Preview text:

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/224199155

Performance analysis of Direct Torque Control (DTC) for synchronous

machine permanent magnet (PMSM)

Conference Paper · October 2010

DOI: 10.1109/SIITME.2010.5649125 · Source: IEEE Xplore CITATIONS READS 27 1,188 4 authors: Badre Bossoufi Mohammed Karim

Faculty of Sciences; Sidi Mohamed Ben Abdel ah University

Sidi Mohamed Ben Abdel ah University

194 PUBLICATIONS 2,892 CITATIONS

118 PUBLICATIONS 1,672 CITATIONS SEE PROFILE SEE PROFILE Ahmed Lagrioui Silviu Ionita

National High School of Arts and professions in Meknes (ENSAM) University of Pitesti

63 PUBLICATIONS 1,233 CITATIONS

74 PUBLICATIONS 601 CITATIONS SEE PROFILE SEE PROFILE

Al content fol owing this page was uploaded by Badre Bossoufi on 26 February 2015.

The user has requested enhancement of the downloaded file.

2010 IEEE 16th International Symposium for Design and Technology in Electronic Packaging (SIITME)

Performance Analysis of Direct Torque Control

(DTC) for Synchronous Machine Permanent Magnet (PMSM)

Badre Bossoufi, Mohammed Karim, Ahmed Lagrioui

Badre Bossoufi, Silviu Ioniţă (Membre IEEE)

Laboratory of Data processing, Imagery and Analyzes

Center of Modeling and simulation of the systems, Faculty

Numerical (LIIAN), Faculty of Sciences Dhar El Mahraz.

of Electronics, Communications and Computers, University Fez, Morocco of PITEŞTI

Badre_isai@hotmail.com, karim_lessi@yahoo.fr, PITEŞTI, Romania lagrioui71@gmail.com

Badre_isai@hotmail.com, silviu.ionita@upit.ro

Abstract -- The Direct Torque Control is a technique increasingly

Elimination of rotor position sensor.

used for the ordering of the invertors and synchronous machine.

This system can be regarded as a hybrid dynamic system whose

The amplitude and the frequency of the controlled variables

continuous component is the permanent magnet synchronous

are considered. In the controlling of vector the amplitude and

machine and the discrete component, the inverter of tension. In

the position of a controlled vector of space are considered.

this article, we propose a modeling of this whole by a system with

These reports are valid even during cuts which are essential discrete events. This model is then simulated on

for the precise ordering of couple and speed. Matlab/Simulink.

Keywords- Direct Torque Control (DTC), Permanent Magnet II.

MODELING OF THE SYNCHRONOUS PERMANENT

Synchronous Machine (PMSM). MAGNET MACHINE (PMSM):

