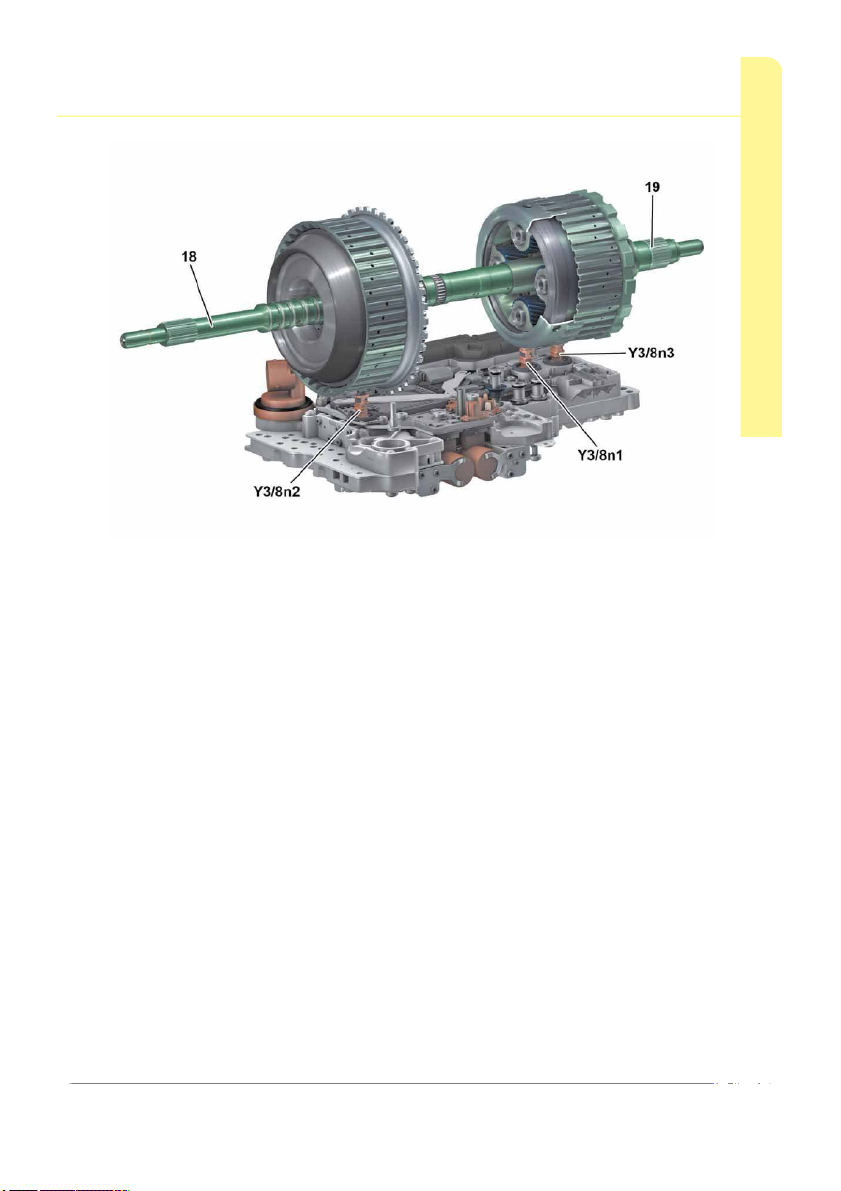

– This printout will not be recorded by the update service. Status: 06 / 2013 – Rpm sensor system s ubsystem S P27.19-2625-00 Rpm sensors 18 Drive sha Y3/8n2

Internal transmission rpm sensor 19 Output sha Y3/8n3 Output sha rpm sensor Y3/8n1 Turbine wheel rpm sensor System description A

| utomatic transmission 9G-TRONIC 725.0 19

– This printout will not be recorded by the update service. Status: 06 / 2013 –