Preview text:

lOMoAR cPSD| 58562220 Lê Ngọc Liễu Office: A1-706 Email: lnlieu@hcmiu.edu.vn lOMoAR cPSD| 58562220 Evaporation Diluted liquid Concentrated liquid food products Objectives

Provide microbiological stability

Assist in reducing transportation and storage costs

What is the difference between evaporation and drying/distillation? 2 lOMoAR cPSD| 58562220

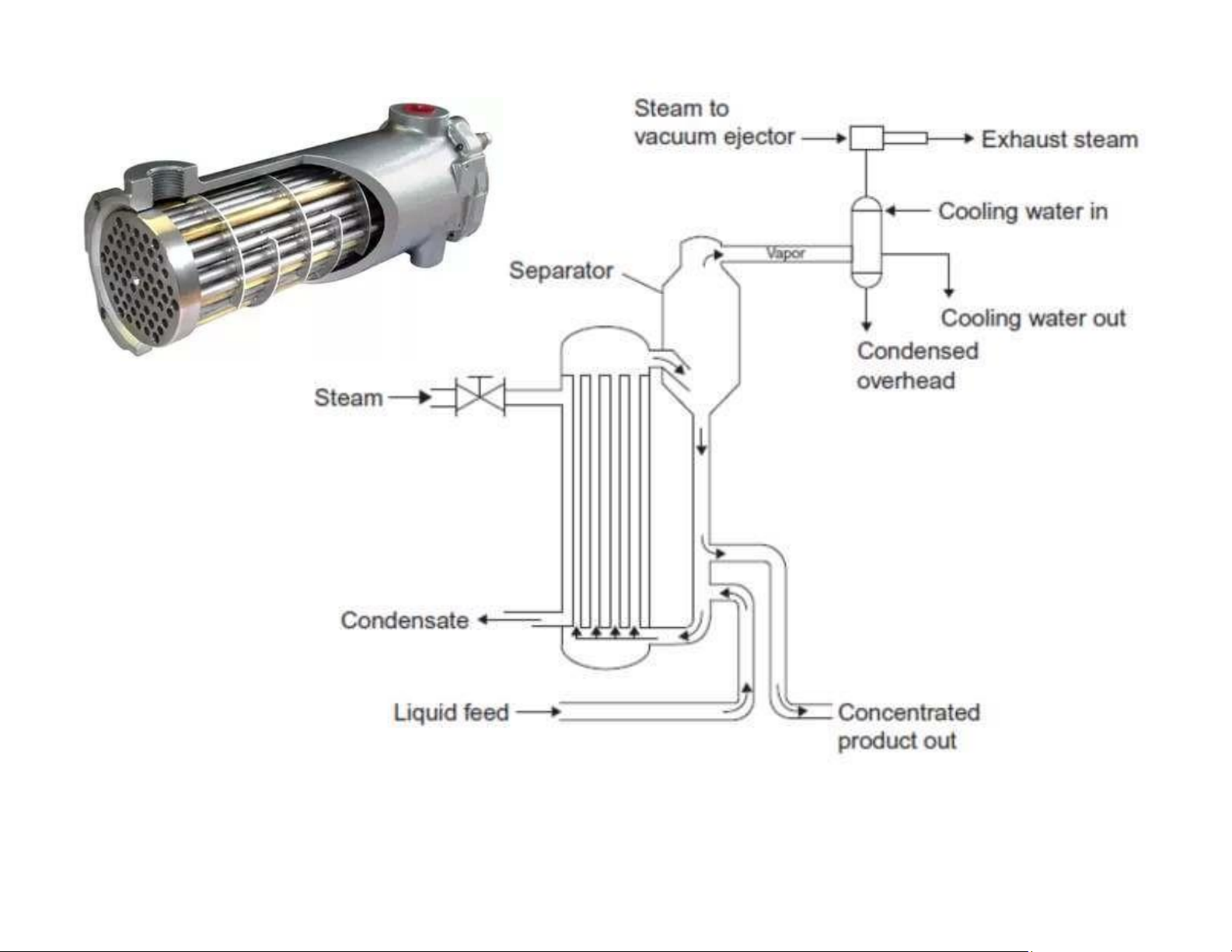

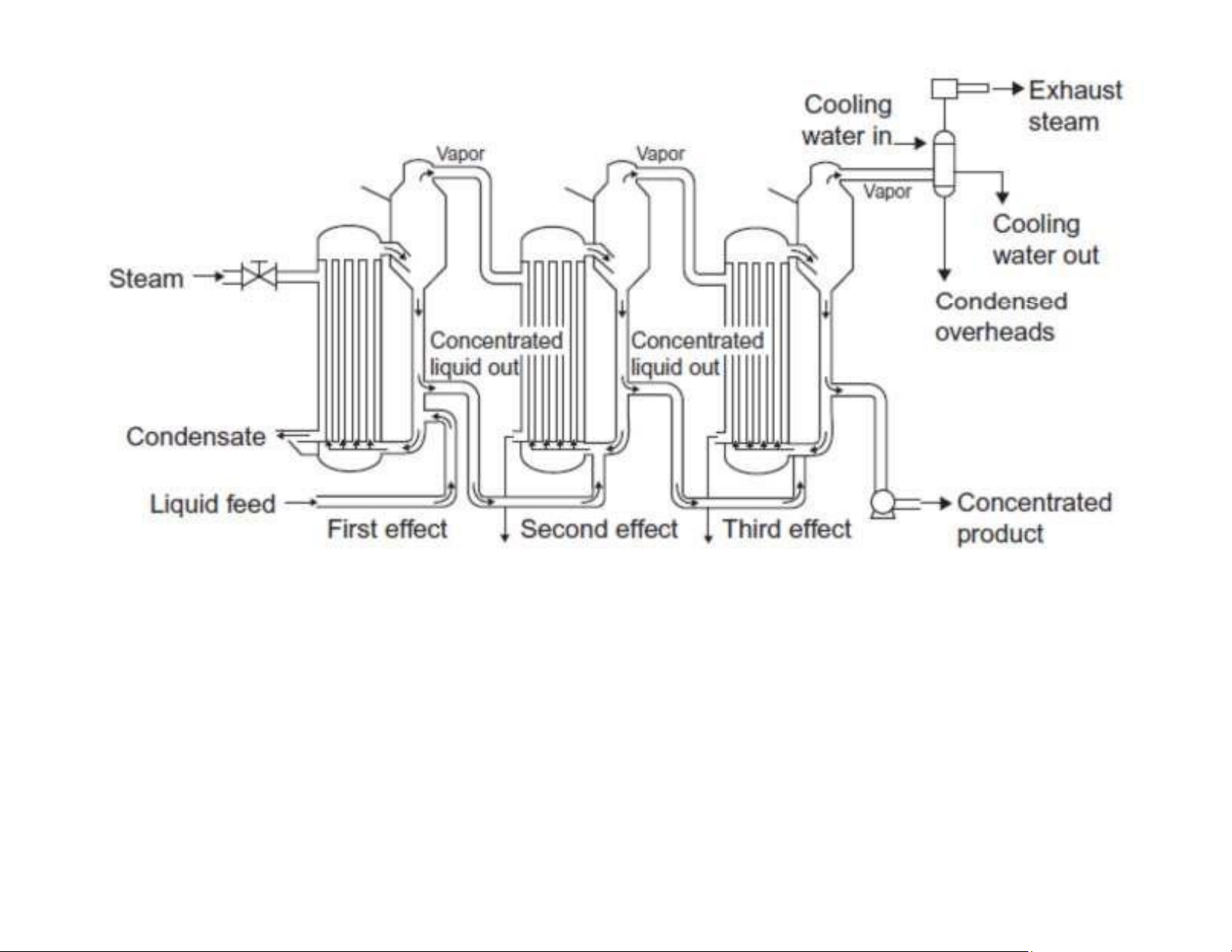

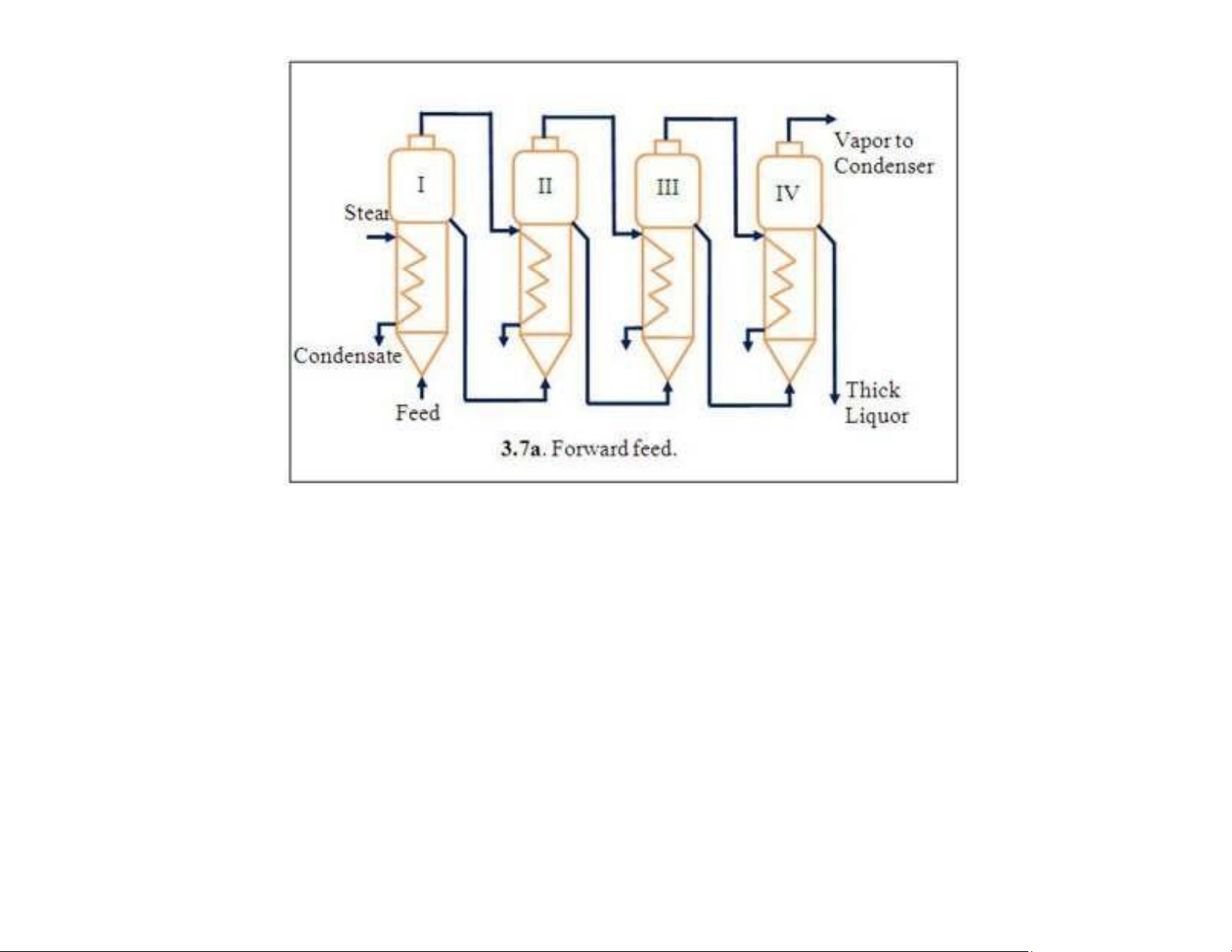

The vapor released in the evaporation chamber contains energy that may

be used for other industrial purposes. lOMoAR cPSD| 58562220

Such vapor has a temperature lower than that of steam, so its latent heat

of condensation is greater; for this reason, it is very important to take