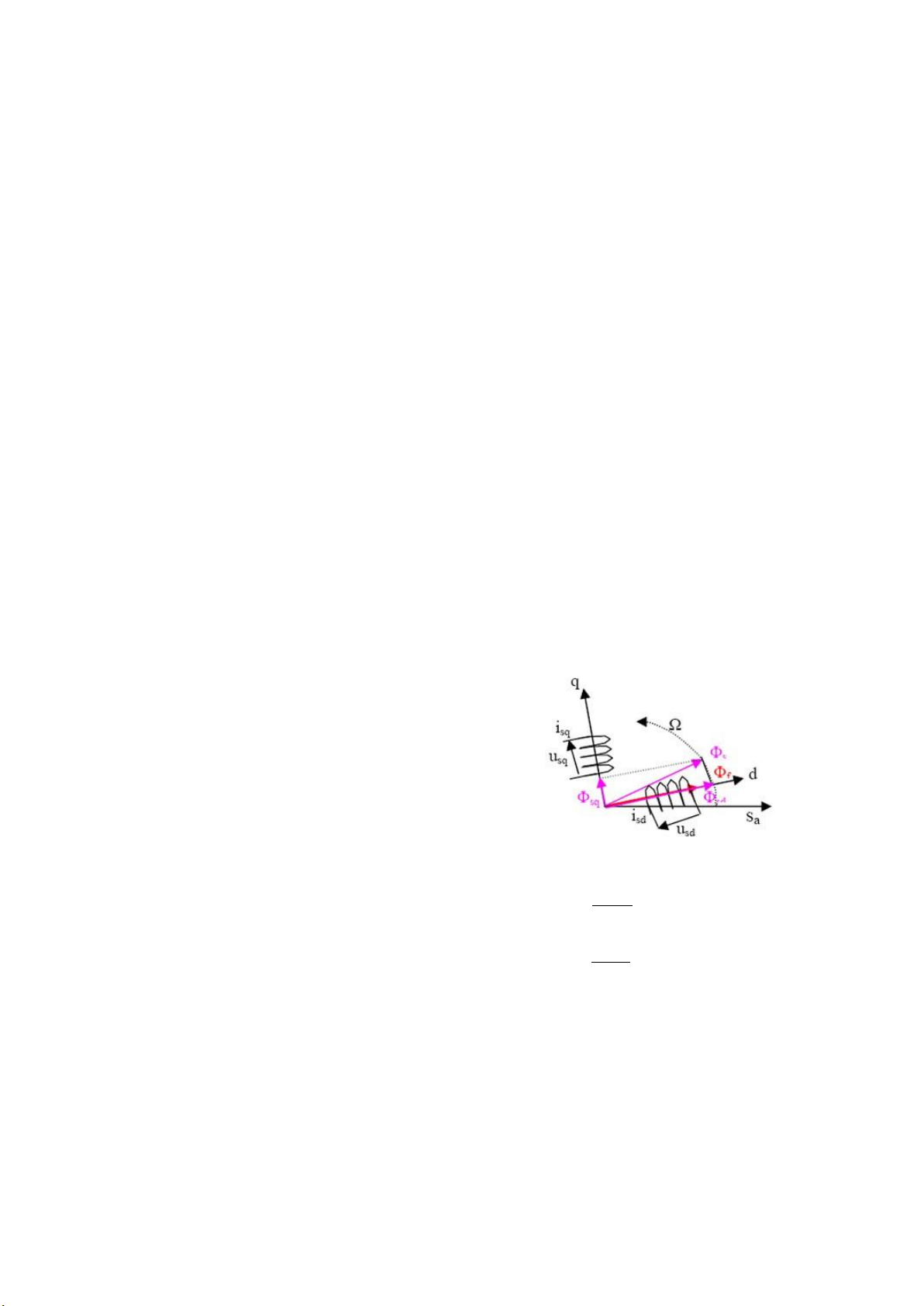

The motor considered in this paper is an interior PMSM I. INTRODUCTION

which consists of a three phase stator windings and a PM rotor.

Permanent magnet synchronous motor drives (PMSM)

The voltage equations in a synchronous reference frame can be

offers many advantages over the induction motor, such as derived as follows,

overall efficiency, effective use of reluctance torque, smaller

losses and compact motor size. In recent years many studies

have been developed to find out different solutions for the

PMSM drive control having the features of quick and precise

