Preview text:

2010 International Conference on Measuring Technology and Mechatronics Automation

Braking Force Distribution Strategy for HEV Based on Braking Strength

Liang Chu, Mingli Shang, Yong Fang, Jianhua Guo, Feikun Zhou

State Key Laboratory of Automobile Dynamic Simulation, Jilin University, Changchun, 130025, P.R. China shangmingli@foxmail.com

Abstract—The possibility of recovering vehicle kinetic energy

maximizing the recovery of braking energy, using the

is one inherent advantage of hybrid electric vehicle (HEV).

braking strength sub-design method to design the

Due to the introduction of electric regenerative braking, the distribution strategy.

structure, design and control of a hybrid electric vehicle is

quite different from the pure mechanical braking of II. STRUCTURE AN D PRINCIPLE

conventional vehicles. In this paper, the decelerations of the

In this paper, the hybrid electric vehicle is equipped with

vehicle in typical urban driving cycles and the influences of

ESP system and motor, so the design of the braking system

regenerative braking have been investigated. The results

is different from the conventional vehicles.

provide strong supports to the design of the braking force

distribution strategy for the hybrid electric vehicle. This paper A. Structure

designs a deceleration sensitive braking force distribution

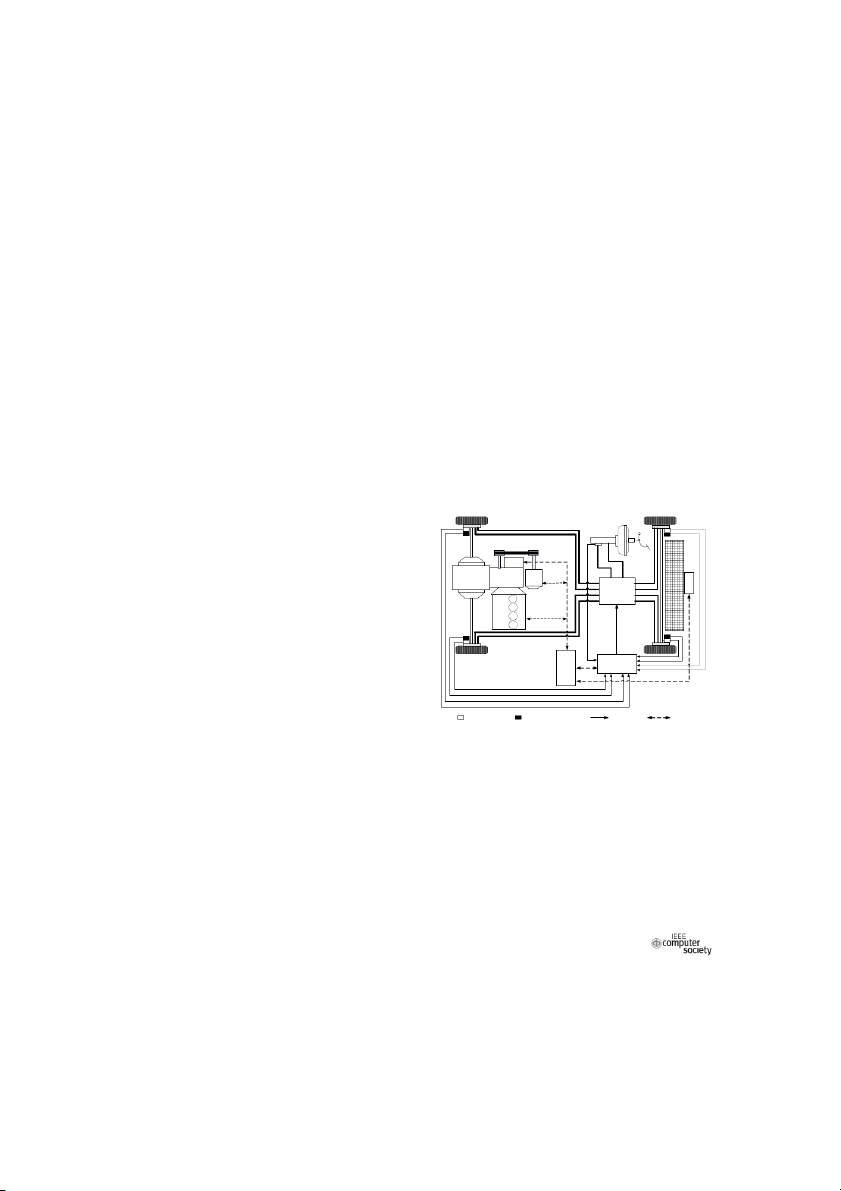

Figure 1 show the structure of the HEV this paper

strategy to distribute the desired total braking force to the

studied. The HEV is a front wheel driven vehicle. Motor is

front and rear axles. This strategy can recovery more braking

installed in the automatic transmission input axle. This

energy and can keep the vehicle more stable while the vehicle

structure increases the motor torque which acting on the

is braked. The proposed distribution strategy is tested through

the simulation, and the simulation results show the

wheels. The HEV which is studied is equipped with ESP.

distribution strategy is effective.

Compared with the original vehicle, the HEV braking

system only increases the vacuum pump and the pedal travel

Keywords-HEV; Braking force distribution; regenerative

simulator and the pressure sensors. Rest parts are unchanged.

braking; hybrid braking system; motor braking

This effective uses the existing systems and saves cost. I. INTRODUCTION

Almost half of the energy is dissipated in the brakes TC T U C

while a vehicle drives in heavy traffic [1]. Therefore, y C r AM A U T T mo m t o o t r o U

recovering braking energy is an effective approach for M tte a C B HC H U C

improving the energy efficiency of hybrid electric vehicle B [2]-[4].