advantage of this latent heat.

There are different methods for using this energy: vapor recompression and multiple effect. 4 lOMoAR cPSD| 58562220

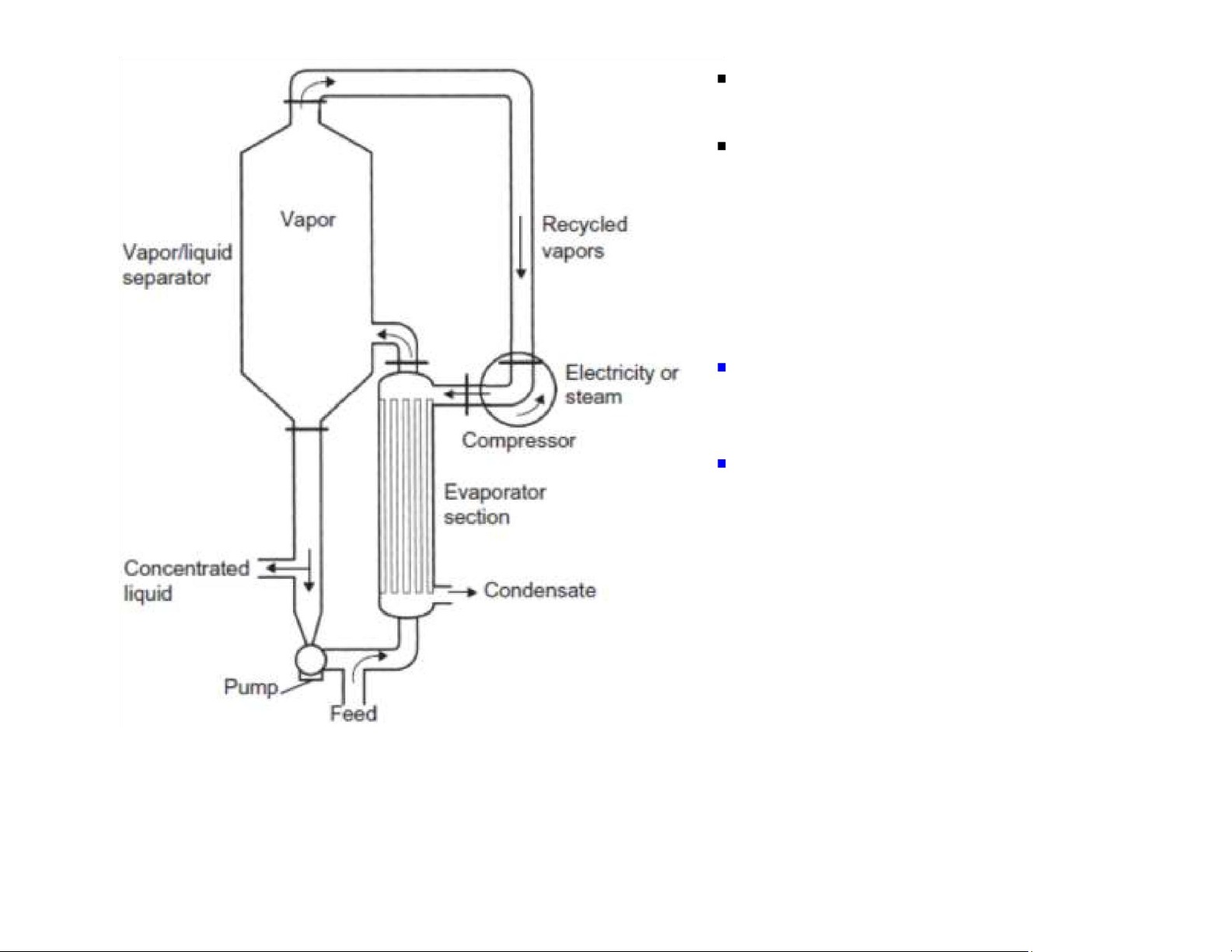

Compress all vapors leaving the evaporator Accomplished

mechanically, using a compressor

driven by an electric motor, a steam turbine, or a gas engine Effective in reducing energy