torque response, and reduction of the complexity of field

oriented control algorithms [1-3]. The DTC technique has been

recognized as viable and robust solution to achieve these requirements.

In the existing literature, many algorithms have been

suggested for the DTC control [1, 4-6]. The eight voltage-

vector switching scheme seems to be suitable only for high

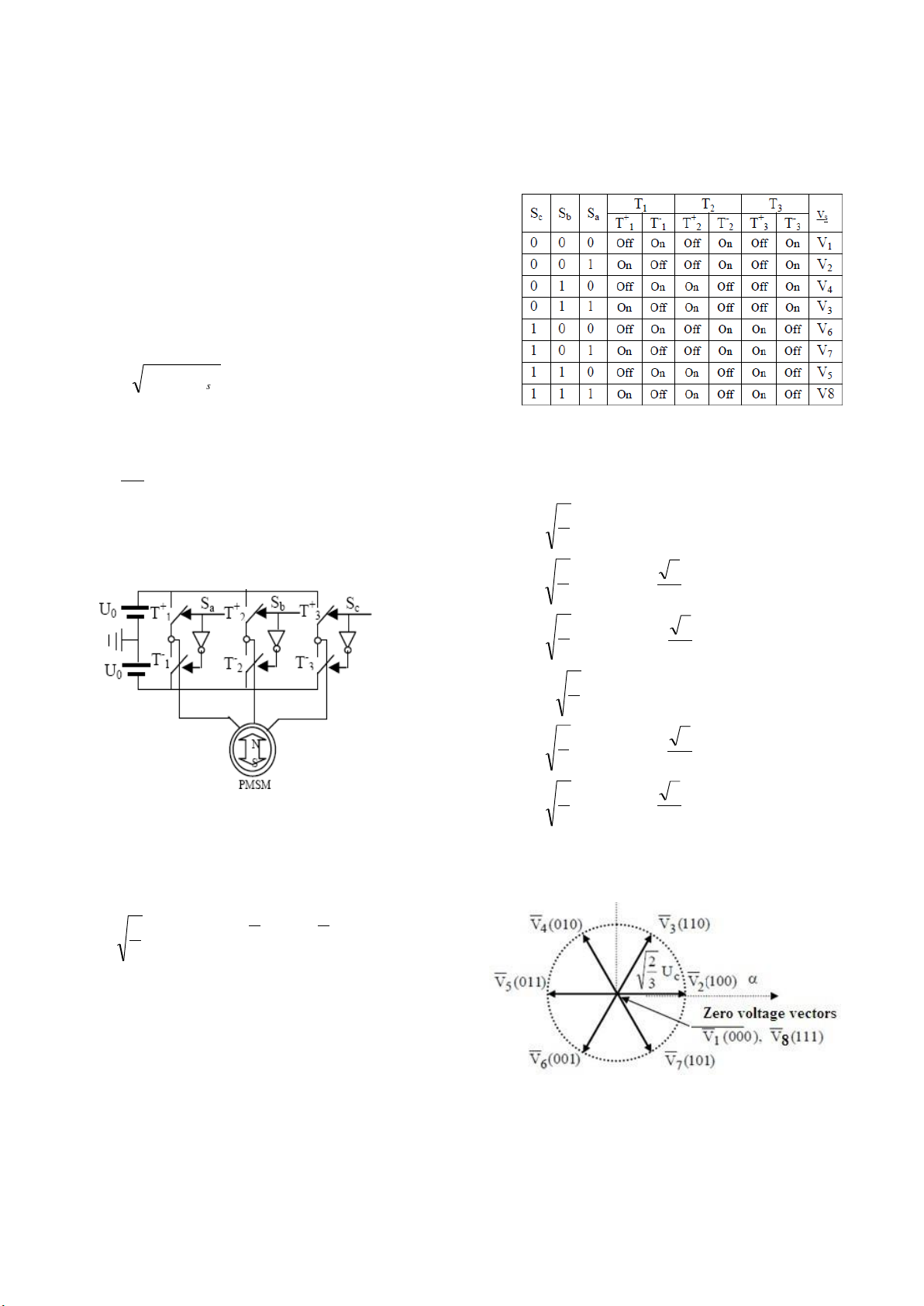

Figure 1. scheme of the synchronous machine

speed operation of the motor while at low speed the six

voltage-vector switching scheme, avoiding the two zero d

voltage-vectors, seems to be appropriate for the permanent u sd .