The research and development activities on hybrid

electric vehicles have been mainly concentrated on the

drivetrain architectures, parametric design, drivetrain

control, modeling and simulation etc.[5]-[7] However, le ic U ES E P S _ P E _ C E U C h C

relatively less effort has been made on the research of the h e H V

braking system for hybrid electric vehicles, and publications

on this topic are much less than those for powertrain technology development. Speed sensor Pressure sensor Signal CAN bus

In braking system design for the HEV, two basic

concerns are: (1) properly applying braking force on front

Figure 1. Schematic structure of the hybrid vehicle

and rear axles to quickly reduce the vehicle speed, and

meanwhile, maintaining the vehicle traveling direction stable B. Basic principle

and controllable, (2) recovering the braking energy as much

The drivers’ braking force demand is calculated from the

as possible in order to improving the energy utilization

pedal stroke which is measured by the stroke sensor. Then efficiency [8].

under the braking force distribution strategy, we can

In this paper, the HEV is equipped with ESP system, and

calculate the motor braking force and hydraulic braking

the regenerative braking system of the HEV is utilized the

force. Via CAN communication, the demand of motor torque

ESP valve. This paper designs the regenerative braking

is sent to motor controller to achieve to recovery the braking

system structure of the HEV, and designs the braking force

force. Hydraulic braking force is achieved by controlling the

distribution strategy. By analyzing the driving cycles, as well

ESP valves. As the ESP valves have the fine adjustment

as the performance of the motor, designs the braking force

function, therefore, the HEV braking system is able to meet

distribution strategy. Fully taking into account the

the drivers’ dynamic braking demand needs.

contradiction between the drivers’ driving demand and

978-0-7695-3962-1/10 $26.00 © 2010 IEEE 759 DOI 10.1109/ICMTMA.2010.344

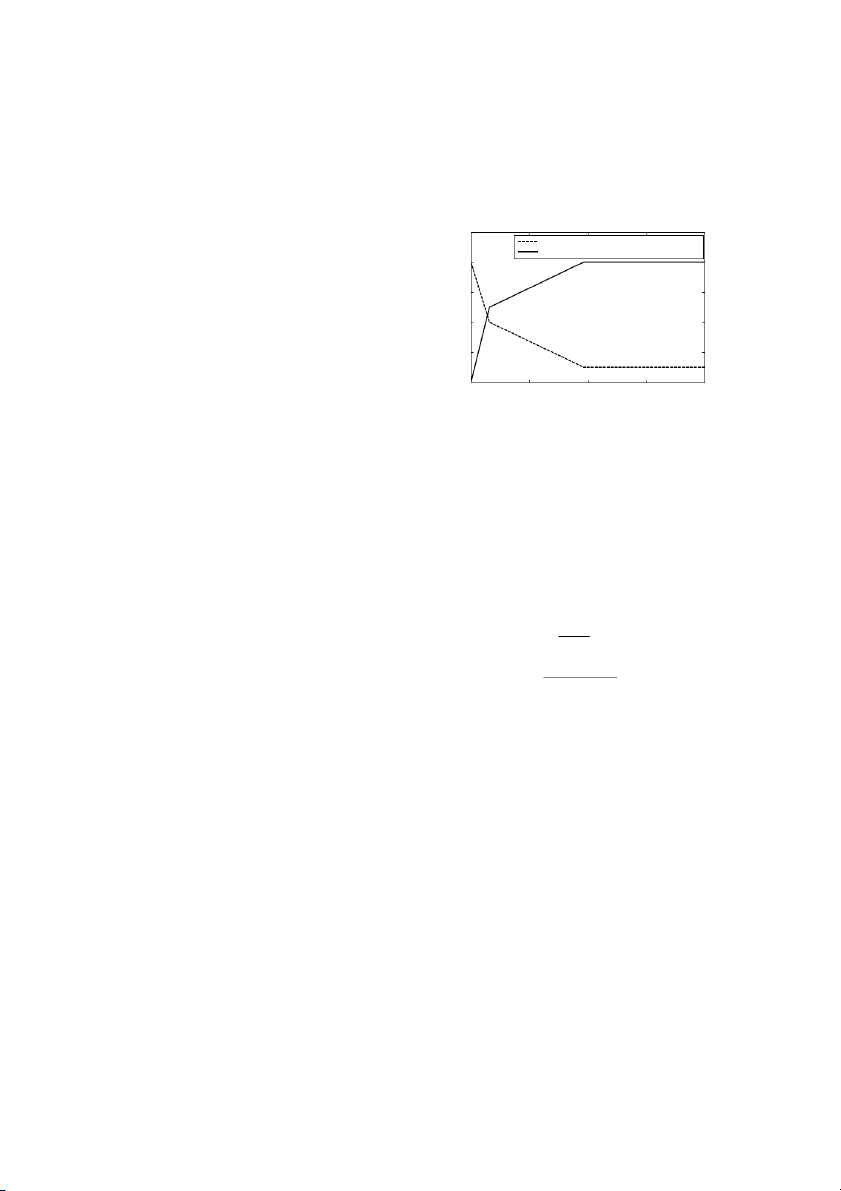

In hydraulic pressure control process, the vacuum pump 300 peak power torque

provides the required hydraulic pressure. The control of the rated torque

vacuum pump is based on the maximum front and rear axle peak power braking torque 200 rated braking torque

hydraulic pressure, this can reduce the ESP valves operation )

times and extend the ESP valves life. .m 100 (N

In the regenerative braking control process, the e u

regenerative braking strategy is in the vehicle controller, 0 rq

vehicle controller, ESP controller and motor controller via r to to

CAN to communicate each other and coordinate each system -100 o m to work well. -200