demands: equivalent to 15 effects

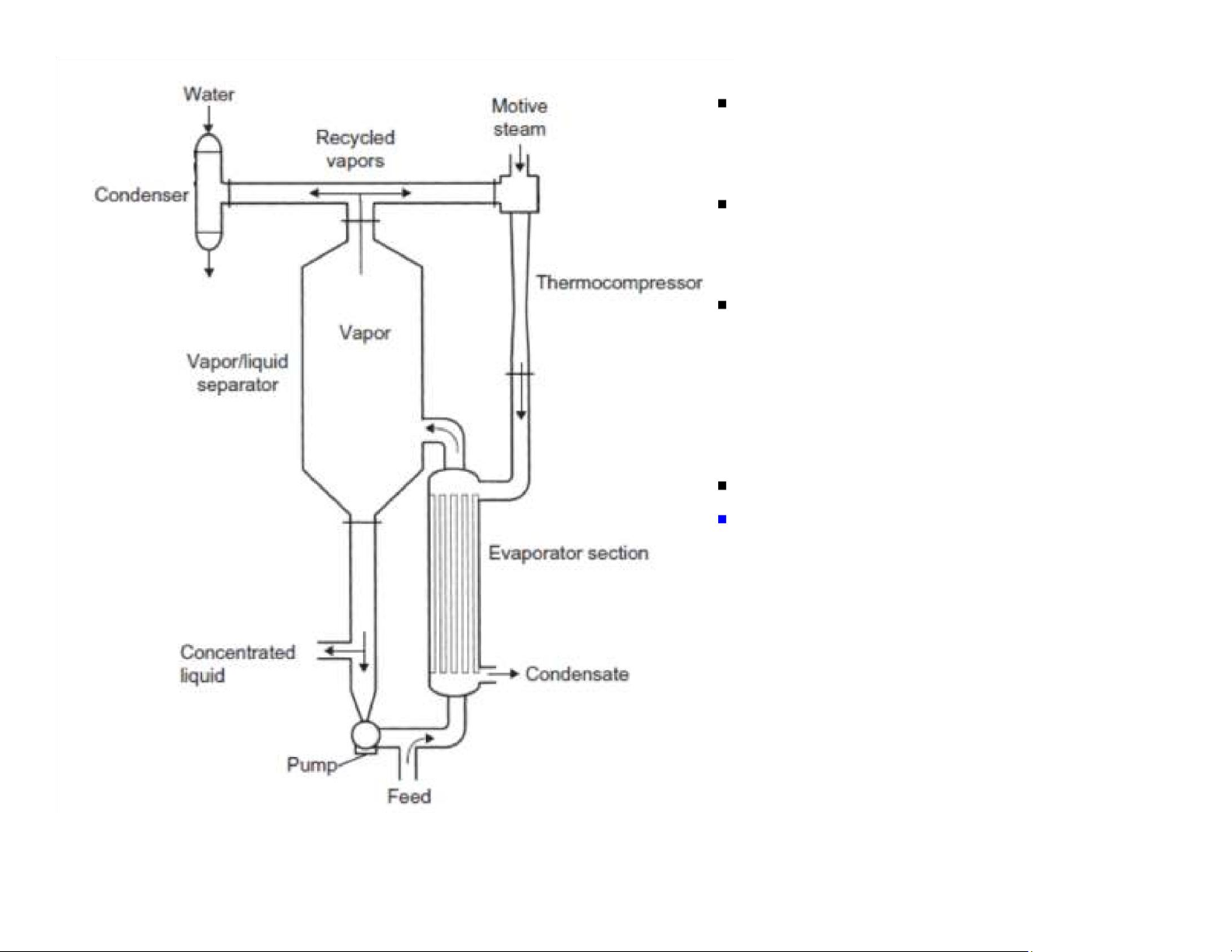

Noisy to operate due to the use of large compressors lOMoAR cPSD| 58562220 Use a steam jet booster (highpressure steam) to