sd r .i (1)

magnet synchronous motor drive The voltage vector strategy s sd dt sq

using switching table is widely researched and commercialized, dsq

because it is very simple in concept and very easy to be

u r .i . (2)

implemented. The stator fluxes linkages are calculated from sq s sq

voltage and current models PMSM drive. The DTC is dt sd

increasingly drawing interest because of,

Where the direct and quadrate axis flux linkages are,

Simplicity of its structure.

L .i (3) sd d sd f

Elimination of the current controllers. L .i (4) Inherent delays. sq q sq

978-1-4244-8122-4/10/$26.00 ©2010 IEEE 275

23-26 Sep 2010, Pitesti, Romania

2010 IEEE 16th International Symposium for Design and Technology in Electronic Packaging (SIITME)

The electromagnetic torque of the motor can be evaluated

the output states of the hysteresis controller change. Therefore, as follows,

the switching frequency is usually not fixed; it changes with

the rotor speed, load and bandwidth of the flux and torque 3

Ce p.I L ).I controllers. (5) q (Ld q d .I 2 f q

The motor dynamics can be simply described by the equation (6). d Ce C J . f . (6) r dt With:

Ω: rotation's speed mechanical of the PMSM

ω: rotation's speed electric. P: Number of pairs of poles.

J : Total moment of inertia brought back on the tree of the PMSM.