III. INFLUENCING FACTORS OF REGENERATIVE BRAKING -300 FORCE 0 1000 2000 3000 4000 5000 6000 7000 8000

The braking force distribution strategy is one most motor speed(r/min)

important thing of the braking system design of the hybrid

Figure 2. Characteristic of the PMSM

electric vehicle. Beginning the design the braking force

distribution, we need consider the influence factors of

The torque characteristic of the permanent magnet

regenerative braking. In this paper, we consider the

synchronous motor can be expressed as [5]:

performance of the motor and the battery. T ⎧ (ω ≤ ω ) max m b

A. Desired Braking Force ⎪ T = ⎨ P (5) m 9550

According to the definition of the braking strength [8], max (ω > ω ) ⎪ m b

the desired total braking force can be obtained. ⎩ ωm F = mzg (1) B

C. The Maximum Motor Braking Torque Determined by

Where, m is the vehicle mass in kg, z is the braking the Battery

strength, FB is the total braking force acting on the vehicle.

During the regenerative braking, the electric current

In this paper, by actually measures the braking pedal

which is generated by the motor is charged to the battery, so

travel, the relationship between the brake pedal travel and

the performance of the battery influences the maximum

the braking strength can be calculated by: motor braking force. z = k S (2) z

The relationship between the power, electric current and Where, k

the resistance of the battery can be expressed as:

z is the braking strength coefficient, S is the braking pedal travel. P = (E − IR )I (6) b soc soc

Adopted Equ.(1) and Equ.(2), the relationship between Where, P

the desired braking force and the brake pedal travel can be

b is the power of the battery in W, ESOC is the

EMF of the battery which is changing with the SOC of the obtained:

battery in V, I is the electric current in A, and RSOC is the F = k S B b (3)

resistance which is changing with the SOC of the battery in Ω k = mgk . b z (4)

Therefore, the maximum braking power of the motor Where, k must be met:

b is the braking force coefficient. P ≤ P B. Motor Braking Force (7) M max b

During the regenerative braking of the hybrid electric

Where, PMmax is the maximum braking power of the

vehicle, the motor is the energy recovery device. Therefore, motor.

the braking performance of the motor is an important

In order to protect the battery and to extend the life of the

influence factor for the regenerative braking performance of

battery, while the SOC of the battery is larger than a the vehicle.