recompress major part of the exit vapors Through recompression,

the pressure and temperature of

exit vapors are increased Applied

to single-effect evaporators or to

the first effect of multiple-effect evaporators

Better suited to vacuum operation

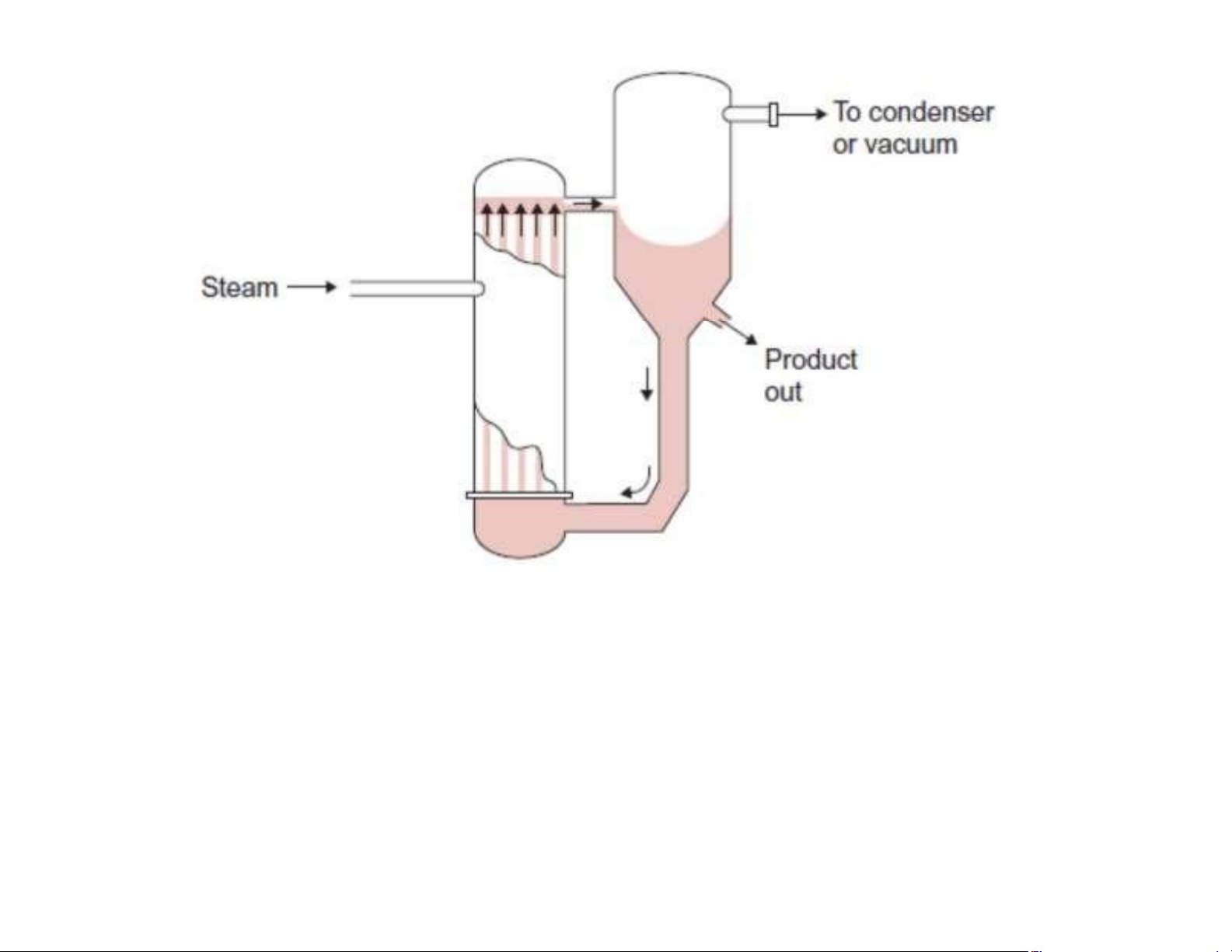

Cheaper and easier to maintain 6 lOMoAR cPSD| 58562220 lOMoAR cPSD| 58562220 ! " " # $ 8 lOMoAR cPSD| 58562220 ! " " lOMoAR cPSD| 58562220 % 10 lOMoAR cPSD| 58562220 & ! lOMoAR cPSD| 58562220 " 12 lOMoAR cPSD| 58562220 Tube: 1-2 m long lOMoAR cPSD| 58562220 14 lOMoAR cPSD| 58562220 # lOMoAR cPSD| 58562220 # $ lOMoAR cPSD| 58562220 % lOMoAR cPSD| 58562220