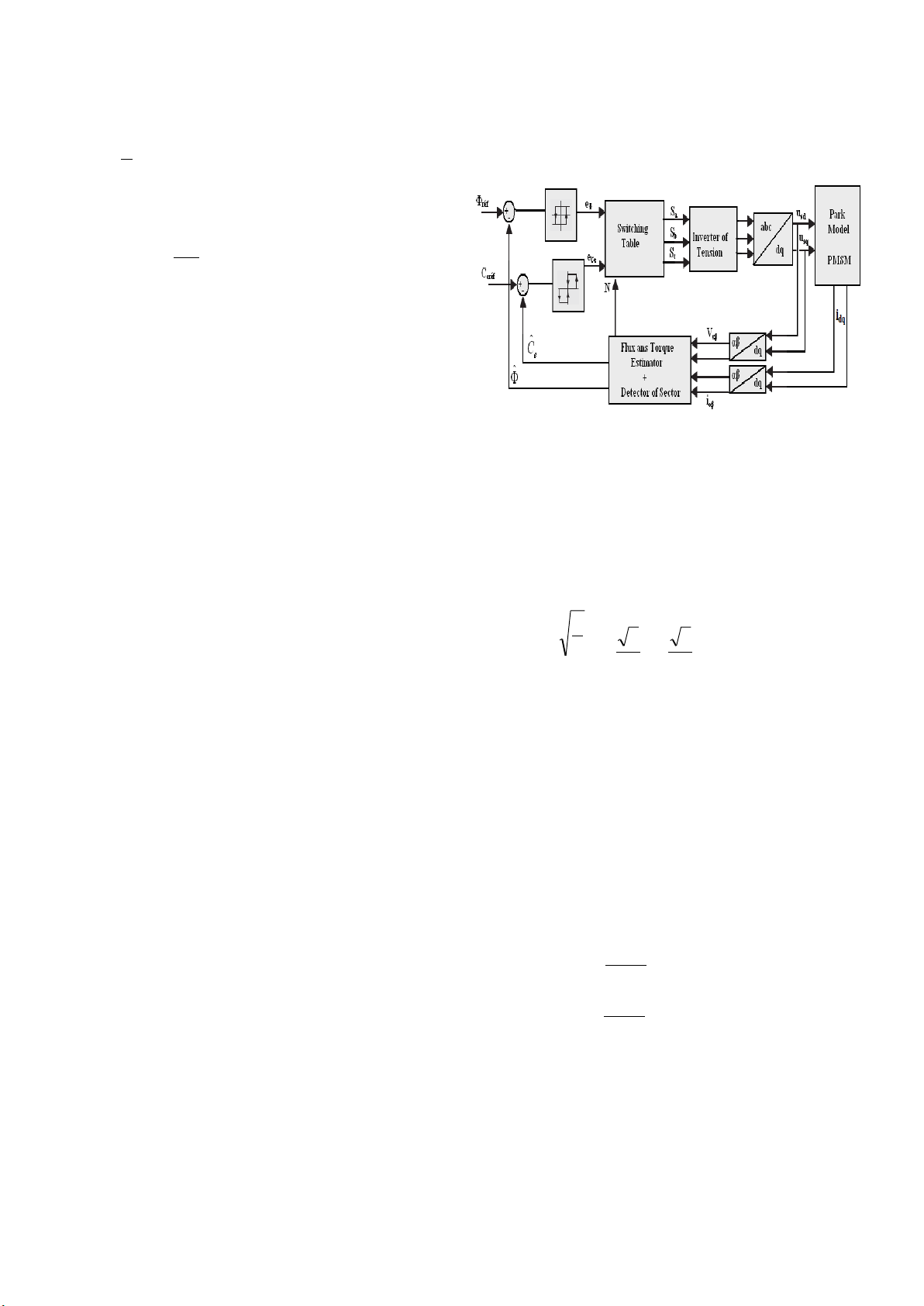

f : Coefficient of viscous friction. Figure 2. Control of DTC C r: Resistive torque.

A. Transformation abc-αβ (Clark):

f: flux produced by the permanent magnet.

As control DTC is a vectorial control, it is necessary to

sd: d axis stator magnetic flux,

have the components of Concordia of the currents and stator

tensions of the PMSM. One thus breaks up the three stator

sq: q axis stator magnetic flux,

currents isabc and the three stator tensions vsabc into components L direct (v

sd: d axis stator leakage inductance,

s) and quadratic (vs) such as: L

sq: q axis stator leakage inductance, x

1 0.5 0.5xsa r s 2 s: stator winding resistance, x (7) x 3 3 sb C 3 0 e: electromagnetic torque, s 2 2 x sc III.

CONTROL DTC (DIRECT TORQUE CONTROL): With x = Vs or is.

Since Depenbrock and Isao Takahashi proposed

Since the model of the PMSM is expressed in the reference

Direct Torque Control for induction machines in the middle of

mark (d-q), a passage of the two-phase system (α -β ) to the

1980's [9, 11], more than one decade has passed. The basic

two-phase system (d-q) (Concordia) proves to be essential:

idea of DTC for induction motor is slip control, which is based

on the relationship between the slip and electromagnetic i cos( ) sin( ) sd is

torque [2]. In the 1990's, DTC for Permanent Magnet . (8)

Synchronous Machines was developed [7, 12, 13]. Compared

isq sin( )

cos( ) is

with Rotor Field Oriented Control, the DTC has many

advantages such as less machine parameter dependence, B. Estimator:

simpler implementation and quicker dynamic torque response. 1) Flux Estimator :

There is no current controller needed in DTC, because it

The stator electric equations of the PMSM, in the reference

selects the voltage space vectors according to the errors of flux mark (α-β) are given by:

linkage and torque. The most common way to carry out the

DTC is a switching table and hysteresis controller, as in [8, d s

14]. Fig. 2 is a typical DTC system. It includes flux and torque V r .i s s s

estimators, flux and torque hysteresis controllers and a dt (9) switching table.

V r .i d s

Usually a DC bus voltage sensor and two output current s s

sensors are needed for the flux and torque estimator. Speed s dt

sensor is not necessary for the torque and flux control. The What:

switching state of the inverter is updated in each sampling time.

Within each sampling interval, the inverter keeps the state until

978-1-4244-8122-4/10/$26.00 ©2010 IEEE 276

23-26 Sep 2010, Pitesti, Romania

2010 IEEE 16th International Symposium for Design and Technology in Electronic Packaging (SIITME) t

thus 23 = 8 possibilities for the Vs vector. 2 vectors (V1 and ˆ V

(V r .i ).dt

8) correspond to the null vector: (Sa,Sb,Sc) = (0,0,0) et s s s s 0 (S ,S ,S ) = (1,1,1) t a b c ˆ s

(V r .i ).dt (10) s s s

Different configuration from the interrupters 0

ˆ ˆ j.ˆ s s s

For raised speeds, one neglects the voltage drop the equations become:

ˆ t V .dt s s t ˆ t

V .dt (11) s s t 2 s 2 s s 2) Torque Estimator : What:

The electromagnetic couple is given by: 3 p Ce ( .i .i )

V V 0 s s s s (12) 2 1 8

With p: Number of pairs of poles 2 V .U 2 0 3

C. Control switches of the inverter: 2 3 V .U ) 3 0.(0.5 j 3 2 2 3 V .U ) (14) 4 0.(0.5 j 3 2 2 V5 .U 0 3 2 3 V .U ) 6 0.(0.5 j 3 2 V 2 3 .U ) Figure 3. Inverter of tension 0.(0.5 j 7 3 2

The switches of the inverter of tension (Fig.3) must be

ordered so as to maintain the flow and the couple of the

The eight tensions Vi can be represented on the plan

machine. The vector of the stator tension can be written in the complexes as follows: form: 2 4 j j 2 V

.U .(S S .e 3 S .e 3 ) (13) s 0 a b c 3

Where (Sa, Sb, Sc) represent the logical state of the 3

switches: Si = 1 means that the high switch is closed and the

low switch is open (Vi = +U0) and Si = 0 mean that the high

switch is opened and the low switch is closed (Vi = -U0).