threshold, the battery is not charged, that means the

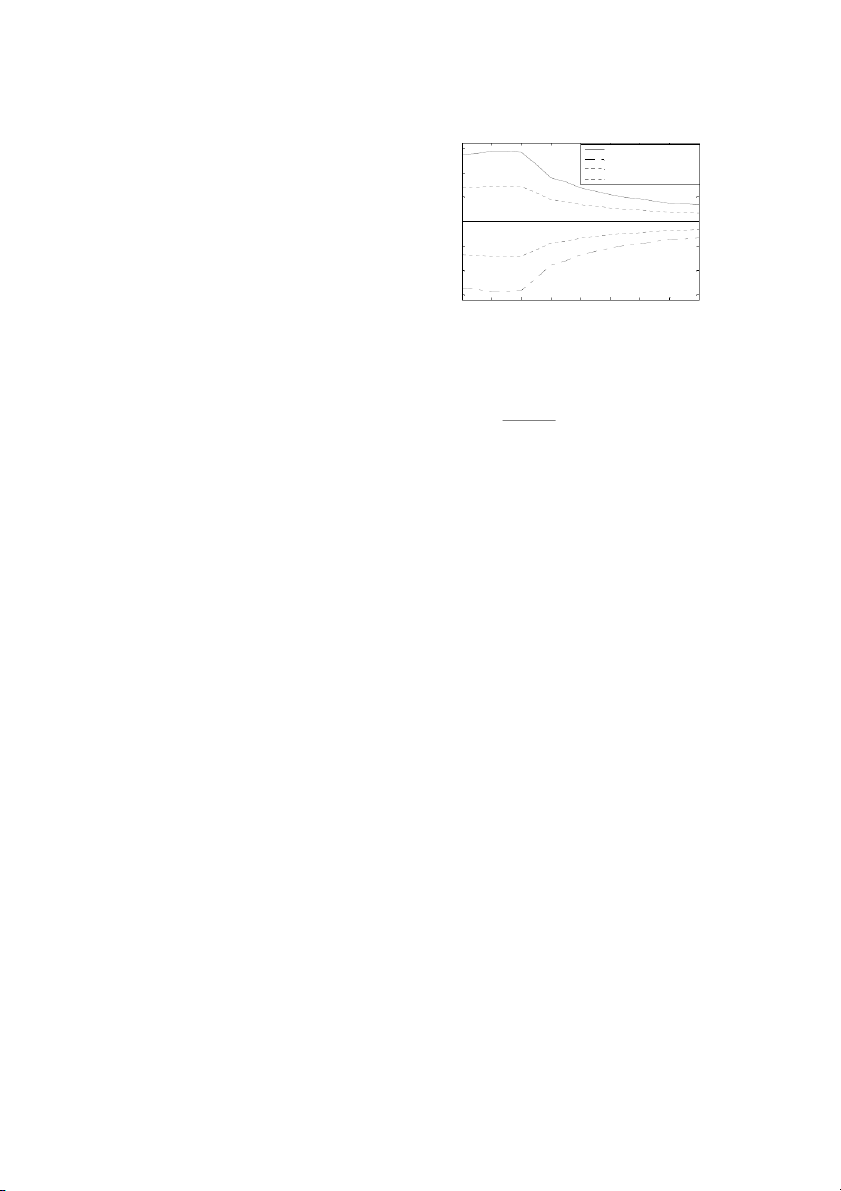

In this paper, the motor of the HEV is a permanent

regenerative braking system of the HEV is stopped and the

magnet synchronous motor (PMSM). Permanent magnet

total desired braking force is applied to the hydraulic

synchronous motor has advantages of high efficiency and

braking. Therefore, the maximum braking power of the

wide speed range, so it has been widely used in the hybrid

motor which is determined by the battery can be expressed electric vehicles. as:

When the motor speed is below the base speed of the ⎧P (SOC ≤ SOC ) b max

motor, the motor works at constant torque, and when the P = ⎨ (8) M max

motor speed is above the base speed of the motor, the motor ⎩0 (SOC > SOC ) max

works at constant power. Figure2 shows the characteristic of

the permanent magnet synchronous motor which is used in the HEV that is been studied. 760

IV. REGENERATIVE BRAKING FORCE 0.3 DISTRIBUTION STRATEGY 0.2

After investigating the performance of the motor and the th g

battery, we should analysis the driving cycles. We can use 0.1 n

the results to design the braking force distribution of the tre 0 s

front and rear axles. Then, considering the stability of the g in

vehicle, we can design the braking force distribution of the k -0.1 motor and hydraulic braking. ra b -0.2

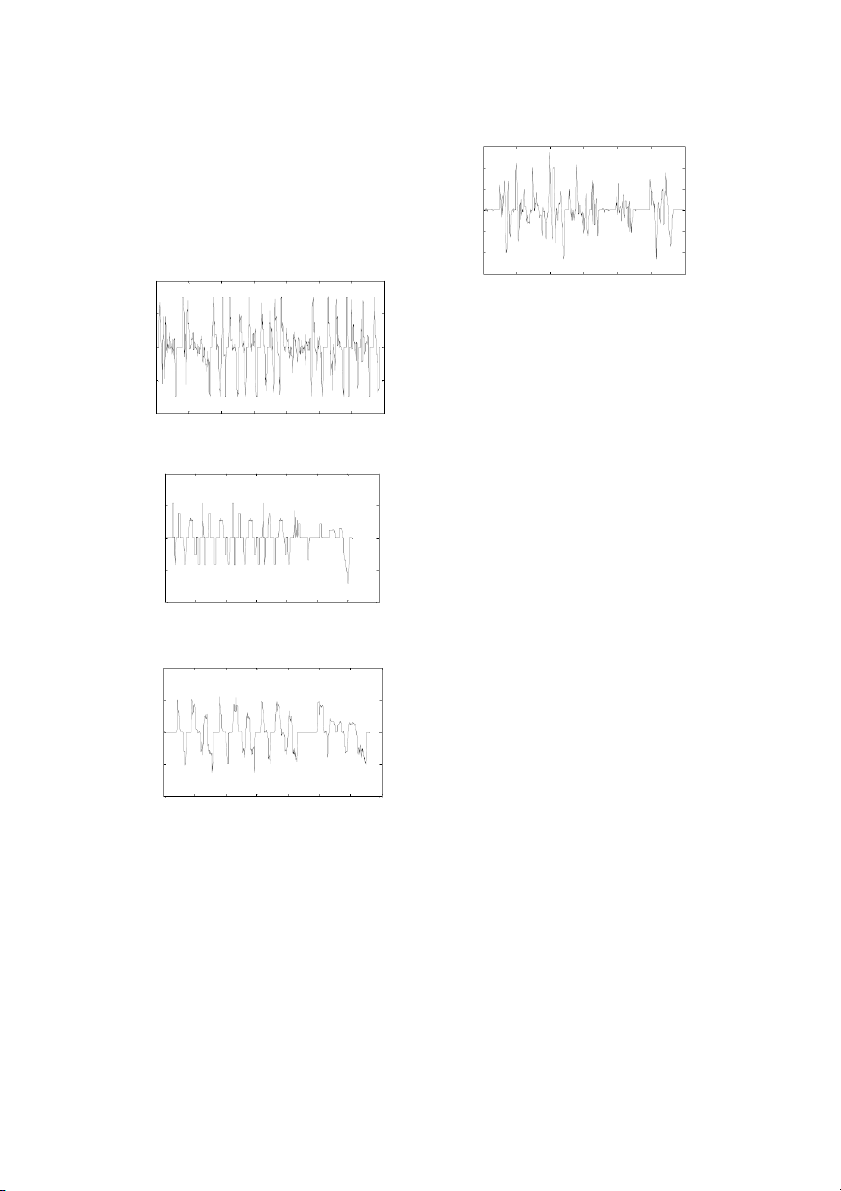

A. Driving Cycles Analysis 0.2 0 100 200 300 400 500 600 time(s)

Figure 6. The braking strength of NYCC 0.1 th g n

The investigation of the braking characteristics of the tre

driving cycle is conducted based on some standard urban 0 s g

driving cycles. The typical driving cycles that are used in in k

this paper are: UDDS, EUDC, 1015, and NYCC. Based on -0.1 bra

the four driving cycles, the braking strength of each driving

cycle can be calculated which is shown in Figure 3-Figure 6.