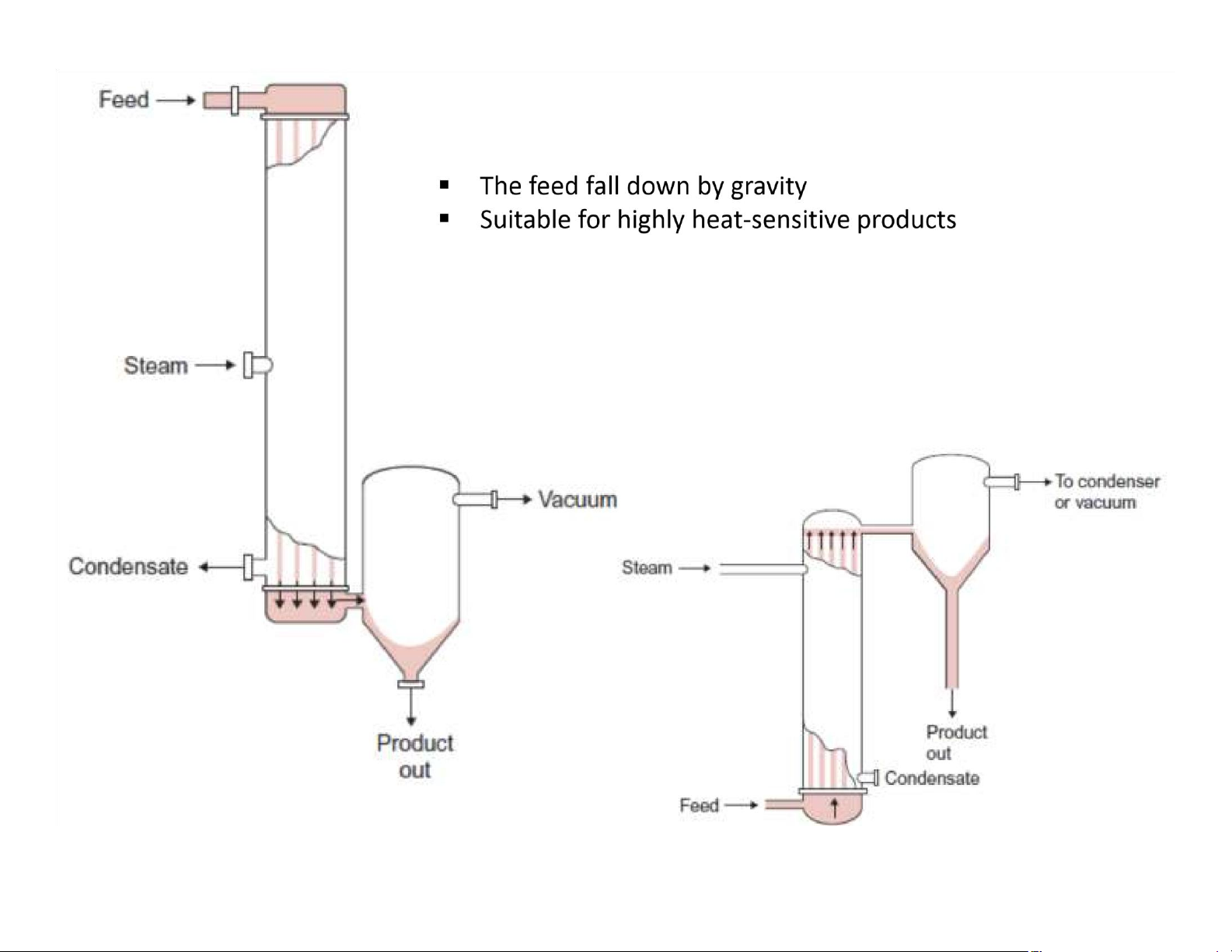

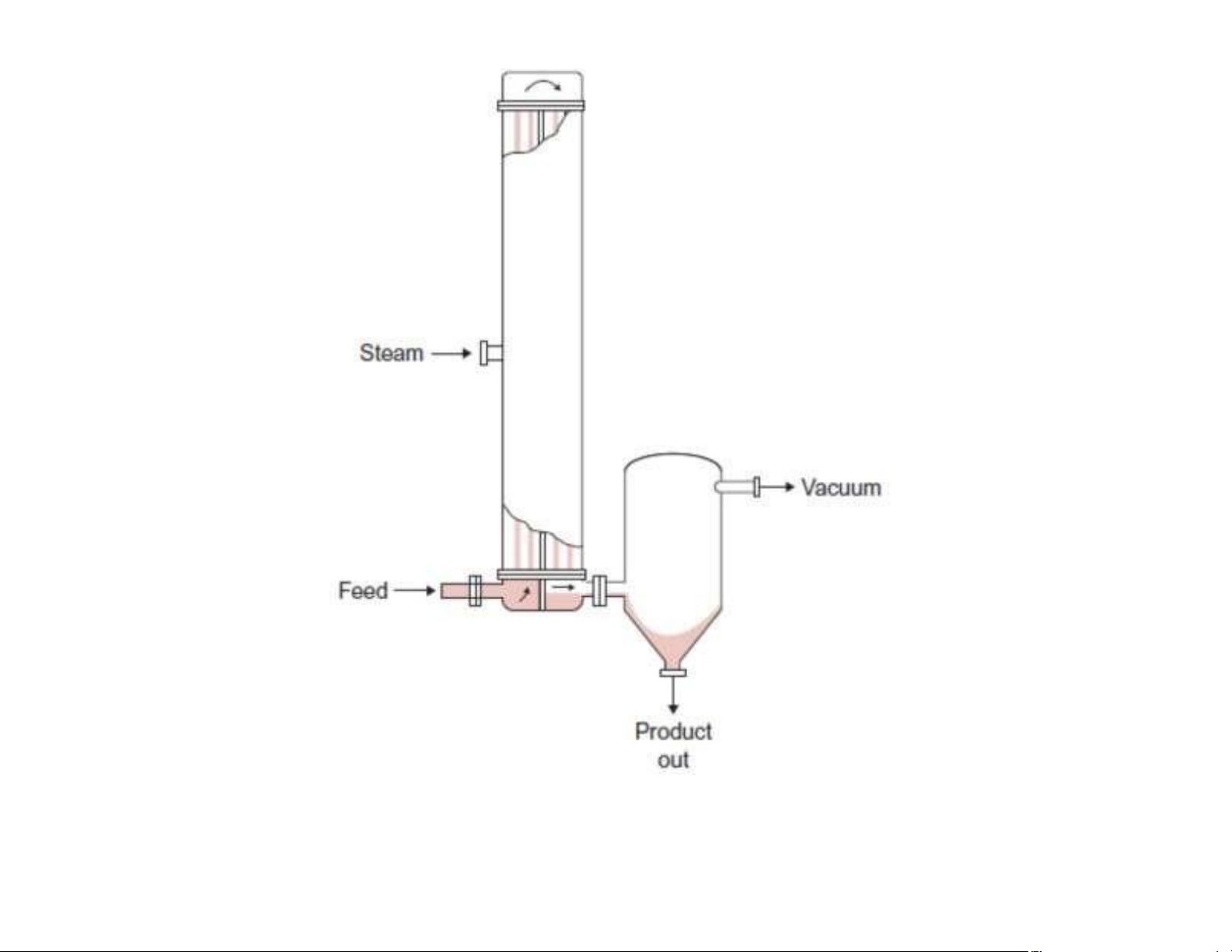

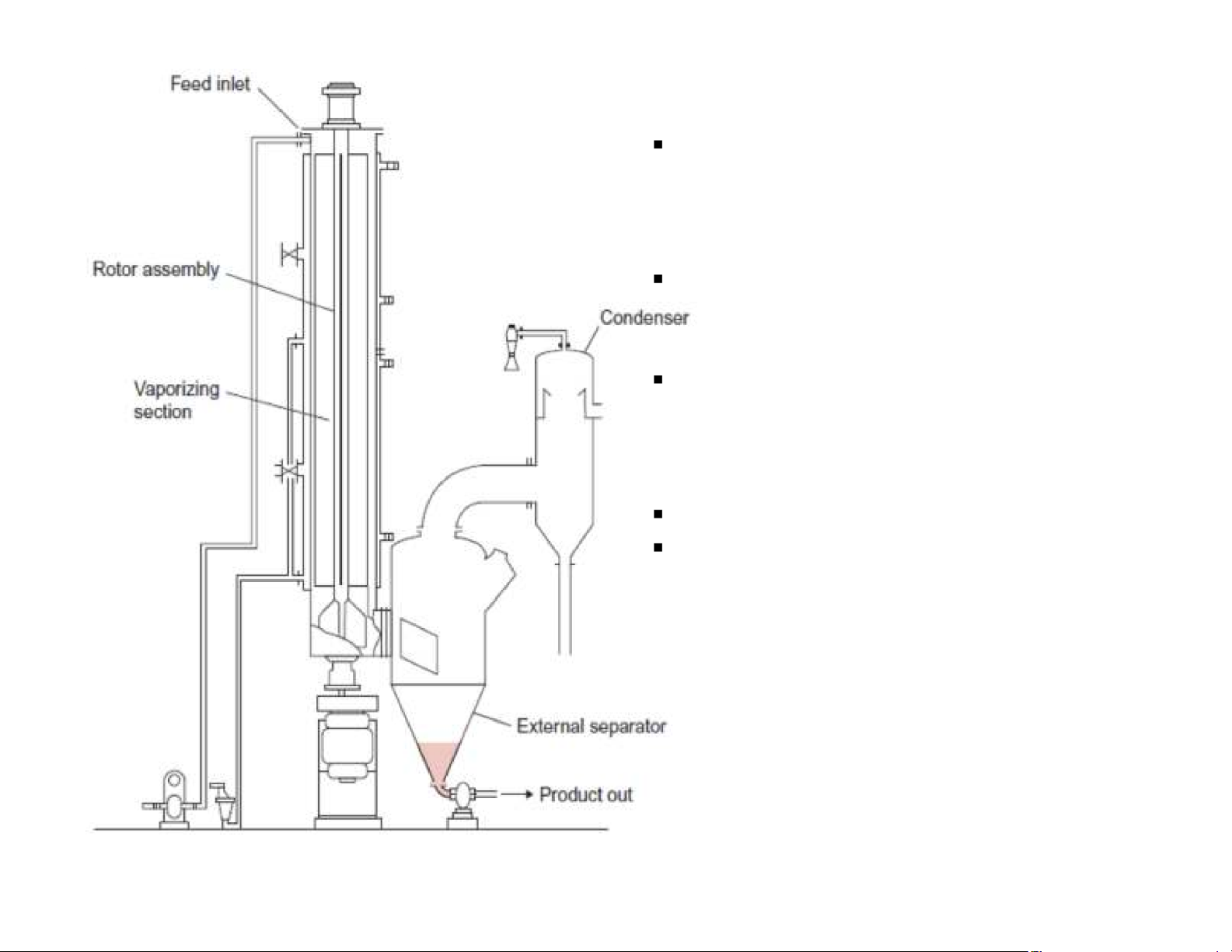

For very viscous fluid foods, feed is

spread on the inside of the cylindrical

heating surface by wiper blades High rate of heat transfer

The cylindrical configuration results in

low heat-transfer area per unit volume of the product

High-pressure steam is used as the

heating medium to obtain high wall temperatures for reasonable evaporation rates

High capital and maintenance costs Low processing capacity & Heat sensitivity: low heating temperature, or short residence time, or

both Fouling: caused by solid in the feed gradual lOMoAR cPSD| 58562220

reduction in overall heattransfer coefficient eventually require shutdown

and cleaning production downtime + additional maintenance labor

Foaming: common. Reduce foaming by special design of feed inlet,

vapor/liquid separation area, reducing the boiling intensity, addition of antifoam