One will thus seek to control flow and the couple via

the choice of the vector of tension which will be done by a

configuration of the switches. As we have 3 switches, there are

Figure 4. Vectors tensions and sectors of detection

978-1-4244-8122-4/10/$26.00 ©2010 IEEE 277

23-26 Sep 2010, Pitesti, Romania

2010 IEEE 16th International Symposium for Design and Technology in Electronic Packaging (SIITME)

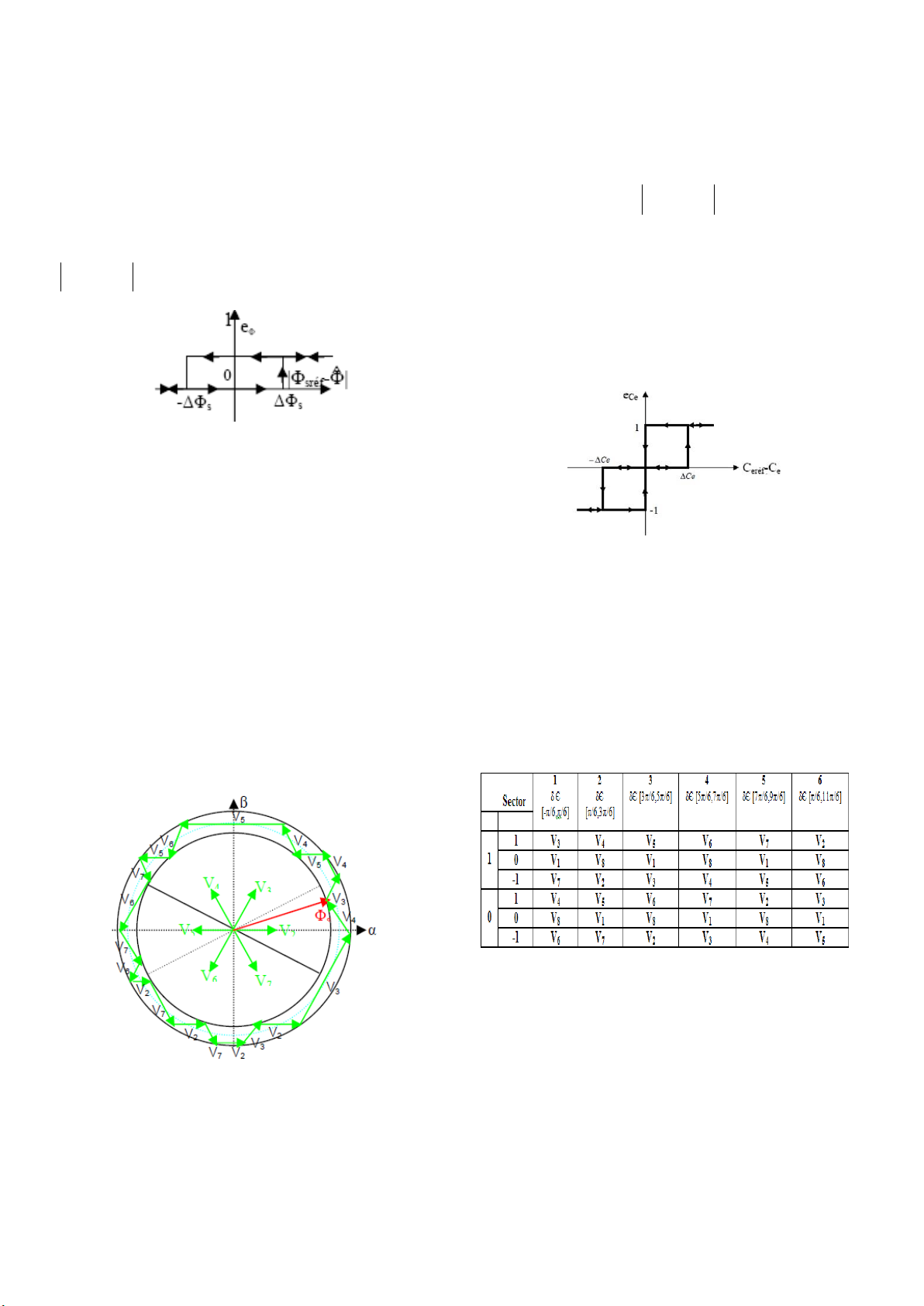

D. Control Vector flux: E. Control Couple:

So as to obtain very good dynamic performances, the

The corrector on three levels. He makes it possible to

choice of a corrector with hysteresis with two navels seems to

control the engine in the two directions of rotation that is to say

be the simplest solution and best adapted to the studied control.

for a positive or negative couple. The exit of the corrector,

Indeed, with this type of controller, one can easily control and

represented by the Boolean variable eCe what must limit the

maintain the end of the vector flux Φs in a circular ring.

couple to a value such as C

Cˆ C , e eref e e Ce can take 3

The exit of the corrector represented by a Boolean variable values:

eΦ (=0 or 1) must indicate if the module of flow must decrease

(eΦ=0) or increase (eΦ=1) by such kind to always maintain

If the error of the couple Ceréf Ce >0, it is necessary to ˆ increase the couple eCe=1 ; sref s

If the error of the couple Ceréf Ce<0, the couple should be decreased eCe=-1 ;

If the error of the couple -∆C e ≤

Ceréf Ce ≤ ∆Ce it is

necessary to keep the same value of the couple

Figure 5. Corrector Flow with Hysteresis on 2 Levels

The practical realization of order DTC is generally done on

charts DSP, FPGA or with microcontrollers having one period

of sampling for the period you to you, the vector tension

chooses does not change what allows, starting from the equation (11), to write: ˆ T

Figure 7. Corrector of the Couple with Hysteresis on 3 levels e

V .dt V .T s s e ˆ 0 s T F. Law of control: e s

V .dt V .T 0 s s e (15)

According to the sector determined by the phase (δ=Arctang(Φ ˆ

β/Φα)) of estimated flow and the evolution ˆ j.ˆ s s s V .T

magnitude of this last as well as the evolution of the estimated s e

couple one can choose the tension Vs to be applied so as to

respect the instructions of flow and the couple. There are thus

The direction of the vector flow Φ s is thus given by the

3 parameters for the choice of vector V selected vector of tension V S, allow choosing the i the figure below shows the adequate vector.

sequence of the vectors tensions maintaining flow in a crown

thickness equal to the width of hysteresis.