Through analysis Figure 3 to Figure 6, one conclusion -0.20 200 400 600 800 1000 1200 1400

can be obtained: all of the four driving cycles’ braking time(s)

strength are small and less than 0.15, only the braking

strength of the NYCC driving cycle is little large, but most

Figure 3. The braking strength of UDDS

of its’ braking strength is also less than 0.15. This also 0.2

implied that the vehicle is in a small braking state on the

whole while the vehicle is in urban driving condition. So, in

this paper, the most working range of the motor braking is 0.1 th

that the braking strength is less than 0.15. The vehicle is g n

stable because the vehicle is in linear region when a small 0

braking strength is applied to the vehicle. stre g in

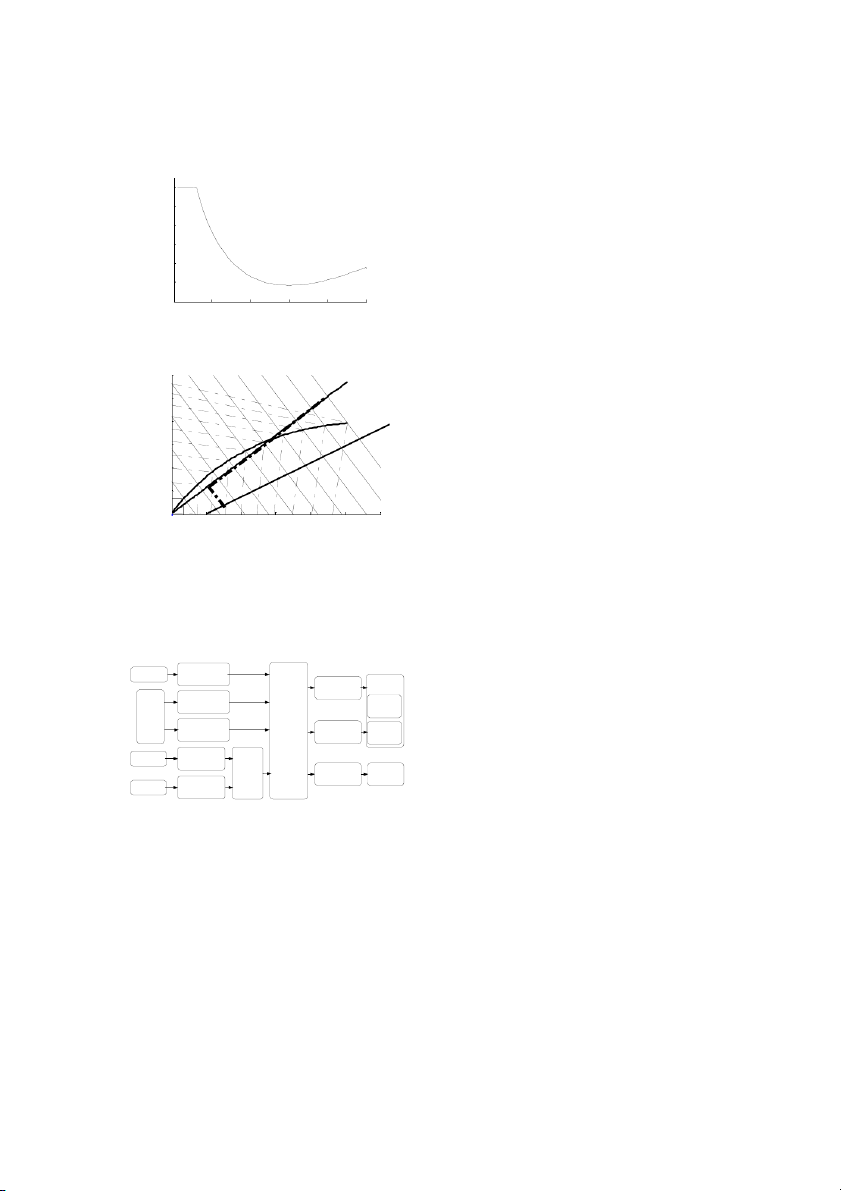

B. Front and rear axle braking force distribution curve k ra-0.1 b

In order to guarantee the braking distance and stability of

the hybrid vehicle to meet the ECE braking regulation [3], it -0.2

is necessary to calculate the relationship between the 0 200 400 600 800 1000 1200 1400

permission braking force distribution coefficient and the time(s)

braking strength. Figure 7 shows the curve between the

Figure 4. The braking strength of EUDC

permission braking force distribution coefficient and the

braking strength of the studied hybrid electric vehicle.