Solid: cause tube plugging, fouling, viscosity increase

Viscosity: affect heat-transfer coefficient

Distillate-to-concentrate ratio: affect wall wetting

Distillate vapor velocity: affect pressure drop

Heat transfer medium: hot oil or steam

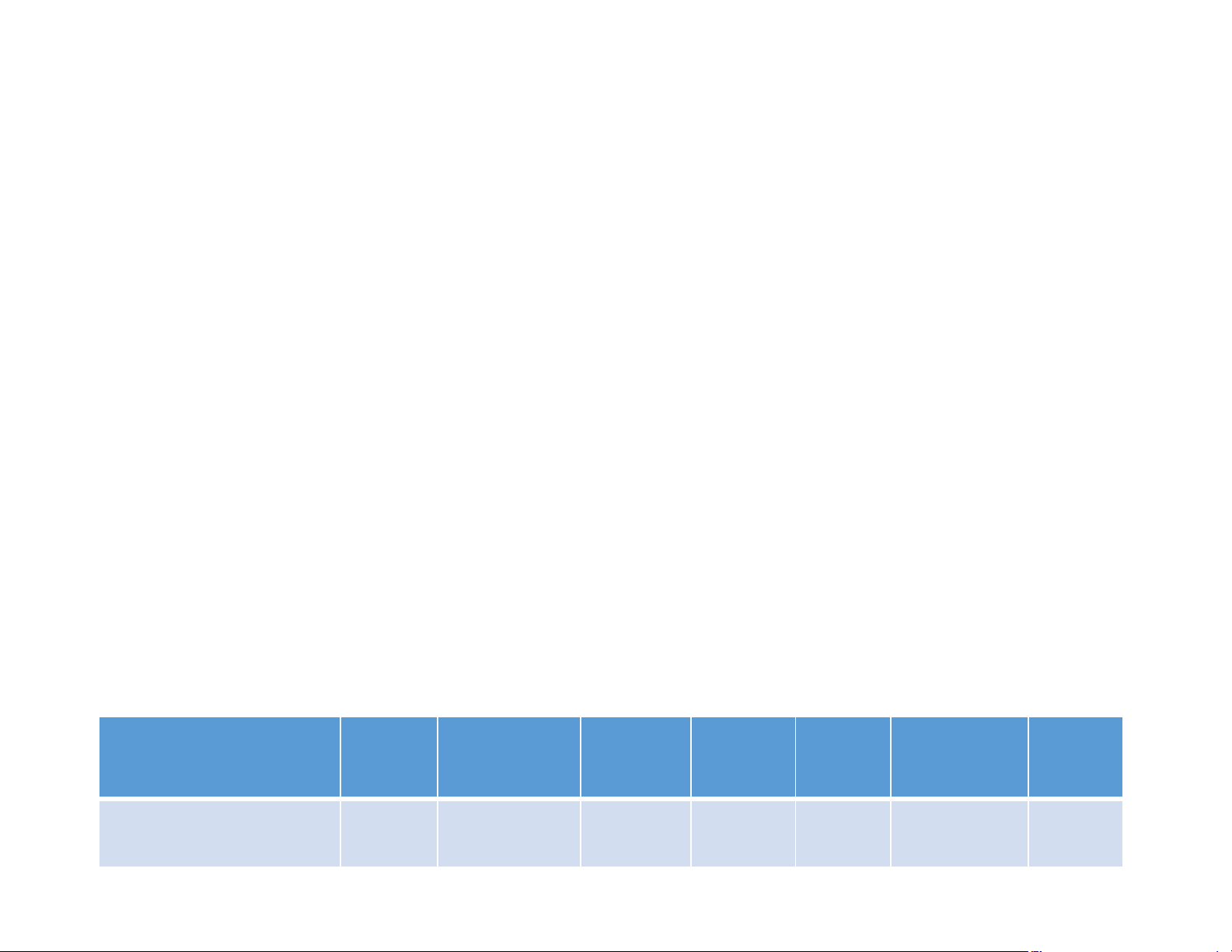

Required materials of construction: affect cost and determine the thermal conductivity Type of evaporator Clean

High capacity Solids or Fouling Foamy Temperature Viscous Crystals sensitive Batch x x lOMoAR cPSD| 58562220 Horizontal tube x Vertical short tube x Vertical long tube x x Rising/falling film x x x Falling film x x x x x Forced circulation x x x x x Agitated thin film x x x x x x x ’ ( ’ ) ’ ’