In the example of figure 7, flow is in sector 1, If flow Φ s

increases (eΦ=1) and if the couple also increases (eCe=1), the

vector tension to be applied to the PMSM will be V3 this

choice will make it possible to make decrease.

The magnitude of flux Φ s and the couple bus when the

angle of flux Φ s increases (∆w>0) the couple also increase

Figure 6. Sequence of the Vectors Tensions

whereas when (∆w<0) the couple decreases.

978-1-4244-8122-4/10/$26.00 ©2010 IEEE 278

23-26 Sep 2010, Pitesti, Romania

2010 IEEE 16th International Symposium for Design and Technology in Electronic Packaging (SIITME)

If V6 is then selected flow must decrease (eΦ=0) and also couples it (eCe=-1).

If V1 or V8 is selected flow must remain constant (eΦ=

the preceding state) and the couple decreases (e Ce=0).

If V3 is then selected flow must increase (eΦ=1) and also couples it (e Ce=1).

If V7 is then selected flow must increase (e Φ =1) and

the couple must decrease (eCe=-1).

If V4 is then selected flow must decrease (eΦ=0) and

Figure 8. Detection of the Vector Tension when it Vector Flux is Located in the couple must increase (e the Sector Ce=1). IV. SIMULATION AND RESULTS:

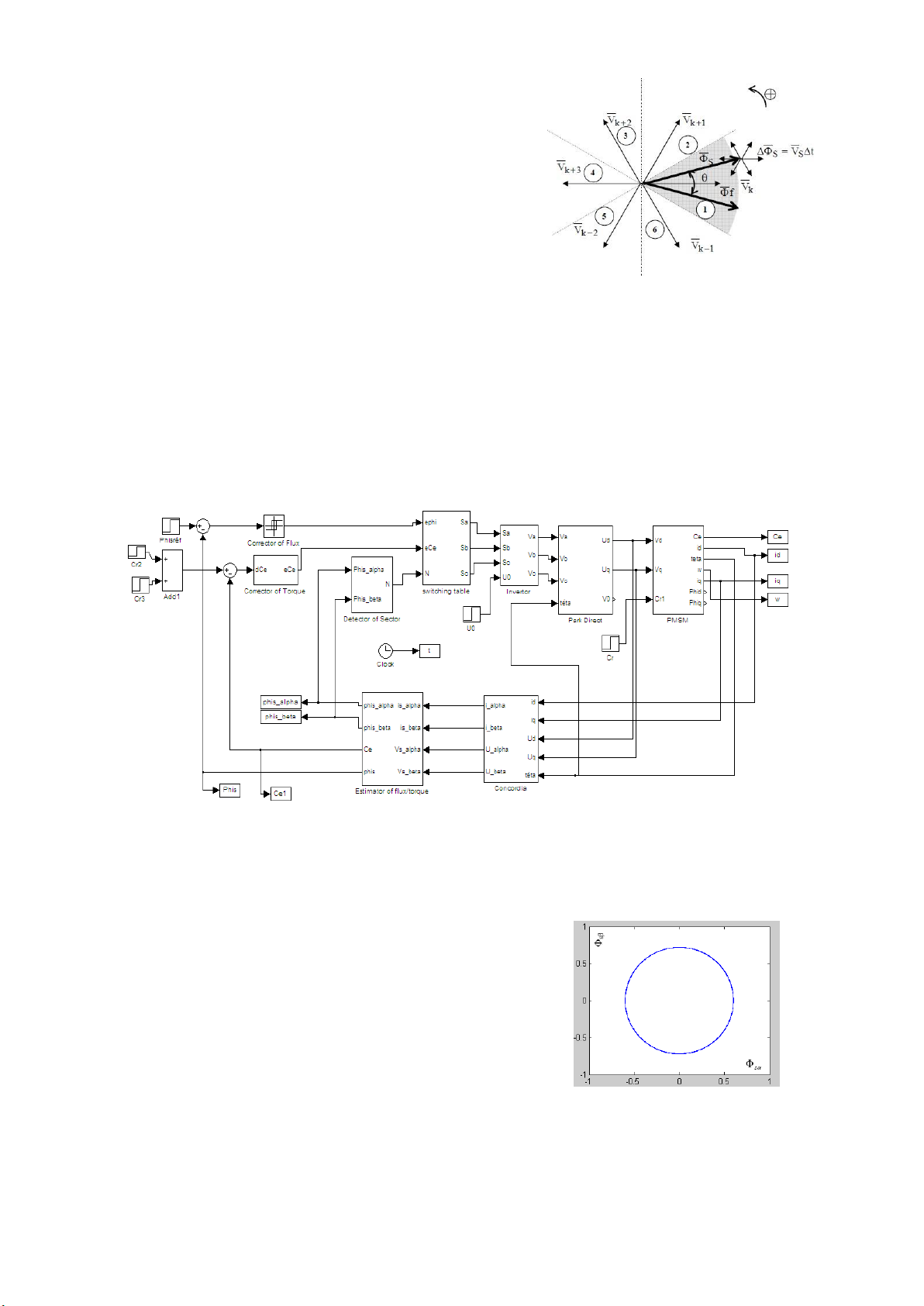

A. Diagram of control DTC applied to a PMSM.

Here the MATLAB/Simulink model of the permanent magnet synchronous motor is developed according to the dq model. In

the simulation, the stator magnetic flux amplitude value is assumed to be the same as the value of the permanent magnet flux. The

inverter dc bus voltage is 300V. Also at t=0.07s, a differential step from 8Nm to 0Nm and at t=0.14s from 0Nm to 8Nm is applied

to the referents torque value. Motor parameters are; p=4, rs=0.4578Ω, Φf=0.171Wb, Lsd=3.34mH, Lsq =3.58mH, J = 0.001469kgm2,

Figure 9 shows the Simulink diagram of the direct torque control for PMSM.

Figure 9. Blocks for the simulation of the DTC under Matlab/Simulink 1) Princip :

and Vsq are applied in average values at the boundaries of

The figure 9 presents the general diagram of the structure

the phases stator of the PMSM.

of the Direct Torque Control DTC of the PMSM in the

2) Results of Simulation:

reference mark dq, the currents isd, isq, Vsd and Vsq are

subjected to the transformation of Clark in order to obtain

the components isα, isβ, Vsα and Vsβ its components are

applied has a block of estimator of couple and flow as well

as the detector of sector, these values estimated thereafter

are compared with values of reference to be included in

correctors of hysteresis to 2 and has 3 levels, to introduce its

errors into a table of commutation which functions by report

sector to generate the impulses of the inverter which will

generate the tension three-phase current thereafter which will

be transformed into co-ordinates dq, the output voltages Vsd

978-1-4244-8122-4/10/$26.00 ©2010 IEEE 279

23-26 Sep 2010, Pitesti, Romania

2010 IEEE 16th International Symposium for Design and Technology in Electronic Packaging (SIITME) Figure 10. Trajectory of flux

and stator flux space vector. Vector locations are shown in Figure 10. CONCLUSION:

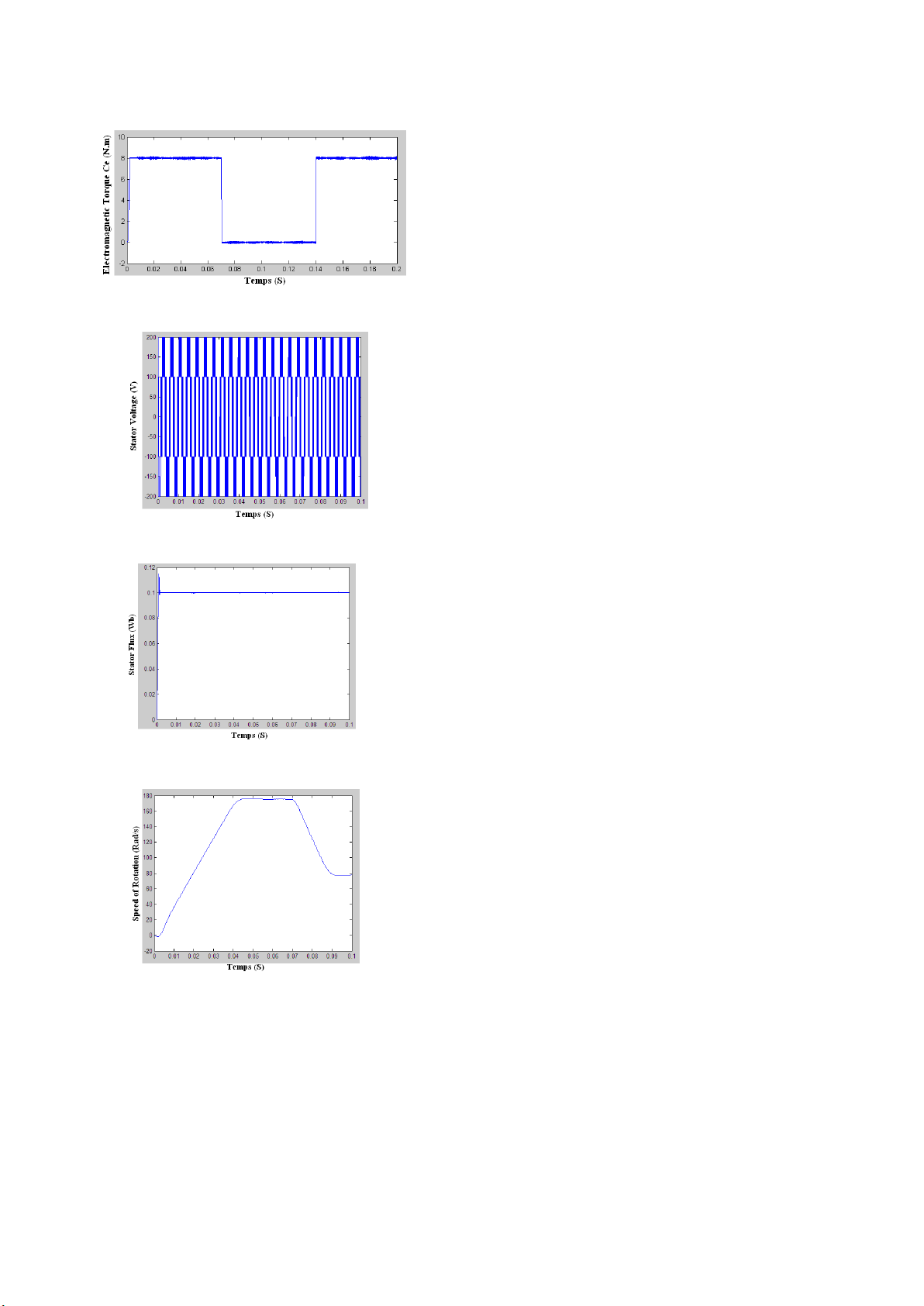

In this article we presented a modeling under

Matlab/Simulink of unit PMSM, inverter of tension and

order known as DTC. The latter allows uncoupled control

from the torque and flux. This order has the following

advantages: an optimal response time, it controls almost

perfect undulation of the couple and flow, it does not have

mechanical sensors and sensitivity live with screw the

Figure 11. Electromagnetic Torque

variation of certain parameters of the machine, it allows to

obtain excellent dynamic performances. REFERENCES:

[1] [1] : A. Lagrioui, H. Mahmoudi “Modélisation et Simulation de la

commande directe du couple appliquée à une MSAP” ICEE’08, 2008.

[2] [2]: H. Bausch, W.Zeng K.Kanelis B.Lange “Torque Control of

current excited synchronous machines for electric vehicules” ICEMA

proceeding Vol2 septembre 1993.

[3] [3] : I. Boldea N. Muntean “Direct Voltage vector speed control of

surface permanent magnet synchronous motor drives” ICEM proceeding Vol2 septembre1994

[4] [4]: J. Thomas K. René A.A. Melkebeek “Direct Torque Of

Permanent Magnet Synchronous Motors- An Overview” 3RD IEEE – April 2006. Figure 12. Stator voltage (V)

[5] [5] : M. Kadjoudj1, S. Taibi “Modified Direct Torque Control of

Permanent Magnet Synchronous Motor Drives”, IJ-STA, Volume 1,

N° 2, December 2007, pp. 167−180.

[6] [6] : Carlos Canudas de Wit « Modélisation contrôle vectoriel et DTC

» , HERMES Science Europe Ltd,2000.

[7] [7]: M. W.Naouar, L. Charaabi, E. Monmasson, and I. Slama-

Belkhodja; "Realization of a library of FPGA reconfigurable IP-Core

functions for the control of electrical systems," in Proc EPE-

PEMC'04, Riga-Latvia September 2004.

[8] [8] : M. W.Naouar, E. Monmasson, and I. Slama-Belkhodja, "FPGA-

based torque controller of a synchronous machine," in Proc. IEEE-

ICIT'04, pp.8-10, Hammamet, Tunisia, Dec.2004.

[9] [9] : Zhong, L.; Rahman, M.F.; Hu, W.Y.; Lim, K.W. "Analysis of

direct torque control in permanent magnet synchronous motor drives"

Figure 13. Evolution of the Amplitude of Φ s

Power Electronics, IEEE Transactions on Volume: 12 Issue: 3 , May 1997 Page(s): 528 – 536

[10] [10]: Tang, P., Yang, G., Luo, M., Li, T., “A Current Control Scheme

with Tracking Mode for PMSM System”, Systems and Control in

Aerospace and Astronautics 1st International Symposium, pp. 872- 876, 2006

[11] [11]: Laurent, J., Jabbar, M. A.,Qinghua, L., “Optimization of the

Constant Power Speed Range of a Saturated Permanent-Magnet

Synchronous Motor”, IEEE Transactions on Ind. App., Vol.42, No.4, pp. 1024- 1030, 2006.

[12] [12]: M. Pacas and J. Weber, “Predictive direct torque control for the

PM synchronous machine,” IEEE Trans. Ind. Electron., vol. 52, no. 5, pp. 1350–1356, Oct. 2005.

[13] [13]: J. Luukko, M. Niemel¨a, and J. Pyrh¨onen, “Estimation of the

flux linkage in a direct-torque-controlled drive,” IEEE Trans. Ind.

Electron., vol. 50, no. 2, pp. 283–287, Apr. 2003. Figure 14. Rotor Speed

[14] [14]: M. Boussak, “Implementation and experimental investigation of

sensorless speed control with initial rotor position estimation for

interior permanent magnet synchronous motor drive,”

In the performed simulation, certain stator flux and IEEE Trans.

Power Electron., vol. 20, no. 6, pp. 1413–1422, Nov. 2005.

torque references are compared to the values calculated in

the driver and errors are sending to the hysteresis

comparators. The outputs of the flux and torque comparators

are used in order to determine the appropriate voltage vector

978-1-4244-8122-4/10/$26.00 ©2010 IEEE 280

23-26 Sep 2010, Pitesti, Romania View publication stats