In order to maximize the recovery of the braking energy, 0.2

it is necessary to distribute braking force to front axle as

more as possible under the premising of the vehicle stability. 0.1 th

Based on the above considerations, this paper determines g n

the braking force distribution based on braking strength. tre 0

Figure 8 shows the braking force distribution curve of this s g paper. in k

The braking strength is divided into four grades: z ≤ ra-0.1 b

0.15, 0.15 < z ≤ 0.3, 0.3 < z ≤ 0.6, and z > 0.6. In order to

comply with the requirement of the ECE regulations and -0.2

reduce the operations times of the ESP valves, this paper 0 100 200 300 400 500 600 700

distribute 80% total braking force to front axle while the time(s)

braking strength is 0.15< z ≤0.3. And taking the vehicle

Figure 5. The braking strength of 1015

stability into account, this paper distributes the total braking

force according to the original braking force distribution

coefficient of the vehicle while the braking strength is 0.3< z

≤0.6. In order to prevent the influence of the fluctuation of

the motor torque to the vehicle at large braking closes the 761

regenerative braking function of the motor while the braking

braking force and the motor braking force. Thus, the process strength is z > 0.6

of the regenerative braking control can be completed. t n

Taking into account the inertia and torque fluctuation of ie 1

the motor, turns off the regenerative braking system while ffic e o

the vehicle is under ABS or ESP control. 0.98 c

This paper uses the deceleration of the vehicle to design n 0.96 tio

the braking force distribution strategy of the HEV. The u

strategy is a deceleration sensitive strategy (DS). Detailed 0.94 trib is

control strategies are as follows: d 0.92 e (1) While z ≤ 0.15 rc 0.9

The braking force distribution strategy distributes all of fo g

the desired braking force to the front axle. If at this time, the in 0.88 k

torque of the motor can meet the total desired braking force, 0.1 0.2 0.3 0.4 0.5 0.6 ra braking strength b

then, the motor supplies the total desired braking force. If

this moment, the torque of the motor can not able to meet the

Figure 7. The relationship between the braking force distribution

coefficient and the braking strength

total desired braking force, then, the motor supplies the

current maximum braking force of the motor, the inadequate

desired braking force is distributed to front hydraulic braking 6000 )

and rear hydraulic braking according to the original braking (N β

distribution curve of the vehicle. This can reduce the e 5000 rc

operation times of the ESP valves. The maximum braking fo I 4000 g

force of the motor is calculated from the maximum power of in k

the motor which considered the influence of the battery. The 3000 ra 80%

above process can be expressed as follows: b D le ⎧ x F ( F ≤ F ) 2000 b b M max F = ⎨ r a (9) m a ⎩F ( F > F ) 1000 re C M max b M max A B ⎧0 (F ≤ F ) 0 b M max 0 2000 4000 6000 8000 10000 12000 F = ⎨ (10) Hf front axle braking force(N) ⎩(F − F )β ( F > F ) b M max b M max ⎧

Figure 8. The braking force distribution curve of the HEV 0 ( F ≤ F ) b M max F = ⎨ (11) Hr ⎩( F − F

)(1 − β ) ( F > F ) b M max b M max

C. Braking force distribution strategy

Where, Fb is the total desired braking force in N, Fm is

After determining the front and rear axle braking force

the braking force of the motor in N, FMmax is the current

distribution curve, it can be used to design the braking force

maximum braking force of the motor in N, FHf is the front strategy of the vehicle.

axle hydraulic braking force in N, FHr is the rear axle

Figure 9 shows the overall regenerative braking control

hydraulic braking force in N, β is the original braking

block diagram of the hybrid electric vehicle.

distribution coefficient of the vehicle. Wheel speed ABS/TCS/ESP Front axle Braking (2) While 0.15 < z ≤ 0.3 hydraulic ECU

The braking force distribution strategy distributes 80% Deceleration braking force

desired braking force to front axle in order to recovery Braking calculate ESP ECU pedal

braking energy as more as possible. While braking strength RBS stoke Desired Rear axle distribution Pump

is in this range, the tire of the vehicle is in linear range, so braking force hydraulic strategy ECU braking force

the vehicle is stable, and at this moment, the recovering Motor Motor Motor maximum

braking energy is more important than the stability of the speed braking braking force Motor braking Motor

vehicle. If at this moment, the torque of the motor can meet force Battery force ECU Battery can

the distributed braking force of the front axle, then the motor maximum infomation supply braking forcr

supplies the total front axle braking force. If at this moment,

the torque of the motor can not able to meet the distributed

Figure 9. The regenerative braking control block diagram of the vehicle

braking force of the front axle, then, the motor supplies the

Firstly, using the braking pedal stroke to calculate the

current maximum braking force of the motor, the inadequate

desired braking force, then integrating the current

front axle braking force is distributed to front hydraulic

information of the maximum braking force of the motor and

braking and rear hydraulic braking according to the original

the maximum allowable braking force of the battery, after

braking distribution curve of the vehicle. The above process

these, the braking force distribution strategy can be used to can be expressed as follows:

calculate the current front axle braking force, rear axle 762 ⎧F (F ⎪ ≤ F )

And the simulation results are compared with the simulation f f M max F = ⎨ (12)

results of the ADVISOR braking force distribution strategy. m F ⎪ (F > F ) ⎩

Prior to comparing analysis, it is necessary to introduce the M max f M max

braking force distribution strategy of the ADVISOR. Figure ⎧0 (F ⎪ ≤ F )

10 shows the braking force distribution strategy of the f M max F = ⎨ (13) ADVISOR. Hf ⎪(F − F )β (F > F ) ⎩ f M max f M max t 1 n ⎧⎪0.2F (F ≤ F ) ie

front axle friction braking distribution coefficient b f Mmax F = ⎨

motor braking distribution coefficient (14) ffic Hr e 0.8 ⎪(F −F

)(1−β) +0.2F (F > F ) ⎩ o f Mmax b f Mmax c n F = 0.8 F (15) tio 0.6 f b u Where, F trib

f is the front axle braking force in N. is (3) While 0.3 < z ≤ 0.6 0.4 d e

The braking force distribution strategy distributes the rc

desired braking force to front axle and rear axle according to fo g 0.2

the original braking distribution coefficient of the vehicle. in k

Thus, the braking stability performance of the vehicle can be ra b 0

ensured while the vehicle is in medium braking strength. If 0 50 100 150 200

at this moment, the torque of the motor can meet the vehicle speed(Km/h)

distributed braking force of the front axle, then the motor

Figure 10. The braking force distribution strategy of the ADVISOR

supplies the total front axle braking force. If at this moment,

the torque of the motor can not able to meet the distributed

The braking force distribution strategy of the ADVISOR

braking force of the front axle, then, the motor supplies the

is speed-sensitive type. As the vehicle speed increasing, the

current maximum of the motor, the inadequate front axle

braking force distribution coefficient of the motor increases.

braking force is distributed to front hydraulic braking. The

The biggest problem of this distribution strategy is it not

above process can be expressed as follows:

considers the impact of the vehicle deceleration. The strategy ⎧

of this paper is deceleration sensitive type (DS). ⎪F ( F ≤ F ) f f M max F = ⎨

In order to effectively evaluate the effect of the (16) m ⎪F ( F > F ) ⎩

regenerative braking, this paper selects four evaluation M max f M max

indicators as follows: the SOC of the battery; the fuel ⎧0 (F ≤ F ) ⎪

consumption of the vehicle; the recovery efficiency of the f M max F = ⎨ (17)

braking energy; the efficiency of the overall vehicle system. Hf ⎪F − F ( F > F ) ⎩ f M max f M max

The definition of the recovery efficiency of the braking

energy and the efficiency of the overall vehicle system can

F = (1− β )F (18) Hr b be expressed as follows: F = F β (19) E f b regen η = (23) (4) While z > 0.6 regen Ebrake

While the braking strength of the vehicle is in this range,

the vehicle is in heavy braking status, therefore, the E + E aero roll η = (24)

important thing of this moment is the stability of the vehicle vehicle E − E fuel charg e

not the recovering the braking energy. As the time of the Where, E

heavy braking is short and the recovering energy of the

regen is the recovery braking energy, Ebrake is the

total braking energy of the driving cycle. E

motor is small, so, the regenerative braking system is closed, aero is the

and the desired braking force is distributed to front and rear

aerodynamic drag energy, Eroll is the rolling resistance

hydraulic braking according to the original braking

energy, Efuel is the fuel consume energy, Echarge is the charged

distribution coefficient of the vehicle. The above process can energy of the battery. be expressed as follows:

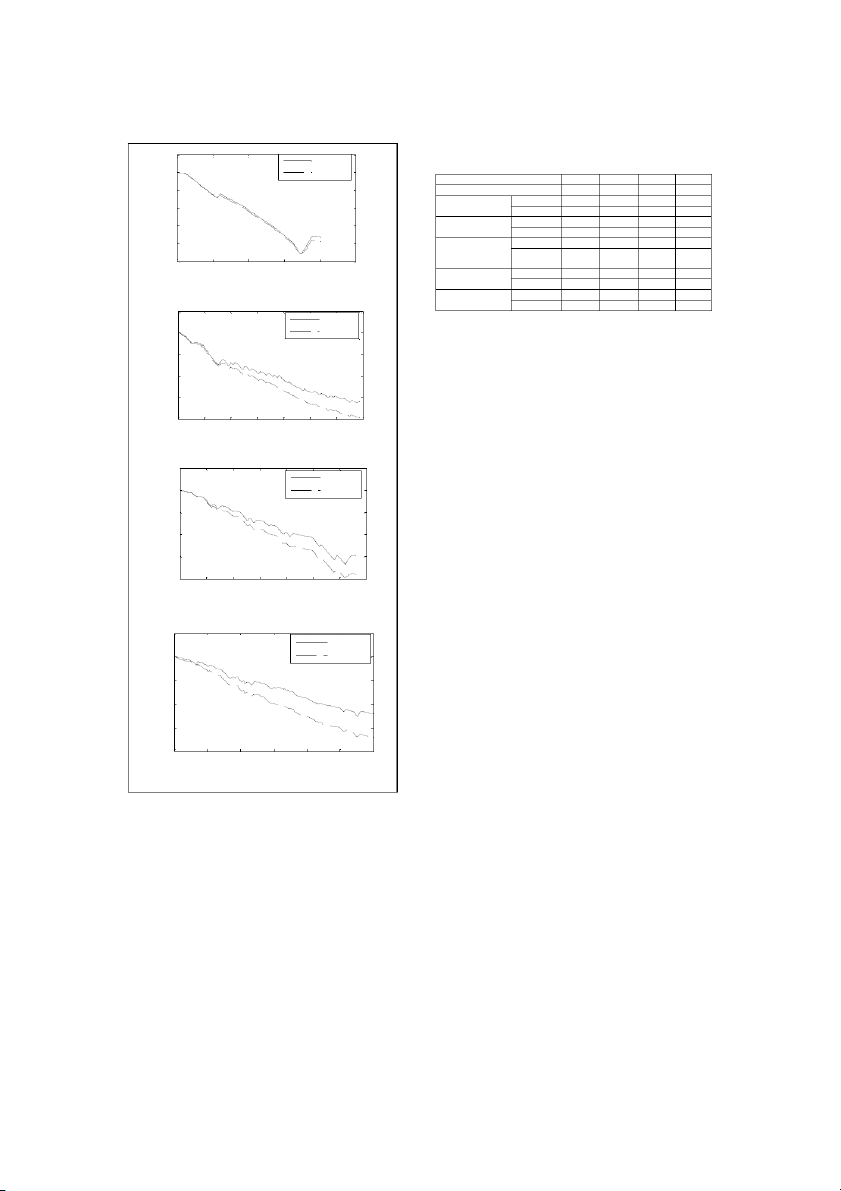

This paper selects four kinds of driving cycles: EUDC,

UDDS, 1015, NYCC to analysis the braking force F = 0 (20) m

distribution strategy of this paper.

F = (1− β )F (21)

Figure 11 shows the SOC status of the four driving cycles. Hr b

Where, the DS in the figure is the deceleration sensitive F = F β (22)

braking force distribution strategy of this paper. The figures Hf b

show that the SOC of the deceleration sensitive is higher V. SIMULATION RESULTS

than the SOC of the ADVISOR. The results indicate that the

deceleration sensitive strategy can recover more energy than

In this paper, the ADVISOR2002 software is used to

the speed sensitive strategy of the ADVISOR.

simulate and analysis the braking force distribution strategy. 763 TABLE I.

THE RESULTS OF THE EVALUATION OF DRIVING 0.705 CYLES DS 0.7 ADVISOR Driving cycle UDDS EUDC 1015 NYCC 0.695 Traveling distance, Km 12 7 4.2 1.9 C Fuel consume ADVISOR 5 4.3 5.6 11.1 0.69 O Per cycle, L/Km DS 4.9 4.2 5.5 11 S braking energy, ADVISOR 1856 542 660 614 0.685 KJ DS 1925 531 658 670 0.68 Regenerative ADVISOR 1017 166 367 302 braking energy, DS 1640 457 658 568 0.675 KJ 0 100 200 300 400 500 Regenerative ADVISOR 0.55 0.31 0.56 0.49 time(s) braking efficient DS 0.85 0.86 1 0.85 (a) EUDC Overall vehicle ADVISOR 0.112 0.209 0.087 0.033 system efficient DS 0.115 0.244 0.09 0.035 0.71 DS 0.7 ADVISOR VI. CONCLUSION 0.69

This paper studied the braking strength of four typical C O

driving cycles. Then, the paper studied the performance of S 0.68

the motor and the battery. And some important conclusion

can be used to design the braking force distribution strategy. 0.67

The braking force distribution strategy of this paper is 0.66

deceleration sensitive strategy. This strategy considers the 0 200 400 600 800 1000 1200 1400

braking strength of the typical driving, and then the braking time(s)

strength is divided into four grades to design the front and (b) UDDS

rear axles braking force. Then, considering the influence of 0.705

the battery, the motor braking force can be calculated. And DS

the front and rear axle hydraulic braking force can be 0.7 ADVISOR

calculated also. The simulation results show the braking

force distribution strategy can recover more braking energy. 0.695 C O S ACKNOWLEDGEMENT 0.69

This work is supported by the key project of the science 0.685

and technology research of the eduction department

(NO01059): the regenerative braking control system of the 0.68 0 100 200 300 400 500 600 700

hybrid electric vehicle key technologies. time(s) REFERENCES (c) 1015

[1] Yimin Gao, Liping Chen, and Mehrdad, “Investigation of the 0.705

Effectiveness of Regenerative Braking for EV and HEV,” SAE paper, DS 1999-01-2910. 0.7 ADVISOR

[2] Yimin Gao, Liang Chu, and Mehrdad, “Design and Control

Principles of Hybrid Braking System for EV, HEV and FCV,”IEEE 0.695

Transaction on vehicular Technology, Vol.54, NO.2, Sep.2008. C O

[3] R.Apter, M.Prathaler, “Regeneration of Power in Hybrid Vehicles” S 0.69

IEEE Transaction on vehicular Technology, Vol.35, NO.3, Sep.2002.

[4] A.M.Walker, M.U.Lamperth and S.Wilkins, “On Friction Braking 0.685

Demand with Regenerative Braking,”SAE paper, 2002-01-2581.

[5] Ahu E.Hartavi, Ismail M.C.Uygan, and Volkan Sezer, “Electric 0.68

Regenerative Power Assisted Brake Algorithm for Front and Rear 0 100 200 300 400 500 600

Wheel Drive Parallel Hybrid Electric Commercial Van,” SAE paper, time(s) 2008-01-2606. (d) NYCC

[6] Nobuyoshi Mutoh, and Hiromichi, “Electrical Braking Control

Figure 11. The SOC status of the four driving cycles

Methods for Electric vehicles with Independently Driven Front and

Rear Wheel Structure,”Industrial Electronis, IEEE transaction on, Vol.54, Issue 2. April 2007.

Table 1 shows the detail calculation results of the four

[7] M.Ehsani, Y.Gao, S.E.gay and A.Emadi, Modern Electric, Hybrid,

evaluation indicators in four driving cycles. The results

and Fuel Cell Vehicles: Fundamentals, Thory and Design, CRC

indicate that the strategy of this paper can recover more Press,2005.

braking energy than the strategy of the ADVISOR. So the

[8] J.Y.Wong, Theory of Ground Vehicles. John Wiley and Sons, New

effective of the deceleration braking force distribution York, 1978 strategy is certificated. 764